Abstract

To ensure that the discrete element model of the coal wall accurately reflects the actual cutting process of coal and rock during virtual prototype simulation of mining equipment, this study aims to expedite the development of intelligent mining machinery. Using coal samples from the 4602 working face of Yangcun Coal Mine, operated by Yanzhou Coal Mining Group, we conducted coal rock packing experiments and uniaxial compression tests to obtain the packing angle and compressive strength of the coal samples. Based on the experimental results, we designed Plackett–Burman experiments (PB experiments), steepest ascent experiments, and Box-Behnken experiments to study the influence of particle contact mechanics parameters and bonding mechanics parameters on the packing angle and compressive strength, using the packing angle and compressive strength as response variables. Our objective is to minimize the relative error between the simulated packing angle and the measured packing angle. We solved and optimized the parameter calibration model and conducted simulation calibration experiments based on the optimization results. A comparative analysis with the actual test results revealed that the maximum relative errors between the simulated and measured values for the packing angle and compressive strength were only 2.9% and 5.0%, respectively. Additionally, a discrete element model of a typical working face coal wall was established based on the parameters obtained from this calibration method. A bidirectional coupling model of the cutting process between the coal and rock was created using EDEM-RecurDyn to simulate the rigid-flexible coupling of the coal cutter. An experimental coal wall model was constructed based on similarity theory, and both simulation and physical experiments were conducted. The evaluation metrics for comparison were the time-domain and frequency-domain characteristics of the drum’s vibration signals. The maximum relative error for the time-domain signal characteristics between the two experimental setups was only 4.19%, while the maximum relative error for the frequency-domain signal characteristics was 3.75%. This validates the feasibility of the proposed calibration method for the discrete element coal wall model and the accuracy of the calibration results. Furthermore, it demonstrates that the constructed discrete element coal wall accurately represents the actual coal and rock properties. The virtual simulation based on this model effectively replicates the interaction process between mining machinery and coal, providing a safe, efficient, and low-cost technological approach for performance analysis of mining equipment and intelligent control of supporting devices.

Similar content being viewed by others

Introduction

The drum shearer is a primary excavation equipment used in modern underground mining. When the drum cuts coal and rock of varying properties, it experiences different operational conditions. Investigating the comprehensive performance of the drum under varying mechanical properties of coal and rock, as well as under intelligent control strategies, is crucial for achieving smart control of the shearer. However, research often encounters high experimental costs and safety concerns. The integration of Discrete Element Method (DEM) virtual prototyping technology effectively shortens research cycles and significantly reduces costs, allowing for virtual testing of the intelligent control process prior to physical prototype experiments. Given the inherent discrete nature of coal and rock, establishing a discrete element model that accurately simulates real operational conditions is particularly important.

The DEM was initially proposed to address issues in rock mechanics; however, it has since found widespread application across various fields, including powder mixing and stirring, slope stability analysis, material flow characteristics analysis, cutting and crushing process research, and particle parameter calibration1,2,3,4,5,6,7,8,9. Its application in agriculture is particularly common and technologically advanced, primarily for simulating processes such as seed transport, mixing, and planting10,11,12. In recent years, researchers both domestically and internationally have introduced the DEM into the mining sector, primarily to develop coal wall models that simulate the actual coal and rock mass underground13,14,15,16,17. To ensure that virtual simulation results effectively guide practical production, it is essential to calibrate the discrete element parameters of the coal and rock mass. MICHELE et al.18 also noted that the greatest challenge in using DEM to study the dynamics of particle materials lies in the accurate calibration of macroscopic parameters, as these results determine the degree of correspondence between the simulation model and the actual physical model. However, the parameters required for establishing coal wall models in the aforementioned literature are largely derived from analogies and references to parameters in other fields, lacking a calibration method for DEM parameters based on the actual conditions of coal seams. Researchers both domestically and internationally have proposed experimental methods to determine discrete element parameters. Zhao Chuan et al.19 used the angle of repose as a response indicator, employing funnel stacking tests to ascertain the fundamental contact parameters between particles and the mechanical structure. However, this approach is somewhat arbitrary and relies heavily on empirical data, making it particularly time-consuming when calibrating multiple parameters. To address the limitations of traditional experimental methods for determining discrete element parameters, this paper introduces a combined experimental-simulation approach for calibrating coal and rock parameters. By conducting angle of repose and uniaxial compression tests to determine the characteristic parameters of coal and rock, these measured parameters serve as evaluation metrics. The macro parameters required for the coal wall model (contact mechanics parameters and bonding mechanics parameters) are continuously adjusted through discrete element virtual simulations to achieve results closely matching the experimental data20. This process ensures that the mechanical properties of the constructed discrete element model closely resemble those of actual coal walls, thus enhancing the accuracy and reliability of the simulation results. Essentially, this represents a reverse calibration method21,22. Furthermore, to effectively establish the relationship between experimental evaluation metrics and the parameters to be calibrated, this paper proposes a calibration method for coal and rock particle contact mechanics parameters and bonding mechanics parameters based on significance analysis and response surface methodology. Utilizing experimental data, angle of repose and compressive strength are designated as response variables. The Plackett–Burman experiment (PB experiment), steepest ascent method, and Box-Behnken design are employed to study the influence trends of particle contact mechanics parameters and bonding mechanics parameters on the angle of repose and compressive strength of coal and rock. The objective is to minimize the relative error between simulated and measured angles of repose, leading to the optimization and resolution of the parameter calibration model. Based on the optimization results, subsequent simulation calibration experiments are conducted, followed by comparative analysis with experimental results. Additionally, both simulation and physical experiments are performed to validate the feasibility and accuracy of the proposed parameter calibration method for the discrete element coal wall model.

