Abstract

Developing predictive models for solid solution strengthening is a key tool in alloy design, enabling the optimization of mechanical properties. This study aims to identify the primary factor governing solid solution strengthening, providing foundations for more accurate predictive models. In this work single-phase solid solution alloys are developed with differences in atomic volume and electronegativity among constituent elements. Unlike previous studies focusing on only one factor, this work employs alloys specifically designed to assess both variables simultaneously, operating at the boundary conditions of different strengthening models. Vanadium is selected for its large electronegativity difference relative to nickel, while palladium is chosen for its significant atomic volume difference. We demonstrate that atomic volume differences play a dominant role in solid solution strengthening. Moreover, each solid solution exhibits a critical grain size below which grain refinement influences mechanical properties more than solid solution strengthening. Finally, a Ni₅₀Pd₅₀ alloy is produced showing a stability of mechanical properties with increasing grain size.

Similar content being viewed by others

Introduction

The lattice friction stress, quantified by the Peierls stress1,2,3,4, describes the resistance a single dislocation faces while moving through an alloy’s lattice, which is closely linked to atomic-scale lattice distortions. In alloys with solid solution, numerous solute atoms with varying sizes and properties create distorted lattices, resulting in extensive lattice friction5,6,7. This distortion raises the energy barrier against dislocation mobility, thereby strengthening the material8,9,10,11,12,13.

Solid solution strengthening (SSS) arises from the interaction between dislocations and solute atoms introduced into a lattice site. When a solute atom replaces a solvent atom, differences in atomic size and elastic moduli create an elastic stress field around the solute. This field resists the movement of dislocations, thereby increasing the force required for dislocation motion and contributing to the strengthening of the alloy14,15.

Important pioneering models to quantify SSS were originally introduced by Fleischer16,17, latter followed by Labusch18,19. The strong-pinning model, introduced by Fleischer16,17, conceptualizes solute atoms as discrete, independent obstacles that pin dislocations within the glide plane. In this approach, the dislocation bows out between solute atoms, which are treated as strong, point-like obstacles. Fleischer developed statistical models that relate the flow stress of an alloy to parameters, such as dislocation line tension and the mean distance between obstacles in the glide plane14,15,20,21.

In contrast, the collective pinning model, or weak pinning model, proposed by Labusch18,19, attributes strengthening to fluctuations in the collective force exerted by multiple solutes along the dislocation line. Unlike the model proposed by Fleischer16 that treat solutes as independent obstacles, this approach considers the combined interaction of many solutes, where favorable statistical fluctuations in solute distribution create a pinning effect that individual solutes alone could not achieve at the same stress level. Although Labusch initially formulated the model for solutes within the dislocation glide plane, the concept inherently extends to three-dimensional interactions14,15,20,21.

According to these models, solutes can be effectively represented as point defects that will distort the crystal lattice, giving rise to a solute-dislocation elastic interaction energy, which in turn is the primary factor governing the SSS mechanism. Despite their contributions, these classical models were originally developed for solutions with solvents up to 10 at.% in a single component matrix14.

Over time, numerous researchers have refined and extended these theories to accommodate higher solute concentrations and more complex alloying systems, improving their applicability to modern engineering materials22,23. As a result, contemporary models now provide a more comprehensive understanding of SSS, incorporating both theoretical and experimental advancements to enhance predictive accuracy in alloy design.

In the context of multi-principal element alloys (MPEAs)24,25,26,27, distinguishing between solvent and solute atoms is challenging due to the random occupation of lattice sites by multiple atom species, leading some solid solution models to perform inadequately. Researchers have recently developed models to explain SSS in MPEAs, which rely heavily on input parameters like atomic size and shear modulus mismatch8,28,29, and more recently, electronegativity differences30,31.

For example, the Varvenne model8, based on first principles calculations, posits that differences in atomic volume control the mechanical strength of alloys by calculating the interaction energy between dislocations and solute atoms. This energy is integrated into a conventional equation to account for thermal effects, yielding a comprehensive representation of critical resolved shear stress and thus, yield stress. The Varvenne model also takes into account the shear modulus and Poisson’s ratio of each element in its final calculation to obtain the SSS component. This model’s ability to accommodate strain rate and temperature variations enhances its predictive accuracy.

Conversely, Oh’s model30 attributes SSS in MPEAs to differences in electronegativity among the constituent elements. Using a quantum-mechanical approach, it approximates atomic-level pressure to identify optimal element combinations for high SSS, focusing on electronegativity disparities rather than atomic volume differences.

Although both the Varvenne8 and Oh30 models are applied to face-centered cubic (FCC) systems, they are fundamentally different. As one model predicts the SSS based on atomic volume differences, without accounting for electronegativity, while the other relies exclusively on electronegativity differences, omitting atomic volume in its mathematical formulation, it becomes virtually impossible for both models to produce convergent trends or identical outcomes. Hence, the present study aimed to compare the outputs of the two models, specifically regarding which factor most significantly enhances SSS. This approach is crucial as contemporary science increasingly relies on predictive models to optimize time and resources, reducing dependence on empirical trial-and-error methods wherever possible.

Hence, in this work, different alloys were intentionally designed to exhibit marked differences in electronegativity and/or atomic volume. This work stands apart from other studies by utilizing alloys precisely engineered to operate at the boundary conditions of the Varvenne8 and Oh30 models. For example, Yin et al.32 investigated the effects of misfit and solute interaction on strengthening in an AuNi alloy, which has a substantial atomic radius difference but a nearly negligible electronegativity difference (0.02 on the Allen scale). In another study33, the authors examined a CrCoNiFePd alloy, suggesting that its strengthening is primarily due to its large misfit volume. However, this alloy also exhibits a lower electronegativity difference (0.11) than any alloy used in our present research.

Thus, while other studies focus exclusively on atomic volume difference or electronegativity difference among elements in a solid solution, this research uniquely considers both factors simultaneously, using alloys that are precisely designed to assess both variables. An analysis of various 3D transition metal elements was conducted, focusing on those that form a solid solution in Ni and provide significant differences in electronegativity and/or atomic volume compared to pure Ni. Furthermore, among the alloys used in this present study, Ni63.2V36.8 and Ni50Pd50, display not only a significant atomic volume difference but also a notable electronegativity difference among the constituent atoms in the solid solution.

V was chosen for its high electronegativity difference to Ni, while Pd was selected for its smaller electronegativity impact but greater atomic volume difference. Figure 1a illustrates the selection process, highlighting the 3D elements forming an appreciable solid solution in Ni (above 30 at.% solute). To analyze the implications of adding Pd and V and their effects on the solid solution system, the equiatomic CrCoNi was also taken as a benchmark.

a Normalized electronegativity difference (Allen scale) vs. normalized atomic volume difference when adding elements to pure Ni. Atomic volume were estimated based on atomic radius of pure elements40; b Variation in crystalline lattice distortion (\(\delta\)) vs. electronegativity difference (Δχ) for the chosen alloys, with estimated values for \(\delta\) and Δχ according to41 and30, respectively. E.D stands for electronegativity difference and A.V.D stands for atomic volume difference.

