Abstract

Improving the quality of extracts derived from medicinal plants is a critical concern due to their extensive use across various industries. The Arvaneh plant (Hymenocrater platystegius Rech. F), a species native to the Khorasan province in Iran and belonging to the mint family, was the focus of this study. We optimized the extraction of Arvaneh plant using both microwave (MW) and pulsed electric field (PEF) techniques. The MW method was tested at different processing times (90, 180, and 270 s) and power levels (180, 540, and 900 W), while the PEF method was evaluated with varying electric field intensities (0.25, 3.25, and 6.25 kV/cm) and pulse numbers (10, 45, and 80) using a central composite design (CCD). The results revealed that extraction efficiency, total phenolic content, and total flavonoid content were significantly higher with the PEF method compared to the MW method (p < 0.05). Moreover, the PEF technique showed superior performance in preserving the antioxidant properties of the extract, as assessed by DPPH and FRAP methods. GC/MS analysis confirmed the presence of 27 bioactive compounds in the Arvaneh extract obtained through PEF-assisted extraction. In conclusion, the PEF method proved to be highly efficient for extracting bioactive compounds from the Arvaneh plant.

Similar content being viewed by others

Introduction

In recent years, there has been growing interest in utilizing plant extracts in the food industry, primarily due to their antioxidant properties and potential health benefits for consumers. These positive effects are largely attributed to the vitamins, minerals, and various phenolic compounds found in plant extracts1.

The Arvaneh plant (Hymenocrater platystegius Rech. F.), native to the Khorasan province of Iran, belongs to the mint family2. Traditionally, Arvaneh flowers have been used in Iranian medicine for their medicinal properties, antimicrobial effects, aromatic essences, and unique chemical compounds3. Many species of this plant are known to contain beneficial compounds such as rosmarinic acid, flavonoids, tannins, and saponins4.

The increasing use of medicinal plants in various industries has posed researchers with the challenge of selecting effective methods for extracting these compounds and increasing extraction efficiency. Traditional extraction methods, based on water distillation, are among the oldest and most widely used techniques. However, these methods suffer from several disadvantages, including long extraction times, low yields, high solvent and energy consumption, and degradation of bioactive compounds due to high temperatures5.

As a result, modern extraction techniques such as supercritical fluid extraction, ultrasonic-assisted extraction, ohmic heating extraction, as well as microwave (MW) and PEF methods have gained attention as potential alternatives6. Supercritical fluid extraction, for instance, offers the advantage of operating at low temperatures, which helps preserve thermolabile compounds. However, it requires expensive equipment and has limitations in terms of solvent selectivity7. Ultrasonic-assisted extraction is known for its ability to enhance mass transfer, yet it can lead to mechanical damage of bioactive compounds and often requires prolonged processing times. Ohmic heating is efficient in terms of energy usage, but it may cause uneven heating and requires complex setup6.

In contrast, Microwave (MW) and PEF methods offer unique advantages. MW heating is rapid and uniform, minimizing the loss of volatile and heat-sensitive compounds. PEF, on the other hand, is a non-thermal technique that enhances cell membrane permeability through electroporation, leading to improved extraction yields without significant thermal degradation of bioactive compounds8. Microwaves interact with materials within an electromagnetic field, generating heat internally rather than through traditional thermal energy transfer. This process primarily involves ion conduction and dipole interaction. Many chemical solutions and food items contain water and dissolved salts, which dissociate into charged particles under microwave fields. These charged particles experience alternating forces, leading to acceleration and collisions with neighboring molecules, thereby transferring kinetic energy. This energy conversion occurs in two stages: first, electromagnetic field energy is transferred to the charged particles, which then pass this kinetic energy to surrounding molecules, uniformly increasing their temperature throughout the material. This uniform heating effectively facilitates moisture removal from food items with minimal impact on product quality9.

In recent decades, PEF technology has gained significant attention for extracting plant compounds10. PEF is an innovative physical method that offers a promising alternative to conventional cell lysis techniques, such as grinding, heating, or enzymatic treatment, by enhancing the mass transfer of water and intracellular compounds during extraction. The PEF process involves exposing plant tissues to medium-intensity electric pulses (1–10 kV/cm) with relatively low energy (1–10 kJ/kg) over a short duration. This exposure induces the formation of pores in the cell membrane (electroporation), which increases membrane permeability and facilitates the release of cell contents. As a non-thermal process, PEF preserves nutritional qualities while enhancing productivity in food processing11. Previous studies, such as those by Golmakani et al. (2021), Elakremi et al. (2022), Pimentel-Moral et al. (2018), Redondo et al. (2018), Nowacka et al. (2019) and Shiekh et al. (2021), have demonstrated the effectiveness of MW and PEF in extracting bioactive compounds from various plant sources7,12,13,14,15,16.

Despite the growing body of research on MW and PEF methods, no studies have investigated the use of these techniques for extracting bioactive compounds from Hymenocrater platystegius Rech. F., a plant with significant medicinal potential. This study aims to fill this gap by evaluating the effectiveness of MW and PEF methods in extracting antioxidant compounds from Arvaneh plant extract (APE), providing insights into their applicability and potential advantages over other extraction methods.