Particle contact theory of discrete element method

The DEM simulates the process of particle movement within the studied object or system, resulting in collisions and interactions between particles. Given the complex contact dynamics between the fragmented coal-rock mass and the mining equipment, as well as the physical and mechanical properties of the coal-rock, the interactions among coal-rock particle units exhibit nonlinearity, time variability, and anisotropy. The contact stiffness in the Hertz-Mindlin viscoelastic contact model demonstrates a nonlinear relationship with particle displacement and contact force, aligning with the nonlinear characteristics of coal-rock particle interactions. This study employs the Hertz-Mindlin (no slip) model and the Hertz-Mindlin with bonding model. In the Hertz-Mindlin (no slip) model, the normal and tangential contact forces between particle units are calculated using the Hertz and Mindlin theories, respectively23. The particle vibration model is illustrated in Fig. 1.

The normal contact force of a particle unit \(F_{\text{n}}\) is composed of the normal spring force \(F_{\text{n}}^{s}\) and the normal damping force \(F_{n}^{d}\).

The normal spring force \(F_{n}^{s}\) acting between particle units is given by:

where,\(F_{n}^{s}\) is the normal spring force between particle units, N;\(E^{*}\) is equivalent elastic modulus of the particle unit,MPa;\(R^{*}\) is the equivalent radius of the particle unit,mm;\(\delta_{n}\) is the normal overlap between particle units,mm;\(E^{*}\), \(R^{*}\) and \(\delta_{n}\) can be calculated using Eqs. (2) to (4).

where,\(E_{1,2}\) is the elastic modulus of particle units 1 and 2, MPa; \(\mu_{1,2}\) is the Poisson’s ratio of particle units 1 and 2; R1,2is the physical radius of particle units 1 and 2,mm;\(X_{1,2}\) is the displacement value of the centers of particle units 1 and 2, mm.

When the displacement of the contacting particle units changes, the variation in the contact overlap results in a continuous alteration of the normal spring force according to the rules outlined in Eq. (5).

where,\(\vartriangle F_{n}^{s}\) is the change in the normal spring force, N;\(\vartriangle \delta_{n}\) is the change in the contact overlap of the particle units,mm.

The normal damping force \(F_{n}^{d}\) acting between the particle units is:

where,\(C_{n}\) is the normal damping coefficient,N·s/m;\(S_{n}\) is the normal stiffness, N/m3;\(m_{1,2}\) is the mass of particle units 1 and 2, kg;\(v_{p1,p2}\) is the velocity of particle units 1 and 2, mm/s; Additionally,\(C_{n}\) and \(S_{n}\) can be calculated using Eqs. (7) to (8).

where, e is the restitution coefficient between the particle units.

The tangential spring force \(F_{t}^{s}\) acting between the particle units is:

where, \(S_{t}\) is the tangential stiffness, N/m3,the result can be obtained from Eq. (10);\(\delta_{t}\) is the tangential overlap between particle units,mm.

where, \(G^{*}\) is the equivalent shear modulus of the particle units,MPa;\(G_{1,2}\) is the shear modulus of particle units 1 and 2, MPa。

The tangential damping force \(F_{t}^{d}\) acting between the particle units is:

where, \(C_{t}\) is the tangential damping coefficient, N·s/m;\(v_{t}^{rel}\) is the tangential relative velocity, mm/s.

Based on the Hertz-Mindlin contact model, the Hertz-Mindlin with bonding model is developed by incorporating bonding forces and moments. This model is particularly well-suited for simulating structural fracture in materials such as concrete, coal, and rocks24,25,26,27,28,29.

During the simulation process, the bonding between particle elements initiates after a predefined bonding generation time. Prior to this, particle interactions are calculated using the Hertz-Mindlin contact model. At the onset of bonding, both the bonding forces and moments on the particles are initially set to zero, and then, within the specified simulation time step, calculations are conducted iteratively according to Eqs. (13)–(18).

where,\(v_{n}\) and \(v_{t}\) is the normal and tangential velocities of the particle elements respectively,mm/s;\(\Delta t\) is the simulation time step,s;\(R_{B}\) is the bonding radius between particle elements,mm;\(\omega_{n}\) and \(\omega_{t}\) is the normal and tangential angular velocities of the particle elements,respectively,rad/s;\(J\) is the moment of inertia,N.m.