The alloys used here were Ni50Pd50, Ni63.2V36.8, Cr33Co33Ni33, Cr30Co30Ni30Pd10, and Cr30Co30Ni30V10, chosen for significant lattice distortion and/or electronegativity differences (Fig. 1b). These alloys are ideal for testing both models due to their properly designed variations in electronegativity and atomic volume.

It is worth mentioning that the selection of Pd sets this study apart from previous research efforts concentrated on the inclusion of other 3D transition elements, which commonly share comparable atomic volumes. Finally, this study aims not only to understand the fundamental differences between the Varvenne8 and Oh30 models but also to propose a more accurate strategy towards alloy design, focused on optimizing mechanical properties with greater precision.

This study shows that SSS is not always the dominant strengthening mechanism across all investigated alloys, as there exists a critical grain size below which grain boundary strengthening (GBS) becomes predominant. Moreover, the development of a general predictive model for SSS remains challenging due to the system-specific nature of solid solutions. Finally, based on experimental results and comparison with literature data, this study demonstrates that atomic volume differences have a greater impact on SSS than electronegativity differences.

Results and discussion

Microstructural characterization

The thermodynamic calculations depicted in Supplementary Fig. 1 illustrate the FCC single-phase field for the Ni50Pd50 Ni63.2V36.8, Cr33Co33Ni33, Cr30Co30Ni30Pd10, Cr30Co30Ni30V10 alloys.

Subsequently, Fig. 2 displays the X-ray diffraction (XRD) patterns for the recrystallized samples, confirming the presence of the FCC phase in all samples and the correspondent inverse pole figure (IPF-Z) maps from EBSD analysis showing the microstructure of the alloys. For comparison, XRD for pure Ni is shown in Supplementary Fig. 2. The SEM-EDS elemental distribution maps showcased in Supplementary Figs. 3–7 revealed the compositional homogeneity of the recrystallized microstructure at the microscale on each alloy.

X-ray diffraction results confirming the single-phase FCC structure for the a Ni50Pd50, b Ni63.2V36.8, c Cr33.3Co33.3Ni33.3, d Cr30Co30Ni30Pd10, and e Cr30Co30Ni30V10 alloys. The respective microstructures of each alloy, evaluated via EBSD, are depicted in the insets of each figure. ♦ Represents the second harmonic of the main FCC peaks, caused by a secondary, low-intensity radiation with approximately twice the energy of the primary X-ray source. Vanadium (V) and Nickel (Ni)-rich oxides are also shown.

It was also found V-rich oxides peaks for the Ni63.2V36.8 and Cr30Co30Ni30V10 alloys and Ni-rich oxides peaks for the Ni50Pd50 alloy, which were consistent with SEM-BSE/EDS examinations in Supplementary Fig. 8. These oxides typically form when alloys containing reactive elements are melted and cast in an arc melting furnace. Due to their micrometer-scale size, there is minimal interaction between these oxides and dislocations. Consequently, the contribution of oxide hardening is limited to around 3 MPa, rendering it an insignificant factor to the yield stress of the alloys under study34,35. Moreover, the low-intensity diffraction peaks at specific Q values positions are attributed to FCC phase reflections caused by the 2nd harmonics36,37,38.

Influence of atomic volume

The analysis of the diffractograms in Fig. 2a, b reveals that the addition of Pd and V to pure Ni results in a significant shift of all reflections toward lower Q values when compared to pure Ni (Supplementary Fig. 2). A similar pattern is observed in Fig. 2d, e, where Pd and V are added to the CrCoNi system (Fig. 2c). As per Bragg’s law39 these shifts toward lower 2θ values correspond to an increase in atomic radius (or atomic volume).

Accurately determining atomic volume in solid solutions with multiple atoms is challenging due to variations in atomic radii depending on the environment in which a certain atom is inserted. For example, α-Fe (BCC) and γ-Fe (FCC) have different radii (1.239 Å and 1.287 Å, respectively), as do α and β Ti in different structures (1.475 Å and 1.432 Å, respectively)40. Pure Ni (FCC) has a radius of 1.243 Å, but a radius of 1.257 Å in a binary FCC solution with Cr (30 at.%)8. To address this, we propose using the concept of apparent atomic volume (\({A}_{{\mathrm{av}}}\)), which relies on the principles that the unit cell represents the entire system and contains atoms in the same proportion as the solid solution.

Considering a system with a composition of Cr33Co33Ni33, forming an FCC solid solution, the atomic volume of the unit cell is crucial because it must include the three elements in the same stoichiometry as the system. Thus, each element—Cr, Co, and Ni—occupies approximately one-third of the atomic volume in the cell. For an FCC cell, and assuming the simplified spherical geometry for the atoms, the following relationship is established:

Where \(Q\) is the number of atoms in a FCC unit cell, \(V\) is the volume of one atom, and \({a}^{3}\) is the unit cell volume. Thus, taking into account that an FCC cell is occupied by four atoms, the \({A}_{{\mathrm{av}}}\) might be expressed as:

Therefore, for solid solutions, \({A}_{{\mathrm{av}}}\) provides an effective and functional measure of the volume occupied by atoms in a unit cell, regardless of the quantity of atoms composing the solid solution. It should be noted that atoms are not spheres, and the volume occupied by a single atom might be the entire 1/4th of the FCC unit cell if the atom is now viewed in this way. However, the simplification of taking atoms as spheres is convenient to directly apply the results to many equations in the literature that consider the atomic radii as the intrinsic measurement for the atomic volume and either option, atomic radii or volume, will lead to the same outcome using these models.

Furthermore, a distorted lattice may result if a significant difference in atomic sizes is present. The distortion generated in the crystalline lattice (\(\delta\)) can be estimated by the model proposed by Zhang et al.41:

where n is the total number of elements in solid solution, \({c}_{i}\) is the atomic fraction of the ith element, \({r}_{{{\rm{i}}}}\) is the atomic radius of element i and \(\bar{r}\) \(({\sum }_{i=1}^{n}{c}_{{{\rm{i}}}}{r}_{{{\rm{i}}}})\) is the average atomic radius. The \(\delta\) parameter is very common in the MCA literature to describe the difference in atomic radii in solid solutions.

Using the XRD results shown in Fig. 2, the apparent atomic volume (\({A}_{{\mathrm{av}}}\)) was calculated for the investigated materials, detailed in Table 1. Table 1 also presents the \(\delta\) values for pure Ni and the CrCoNi system, including changes from adding Pd and V. For precise \(\delta\) determination, we used “solution atomic radii”. These radii represent the size that an element would have in a FCC system. These values were derived from binary FCC alloys of the element with Ni8,42, as detailed in Supplementary Table 1.