Materials and methods

Materials

Methanol, diphenylpicrylhydrazyl reagent (DPPH), aluminum chloride, gallic acid, quercetin, ferric chloride, Folin-Ciocalteau reagent, calcium carbonate, phosphate buffer, trichloroacetic acid, potassium acetate, and potassium ferricyanide were purchased from Merck Company (Germany).

Preparation of plant sample

The Arvaneh plant was purchased from local groceries in Birjand, Iran. It was air-dried at room temperature in a dark, well-ventilated area, then ground into powder using an electric mill (Janke and Kunkel, Germany) and sieved through a 40-mesh sieve. The prepared powder was stored in a sealed container in a moisture-free environment until extraction17.

Extraction using the PEF and microwave (MV) methods

A specific ratio of the sample (20 g) to solvent (300 mL of distilled water) was used for extraction. The PEF process was conducted at three field intensity levels (0.25, 3.25, and 6.25 kV/cm) and three pulse levels (10, 45, and 80) using a Pulsemaster system (Netherlands) with a parallel plate configuration. The chamber, made of polycarbonate, and the sample was evenly distributed between two stainless steel electrodes with a spacing of 2 cm. The electrodes were gold-plated to ensure optimal conductivity and prevent corrosion. Temperature sensors inside the chamber ensured the sample temperature did not exceed 25 °C during the treatment. A graphical schematic of the PEF setup is provided in Fig. 118.

Meanwhile, the MW process was performed at three power levels (180, 540, and 900 W) and three time intervals (90, 180, and 270 s) using a MicroSYNTH microwave apparatus (Milstone. Italy)19. The microwave device operated at a frequency of 2.45 GHz, with a maximum power output of 1000 W, adjustable in increments of 1 W. The internal dimensions of the oven were 35 × 35 × 35 cm³. Temperature regulation was managed by an external infrared sensor capable of monitoring temperature increases up to 250 °C with a precision of 0.1 °C. The pressure sensor, APC-55E, could handle a maximum pressure of 55 bars. To ensure even distribution of microwaves, the oven featured an HPR-1000 rotor. The resulting extracts were converted into powder by evaporating the solvent in an incubator (Fisher, USA) at 40 °C and then stored at -18 °C for further testing20,21. By Kuster and Schönborn (2000), the experimental design met the necessary standards for electromagnetic field exposure22.

Experimental design

The extraction conditions for both PEF and Microwave (MW) methods were optimized using a Central Composite Design (CCD), a standard approach in Response Surface Methodology (RSM). This design included two variables (field intensity and pulse number for PEF) and (time and power for MW) at three different levels. The variables used in this design were:

-

For PEF:

-

Field intensity: 0.25, 3.25, and 6.25 kV/cm.

-

Pulse number: 10, 45, and 80.

-

For MW:

-

Power: 180, 540, and 900 W.

-

Time: 90, 180, and 270 s.

In this study, a second-order model was used to fit the data. The general equation of the model is as follows:

Where:

Y is the response variable, β0 is the intercept, βi are the linear coefficients, βii are the quadratic coefficients, βij are the interaction coefficients between variables.

This design was employed to identify the optimal conditions for extraction due to its efficiency in exploring the response surfaces23.

Extraction efficiency

The extraction efficiency was obtained by dividing the weight of the dried extract by the original plant in percentage24.

Total phenolic content (TPC)

The amount of total phenolic compounds was investigated by the colorimetric method of Folin-Ciocalteau25. Gallic acid was used as a standard phenolic compound. The TPC was expressed based on gallic acid equivalent in grams of the dry weight of the extract.

Total flavonoids

The aluminum chloride colorimetric method was used to determine the content of flavonoids, expressed as milligrams of quercetin equivalents per gram of extract26.

DPPH radical scavenging activity

The assessment of free radical scavenging ability was conducted by method of Abdelmaksoud et al., using below Equation:27.

which, Ablank shows the light absorbance of the negative control, which does not contain the extract, and Asample is the light absorbance of different concentrations of the extract.

The positive control was ascorbic acid.

Ferric-reducing power assay (FRAP)

The antioxidant capacity of the extracts was assessed using the ferric ion (Fe³⁺) reduction method. The results were expressed as millimoles of ferrous ions produced per gram of extract28.

GC-MS analysis

The gas chromatography (GC) system comprised an Agilent 6890 chromatograph equipped with a flame ionization detector (FID), an Agilent 5973 network mass selective detector (MSD) (Wilmington, Delaware, USA), and a Gerstel ODP-2 sniffing port (Linthicum, Maryland, USA). Volatile compounds were separated using a DB-Wax column (30 m length × 0.25 mm i.d. × 0.5 μm thickness, J&W Scientific, Folsom, California, USA). A 3 µL extract was injected in pulsed splitless mode (40 psi; 0.5 min). The temperatures for the injector and FID detectors were set at 270 °C and 280 °C, respectively. The flow rate of the carrier gas (helium) was 1.5 mL/min. The oven temperature of the DB-Wax column was increased from 50 °C to 250 °C at a rate of 4 °C/min, with a final hold at 250 °C for 10 min29. The identified compounds were expressed in terms of percentage area of the total chromatogram.