When the normal and tangential shear stresses exceed the specified threshold, the bonding connections are broken. Subsequently, the particle elements are resolved using the Hertz-Mindlin contact model as hard spheres30.

where, \(\sigma_{\max }\) and \(\tau_{\max }\) is the maximum tensile stress and maximum shear stress of the bonding connections,respectively,MPa;\(T_{t}\) and \(T_{n}\) is the torsional moment and bending moment, respectively,N·m.

Determination of mechanical properties of coal and rock and establishment of discrete element models

Determination of mechanical properties of coal and rock

The parameters of coal and rock particles include intrinsic parameters (density, Poisson’s ratio, elastic modulus,and uniaxial compressive strength), contact mechanics parameters, and bonding mechanics parameters. The intrinsic parameters of coal and rock can be measured through physical and mechanical property tests. Following the sampling principles and testing standards, physical and mechanical properties of coal samples from the 4602 working face of Yangcun Coal Mine, operated by Yanzhou Coal Mining Group, were tested. The testing process is illustrated in Fig. 2, and the physical and mechanical property parameters of the coal samples are presented in Table 1.The contact mechanics parameters include the restitution coefficients for collisions between coal and rock particles and between particles and equipment, as well as static and rolling friction coefficients. The bonding mechanics parameters encompass the normal stiffness, tangential stiffness, maximum normal stress, and maximum tangential stress between particles. The contact mechanics and bonding mechanics parameters can be derived through simulations of angle of repose, uniaxial compression tests, and comparisons with physical test results31,32,33.

Construction of typical coal and rock particle models

To enhance the realism of the particle models in the discrete element model of the coal wall, three primary shapes of coal and rock particles “ellipsoidal, spherical, and block-like”were selected through screening of the fragmented coal and rock mass at the working face34.Using the EDEM software, an irregular particle model was established to simulate the ellipsoidal,spherical,and block-like non-spherical particles,as illustrated in Fig. 3.The sizes and spatial positions of the different particle shapes are presented in Table 2. Additionally, the screening results indicate that even particles of the same shape may differ in size. In EDEM, the particle size distribution is generated within a range of 0.8 to 1.2 times the initial particle volume, and the particle generation method is set to random generation within the particle factory, with each shape type accounting for one-third of the total mass.

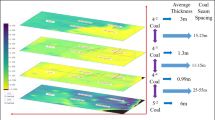

A discrete element model of the coal wall was established using the simulated non-spherical particles, which include ellipsoidal, spherical, and block-like shapes.

Calibration of discrete element parameters for coal rock particles

In the EDEM software, the discrete element model parameters for coal rock particles include both contact mechanics parameters and bonding mechanics parameters. The contact mechanics parameters comprise the static friction coefficient, rolling friction coefficient, and restitution coefficient. The bonding mechanics parameters include the normal stiffness, tangential stiffness, maximum normal stress, and maximum tangential stress between particles.

Calibration of contact mechanics parameters for coal rock particles

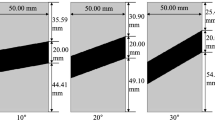

The calibration of contact mechanics parameters for coal rock particles is conducted according to the technical route shown in Fig. 4. Physical experiments and simulation studies are performed using the typical coal rock particles selected based on the angle of repose formed by the injection method. The results from three physical experiments yield measured angles of repose of 30.21°, 31.85°, and 30.43°, with an average value of 30.83°.

Plackett–Burman factor screening experiment

A discrete element simulation apparatus consistent with the structure of the coal rock angle of repose model is established, and parameter calibration is performed through simulation experiments. The process of simulating the coal rock particle stacking experiment is illustrated in Fig. 5.

The Plackett–Burman experiment is designed based on the parameter values established by previous researchers regarding the contact parameters between coal rock particles and between coal rock and equipment32,35,36,37,38,39,40. In the simulation experiments, six real parameters (ID1-ID6) and five virtual parameters (ID7-ID11) are selected based on the required contact parameters. The high and low levels of these parameters are defined using + 1 and −1 coding, as shown in Table 3. Other parameter settings are as follows: taking coal sample 1 as an example, the calibration process for its contact mechanics parameters is detailed. The Poisson’s ratio of coal sample 1 is 0.28, the elastic modulus is 2.01 × 103 MPa, and the density is 1280 kg/m3. The material of the spiral drum directly involved in coal cutting is steel, with a Poisson’s ratio of 0.31, an elastic modulus of 2.122 × 105 MPa, and a density of 7850 kg/m3.

Simulation experiments are conducted according to the experimental design scheme outlined in Table 3, with the average value of three repetitions in each group serving as the angle of repose for that group. The angle of repose for coal rock particles is determined using image processing methods, as illustrated in Fig. 6. The final results of the angle of repose experiments conducted using the injection method are presented in Table 4.

A significance analysis of the Plackett–Burman simulation results is conducted to assess the impact of various contact mechanics parameters on the angle of repose for coal rock particles. The results are presented in Table 5.