Table 1 reveals that adding Pd to pure Ni increases \({A}_{{\mathrm{av}}}\) by 19.44%, much more than the 7.39% increase from adding V. The \(\delta\) values are also higher with Pd additions. Similarly, Table 1 shows that Pd increases \({A}_{{\mathrm{av}}}\) by 4.01% in the CrCoNi system, compared to 1.87% for V, with higher \(\delta\) values for Pd as well. This larger increase in \({A}_{{\mathrm{av}}}\) and \(\delta\) when adding Pd to both Ni and CrCoNi is due to Pd’s larger atomic size compared to V. Consequently, considering only atomic volume differences, alloys with Pd are predicted to exhibit stronger SSS due to greater lattice distortion.

Moreover, it is worth noting that these findings corroborate what has been shown before by other authors43,44, indicating that the presence of a greater number of elements in solid solution does not invariably induce larger distortions in the crystal lattice. This is exemplified by the higher values of \({A}_{{\mathrm{av}}}\) and \(\delta\) observed for the binary alloys in comparison to their counterparts in the ternary and quaternary alloy systems.

Influence of electronegativity

Based on the assumption that it’s possible to predict configurational fluctuations of charge transfer and atomic-level pressure, the model introduced by Oh et al.30 depends on the average charge transfer of each element in a solid solution, approximated by the local difference in electronegativity. The electronegativity difference between the constituent elements (\(\Delta \chi\)) can be calculated as follows:

where \({{{\rm{\chi }}}}_{{{\rm{x}}}}\) represents the electronegativity of element X, and \({\left\langle {{\rm{\chi }}}\right\rangle }_{{{\rm{element}}}}\) stands for the weighted average electronegativity across the element. Using the model proposed by Oh et al.30, the \(\Delta \chi\) values were calculated for the alloys under investigation and are presented in Table 2. In their model, the authors claim the Allen electronegativity scale should be the one to be used. The values of electronegativity used for each element are listed in Supplementary Table 1.

Table 2 shows that the introduction of V into pure Ni results in slightly higher \(\Delta \chi\) values compared to the addition of Pd. Similarly, V addition to the CrCoNi system leads to a higher \(\Delta \chi\) values than the addition of Pd. According to the Oh model30, alloys with V should exhibit stronger SSS due to the greater \(\Delta \chi\) values. It is important to note that the values presented in Table 2 may vary depending on the electronegativity scale used. For example, based on the electronegativity according to the Pauling scale, the Ni50Pd50 alloy would exhibit the greatest \(\Delta \chi\) values (Supplementary Tables 1 and 2).

In light of the exposition thus far, it becomes clear that the models proposed by Varvenne and Oh contain a fundamental contradiction. According to the Varvenne model, alloys containing palladium (Ni50Pd50 and Cr30Co30Ni30Pd10) should exhibit the highest contribution of SSS. Conversely, the Oh model posits alloys with vanadium addition (Ni63.2V36.8 and Cr30Co30Ni30V10) should have the greatest SSS contribution. Therefore, the following section delves into both models and attempts to clarify the fundamental difference between them.

Prediction of SSS solution using the evaluated models

The Varvenne model evaluates the energy associated with the interaction between a dislocation and a solute atom. This energy calculation is subsequently included in a standard equation to adapt to thermally induced deformation. As a result, the determined interaction energy becomes part of an equation to handle thermally driven deformation. The resulting outcome is a model for the SSS component in the yield stress, which considers the impact of strain rate and temperature. This final formulation offers a direct method for calculating the activation energy needed for dislocation movement (\({\Delta E}_{{{\rm{b}}}}\)) and the Peierls stress at absolute zero (\({\tau }_{0}\)), as expressed in the following equations:

Where \(\nu\) is the Poisson’s ratio, \(\alpha\) (0.123 in this work) represents a constant related to the value of the line tension of the dislocation (Γ = \(\alpha {Gb}\)²), G denotes the shear modulus, b represents the Burger’s vector and Xn represents de fraction of nth element in solid solution. The functions f\(\left({{{\rm{W}}}}_{{{\rm{c}}}}\right)\), denoted as \({{{\rm{f}}}}_{1}\left({{{\rm{W}}}}_{{{\rm{c}}}}\right)\) and \({{{\rm{f}}}}_{2}\left({{{\rm{W}}}}_{{{\rm{c}}}}\right)\), are termed to minimize dislocation core-related coefficients. They account for the curved nature of dislocations, which deviate to locate local energy minima; Varvenne employed values of 0.35 and 5.70 for \({{{\rm{f}}}}_{1}\left({{{\rm{W}}}}_{{{\rm{c}}}}\right)\) and \({{{\rm{f}}}}_{2}\left({{{\rm{W}}}}_{{{\rm{c}}}}\right)\), respectively.

In both equations, the pivotal term is \(\Delta {\bar{V}}_{{{\rm{n}}}}\), denoting the average volumetric misfit per atom. It is computed as the difference between the volume of the nth atom and the average atomic volume within the mixture. The atomic volume is derived from the FCC unit cell’s volume divided by four.

The resulting terms from Eqs. (5) and (6) are then inserted into the subsequent equation, delineated as Eq. (7), for the computation of yield stress.

Where k is the Boltzmann constant, \(\dot{{\epsilon }_{0}}\) is a reference term for the strain rate, 10−4 s−1, following Varvenne8. All the experiments conducted in this study were performed at a strain rate (ε) of 10−3 s−1. The calculations were carried out to evaluate the strength at a temperature (T) of 293 K. Hence, the Eq. (7) is a model for the SSS component to the critical resolved shear stress (converted into the respective contribution to the yield stress by the Taylor factor) that incorporates the dependence on strain rate and temperature.

On other hand, Oh et al.30 proposed an alternative model based on quantum-mechanically derived atomic-level pressure, which uses the electronegativity difference to identify the best element mix for achieving a high SSS effect. According to Oh et al.30, atomic-level pressure, and consequently misfit volume in 3d-based MPEAs, are determined by charge transfer rather than atomic size difference. Thus, the relationship between atomic-level pressure (Psolute) and charge transfer (dQ) can be quantified as Psolute ∝ dQ. Based on this relationship, the authors proposed a practical approach to predict SSS using specific elemental information that adequately represents the underlying atomic characteristics, such as electronegativity. On this approach, the average charge transfer (dQx) of each element can be approximated by the local electronegativity difference. Hence, the SSS component (σss) in MPEAs can be elucidated by the electronegativity difference among the constituent elements (χ) as follows:

More specifically, Oh model suggests that the SSS could be predicted by the following equation:

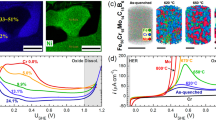

Therefore, taking into consideration Eq. (7), Fig. 3a presents the values of the SSS contribution (\({\sigma }_{{\mathrm{ss}}}\)) alloys under study as per Varvenne model. The variation of \({A}_{{\mathrm{av}}}\) was used to express the difference in atomic volume in each alloy. The \({\sigma }_{{\mathrm{ss}}}\) value for pure Ni was considered to be 0. Moreover, based on Eq. (9), Fig. 3b illustrates the SSS contribution values as per Oh model.

a Solid solution strengthening component (σss) X apparent atomic volume (\({A}_{{\mathrm{av}}}\)) according to the Varvenne model8 and b σss X electronegativity difference (Δχ) according to the Oh model30 for the Ni63.2V36.8, Ni50Pd50, Cr33Co33Ni33, Cr30Co30Ni30Pd10, and Cr30Co30Ni30V10 alloys. The error bars denote the model-associated uncertainty as defined in the approach proposed by Oh et al.30.