Statistical analysis

Statistical analysis was conducted using Design Expert statistical software (version 10), applying a central composite design model to optimize the variables (Tables 1 and 2). After determining the optimal conditions, a comparison of the two extraction methods was performed using SPSS version 22 software. Duncan’s multiple range test was employed to compare the mean values, reported as mean ± standard deviation.

Results

Experimental design

Tables 1 and 2 show the effects of independent variables on extraction efficiency, total phenolic compounds (TPC), flavonoids, DPPH free radical inhibition, and the reducing power of APE. The PEF and response surface methods were utilized for analysis. Similarly, Table 2 presents the effects of independent variables, power (A) and time (B), on the same dependent variables using MW extraction and the response surface method.

The data (Table 1) highlight significant variations in response variables based on the changes in the independent variables, indicating the critical influence of these factors on the extraction efficiency and antioxidant properties of APE. For instance, the highest yield (21.39%) was achieved at a field intensity of 3.25 kV/cm and 80 pulses. Table 2 indicated that the highest extraction yield (11.47%) was achieved at a power of 900 W and an extraction time of 270 s. Meanwhile, the maximum TPC (108.18 mg Gallic acid/g) was observed at a power of 540 W and a time of 180 s. These results demonstrate the significant impact of microwave power and extraction time on the efficiency and antioxidant properties of the APE.

Extraction efficiency

The results from the PEF extraction method showed that the lack-of-fit test was not significant (p > 0.05), indicating that the model is well-fitted to the data. The significant terms in the model included field intensity (A) (p < 0.01), the number of pulses (B) (p < 0.001), and the interaction between field intensity and the number of pulses (AB) (p < 0.05) (Table 1-supplementary). As shown in Fig. 2a, both the field intensity and the number of pulses simultaneously affect the extraction efficiency of APE. Accordingly, the extraction efficiency enhanced with the increase of the electric field intensity from 0.25 to 3.25 kV/cm and the number of pulses from 10 to 80.

In the extraction method of APE using microwaves (MW), the optimized model suggested by the software indicated that the quadratic model was significant for extraction efficiency (p < 0.001) (Table 2-supplementary). Additionally, the lack-of-fit test was not significant (p > 0.05), indicating that the model is appropriate. In this model, power (A) (p < 0.001), time (B) (p < 0.001), and the interaction effect of power and time (AB) (p < 0.05) were significant.

The findings illustrated in Fig. 2a indicate that increasing the field intensity and the number of pulses to 3.25 kV/cm and 80, respectively, led to the highest extraction efficiency. The simultaneous effect of MW power and time on the extraction efficiency of APE is shown in Fig. 2b. Based on the results, the extraction efficiency significantly increased with the increase in time and power up to 270 s and 540 W, respectively.

Determining the total content of phenolic compounds

Figure 3a illustrates the trend of changes in the total phenolic content (TPC) of APE under various extraction conditions (PEF and MWs). As the intensity increased from 0.25 to 3.25 kV/cm, the TPC initially increased and then decreased. The effect of pulse

number on TPC followed a similar pattern to that of PEF intensity. The gallic acid standard curve equation for calculating the number of phenolic compounds is given by Eq. (3):

According to Table 1-supplementary, the lack-of-fit test was not significant (p > 0.05), indicating that the model equation was appropriate.

As shown in Table 2-supplementary, the optimal model suggested by the software for TPC using MW was the second-order model, which was significant (p < 0.001). However, the lack-of-fit test was not significant (p > 0.05), confirming the suitability of the fitted model.

In Fig. 3b, the TPC in APE initially increases with a relatively steep slope and then decreases as MW power increases. This change can be explained by the fact that increasing.

MW power to a moderate level (around 45 W) creates optimal heat, facilitating the release of active compounds from plant cell walls and improving their solubility. Additionally, the rise in temperature enhances mass transfer during the extraction process, leading to an increase in phenolic compounds in the extract5.

Figure 3b also shows that the amount of phenolic compounds increased as pulse number and MW power were elevated to 540 W and 180 s, respectively. Phenolic compounds, as secondary plant metabolites, possess antioxidant properties due to the hydroxyl groups in their structure. The use of natural phenols in the food industry has increased because they delay the oxidative breakdown of lipids, thereby enhancing food quality and nutritional value30. Studies have demonstrated that phenolic compounds are effective antioxidants against lipid peroxidation in phospholipids and biological systems31. Dorneles and Norena (2020) used the MW method with powers of 700, 800, and 1000 W for 10, 15, and 20 min to extract the phenolic compounds from Brazilian pine (Araucaria angustifolia)32. Their study showed that the best treatment for extracting phenolic compounds was 1000 W for 20 min. Wiktor et al. (2015) evaluated the effect of PEF on the extraction of phenolic compounds and antioxidant activity from apple and carrot extracts at intensities of 1.85, 3, and 5 kV/cm with pulse numbers of 10, 50, and 100. Their findings indicated that using PEF with a voltage of 1.85 kV/cm and 10 pulses increased the presence of phenolic compounds. However, as the electric field intensity and pulse number increased, the structure of these compounds was disrupted, leading to a decrease in their quantity33.