As shown in Table 5, the analysis of the influence rates of the parameters reveals that the three most significant factors affecting the angle of repose for coal rock particles are the restitution coefficient, the static friction coefficient, and the rolling friction coefficient between the particles. This study focuses on these three critical parameters for the calibration and optimization of contact mechanics parameters.

Design and results analysis of the steep slope climbing experiment

Simulation experiments are conducted based on the steep slope climbing experiment design outlined in Table 6. The angle of repose for coal rock particles determined by the injection method is recorded and compared to the values obtained from physical experiments to identify the parameter range with the smallest error. The results are presented in Table 6.

Table 6 identifies the optimal ranges for the restitution coefficient, static friction coefficient, and rolling friction coefficient between coal rock particles as 0.5 to 0.7, 0.5 to 0.7, and 0.06 to 0.10, respectively.

Design and results analysis of the Box-Behnken experiment

Based on the Plackett–Burman experiment and the steep slope climbing experiment, significant contact mechanics parameters affecting the angle of repose for coal rock particles and their optimal ranges have been identified. However, a functional relationship mapping these parameters to the angle of repose remains undetermined. To address this, a Box-Behnken experiment is employed to fit a multivariate quadratic regression equation that describes the relationship between the contact mechanics parameters and the angle of repose, thereby guiding the optimization of interparticle contact mechanics parameters.

Based on the ranges of significant contact mechanics parameters identified from the steep slope climbing experiment, a Box-Behnken experiment is designed. The significant parameters are assigned three levels: high (+ 1), medium (0), and low (−1). The experimental parameter levels are presented in Table 7.

Based on the principles of the Box-Behnken experiment, a testing scheme is designed and simulated. The results indicate the relative error between the simulated angle of repose and the measured angle of repose, as presented in Table 8.

A quadratic regression analysis is performed on the experimental data to derive the regression equation relating the relative error between the simulated angle of repose and the measured angle of repose to three contact mechanics parameters: the restitution coefficient, the static friction coefficient, and the rolling friction coefficient between coal rock particles (coded values).

The analysis of variance results for the quadratic polynomial regression model of the relative error between the simulated angle of repose and the measured angle of repose from the Box-Behnken experiment is presented in Table 9. Based on the results of the analysis of variance presented in Table 9, the model exhibits F = 170.94, P < 0.0001, indicating a highly significant relationship between the model response and the independent variables. The significance of each factor affecting the relative error reveals that the static friction coefficient between coal rock particles is the primary influencing factor, followed by the rolling friction coefficient, while the restitution coefficient has the least impact on the error. Furthermore, the interaction between the static and rolling friction coefficients significantly affects the error. The P-value for the lack of fit is 0.07, suggesting that there are no other significant influencing factors. The coefficient of determination (R2) is 0.9968, and the adjusted R2Adj is 0.9909, indicating a high reliability of model fit. The coefficient of variation (C) is 4.48%, and the adequacy precision is 47.799, demonstrating the model’s superior credibility and accuracy.

The objective was to minimize the relative error between the simulated angle of repose and the measured angle of repose by optimizing the regression model. This process yielded a set of optimal solutions that closely approximates the measured angle of repose, with optimal values for the restitution coefficient, static friction coefficient, and rolling friction coefficient between coal rock particles being 0.58, 0.62, and 0.082, respectively. Using these optimized parameters, a series of three repeated simulations of the coal rock angle of repose were conducted, resulting in angles of 30.47°, 31.41°, and 31.72°, with relative errors of 1.2%, 1.9%, and 2.9%, respectively. The calibration results are of reference and practical value41. Following this methodology, the contact mechanics parameters for other discrete element models of coal rock were also calibrated, with the results presented in Table 10.

Calibration of coal rock particle bonding mechanics parameters

Based on discrete element virtual simulations, uniaxial compression tests can establish the relationship between particle bonding mechanical parameters and physical mechanical properties. By continually adjusting the bonding parameters and repeatedly simulating the compression process of coal rock, the goal is to ensure that the compression failure observed in the calibrated simulation model aligns with the failure observed in physical experiments42. The technical route for calibrating the bonding mechanical parameters of coal rock particles is illustrated in Fig. 7.

Construction of uniaxial compression simulation model

A particle factory model was established with dimensions identical to those of the coal rock sample. The particle material parameters were set to match the density, Poisson’s ratio, and elastic modulus of the physical coal rock specimen. The contact mechanics parameters for the coal rock particles were also configured. The particle factory model was used as the filling space for the coal, with particles given an initial velocity of 30 m/s to expedite the filling process. Once the particle velocity decreased to an appropriate bonding speed43, the bonding mechanical parameters were applied. The resulting uniaxial compression simulation model is illustrated in Fig. 8.