Figure 3a shows that adding Pd to pure Ni results in higher SSS, compared to the addition of V, with Ni50Pd50 demonstrating the highest SSS. Similarly, in the CrCoNi system, Cr30Co30Ni30Pd10 exhibits higher SSS than with V addition. These results align with Varvenne model, which indicates that greater differences in \({A}_{{\mathrm{av}}}\) between constituent atoms lead to stronger SSS.

On other hand, Fig. 3b shows that adding V to pure Ni results in higher SSS than adding Pd, with Ni63.2V36.8 demonstrating the highest SSS. Similarly, in the CrCoNi system, Cr30Co30Ni30V10 alloy shows higher SSS compared to Pd addition. These findings support Oh’s model, which suggests that greater Δχ differences result in stronger SSS. However, the model proposed in Eq. (9) should be applied with caution, once the dispersion associated with the model (indicated in Fig. 3b) could led to a widely distribution of \({\sigma }_{{\mathrm{ss}}}\) predict values. Therefore, the inherent dispersion associated with the model and the choice of the electronegativity scale to be employed may lead to inconclusive results when applying Oh’s model, potentially limiting its practicality.

Excluding the effect of grain boundary strengthening

In fact, Oh et al.30 support their perspective by examining the yield stress (\({\sigma }_{{{\rm{y}}}}\)) and σuts values of the Ni63.2V36.8 alloy, in contrast to the equiatomic CrCoNi and CrCoNiMnFe alloys (all with similar grain sizes). Notably, the Ni63.2V36.8 alloy demonstrates higher \({\sigma }_{{{\rm{y}}}}\) and σuts values than the other alloys.

However, in order to conduct an accurate analysis of the isolated contribution of the \({\sigma }_{{\mathrm{ss}}}\), it is essential to disregard the influence of grain boundary strengthening (GBS). This approach was adopted in the present study. According to the Hall–Petch model, the strengthening attributed to grain boundaries can be elucidated by Eq. (10).

In this context, \({\sigma }_{{{\rm{y}}}}\) is the yield stress, \({\sigma }_{0}\) represents the friction lattice stress, \({K}_{{{\rm{H}}}}\) is the Hall–Petch coefficient, and \(d\) denotes the grain size. Theoretically, \({\sigma }_{0}\) includes various contributions to material strength, but since only substitutional solid solution is considered here (all alloys are single-phase), we focus solely on the SSS contribution to \({\sigma }_{0}\). Hence, for this specific case, \({\sigma }_{0}\) (or H0, in case of the hardness analysis) is equal to the SSS contribution. Additionally, Eq. (10) can analyze the influence of grain size on hardness (H) by replacing \({\sigma }_{0}\) with H0. Therefore, examining equation 10 reveals that the same d can produce different hardness and \({\sigma }_{{{\rm{y}}}}\) values across materials with different values for \({K}_{{{\rm{H}}}}\). Consequently, assessing the \({\sigma }_{{\mathrm{ss}}}\) contribution based on absolute \({\sigma }_{{{\rm{y}}}}\) and σuts for fine-grained materials may be misleading.

Hence, to isolate the SSS component, the GBS contribution (\({K}_{{{\rm{H}}}}\)) must be removed. This can be achieved using Hall–Petch plots, where hardness (or \({\sigma }_{{{\rm{y}}}}\)) is measured for the same material at different grain sizes. In this approach, hardness (or \({\sigma }_{{{\rm{y}}}}\)) values are plotted against d−0.5 —as per Eq. (10)—followed by a linear regression (y = ax + b). Here, the intercept (b) represents the isolated SSS contribution—essentially, the SSS effect when the grain size is infinitely large, meaning no GBS—while the slope corresponds to GBS contribution (\({K}_{{{\rm{H}}}}\)- the Hall–Petch constant).

Figure 4a, b present hardness and \({\sigma }_{{{\rm{y}}}}\) values, respectively, plotted against d−0.5 for the alloys under study. \({\sigma }_{{{\rm{y}}}}\) values were estimated from tensile test curves shown in Supplementary Fig. 9. Moreover, the dashed lines in Fig. 4a, b represent the linear regression based on the data for each material. Thus, by extrapolating the curve to an infinite grain size (d−0.5 → 0), it is possible to estimate the intrinsic hardness (or \({\sigma }_{{{\rm{y}}}}\)) of each alloy and, consequently, the SSS. The individual plots of hardness and \({\sigma }_{{{\rm{y}}}}\) against d−⁰.⁵ for each alloy in this study are shown in Supplementary Figs. 10 and 11, respectively.

a Hardness X d−0.5 and b \({\sigma }_{y}\) X d−0.5 plots for Ni50Pd50, Ni63.2V36.8, Cr33Co33Ni33, Cr30Co30Ni30Pd10 and Cr30Co30Ni30V10 alloys. The values of Hall–Petch constant (\({K}_{{{\rm{H}}}}\)), SSS component for hardness (H0) and SSS for yield stress (σ0) were obtained through a linear regression for each alloy. d−⁰⋅⁵ represents the reciprocal of the square root of the grain size. Error bars represent the standard deviation of the Hardness measurements (10 replicates per condition) and of the grain size measurements (3 replicates per condition).

Analyzing the data in Fig. 4a, b, it is evident that both H0 and \({\sigma }_{0}\) values for the binary alloys are higher than those for pure Ni (Ho = 68.6 Hv and \({\sigma }_{0}\) = 14 MPa)44,45. Additionally, the binary alloy with Pd shows higher H0 and \({\sigma }_{0}\) values compared to those with V. This trend is also observed in the quaternary alloys, where those containing Pd and V exhibit higher H0 and \({\sigma }_{0}\) values compared to the Cr33Co33Ni33 alloy. These results suggest that adding V and Pd enhances the SSS of both pure Ni and the CrCoNi system. However, while V-based alloys show higher hardness and \({\sigma }_{{{\rm{y}}}}\), their H0 and \({\sigma }_{0}\) values indicate that V contributes less to SSS compared to Pd.

According to Supplementary Fig. 9, distinct tensile behavior is observed across the different alloys studied. Within each alloy, the primary variations in tensile behavior are due to differences in grain size for each condition. In general, both the yield stress and ultimate tensile strength increase (Supplementary Table 3) as grain size decreases for each respective alloy.