Determining TFC

Figure 4 presents the changes in the flavonoid compounds of APE affected by different extraction methods. The total flavonoid content in the plant extract was calculated based on the quercetin standard. The equation for the quercetin standard curve used to calculate the flavonoid content is:

The software proposed an optimal model for the extraction process of APE using PEF and MW for flavonoid compounds, which was statistically significant (p < 0.001). However, the lack of fit test was not statistically significant (p > 0.05), indicating the suitability of the model.

According to Fig. 4a, flavonoid content initially increased with the pulse number up to 45, after which it decreased. The intensity of the electric field influenced the flavonoid content similarly to the pulse number. Consequently, the flavonoid concentration initially rose and then declined with increasing PEF intensity up to 3.25 kV/cm.

As shown in Fig. 4b, the flavonoid content in APE exhibits an upward trend as extraction time and power increase from 90 to 180 s and 180 to 540 W, respectively. However, flavonoid compounds are sensitive to prolonged extraction times and high MW power, which explains the observed decline in flavonoid content under these conditions.

DPPH assay

As shown in Fig. 5a, the DPPH activity of the plant extract obtained via PEF increased initially, reaching its peak, and then decreased as the pulse number and intensity approached 45 and 3.25 kV/cm, respectively. This decline can be attributed to the degradation of antioxidant compounds due to the elevated intensity and pulse number34. Similarly, the DPPH inhibition percentage demonstrated an initial increase followed by a decline when utilizing the microwave extraction technique, as illustrated in Fig. 5b.

FRAP assay

As shown in Fig. 6, the reducing power of APE varies under different extraction conditions (PEF and MW). The iron reducing power, similar to the DPPH radical inhibition activity, peaked at an electric field intensity of 3.25 kV/cm and a pulse number of 45. Additionally, samples extracted using microwave methods exhibited a trend consistent with the DPPH radical inhibition results.

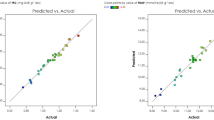

Comparative analysis of PEF and MW

The extraction of APE was optimized using both PEF and MW to achieve maximum extraction efficiency, TPC, TFC, DPPH free radical inhibitory power, and reducing power. After determining the optimal conditions, the extraction experiments were repeated independently three times under these optimal conditions for both the microwave (MW) and PEF treatments. The values reported in Table 3 represent the means of these three independent experimental replications.

The results in Table 3 indicated that the optimal conditions for PEF extraction were achieved at a field intensity of 3.64 kV/cm and a pulse number of 47.41. In contrast, the optimal conditions for MW extraction were found to be 565.92 W and 181.55 s. Notably, all examined parameters in the PEF-extracted sample showed significantly higher values compared to those in the MW-extracted sample, with a significant difference observed (p < 0.05).

The numbers in the table reported in the form of means (three repetitions).

The different letters in each row indicate significant differences (p < 0.05).

Chemical composition of extracts by GC/MS analysis

The GC/MS chromatogram of the hexane crude extract (Table 4) revealed 27 peaks on the fused silica capillary column, representing various compounds detected at specific retention times. The identified compounds primarily included hydrocarbons, esters, alcohols, and ketones. Methandriol was identified as the major chemical constituent, accounting for 20.99% of the extract, followed by octacosane (10.92%) and 3,5,5-trimethylhexyl acetate (7.62%).