Box-Behnken experimental design and result analysis

Uniaxial compressive strength can partially characterize the physical and mechanical properties of coal rock. This study employs uniaxial compression simulation tests to determine the uniaxial compressive strength of coal rock and validates the accuracy of the calibrated bonding mechanical parameters by comparing the results with physical experiment data. To achieve the desired parameter calibration results with fewer simulation trials and in a shorter time, the Box-Behnken experimental design method was utilized, as referenced in literature16,36,43,44, to establish the parameter ranges for bonding mechanics. The bonding mechanical parameters were assigned three levels:high- medium, and low-represented by the codes + 1, 0, and −1, respectively. The experimental factors and levels are summarized in Table 11.

The experimental design is illustrated in Table 12. In the simulation, a plane moving downward at a speed of 0.15 m/s was established to simulate the compression head of the testing machine during the uniaxial compression test. The failure process of the coal sample during the uniaxial compression test is depicted in Figs. 9 and 10. The relative error results between the simulated and measured uniaxial compressive strengths for 27 groups of tests are presented in Table 12.

A multiple quadratic regression analysis was performed on the experimental data presented in Table 12, resulting in a regression equation that relates the relative error between the measured and simulated compressive strengths of the coal rock to four bonding mechanical parameters (coded values) as follows:

The variance analysis results of the relative error between the measured and simulated compressive strengths of the coal rock are presented in Table 13. According to the variance analysis of the Box-Behnken experimental design model,F = 67.57 and P < 0.0001, indicating a highly significant relationship between the model and all independent variables. The significance of each factor’s influence on the relative error reveals that the maximum normal stress between particles is the primary influencing factor, followed by tangential stiffness and maximum tangential stress, while the fluctuations in normal stiffness have the least impact on the error. The interaction between tangential stiffness and maximum normal stress has the strongest effect on the error. The P-value for the lack of fit is 0.2492, indicating that there are no significant additional influencing factors. The coefficient of determination R2 is 0.9875, and the adjusted coefficient R2Adj is 0.9729, demonstrating high reliability in the model fit. The coefficient of variation C is 7.77%, and the adequate precision is 29.9309, indicating the model has strong credibility and accuracy.

To minimize the relative error between the measured and simulated compressive strengths of the coal rock, the regression model was optimized to obtain a set of values that closely match the measured compressive strength. The optimal values for the normal stiffness, tangential stiffness, maximum normal stress, and maximum tangential stress of the coal particles are 1.3008 × 108N/m3, 1.0104 × 108N/m3, 7.7841 MPa, and 2.0147 MPa, respectively. Using these optimized parameters, uniaxial compression simulation tests were conducted, with three repetitions resulting in simulated compressive strengths of 12.54 MPa, 12.28 MPa, and 12.58 MPa. The corresponding relative errors were 4.5%, 2.3%, and 5.0%. Based on this methodology, the bonding mechanical parameters for other discrete element models of coal rock can also be calibrated, with the calibration results shown in Table 14.

Experimental validation

The degree of consistency between the characteristic information obtained from simulations and physical experiments significantly influences the practical implications and application value of studying different coal rock mechanical properties and intelligent control strategies for shearer. To validate the accuracy of the simulation results for coal wall cutting, physical experiments were conducted using a comprehensive test platform for shearer, comparing the performance of the virtual prototype model based on calibrated parameters.

Construction of a rigid-flexible coupling model for a shearer’s virtual prototype in coal rock cutting

Based on the complex coal seam discrete element simulation model established for the 4602 working face at Yangcun Coal Mine of Yanzhou Coal Mining Group, this study focuses on the MG2 × 55/250-BWD thin coal seam shearer as the engineering object. The spiral drum and the cutting teeth directly engage in the cutting and fragmentation of coal rock, making their deformation significant. A flexible treatment is applied to the spiral drum, leading to the creation of a rigid-flexible coupling model. An essential aspect of the model development is the calculation of contacts, which involves a self-checking process where the geometric positions are assessed for contact status at each incremental step45,46. The contact analysis algorithm, based on a relative coordinate system47, determines the calculation process as defined by Eq. (23).

where:\(\delta\) is the penetration depth,mm;\(K\) is the contact stiffness, N/m3;\(\vec{v}\) is the relative velocity at the contact point,mm/s;\(C\) is the contact damping,\({{\left( {N \cdot s} \right)} \mathord{\left/ {\vphantom {{\left( {N \cdot s} \right)} {mm}}} \right. \kern-0pt} {mm}}\).The addition of contact parameters requires the determination of penetration depth, contact stiffness,and contact damping.The calculation of contact stiffness is detailed in Eqs. (24) to (27):

where:\(K\) is composed of Hertz stiffness \(k_{h}\),bending stiffness \(k_{b}\),and deformation stiffness \(k_{f}\) of the contact body;\(E\) is the elastic modulus,MPa;\(\mu\) is the Poisson’s ratio;\(R\) is the contact radius,mm;\(B\) is the tooth width,mm;\(\alpha\) is the pressure angle,°;\(\beta_{1}\) is the complementary angle between the involute profile of the tooth tip and the midline of the tooth shape,°;\(\beta_{2}\) is half of the arc angle formed by the involute curve of the tooth profile at the base circle,°;\(\omega_{f}\) is the distance from the intersection of the initial contact curvature line and the tooth profile centerline to the root circle,mm;\(b_{f}\) is the width of the tooth profile at the root circle,mm;The parameters l, m, n and p are the coefficients related to contact deformation stiffness. The calculation of contact damping is presented in Eqs. (28) and (29).

where:\(w\) is the effective contact area of the contact body, mm2;\(s\) is the deformation coefficient;\(\gamma\) is the stiffness ratio.Based on the structure and materials of the components in the shearer’s cutting section, the values of contact stiffness, damping, maximum penetration, and nonlinear index in the contact force calculation model are presented in Table 3.

