Abstract

This paper focuses on a defective one-dimensional photonic crystal thermal sensor with fabricated layers of gallium nitride, glycerin, and air. The transmission features of this sensor have been presented based on the transfer matrix approach using MATLAB software. Interest in the sensor’s sensitivity to temperature variation is for the sake of the photonic bandgap behavior of the 1D photonic crystal and the thermo-optic effect of glycerin must be preserved over a long time in protecting archaeological artifacts. In this direction, theoretical modeling together with numerical simulation studies are conducted to optimize the refractive index of GaN to enhance sensitivity. This work is going to evaluate the performance of the sensor in terms of the shift in the transmission spectrum of the sensor with the imposition of changes in temperature. The effect of the thickness of the defect layer together with the incident angle on the performance of the sensor will be discussed further. Sensor sensitivities are about 10 nm/°C, with a quality factor reaching a high value of 35,443 at an incident angle of 30°, while sensitivities at an incident angle of 65° have 20 nm/°C and a quality factor of 14,723.

Similar content being viewed by others

Introduction

Photonic crystals (PhCs) are a novel optical material with significant research potential due to their unique applications, which can be enhanced by controlling their structure1,2,3,4. A PhC is an optical nanostructure with periodic changes in refractive index, affecting light propagation, similar to how natural crystals create electronic band structures5,6,7. Photonic band gaps (PBGs) are structural coloration animal reflectors found in nature. Since Eli Yablonovitch7 and Sajeev John’s5 1987 work, research on PhCs has grown, with a focus on their sensing applications, offering unique capabilities for high-sensitivity devices. PhCs can be used as excellent optical sensors such as biochemical sensors8,9,10,11, mechanical sensors12, temperature sensors13,14,15, chemical sensor16, refractive index (RI) sensors17,18, and gas sensors19,20. They are also used in the applications of light flow control, such as optical fibers,

waveguides, and optical filters21,22,23,24. Additionally, PhCs could be used for angular velocity sensing25. PhCs, fabricated in various dimensions, are optical materials used for controlling light flow and manipulating it. They exhibit photonic band gaps, limiting light propagation, and are extensively researched for high-sensitivity sensing devices26.

One-dimensional photonic crystals (1D PhCs) modulate their refractive index by alternating layers of materials with different indices. They have applications in silicon photonics, self-collimation, negative refraction, optical diodes, light bending, and sensing devices doped with bio-active metals like silver, which are proposed as sensing devices for bacterial contaminants27. The technology has potential applications in high-efficiency solar cells and optoelectronic devices, including angle sensors for optical fiber systems and polarization-sensitive couplers28. The subject has been extensively researched in thermal sensors, sensing platforms, photovoltaic devices, and full color displays29,30,31,32. The temperature sensors’ sensing principle involves the change in photonic band gap due to the variation in refractive index with temperature29. The applications showcase the versatility and potential of 1D PhCs in various fields such as photonics, sensing, and solar energy. Temperature sensors utilize photonic band gap changes due to refractive index variation, demonstrating the versatility and potential of 1D PhCs in photonics, sensing, and solar energy.