Discussion

The lack of fit test, coefficient of variation, R2, and Adj-R2 values were determined to evaluate the accuracy of the fitted models. The essential part of the analysis of variances section is the parameter of poor fit. A model is suitable when the fit test is significant, indicating the suitability of the model. In addition, the values of R2 and Adj-R2 should be as close to 1 as possible for a model with a good fit. The power of the fitted model in describing response changes is greater as a function of independent variables35. The increase in permeability of cells caused by electric fields enhances extraction efficiency. PEF damage the cell membrane and cause temporary (reversible) or permanent (irreversible) deformation of the cell pores11. El Kantar et al. (2018) showed that phenolic compounds were extracted from oranges, lemons, and honey more efficiently by increasing the number of pulses. There was no significant increase in extraction efficiency for oranges when the number of pulses exceeded 8036. The extraction of Sargassum brown algae extract using MW showed that using an aqueous solvent for 30 min and a 1:20 algae-to-solvent ratio was the most effective treatment37. Belwal et al. (2020) used the response surface methodology to optimize the extraction efficiency and the effect of MW power variables, process time, substance-solvent ratio, and solvent pH on extraction efficiency38. These results showed the ability of the above method to reduce the number of tests using the response method and modeling with appropriate precision for process optimization. The enzymatic or thermal decomposition at high MW powers significantly impacts the stability of phenolic compounds. This is primarily attributed to the rise in extraction temperature, which leads to a reduction in the amount of phenolic compounds due to evaporation39. Structure changes and membrane breakdown are the primary effects of this process on flavonoids, which serve as semi-selective inhibitors and regulate cell transfer. The normal potential difference across the membrane is approximately 10 mV. External electric fields increase the potential difference across the membrane, leading to a reduction in membrane thickness. When the potential difference reaches a critical level (about 1 V), the membrane forms pores, resulting in cell damage and discharge. Small pores may reversibly affect membranes, but large pores lead to membrane destruction due to the pulses causing significant holes40. del Carmen Razola-Díaz et al., (2024) examined the effect of PEF on the bioactive compounds of orange peel and stated that structural changes in the cell wall affected by PEF treatment could increase the number of flavonoids to hesperidin and narirutin content increased by 29.4 and 38.9%, respectively41. Different compounds may be reduced or increased differently by MW power due to selective and differential heating within a material because each composition has different MW absorption characteristics (dielectric constant and loss factor)42. The use of average MW power for obtaining the maximum amount of flavonoids is more efficient from an industrial standpoint43. Taşkın and Özbek (2020) extracted flavonoid compounds from green tea bags by MW and reported that among different extraction times and power, the amount of flavonoid compounds was optimum in Power of 350.65 W and extraction time of 5 min44. Golmakani (2015) optimized the extraction of bioactive compounds from red beet using MW. Several variables were investigated, including power, time, and the ratio of methanol to sample solvent, extraction efficiency, free radical inhibitory activity, total phenol, flavonoid content, and betalain content. According to the results, the treatment with a ratio of 1 to 20 samples to solvent, an extraction time of 30 min, and a MW power of 270 W was the best for extraction24. Parniakov et al. (2015) studied the effect of PEF on extracting protein, phenolic compounds, carbohydrates, and isothiocyanates from papaya seeds. According to this study, the extraction efficiency of proteins, carbohydrates, phenolic compounds, and free radical inhibitory power in PEF treatments was higher than the aqueous extraction method20. The decrease of these compounds with increasing intensity of PEF can be attributed to destructing certain groups of bioactive compounds, including anthocyanins45. Zhang et al. (2015) found that applying PEF for vitamin C, can change their structure and properties. This can either increase or decrease their ability to inhibit free radicals. The PEF treatment was shown to increase the number of antioxidants in the molecules and improve their overall antioxidant capacity. Additionally, PEF treatment does not damage vitamin C and can help delay its oxidation process. Overall, PEF can enhance the antioxidant properties of protein molecules by helping to neutralize free radicals46. The enhancement in DPPH antiradical activity by the PEF method may be attributed to the liberation of additional antioxidant compounds from cells, the newly formed synthesis of phenolic compounds, and the creation of secondary metabolites47. El Darra et al. (2013) showed that the PEF treatment increased the content of phenolic compounds, anthocyanins, and radical scavenging activity of extracts obtained from cold extraction of red grapes and significantly raised flavonoids (quercetin and epicatechin) and anthocyanins48. According to Wiktor et al. (2015), as the number of pulses increased, the antioxidant activity of the extracts decreased. The decrease in antioxidant activity could be attributed to the change in the spatial structure of phenolic compounds with a large molecular structure to smaller compounds. These smaller compounds can better reduce iron ions33. The reducing power has a direct relationship with the number of phenolic compounds49. In other words, reduction properties are associated with the presence of electron-donating compounds. Thus, extracts with more phenolic compounds have greater reducing power50. Plant extracts, which contain large amounts of phenolic compounds, have more potent antioxidant activity. These compounds possess antioxidant properties due to their reducibility, which allows them to act as reductants of hydrogen denaturants and iron chelators51,52. The inactivation of some enzymes and the release of substances that participate in iron reduction may have caused this increase53. In a non-radical method based on electron transfer, the reduction of ferric ion-ligand complexes to ferrous ion-ligand complexes by antioxidants is measured. This method shows a weak correlation with other methods used to assess antioxidant activity. Therefore, it is often combined with other techniques to better understand the dominant mechanisms of action for different antioxidants54. In this method, the initial yellow color of the solutions turned green, indicating compound regeneration in the environment. Therefore, the increase in absorbance at 700 nm indicates higher reducing power55. The long extraction time of extracts in high MW power destroys phenolic compounds and reduces their antioxidant properties. In this regard, Singh et al. (2011) extracted an extract from potato skin using a MW and investigated its antioxidant activity56. In their study, the amount of ascorbic acid in the extract decreased with increasing power (at more than 200 W). Lin et al., (2020) developed a microwave-assisted extraction (MAE) technology to optimize the extraction of polyphenols from the strawberry leaves. Their outcomes showed in optimum condition (40 s and 300 W), the TPC, inhibition percentage of DPPH radical, and FRAP were 89.21 mg GAE/g, 79.80%, and 34.62 mM FE/g57. Schroeder et al. (2009), and Wiktor et al. (2015) have shown that the PEF increase the extraction efficiency, total amounts of phenol, and ability to inhibit DPPH free radicals compared to the MW due to the electrical disintegration of cells and their permeability33,58. Many researchers have studied the effect of the electric field as a pretreatment during mechanical extraction with a press. Reports have indicated a positive effect of this method on the qualitative and sensory properties of the extract59. Parniakov et al. (2015) found that the extraction efficiency of phenolic compounds, carbohydrates, and free radical inhibitory power in treatments processed by PEF was higher than the aqueous extraction method20. Lončarić et al. (2020) have demonstrated that PEF, as per their findings, holds great potential as a green extraction technique that can enhance the extraction yield of polyphenols from blueberry pomace60. In the GC/MS analysis, several bioactive compounds were identified from the hexane crude extract of Hymenocrater platystegius, with Methandriol being the major constituent (20.99%). When comparing these results with previous studies on Hymenocrater platystegius or related species, it was observed that compounds such as Octacosane has been reported before, suggesting a consistent presence of these compounds across different studies61. However, Methandriol and 3,5,5-Trimethylhexyl acetate appeared to be a significant finding in this study, as they have not been prominently reported in prior research on this species, indicating a potential novel discovery. Methandriol, a pharmaceutical substance, falls under the category of androgen and anabolic steroid (AAS) medications62. It has been utilized for the treatment of breast cancer in female patients63. Octacosane, as an endogenous metabolite, has the potential to enhance the healing of diabetic wounds by its strong ability to scavenge free radicals, as well as its antioxidant properties involving hydroxyproline and glutathione64. The major constituents of the essential oil of Hymenocrater platystegius, as revealed by the GC/MS analysis conducted by Emrani et al. (2015), included 1, 8-cineole (14.27%), ß-pinene (4.89%), Terpinolene (4.83%), and Sabinene (4.59%)65.