Another notable observation is that the increase in yield stress values differs among the alloys studied. For example, in the Ni50Pd50 alloy, a grain size reduction of 80% (from 64.30 to 13.40 μm) led to a yield stress increase of 13.7%. Conversely, for the Ni63.2V36.8 alloy, a grain size reduction of 82% (from 23.66 to 4.17 μm) resulted in a yield stress gain of 51.7%. These results indicate that different materials exhibit varying responses to grain size reduction, likely due to the unique Hall–Petch constants associated with each alloy.

Examining the \({K}_{{{\rm{H}}}}\) values (extracted from hardness and \({\sigma }_{{{\rm{y}}}}\) Hall–Petch plots-Fig. 4a, b) it is revealed that Ni63.2V36.8 has a significantly higher \({K}_{{{\rm{H}}}}\) than Ni50Pd50. Similar trends are observed in Cr30Co30Ni30Pd10 and Cr30Co30Ni30V10 alloys, with the V-based alloy showing a higher \({{{\rm{K}}}}_{{{\rm{H}}}}\) than the Pd-based alloy. This indicates that GBS is much more pronounced in V-based alloys. Also, Ni63.2V36.8 exhibited the highest GBS among the studied alloys. A high \({K}_{{{\rm{H}}}}\) indicates a notable increase in hardness and \({\sigma }_{{{\rm{y}}}}\) as grain size decreases46. Therefore, directly comparing absolute hardness, \({\sigma }_{{{\rm{y}}}}\) and σuts values across different alloys is not feasible for isolating the effects of SSS, given the varying contributions of GBS.

In this context, Supplementary Fig. 12a, b shows the projected hardness and \({\sigma }_{{{\rm{y}}}}\) of these alloys, assuming a uniform grain size of 10 µm, based on their respective \({K}_{{{\rm{H}}}}\) values. The Ni63.2V36.8 alloy has higher hardness and \({\sigma }_{{{\rm{y}}}}\) values at this grain size compared to other alloys. Despite Ni50P50 exhibiting the lowest \({K}_{{{\rm{H}}}}\) for \({\sigma }_{{{\rm{y}}}}\) (Fig. 4b), its \({\sigma }_{{{\rm{y}}}}\) value (Supplementary Fig. 12b) exceeds those of the ternary and quaternary alloys due to its highest \({\sigma }_{0}\) for a large range of grain sizes. This demonstrates that analyzing hardness or \({\sigma }_{{{\rm{y}}}}\) values alone can lead to incorrect conclusions regarding the SSS effect in different alloys.

The \({K}_{{{\rm{H}}}}\) values should be approached with caution, as the same constant can exhibit different values depending on whether hardness or \({\sigma }_{{{\rm{y}}}}\) is being analyzed. As illustrated in Fig. 4a, b, except for the Ni50Pd50 alloy, the \({K}_{{{\rm{H}}}}\) values associated with hardness are consistently higher than those for \({\sigma }_{{{\rm{y}}}}\). This discrepancy arises because hardness measurements are conducted in a localized region of the material, where the plastic deformation is restricted to only a few grains. Additionally, during hardness testing indentation, significant work-hardening effects occur, directly influencing the hardness values obtained. Specifically, the Ni50Pd50 alloy exhibits an unusually low \({K}_{{{\rm{H}}}}\) for hardness (i.e., the hardness remains unchanged with increasing grain size), potentially indicating a low work-hardening coefficient for this alloy. Consequently, the mechanical behavior of the Ni50Pd50 alloy requires more in-depth analysis.

Figure 5 presents a comparison between the experimental and calculated \({\sigma }_{0}\) values using the Varvenne (with solution radii as an input) and Oh models. The analysis indicates that, although both models fail to precisely predict the SSS, the theoretical σss values predicted by the Varvenne model exhibit a closer correlation to the experimental data.

Interestingly, the results indicate that alloys in this study exhibiting the highest \(\delta\) values also demonstrated the highest SSS values, primarily observed in the binary alloy systems. For comparison, Supplementary Tables 4 and 5 present the SSS components obtained from hardness and yield stress measurements for the alloys used in this study (from Fig. 4a, b), as well as for several other multicomponent alloys with significant atomic volume differences among the atoms in solid solution.

The results presented in Supplementary Tables 4 and 5 indicate that, while a linear relationship between the increase in lattice distortion (\(\delta\)) and the increase in the solid SSS component was not observed across all alloys, there is a clear trend suggesting that a higher \(\delta\) value correlates with an increase in SSS (Fig. 6). This trend was derived from both hardness measurements (Fig. 6a and Supplementary Table 4) and yield stress measurements (Fig. 6b and Supplementary Table 5). Furthermore, no similar correlation was found when comparing the SSS component with electronegativity values (Fig. 6c, d); that is, an increase in electronegativity did not correspond to an increase in the SSS component for the alloys shown in Supplementary Tables 4 and 5.

At this stage of the discussion, it is essential to highlight the findings of Sohn et al.47, which report on the equiatomic CoNiV alloy. The authors demonstrate that this alloy exhibits a \({\sigma }_{0}\) value of 383 MPa and a \({K}_{{{\rm{H}}}}\) value of 864 MPa μm0.5. These values are remarkably high, particularly the \({\sigma }_{0}\) value of 383 MPa, which exceeds those of all alloys discussed in this study. This observation suggests that the contribution of this alloy to SSS is the highest among the alloys here evaluated. Furthermore, the Δχ value (on the Allen scale) is 0.156, the highest among all alloys presented here, while the \(\delta\) value is only 2.71.

Initially, it may appear that the SSS of the equiatomic CoNiV alloy could be accounted for by Oh’s model, given that this alloy presents notably high Δχ and \({\sigma }_{0}\) values, once again exceeding those of all alloys studied herein. However, it is crucial to note that this advantage in Δχ is observable only on the Allen scale. The Δχ values for the CoNiV alloy on the Pauling and Allred–Rochow scales are 0.141 and 0.131, respectively. When these values are compared with the Δχ values in Supplementary Table 2, no consistent relationship between SSS and Δχ emerges.

In light of these findings, the data and discussions presented here point to the Varvenne worked better in prediction of SSS. This model suggests that atomic volume differences among species in solid solutions are likely to play a more critical role in determining the SSS of FCC alloys.

However, the Varvenne model has not yet been able to accurately predict the SSS component for all the alloys in study. Since the analysis of solid solutions involves interactions between different atoms within a metallic bond, more complex parameters are needed to accurately describe the interactions of diverse atoms in various environments. For comparison purposes, Supplementary Fig. 13a, b presents a comparison between the experimental and calculated \({\sigma }_{0}\) values using the Varvenne model, with solution radii and metallic radii as input.