The construction of the shearer’s rigid-flexible coupled virtual prototype for cutting coal rock, utilizing the discrete element model (DEM-MFBD bidirectional coupling model) in EDEM and RecurDyn, is depicted in Fig. 11. The EDEM-RecurDyn coupled simulation model is established based on the coupling interface between the two software systems.

Feasibility verification of parameter calibration results

Based on similarity theory, a test coal wall model that aligns with the structural design of the coal wall model shown in Fig. 11 was constructed, along with a comprehensive test platform for the shearer, as depicted in Fig. 1250. An accelerometer was installed between the drum and the hydraulic motor to test the vibration characteristics during the coal cutting process. Simulations were conducted at a speed of vq = 4m/min and a rotation speed of n = 90r/min.Kinematic parameters obtained through similarity were used for the experimental cutting, and both simulated and experimental time-domain signals of the vibration characteristics in the cutting resistance direction of the drum were extracted. Time-domain and frequency-domain analyses were performed on these signals, resulting in similar outcomes as illustrated in Figs. 13 and 14. The statistical results of the vibration characteristic values are presented in Table 15.

The time-domain signals of both datasets were converted into frequency spectra using Fourier transformation, as illustrated in Figs. 15 and 16.

The vibration characteristic curves of the drum shown in Figs. 13 and 14 indicate that the vibration patterns in the time domain are similar. As shown in Table 16, the maximum relative error in the drum’s vibration characteristics is only 4.19%, which falls within an acceptable range. Additionally, the amplitude frequency spectra in Figs. 15 and 16 reveal that the frequency characteristics of both the simulation and experimental conditions are also quite similar. Under simulation conditions during coal cutting, the frequencies are primarily distributed around 80 Hz and 163 Hz, while under experimental conditions, the frequencies are mainly around 83 Hz and 168 Hz, with a maximum relative error of only 3.75%. In summary, the analysis from both time and frequency domains confirms the feasibility of the coal rock parameter calibration method and the reliability of the calibration results.

Conclusion

This paper focuses on the coal sample from the 4602 working face of the Yangcun Coal Mine, part of the Yanzhou Coal Mining Group. It proposes a calibration method for mechanical contact and bonding parameters of coal-rock particles based on significance analysis and response surface methodology. Relying on experimental measurements, the Plackett–Burman, steepest ascent, and Box-Behnken experimental designs were used, with the angle of repose and compressive strength as response variables, to explore the influence of mechanical contact and bonding parameters of coal-rock particles on the angle of repose and compressive strength. The calibration model was solved and optimized, aiming to minimize the relative error between the simulated and measured angles of repose. Finally, a simulation calibration experiment was conducted based on the optimization results, followed by a comparative analysis with the experimental measurements, leading to the following conclusions:

-

(1)

Using the coal-rock angle of repose as an evaluation metric, it was found that the restitution coefficient, static friction coefficient, and rolling friction coefficient between coal-rock particles have significant effects on the angle of repose, with influence rates of 49.22%, 43.10%, and 2.96%, respectively. Aiming to minimize the relative error between the simulated and measured angles of repose, a simulation experiment was conducted based on the optimized parameters, resulting in a relative error of only 2.9%.

-

(2)

To minimize the relative error between the measured and simulated compressive strength of coal-rock, it was determined that the maximum normal stress between particles is the primary factor affecting the error, followed by tangential stiffness and maximum tangential stress, with the fluctuation in normal stiffness having the least impact. A uniaxial compression test of coal-rock using the optimized parameters yielded a relative error of only 5.0%.

-

(3)

Using the time-domain and frequency-domain signal characteristics of drum vibration as evaluation metrics, a comparison between physical and simulation tests showed that the errors in the time-domain signal characteristics, from largest to smallest, were 4.19% for the maximum value, 3.95% for the root mean square value, 3.41% for the peak value, and 2.92% for the minimum value. The maximum relative error in the frequency-domain signal characteristics was 3.75%.

In summary, this paper utilizes the angle of repose and compressive strength as evaluation metrics to accurately calibrate the contact and bonding mechanical parameters required for discrete element modeling of coal walls. The accuracy of the calibration results was verified through both physical and simulation tests. This approach provides a safe, efficient, and cost-effective method for analyzing the performance of mining machinery and for conducting research on the intelligent regulation of supporting equipment.