Conclusion

In this study, the impact of operating parameters on the extraction of Arvaneh plant extract (APE) using both microwave (MW) and PEF techniques was investigated. PEF involves applying a pulsed electric field to the material, which enhances the extraction efficiency of intracellular substances through a non-thermal process. The results indicate a significant improvement in extraction efficiency with the PEF method compared to the MW method (p < 0.05). Furthermore, the PEF method demonstrated superior preservation of antioxidant properties compared to the MW method, underscoring its effectiveness in food processing.

However, challenges such as optimizing energy consumption, ensuring uniform treatment of plant materials, and scaling up the PEF process for industrial applications remain. Addressing these challenges is crucial for maximizing the potential of PEF in the extraction of bioactive compounds from medicinal plants. Future research should focus on refining the PEF technique, including exploring its application to a broader range of plant species and evaluating its long-term effects on the quality and stability of the extracts. Overall, while PEF has emerged as one of the most efficient techniques for extracting medicinal plants, continuous advancements and assessments are necessary to fully realize its benefits in commercial applications.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Csepregi, R. et al. Cytotoxic, antimicrobial, antioxidant properties and effects on cell migration of phenolic compounds of selected transylvanian medicinal plants. Antioxidants 9(2), 166 (2020).

Morteza-Semnani, K., Ahadi, H. & Hashemi, Z. The genus hymenocrater: A comprehensive review. Pharm. Biol. 54(12), 3156–3163 (2016).

Abad, M. J., Ansuategui, M. & Bermejo, P. Active antifungal substances from natural sources. Arkivoc 7(11), 6–145 (2007).

Sun, W. & Shahrajabian, M. H. Therapeutic potential of phenolic compounds in medicinal plants—Natural health products for human health. Molecules 28(4), 1845 (2023).

Jha, A. K. & Sit, N. Extraction of bioactive compounds from plant materials using combination of various novel methods: a review. Trends Food Sci. Technol. 119, 579–591 (2022).

Kumari, B. et al. Recent advances on application of ultrasound and pulsed electric field technologies in the extraction of bioactives from agro-industrial by-products. Food Bioprocess Technol. 11, 223–241 (2018).

Pimentel-Moral, S. et al. Microwave-assisted extraction for Hibiscus sabdariffa bioactive compounds. J. Pharm. Biomed. Anal. 156, 313–322 (2018).

Naik, M., Puttalingappa, Y. J. & Venkatachalapathy, N. Potential of Microwave Heating in Food Processing, in Advanced Research Methods in Food Processing Technologies 239–256 (Apple Academic, 2024).

Nayik, G. A. et al. Ultrasound and Microwave for food Processing: Synergism for Preservation and Extraction (Elsevier, 2022).

Ghoshal, G. Comprehensive review in pulsed electric field (PEF) in food preservation: Gaps in current studies for potential future research. Heliyon 4(6), 1–14 (2023).

Ranjha, M. M. A. et al. A critical review on pulsed electric field: A novel technology for the extraction of phytoconstituents. Molecules 26(16), 4893 (2021).

Golmakani, M. T. et al. Optimization of antioxidant properties of sour orange seed coat extract using microwave-assisted extraction. Iran. Food Sci. Technol. Res. J. 17(4), 605–619 (2021).

Shiekh, K. A. et al. Pulsed electric field assisted process for extraction of bioactive compounds from custard apple (Annona squamosa) leaves. Food Chem. 359, 129976 (2021).

Redondo, D. et al. Pulsed electric fields as a green technology for the extraction of bioactive compounds from thinned peach by-products. Innovative Food Sci. Emerg. Technol. 45, 335–343 (2018).

Elakremi, M. et al. Pistacia vera L. leaves as a renewable source of bioactive compounds via microwave assisted extraction. Sustainable Chem. Pharm. 29, 100815 (2022).

Nowacka, M. et al. The impact of pulsed electric field on the extraction of bioactive compounds from beetroot. Foods 8(7), 244 (2019).

Hamad, M. et al. Phytochemical screening techniques and standardization colorant for commercial Annatto extract and other equality extracts. J. Nutr. Food Sci. 11, 827 (2021).