By comparing the results shown in Fig. 5a and Supplementary Fig. 13a, b, it becomes evident that, although different values for the SSS component can be obtained depending on the input parameters used, the Varvenne model performed better when the solution metal radii were used as input. This is demonstrated by the smaller deviation from the ideal 1:1 linear fit:0.08 for the solution metal radii compared to 0.276 for the pure metal radii. Furthermore, considering that the lattice distortion is greater for the Cr30Co30Ni30V10 alloy than for the Cr33Co33Ni33 alloy, the use of the solution metal radii also produced results that align more closely with reality, as it predicted a higher value of σ₀ for the Cr30Co30Ni30V10 alloy compared to the Cr33Co33Ni33 alloy. Despite the variations observed with different input parameters, the model consistently demonstrated the same trend: a greater atomic volume difference correlates with a higher SSS.

Moreover, based on the principle that maximum strengthening occurs when lattice distortion (\(\delta\)) is at its peak, the extent of SSS will depend on both the specific system under investigation and the quantity of elements involved. For example, in binary alloys, the maximum theoretical SSS is expected at an atomic fraction close to 50 at.% for each element, A and B (towards the element with larger elastic modulus), with the strengthening effect increasing in proportion to the difference in the atomic radii of the elements involved. While this hypothesis holds effectively for the Ni50Pd50 alloy, it does not apply to the Ni63.2V36.8 alloy, where a binary system with 50 at.% V does not exhibit a single-phase FCC structure. Consequently, each system must be analyzed individually due to its distinct characteristics. A comparable situation arises in systems containing three or more elements, where SSS contribution is maximized when the fraction of elements with larger atomic radii is high and the fraction of elements with smaller atomic radii is low. This pattern aligns with findings in other studies examining the SSS model12,48,49

However, the results presented in this work also indicate that additional factors should be considered when developing models to predict SSS. For example, the dislocation line constants might change from case to case or maybe the non-linear variations in the atomic volume of each element. Moreover, another potential source of discrepancy between the experimental results and those calculated using the Varvenne model could be the Stacking Fault Energy (SFE) of each alloy, as the Varvenne model does not account for this parameter50,51,52. This could explain the larger disparity between the experimental and calculated values for the Ni50Pd50 alloy, given that Ni50Pd50 exhibits evidence of high SFE (such as a low Hall–Petch coefficient for hardness and \({\sigma }_{{{\rm{y}}}}\)).

At last, it was also noted that, contrary to current literature on MPEAs5,11, SSS is not always the predominant strengthening mechanism, as shown in Fig. 7. The SSS contribution values, obtained using supplementary Equations (1) and (2), indicate that SSS becomes predominant (SSS > 50%) only above a critical grain size, while GBS dominates below this size. This critical grain size varies for each alloy and is detailed in Supplementary Table 6.

Variation of the solid solution strengthening (SSS) component as a function of grain size in the a hardness and b \({\sigma }_{y}\) of the Ni50Pd50, Ni63.2V36.8, Cr33Co33Ni33, Cr30Co30Ni30Pd10 and Cr30Co30Ni30V10 alloys. GBS stands for grain boundary strengthening. The dashed lines indicate the transition point beyond which solid solution strengthening (SSS) becomes the predominant mechanism over GBS.

Figure 7 (and also Supplementary Fig. 14) was developed based on the premise that, since the alloys are solid solutions, the yield stress (or hardness) of each alloy consists of two components: the SSS component (\({\sigma }_{0}\) or H0) and the grain refinement component (\({\sigma }_{{\mathrm{hp}}}\)). Thus, we have the equation:

For example, considering the values of \({\sigma }_{0}\) (239.21 MPa) and \({K}_{{{\rm{H}}}}{{\rm{}}}\) (862.3 MPa μm0.5) for the Ni63.2V36.8 alloy (Fig. 4b), if the contribution of the \({\sigma }_{0}\) component to this alloy’s yield stress were only 5%, this would result in a contribution of approximately 3.8 GPa from the \({\sigma }_{{\mathrm{hp}}}\) component, assuming a grain size of 50 nm. However, although similar results have already been reported in the literature for alloys containing Pd53,54 and V47, achieving such a fine grain size through conventional plastic deformation and heat treatment methods is challenging. Moreover, the Hall–Petch relationship tends to break down for materials with grain sizes in the nanometer range (<100 nm). Therefore, the results presented in Fig. 7 represent hypothetical values and trends for grain sizes below 10 μm (or for SSS < 50%).

Through this comprehensive investigation of SSS in FCC alloys, it was demonstrated that atomic volume differences among constituent elements have a more pronounced influence on SSS than electronegativity differences. Furthermore, due to the intrinsic characteristics of each solid solution system—such as the elemental fractions, the associated atomic volume variation with compositional changes, and the SFE—each system exhibits distinct behavior. Consequently, developing a general model capable of predicting SSS remains a challenging task.

The results discussed in this work indicated that, for a given solid solution system, there is a critical grain size below which GBS dominates over SSS in contributing to yield stress and hardness. Moreover, the results also show that binary alloys exhibit both greater predicted lattice distortion and higher measured SSS contributions. This suggests that increasing compositional complexity does not inherently lead to enhanced mechanical strength.

Notably, the Ni50Pd50 alloy, due to its relatively low \({K}_{{{\rm{H}}}}\) value, has an extremely small critical grain size (Supplementary Fig. 14), making SSS nearly the sole hardening mechanism. These findings highlight that much work has yet to be done to fully understand SSS for different alloys, and suggest the Ni50Pd50 alloy promising material for future fundamental metallurgical studies due to its minimal mechanical property sensitivity to grain growth.

Methods

In this study, the Ni63.2V36.8 alloy was selected as a benchmark due to its specific stoichiometry, which was identified in Oh’s work30 as having a substantial SSS effect attributed to the alloy’s high electronegativity difference. This alloy thus provided a comparative basis for evaluating our results alongside those reported by Oh.

To further investigate the primary contributors to SSS, an additional alloy with a maximized atomic radius difference and nearly constant electronegativity was developed. By fixing one of these variables, it was sought to discern the primary factor driving SSS—either electronegativity or atomic volume difference. To achieve this, various 3d transition metals that form solid solutions with Ni were analyzed (Fig. 1a), focusing on elements that exhibit considerable differences in either electronegativity or atomic volume relative to pure Ni.

As shown in Fig. 1a, adding Pd to pure Ni increased the atomic radius difference significantly without substantially affecting the system’s overall electronegativity compared to a binary Ni–V system. The Pd content was optimized at 50 atomic percent, balancing the desired atomic radius disparity while controlling for cost, as higher Pd concentrations would over-amplify atomic radius difference and risk excessive lattice distortion.

In designing the quaternary alloys, it was applied a similar principle, incorporating only 10% of Pd and V within a CrCoNi system. This maintained the criteria established for binary alloys, aiming to maximize atomic radius difference while minimizing shifts in electronegativity, and provided a cost-effective approach that preserved the FCC single-phase structure.