Data availability

The data will be provided according to the journal’s requirements.If the journal requires data files, please contact the corresponding author Guocong Lin, E-mail: lgc980121@163.com.

References

Xuan, Y. et al. A discrete element method (DEM) simulation and experimental research on powder mixing process and stirring power. Chem. Ind. Eng. Prog. 40(7), 3598–3607 (2021).

Zhang, H., Zhang, B. & Feng, H. Macro and micro analysis on instability mechanism of coal measure soil slope based on DEM–CFD coupling method. Adv. Eng. Sci. 53(4), 63–72 (2021).

Hassan, S. & El Shamy, U. DEM simulations of the seismic response of particle slopes. Comput. Geotech. 112, 230–244 (2019).

Ding, Y. Design and experiment of pneumatic chili seed planter. Shandong Agricultural University, (2020).

Jie, W. et al. Influence of fragmentation on dynamic characteristics of loess landslide based on DEM simulation. J. Eng. Geol. 31(2), 502–513 (2023).

Xinwei, Y. I. N. et al. Research on discrete element method simulation of crushing force for double-toothed roller crusher. Coal Sci. Technol. 48(6), 154–161 (2020).

Cleary, P. W. et al. Analysis of cone crusher performance with changes in material properties and operating conditions using DEM. Miner. Eng. 100, 49–70 (2017).

Mendoza Rizo J. A. Modeling rock cutting using DEM with crushable particles. University of Pittsburgh, (2010).

Roessler, T. & Katterfeld, A. DEM parameter calibration of cohesive bulk materials using a simple angle of repose test. Particuology 45, 105–115 (2019).

Yong, C. et al. Calibration and testing of discrete element simulation parameters for oil sand bean seeding. Trans. Chin. Soc. Agric. Mach. 54(12), 58–69 (2023).

Zhang, H. et al. Analysis and optimization of vibration characteristics of corn finger clamp seeder based on EDEM RecurDyn. Transact Chin Soc Agric Mach 54(S1), 36–46 (2023).

Fake, S. et al. Research on the effect of mixed fertilizer in powder ridge and rotary tillage operations based on EDEM. J. Agric. Sci. Technol. 25(11), 90–102 (2023).

Li, J. et al. Experimental study of wear resistance of bionie striped middle troughfor scraper conveyors. China Mech. Eng. 32(21), 2542–2551+2561 (2021).

Zhang, Q. et al. Study on spiral conveying performance of side shearer based on EDEM. Coal Sci. Technol. 48(02), 151–157 (2020).

Luo G. Study on Modeling and Dynamics Simulation of Shearer Cutting Section when Oblique Cutting Coal with Parting. Liaoning Technical University, (2019).

Lijuan, Z. H. A. O., Shoujie, W. E. N. & Xunan, L. I. U. The influence of simulated particle radius on complex coal seam of drum cutting. Mech. Sci. Technol. Aerosp. Eng. 39(01), 52–57 (2020).

Lijuan, Z. & Mingyang, Z. Loading performance of thin seam shearer. J. China Coal Soc. 42(07), 1892–1898 (2017).

Michele, M. & Hugh, S. E. Discrete element method (DEM)for Industrial applications:comments on calibration and validation for the modelling of cylindrical pellets. Kona Powder Part. J. 32, 236–252 (2015).

Zhao C. Numerical Research of Landslide Motion Characteristics and Slope Stability of Excavation and Supporting[D].Cheng Du,Xihua University, (2016).

Do, H. Q., Aragon, A. M. & Schott, D. L. A calibration framework for discrete element model parameters using genetic algorithms. Adv. Powder Technol. 29(6), 1393–1403 (2018).

Maccarthy J. K., Borchers B, Aster RC, Efficient stochastic estimation of the model Resolution matrix diagonal and generalized cross–validation for large geophysical inverse problems. J. Geophys. Res.: Solid Earth, 116(B10), (2011).

Ringler, A. T. et al. Estimating pole-zero errors in GSN-IRIS/USGS network. Calibration metadata. Bull. Seismol. Soc. Am. 102(2), 836–841 (2012).

Xu B. DEM simulation analysis of pick assembly parameters of cutting head. Shenyang Ligong University, (2015).

Cho, N., Martin, C. D. & Sego, D. C. A clumped particle model for rock. Int. J. of Rock Mechan. Min. Sci. 44(7), 997–1010 (2007).

Barrios, G. K. P. et al. Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol. 248(2), 84–93 (2013).

Tian, L. et al. Numerically simulating rock cutting process of cutterhead of cutter suction dredger with discrete element method. Mech. Sci. Technol. Aerosp. Eng. 38(12), 1805–1811 (2019).

He, A. Study on the process of breaking coal based on single pick hydraulic impact and cutting. Coal Sci. Technol. 46(08), 119–124 (2018).

Yu, K. et al. Study on rock fragments penetration of overlying strata in sublevel caving. Min. Metal. Explor. 40(6), 2371–2381 (2023).

Yu, K., Zheng, C. & Ren, F. Numerical experimental study on ore dilution in sublevel caving mining. Min. Metal Explor 38(1), 457–469 (2021).