Razghandi, E. et al. Application of pulsed electric field-ultrasound technique for antioxidant extraction from Yarrow: ANFIS modeling and evaluation of antioxidant activity. J. Food Process. Preserv. 2024(1), 2951718 (2024).

Bakhshabadi, H. et al. The effect of microwave pretreatment on some physico-chemical properties and bioactivity of Black cumin seeds’ oil. Ind. Crops Prod. 97, 1–9 (2017).

Parniakov, O. et al. New approaches for the effective valorization of papaya seeds: Extraction of proteins, phenolic compounds, carbohydrates, and isothiocyanates assisted by pulsed electric energy. Food Res. Int. 77, 711–717 (2015).

Rezaei, N. et al. Optimization of extraction conditions of antioxidant and polyphenolic compounds of Ferula Persica extract by using response surface methodology. J. Food Sci. Technol. (Iran) 15(85), 151–164 (2019).

Kuster, N. & Schönborn, F. Recommended minimal requirements and development guidelines for exposure setups of bio-experiments addressing the health risk concern of wireless communications. Bioelectromagnetics: Journal of the Bioelectromagnetics Society, The Society for Physical Regulation in Biology and Medicine, The European Bioelectromagnetics Association 21(7), 508–514 (2000).

Kamboj, A. et al. Effect of pulsed electric field parameters on the alkaline extraction of valuable compounds from perilla seed meal and optimization by central composite design approach. Appl. Food Res. 2(2), 100240 (2022).

Golmakani, M. T. Optimization of microwave-assisted extraction of betalains from red beet (Beta vulgaris) and evaluating the antioxidant activity of obtained extract. J. Food Process. Preserv. 7(2), 39–60 (2015).

Hesarinejad, M. A. et al. The study of physicochemical and antioxidant properties of encapsulated Portulaca oleracea aqueous extract prepared by spray drying method. Innovative Food Technol. 8(3), 325–335 (2021).

Gülçin, I. et al. Polyphenol contents and antioxidant activity of lyophilized aqueous extract of propolis from Erzurum, Turkey. Food Chem. Toxicol. 48(8–9), 2227–2238 (2010).

Abedelmaksoud, T. G., Hesarinejad, M. A., Shokrollahi, B. & Yancheshmeh The effect of cold plasma on the enzymatic activity and quality characteristics of mango pulp. Res. Innov. Food Sci. Technol. 10(4), 341–350 (2022).

Mazaheri, T. et al. Comparing physicochemical properties and antioxidant potential of sumac from Iran and Turkey. MOJ Food Process. Technol. 5(2), 288–294 (2017).

Keser, D. et al. Characterization of aroma and phenolic composition of carrot (Daucus carota ‘Nantes’) powders obtained from intermittent microwave drying using GC–MS and LC–MS/MS. Food Bioprod. Process. 119, 350–359 (2020).

Zeb, A. Concept, mechanism, and applications of phenolic antioxidants in foods. J. Food Biochem. 44(9), e13394 (2020).

Kruk, J. et al. Antioxidative properties of phenolic compounds and their effect on oxidative stress induced by severe physical exercise. J. Physiological Sci. 72(1), 19 (2022).

Dorneles, M. S. & Noreña, C. P. Extraction of bioactive compounds from Araucaria angustifolia bracts by microwave-assisted extraction. J. Food Process. Preserv. 44(6), e14481 (2020).

Wiktor, A. et al. The impact of pulsed electric field treatment on selected bioactive compound content and color of plant tissue. Innovative Food Science & Emerging Technologies 30, 69–78 (2015).

Liang, Z. et al. Pulsed electric field processing of green tea-infused chardonnay wine: Effects on physicochemical properties, antioxidant activities, phenolic and volatile compounds. Food Bioscience 54, 102884 (2023).

Vosough, P. R. et al. Biodiversity of exopolysaccharide-producing lactic acid bacteria from Iranian traditional Kishk and optimization of EPS yield by Enterococcus spp. Food Bioscience 49, 101869 (2022).

El Kantar, S. et al. Pulsed electric field treatment of citrus fruits: Improvement of juice and polyphenols extraction. Innovative Food Science & Emerging Technologies 46, 153–161 (2018).

Babakhani Lashkan, A. et al. Optimization of extraction of antioxidant compounds in microwave-assisted extracts of brown algae Sargassum angustifolium. J. Fisheries 65(3), 243–255 (2012).

Belwal, T. et al. Optimized microwave assisted extraction (MAE) of alkaloids and polyphenols from Berberis roots using multiple-component analysis. Sci. Rep. 10(1), 917 (2020).

Olalere, O. A. & Gan, C. Y. Microwave-assisted extraction of phenolic compounds from Euphorbia hirta leaf and characterization of its morphology and thermal stability. Sep. Sci. Technol. 56(11), 1853–1865 (2021).

Tylewicz, U. How Does Pulsed Electric Field work? In Pulsed Electric Fields to Obtain Healthier and Sustainable food for Tomorrow 3–21 (Elsevier, 2020).

del Razola-Díaz, C. Combined effect of pulse electric field and probe ultrasound technologies for obtaining phenolic compounds from orange by-product. LWT 198, 115950 (2024).