Computational thermodynamic calculations using the CALPHAD method identified the FCC single-phase regions for the alloys Ni50Pd50, Ni63.2V36.8, Cr33Co33Ni33, Cr30Co30Ni30Pd10, and Cr30Co30Ni30V10, utilizing the ThermoCalc® software and the TCHEA 5 and TCNI11 databases. These alloys, along with pure Ni, were prepared by arc melting high-purity elements under argon atmosphere and underwent multiple re-melting cycles for compositional homogeneity. To achieve a single-phase, fine-grained microstructure with low dislocation density, the ingots were homogenized, water quenched, cold rolled, annealed, and quenched again. Specific thermomechanical treatments are detailed indicated in Supplementary Table 7, with Ni63.2V36.8 undergoing additional reduction to disrupt its eutectoid structure before the treatment in Supplementary Table 7. For each heat treatment, samples were encapsulated in vacuum-filled quartz ampoules to mitigate oxidation during high-temperature processing.

The phase structure of recrystallized samples of Ni50Pd50, Cr33Co33Ni33, Cr30Co30Ni30Pd10, Cr30Co30Ni30V10 and pure Ni was analyzed using high-energy X-ray diffraction. A monochromatic X-ray beam at 87 keV, generated with a crystal monochromator, was used without harmonic rejection optics. For the Ni63.2V36.8 alloy, however, a higher energy beam at 102.85 keV was employed, this time with harmonic rejection optics. All X-ray measurements were carried out at Petra III, DESY in Germany, using a Perkin Elmer 2D detector to capture Debye–Scherrer rings. The experimental setup featured a 700 × 700 μm2 beam and a 1.226 m sample-to-detector distance, calibrated with LaB6 powder. The 2D diffraction images were converted into 1D patterns through radial integration, with single-peak fitting conducted using GSAS II software. Rietveld refinement was applied to fit the full spectrum, allowing for precise lattice parameter determination.

Scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) analyses were conducted on polished samples using a TESCAN MIRA FEG microscope, operating at 20 kV. Additionally, electron backscatter diffraction (EBSD) was performed on samples at 30 kV. EBSD data were processed using ATEX software©.

Uniaxial tensile tests were conducted, in duplicate, at room temperature using an INSTRON machine, following ASTM E8 standards. A nominal strain rate of 10−3 s−1 was applied, and an optical extensometer was used to measure the strain on the samples during the test. Flat dog bone-shaped tensile specimens (1.0 mm thick) were prepared by electrical discharge machining, aligned parallel to the rolling direction, and the yield stress was determined using the 0.2% proof stress criterion. To evaluate solid solution behavior, Hall–Petch plots were created by measuring hardness and yield stress for different grain sizes. Each alloy underwent various annealing treatments to achieve different grain sizes, and Vickers Hardness measurements were taken on recrystallized samples with a 100 g load and a 15-s dwell time.

Data availability

Source data are provided with this paper. The raw and processed data required to reproduce these findings are fully accessible in a dedicated public repository under the address https://doi.org/10.6084/m9.figshare.29664515. Source data are provided with this paper.

References

He, Q. F. et al. A highly distorted ultraelastic chemically complex Elinvar alloy. Nature 602, 251–257 (2022).

Utt, D. et al. The origin of jerky dislocation motion in high-entropy alloys. Nat. Commun. 13, 4777 (2022).

Li, Y. et al. Theoretical insights into the Peierls plasticity in SrTiO3 ceramics via dislocation remodelling. Nat. Commun. 13, 6925 (2022).

Liu, G. et al. Atomically informed nonlocal semi-discrete variational Peierls–Nabarro model for planar core dislocations. Sci. Rep. 7, 43785 (2017).

Tandoc, C. et al. Mining of lattice distortion, strength, and intrinsic ductility of refractory high entropy alloys. npj Comput. Mater. 9, 53 (2023).

Zhang, Z. et al. Influence of nano-BN inclusion and mechanism involved on aluminium-copper alloy. Sci. Rep. 14, 6372 (2024).

He, X. et al. Pt-induced atomic-level tailoring towards paracrystalline high-entropy alloy. Nat. Commun. 14, 775 (2023).

Varvenne, C., Luque, A. & Curtin, W. A. Theory of strengthening in fcc high entropy alloys. Acta Mater. 118, 164–176 (2016).

Oliveira, P. H. F. et al. Evolution of dislocation and stacking-fault densities for a Cu-0.7Cr-0.07Zr alloy during cryogenic tensile test: an in-situ synchrotron X-ray diffraction analysis. Mater. Sci. Eng. A 813, 141154 (2021).

Roy, A. et al. Lattice distortion as an estimator of solid solution strengthening in high-entropy alloys. Mater. Charact. 172, 110877 (2021).

Zhang, H. L. et al. Solid solution strengthening of high-entropy alloys from first-principles study. J. Mater. Sci. Technol. 121, 105–116 (2022).

Winkens, G. et al. The influence of lattice misfit on screw and edge dislocation-controlled solid solution strengthening in Mo-Ti alloys. Commun. Mater. 4, 26 (2023).

Li, H. et al. Uniting tensile ductility with ultrahigh strength via composition undulation. Nature 604, 273–279 (2022).

Freudenberger, J. et al. Solid solution strengthening in medium- to high-entropy alloys. Mater. Sci. Eng. A 861, 144271 (2022).

Wang, M.-X. et al. Solid-solution strengthening effects in binary Ni-based alloys evaluated by high-throughput calculations. Mater. Des. 198, 109359 (2021).

Fleischer, R. L. Substitutional solution hardening. Acta Metall. 11, 203–209 (1963).

Fleischer, R. L. Solution hardening. Acta Metall. 9, 996–1000 (1961).

Labusch, R. Statistische theorien der mischkristallhärtung. Acta Metall. 20, 917–927 (1972).

Labusch, R. A statistical theory of solid solution hardening. Phys. Status Solidi B 41, 659–669 (1970).

Geslin, P.-A. Modeling of solid solution strengthening in FCC alloys: atomistic simulations, statistical models and elastic continuous approaches. Comput. Mater. Sci. 232, 112624 (2024).

Leyson, G. P. M. & Curtin, W. A. Friedel vs. Labusch: the strong/weak pinning transition in solute strengthened metals. Philos. Mag. 93, 2428–2444 (2013).

Leyson, G. P. M. et al. Quantitative prediction of solute strengthening in aluminium alloys. Nat. Mater. 9, 750–755 (2010).

Zaiser, M. Dislocation motion in a random solid solution. Philos. Mag. A 82, 2869–2883 (2002).

Pei, Z. et al. Theory-guided design of high-entropy alloys with enhanced strength-ductility synergy. Nat. Commun. 14, 2519 (2023).

Tsuru, T. et al. Intrinsic factors responsible for brittle versus ductile nature of refractory high-entropy alloys. Nat. Commun. 15, 1706 (2024).

Huang, C.-W. et al. A micromechanical study on the effects of precipitation on the mechanical properties of CoCrFeMnNi high entropy alloys with various annealing temperatures. Sci. Rep. 13, 3379 (2023).

Hsu, W.-L. et al. Clarifying the four core effects of high-entropy materials. Nat. Rev. Chem. 8, 471–485 (2024).