Fang, H. et al. Numerical research of landslide motion characteristics and slope stability of excavation and supporting. Transact. Chin. Soc. Agric. Eng. 32(21), 54–59 (2016).

Xiang, W. et al. Calibration of physical parameters for clay soil simulation based on accumulation test. Transact. Chin Soc. Agric. Eng. 35(12), 116–123 (2019).

Wen, X. et al. Research on accumulation angle of coal particles and parameter calibration on EDEM. China Saf. Sci. J. 30(7), 114–119 (2020).

Huang, Y. et al. Numerical simulation study on influence of loading rate on rock uniaxial compression test. Geol. J. China Univ. 25(03), 423–430 (2019).

In X. Study on the Two-Way Coupling Mechanism and Wear Characteristics of Shearer Drum CuttingCoal-Rock with Gangue. Liaoning Technical University, (2020).

Xu X. Study on the characteristics and influencing factors ofcoal and rock cutting dust generation in fully mechanizedmining face. Anhui University of Science & Technology, (2020).

Zhao, L., Luo, G. & Liu, X. Research on drum load characteristics in oblique cutting process of shearer with coal containing parting. Coal Sci. Technol. 48(4), 218–223 (2020).

Xia R. Wear Characteristics and Prediction of Scraper Conveyor Chute Under Multi-Factor Coupling. Taiyuan University of Technology, (2019).

Li, T. Calibration of DEM Model Parameters for Coa!Particles and Research on Relationships between Macro and Micro Parameters. Taiyuan University of Technology, (2019).

Li, C. Crushing performanee analysis and experimental study on vibration-slow shear crusher. Jiangxi University of Science and Technology, (2018).

Zhao, L. et al. Study on coal-loading capacity of MG400/951-WD shearer. J. Liaon. Tech. Univ. (Nat. Sci.) 37(1), 148–153 (2018).

Zhou Z. Simulation study on the spiral conveying characteristics of a new type of grain spiral stacker based on EDEM. Wuhan University of Technology, (2019).

Fang Z. Study on deformation law of surrounding rock of shield machine passing through filling cave. Shandong University, (2019).

Wang Y. Design and research of high efficiency cutting drum for gangue coal and rock. Liaoning Technical University, 2019.

Jun, M. et al. Simulation research of shearer drum cutting performance based on EDEM. J China Coal Soc. 42(4), 1069–1077 (2017).

Zhang, Q. et al. Research on collaborative optimization of cutting and conveying of separated auger drill. Coal Sci Technol 51(11), 179–189 (2023).

Li, M. et al. Study on magneticfield simulation and shielding design of shearer drum heightmeasurement sensor working environment. Coal Sci Technol 50(8), 204–209 (2022).

Li, M., Zhao, L. & Qlao, J. Fatigue reliability analys is of gears in cutting section of shearer for thin coal seam. Shanxi Cok. Coal Sci. Technol. 46(3), 10–13 (2022).

Cao, D., Shang, P. & Zhao, Y. Calculation andanalysis of modified gear time-varying meshing stiffness based onmatlab. Mech. Drive 46(5), 100–107 (2022).

Wang, F. et al. Parametric vi-bration model for a viscous damper-cable system considering theeffect of additional stifiness. J. Vib. Shock 39(22), 183–191 (2020).

Lijuan, Z. et al. Exploring dynamic cutting process of shearer’s drum. Mech. Sci. Technol. Aerospace Eng. 38(03), 386–391 (2019).

Funding

This work was supported by the National Natural Science Foundation of China [Grant Number 51674134], The Education Technology Research Fund of the Science and Technology Development Center of the Ministry of Education [Grant Number 2018A04025],The Doctoral start-up funds in Liaoning Province [Grant Number 23–1043], The Project of Liaoning Provincial Department of Education[grant number LJ212410147026].

Author information

Authors and Affiliations

Contributions

Yadong Wang: Investigation, Resources, Writing-Original Draft, Guocong Lin*: Formal analysis, Investigation, Writing-Original Draft. Xunan Liu: Conceptualization, Supervision, Writing-Review & Editing. Lijuan Zhao: Resources,Funding acquisition,Provide experimental equipment, Writing-Review & Editing. Baoxuan Jia: Methodology, Validation, Resources, Methodology. Yuan Wang: Supervision, Data Curation. Jingqiang He: Validation, Resources. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Lin, G., Liu, X. et al. Research on coal rock parameter calibration based on discrete element method. Sci Rep 14, 26507 (2024). https://doi.org/10.1038/s41598-024-77538-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-77538-9

Keywords

This article is cited by

-

Modeling of sand-cultivated substrate for Gobi facility agriculture and validation of trenching test

Scientific Reports (2025)

-

Numerical simulation of coal particle motion characteristics in the envelope region of spiral drum based on discrete element method

Scientific Reports (2025)

-

Calibration and verification of contact parameters for firework oxidizer powders based on DEM

Granular Matter (2025)