Agustin, M. N. P. et al. Extraction of essential oils from Sweet Orange leaves (Citrus Aurantium) using the microwave hydrodistillation (MHD) method. J. Biobased Chemicals 3(2), 76–95 (2023).

Bitwell, C. et al. A review of modern and conventional extraction techniques and their applications for extracting phytochemicals from plants. Sci. Afr. 19, e01585 (2023).

Taşkın, B., Aksoylu, Z. & Özbek Optimisation of microwave effect on bioactives contents and colour attributes of aqueous green tea extracts by central composite design. J. Food Meas. Charact. 14(4), 2240–2252 (2020).

Golmohamadi, A. et al. Effect of ultrasound frequency on antioxidant activity, total phenolic and anthocyanin content of red raspberry puree. Ultrason. Sonochem. 20(5), 1316–1323 (2013).

Zhang, Z. H. et al. Effects of pulsed electric fields (PEF) on vitamin C and its antioxidant properties. Int. J. Mol. Sci. 16(10), 24159–24173 (2015).

Younis, M. et al. Pulsed electric field as a novel technology for fresh barhi date shelf-life extension: Process optimization using response surface methodology. Horticulturae 9(2), 155 (2023).

El Darra, N. et al. Pulsed electric field-assisted cold maceration of Cabernet Franc and Cabernet Sauvignon grapes. Am. J. Enol. Viticult. 64(4), 476–484 (2013).

Islam, M. R. et al. Phenolic compounds and antioxidants activity of banana peel extracts: Testing and optimization of enzyme-assisted conditions. Food 10, 100085 (2023).

Kumaran, A. & Karunakaran, R. J. In vitro antioxidant activities of methanol extracts of five Phyllanthus species from India. LWT-Food Sci. Technol. 40(2), 344–352 (2007).

Aida, A., Ali, M. S. & Behrooz, M. V. Chemical composition and antimicrobial effect of the essential oil of Zataria multiflora Boiss endemic in Khorasan-Iran. Asian Pac. J. Trop. Disease 5(3), 181–185 (2015).

Moghadam, H. D., Sani, A. M. & Sangatash, M. M. Inhibitory effect of Helichrysum arenarium essential oil on the growth of food contaminated microorganisms. J. Essent. Oil Bearing Plants. 17(5), 911–921 (2014).

Parcheta, M. et al. Recent developments in effective antioxidants: The structure and antioxidant properties. Materials 14(8), 1984 (2021).

Shahidi, F. & Zhong, Y. Measurement of antioxidant activity. J. Funct. Foods. 18, 757–781 (2015).

Barros, L. et al. Total phenols, ascorbic acid, β-carotene and lycopene in Portuguese wild edible mushrooms and their antioxidant activities. Food Chem. 103(2), 413–419 (2007).

Singh, A. et al. Microwave-assisted extraction of phenolic antioxidants from potato peels. Molecules 16(3), 2218–2232 (2011).

Lin, D. et al. Phenolic compounds with antioxidant activity from strawberry leaves: A study on microwave-assisted extraction optimization. Prep. Biochem. Biotechnol. 50(9), 874–882 (2020).

Schroeder, S., Buckow, R. & Knoerzer, K. Numerical simulation of pulsed electric field (PEF) processing for chamber design and optimization. In International Conference on CFD in the Minerads and Process Industries CSIRO, 17th, Australia (2009).

Knorr, D. et al. Food application of high electric field pulses. Trends Food Sci. Technol. 5(3), 71–75 (1994).

Lončarić, A. et al. Green extraction methods for extraction of polyphenolic compounds from blueberry pomace. Foods 9(11), 1521 (2020).

Asri, Y. et al. Essential oil composition from Hymenocrater calycinus (Boiss.) Benth. In Iran. J. Essent. Oil Bearing Plants 20(3), 712–719 (2017).

Chiruta, V. 20-Hydroxyecdysone’s cyclodextrin complex: A Novel anabolic phytosteroid (APS)? Int. J. Healthc. Sci. 8(1), 250–254 (2020).

Tauchen, J. et al. Medicinal use of testosterone and related steroids revisited. Molecules 26(4), 1032 (2021).

Balachandran, A. et al. Antioxidant, wound healing potential and in silico assessment of naringin, eicosane and octacosane. Molecules 28(3), 1043 (2023).

Emrani, S., Zhiani, R. & Dolatabadi, S. Identification of chemical compositions and protective effects of essential oil of Arvaneh (Hymenocrater platystegius) on oxidative stress Induced by H2O2 in PC12 cells. Neurosci. J. Shefaye Khatam. 3(3), 27–36 (2015).

Funding

The authors received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

Elham Mahdian and Ali Mohammadi Sani supervised the research. Mohammad Reza Radnia performed the experiment and collected the data. Mohammad Ali Hesarinejad advised the research and revised the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Radnia, M.R., Mahdian, E., Sani, A.M. et al. Comparison of microwave and pulsed electric field methods on extracting antioxidant compounds from Arvaneh plant (Hymenocrater platystegius Rech. F). Sci Rep 14, 25903 (2024). https://doi.org/10.1038/s41598-024-77380-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-77380-z