Maresca, F. & Curtin, W. A. Mechanistic origin of high strength in refractory BCC high entropy alloys up to 1900K. Acta Mater. 182, 235–249 (2020).

Toda-Caraballo, I. & Rivera-Díaz-del-Castillo, P. E. J. Modelling solid solution hardening in high entropy alloys. Acta Mater. 85, 14–23 (2015).

Oh, H. S. et al. Engineering atomic-level complexity in high-entropy and complex concentrated alloys. Nat. Commun. 10, 2090 (2019).

Wen, C. et al. Modeling solid solution strengthening in high entropy alloys using machine learning. Acta Mater. 212, 116917 (2021).

Yin, B. et al. Solute misfit and solute interaction effects on strengthening: a case study in AuNi. Acta Mater. 257, 119118 (2023).

Yin, B. & Curtin, W. A. Origin of high strength in the CoCrFeNiPd high-entropy alloy. Mater. Res. Lett. 8, 209–215, (2020).

Fu, X. et al. Uncertainty and statistics of dislocation-oxide interactions on strength and creep failure of oxide dispersion strengthened steels. Eng. Fract. Mech. 293, 109679 (2023).

Sun, G. et al. Orowan strengthening with consideration of thermal activation. Comput. Mater. Sci. 233, 112720 (2024).

Bodner, S. C. et al. Correlative cross-sectional characterization of nitrided, carburized and shot-peened steels: synchrotron micro-X-ray diffraction analysis of stress, microstructure and phase gradients. J. Mater. Res. Technol. 11, 1396–1410 (2021).

Erdely, P. et al. Effect of hot rolling and primary annealing on the microstructure and texture of a β-stabilised γ-TiAl based alloy. Acta Mater. 126, 145–153 (2017).

Silva, D. D. S. et al. Computational thermodynamics-guided alloy design and phase stability in CoCrFeMnNi-based medium-and high-entropy alloys: an experimental-theoretical study. Scr. Mater. 252, 116264 (2024).

Cullity, B. D. Elements of X-ray Diffraction, 3rd edn (Prentice-Hall, 2001).

Pearson, W. B. Pearson’s Handbook of Crystallographic Data for Intermetallic Phases (Pergamon Press, 1986).

Zhang, Y. et al. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 10, 534–538 (2008).

Mishima, Y., Ochiai, S. & Suzuki, T. Lattice parameters of Ni(γ), Ni3Al(γ‘) and Ni3Ga(γ‘) solid solutions with additions of transition and B-subgroup elements. Acta Metall. 33, 1161–1169 (1985).

Owen, L. R. & Jones, N. G. Lattice distortions in high-entropy alloys. J. Mater. Res. 33, 2954–2969 (2018).

Owen, L. R. et al. An assessment of the lattice strain in the CrMnFeCoNi high-entropy alloy. Acta Mater. 122, 11–18 (2017).

Keller, C. & Hug, E. Hall–Petch behaviour of Ni polycrystals with a few grains per thickness. Mater. Lett. 62, 1718–1720 (2008).

Silva, D. D. S. et al. Metastability-engineering strategy in CoCrFeMnNi-based medium- and high-entropy alloys: unraveling the interplay with recrystallization, grain growth, and mechanical properties. Int. J. Plast. 187, 104285 (2025).

Sohn, S. S. et al. Ultrastrong medium-entropy single-phase alloys designed via severe lattice distortion. Adv. Mater. 31, 1807142 (2019).

Coury, F. G. et al. High-throughput solid solution strengthening characterization in high entropy alloys. Acta Mater. 167, 1–11 (2019).

Pei, Z. et al. Toward the design of ultrahigh-entropy alloys via mining six million texts. Nat. Commun. 14, 54 (2023).

Varvenne, C. et al. Solute strengthening in random alloys. Acta Mater. 124, 660–683 (2017).

LaRosa, C. R. et al. Solid solution strengthening theories of high-entropy alloys. Mater. Charact. 151, 310–317 (2019).

Varvenne, C. & Curtin, W. A. Predicting yield strengths of noble metal high entropy alloys. Scr. Mater. 142, 92–95 (2018).

Vu, T.-N., Pham, V.-T. & Fang, T.-H. Maintain sort order of grain boundary to investigate the deformation mechanism of CoCuFeNiPd high–entropy alloys. Curr. Appl. Phys. 59, 46–59 (2024).

Chen, S. et al. Hall–Petch and inverse Hall–Petch relations in high-entropy CoNiFeAlxCu1-x alloys. Mater. Sci. Eng. A 773, 138873 (2020).

Acknowledgements

This research was funded by the São Paulo Research Foundation (FAPESP), Brazil, under grant numbers 2021/12589-5, 2023/06700-6, 2022/02770-7, and 2023/03385-2. Additional support was provided by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior–Brasil (CAPES), Finance Code 001, and by the National Council for Scientific and Technological Development (CNPq), under process numbers 444393/2024-2, 403832/2023-3, and 301757/2022-4. This work was sponsored by the Army Research Office under Grant Number W911NF-23-1-0310. The views and conclusions expressed herein are those of the authors and do not necessarily reflect the official policies or positions of the Army Research Office or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for governmental purposes, notwithstanding any copyright notice contained herein. The authors acknowledge Henry Royce Institute grants EP/R00661X/1, EP/S019367/1, EP/P025021/1, and EP/P025498/1. The authors acknowledge the Laboratory of Structure Characterization (LCE, DEMa/UFSCar) for technical support. The authors also acknowledge DESY (Hamburg, Germany), a member of the Helmholtz Association HGF, for the provision of experimental facilities. Parts of this research were carried out at PETRA III, and we would like to thank Drs. Norbert Schell, Emad Maawad, and Martin Etter for assistance in using the P07 and P02 photon beamlines.

Author information

Authors and Affiliations

Contributions

P.H.F.O., C.B. and F.G.C. conceptualized this research and designed the entire workflow. P.H.F.O., C.L.G.P.M. and G.C.S. conducted all the production and processing of the alloys used in the study. P.H.F.O. performed the X-ray measurements using synchrotron radiation and subsequent analyses, as well as CALPHAD simulations. P.H.F.O., C.L.G.P.M. and G.C.S. conducted the tensile tests. P.H.F.O. and C.L.G.P.M. conducted the microhardness measurements. P.H.F.O. analyzed the mechanical data. P.H.F.O., C.L.G.P.M., G.C.S. and J.S. conducted the EBSD, SEM, and EDS analyses. P.H.F.O., C.B. and F.G.C. drafted the first version of the manuscript. E.J.P., W.J.B. and J.S. revised the manuscript. P.H.F.O., C.L.G.P.M., G.C.S., J.S., E.J.P., W.J.B., C.B. and F.G.C. responded to reviewers.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Oliveira, P.H.F., Martins, C.L.G.P., Stumpf, G.C. et al. Exploring the relative influence of atomic parameters on solid solution strengthening. Nat Commun 16, 8865 (2025). https://doi.org/10.1038/s41467-025-63900-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63900-6