Researchers are increasingly interested in the 1D photonic crystal thermal sensor due to its potential applications and varying sensing parameter values. In 2012, Kumar et al.33 proposed a simple temperature sensor design using a 1D PhC with a silicon defect mode, consisting of a Si/air multilayers system, displaying a linear shift in sensitivity of 0.064 nm/K across a 100–700 K temperature range. In 2012, Chang et al. studied the temperature dependence of defect mode in a defective one-dimensional photonic crystal, focusing on the visible region. They designed a 1D PhC with TiO2 and SiO2 as defects, enhancing sensitivity by 35% at 100 °C. This design can be used as a tunable filtering device and a temperature-dependent optical sensing device. Chang et al.13 conducted a study in 2012 on the temperature dependence of defect modes in a defective one-dimensional photonic crystal. They designed a 1D PhC using TiO2 and SiO2, with SiO2 and Bi4Ge3O12 as defect layers. The design improved sensitivities of 0.37 nm and 0.50 nm at a temperature increase of 100 °C by 35%, making it suitable for tunable filtering and temperature-dependent optical sensing. Zhang34 developed a high-sensitivity temperature sensor in 2016 using PhC nanobeam cavities, achieving a sensitivity of 162.9 pm/k and a quality factor of 4 × 104, making it suitable for small-diameter on-chip systems. Elmahdy et al.'s15 2018 design for a 1D PhC thermal sensor increased sensitivity with temperature and defect thickness, reaching 0.328 nm/°C for TE mode and quality factor value 4840. In 2018, El-Amassi et al.35 proposed a 1D PhC with a polymer layer between Si and SiO2, enhancing temperature sensor sensitivity of 0.380 nm per degree rise in temperature. The study found that polymers like polycarbonate and polystyrene significantly improved the temperature-sensitive transmission peak shift, emphasizing the importance of polymer choice in temperature sensing. Abd El-Ghany14 presented an interest paper discusses the use of 1D PhCs with double defects as temperature sensors, highlighting their potential for practical temperature sensing applications. Chen et al.'s36 2019 PhC structure successfully achieved 88.7 pm/°C temperature sensitivity and 471.4 quality factor value for simultaneous temperature and gas concentration sensing. El-Naggar et al.'s37 2020 study on temperature dependency of defect modes in cylindrical photonic crystals (CPhCs) found that the structure, composed of TiO2 and Al2O3 shells with a single defect layer, showed tunability and peak transmittance sensitivity of 0.0056 nm/ºC. In 2020, Abadla et al.38 conducted a study on the thermal properties of a one-dimensional annular PhC with nematic liquid crystal as a defect circular layer. The study used TMM to analyze transmission spectrum and optimize parameters, revealing a sensitivity of 0.167 nm/°C and 0.224 nm/°C for two defect modes. Abadla et al.'s39 2021 study utilized the transfer matrix method to investigate the thermal properties of one-dimensional defective annular photonic crystals, resulting in a temperature sensor with a sensitivity of 0.01069 nm/°C. Elsayed et al.40 developed a temperature sensor using a one-dimensional photonic crystal with graphene monolayer defect layer on nematic liquid crystal. The sensor’s sensitivity increased with thicker defect layer, reaching 4 nm/°C and quality factor up to 11,000 at 2500 nm thickness. Zaky and Arafa41 proposed a temperature and salinity sensor in 2021 using a 1D-PhC platform and Tamm resonance. The sensor has high sensitivity (from 2.8 to 10.8 nm/°C), a high-quality factor, and a low detection limit of 3 × 10−7 nm. Thara et al.42 proposed temperature sensors in 2022 using 1D random photonic crystals at different temperatures and binary and ternary-based multi-layered structures. The sensor configurations included (Si/SiO2)N, (Si/SiO2/TiO2)N, and (Si/SiO2/PS)N at N = 10. The 1D PhC structure with a ternary-based structure shows maximum wavelength shifts and maximum sensitivity of 0.08758 nm/°C when using Polystyrene instead of TiO2. Kumar and Prasad43 developed a sensor in 2022 that combines graphene and hexagonal boron nitride for improved sensing performance. The sensor can detect temperature changes in various ranges, with 1010 detection accuracy at room temperature and 372,176 high-quality at 49° angle. The device has a 5K detection limit and 0.20pm/K sensitivity with 50-unit cells, which can be expanded to 300K to 900K. Aly et al.30 presented a temperature sensor in 2023 using a one-dimensional photonic crystal structure with alternating silicon and porous silica layers. The sensor effectively detects temperature changes, with a quality factor of 2216.6 and sensitivity of 0.085 nm/°C. Also in 2023, Srivastava44 studied the improvement of temperature sensitivity using a one-dimensional (1D) symmetric defective photonic crystal (PC) made of Si and Bi4Ge3O12 material. The study found that the temperature sensitivity increased by 0.173 nm/°C for symmetric defective PC with an external defect layer and 0.140 nm/°C for symmetric defective PC without an external defect layer. The highest sensitivity (0.173 nm/°C) was achieved with the symmetric defective PC containing an external defect layer. The study also found that symmetric defective 1DPCs with defects have a higher Q factor, with the highest quality factor reaching 2284 at 375 °C. The proposed design is affordable, simple to create, and small in dimension. Recently, in 2024 Bouazzi et al.45 introduces a new 1D topological photonic crystal (PC) mirror heterostructure for advanced thermal sensing. It utilizes a coupled topological edge state mode (CTES) with exceptional light confinement and a high quality (Q) factor. The first NLC configuration achieves an outstanding Q factor of 107, surpassing the intrinsic value. Additionally, it demonstrates exceptional thermal sensitivity (− 0.12317 nm/°C) and a remarkable figure of merit (1002.48 °C−1). The second configuration offers a trade-off between sensitivity and tunability, exhibiting a Q factor in the 106 range, a sensitivity of − 0.05853 nm/°C, and a figure of merit of 86.53 °C−1. This platform holds immense promise for developing high-performance, tunable narrowband filters and ultrasensitive thermal sensors, paving the way for advancements in diverse photonic applications.

Design consideration

Structure without defect

Figure 1 shows a schematic representation of the proposed finite size 1D PhC of structure periodic cells (GaN/air) without glycerin defect material. The periodic cells consist of Gallium nitrite and air with thicknesses of dA = 100 nm and dB = 200 nm respectively. GaN and air have been taken as the high and the low refractive indices (RI) media. The RI of GaN is 2.2775646 and of air is 1.

Gallium Nitride (GaN) is a dielectric material that has been studied for its potential applications in PhC sensors47. It exhibits high electron mobility, wide energy band gap, and excellent thermal properties, making it suitable for various sensing applications, including as a temperature sensor in PhC sensors. It also has excellent thermal properties, making it suitable for various sensing applications, including as a thermal sensor. GaN’s high thermal conductivity, which is about 1.3 W/cmK, allows for efficient heat dissipation, enabling accurate temperature measurements48. Additionally, GaN’s stability at high temperatures, biocompatibility, and chemical stability make it a highly reliable material for thermal sensing47. These properties have led to the development of GaN-based temperature sensors, such as p-GaN/AlGaN/GaN hybrid anode diodes, which have demonstrated wide operation temperatures from 73 to 573 K, showcasing the potential of GaN in high-performance temperature sensing applications49. Also, GaN-based humidity sensors have been fabricated through pulse modulated DC magnetron sputtering, and GaN nanostructures have been used for gas sensing applications47,50. GaN is also used in the production of dielectric power devices, and GaN-based field effect transistor (FET) type gas sensors have been developed51, highlighting the versatility of GaN in sensing technologies, including thermal and gas sensing applications. Research has been conducted on the fabrication of GaN PhCs with photonic band gaps in the visible and infrared wavelength regimes for future optical characterization52,53,54. The use of GaN in PhC sensors demonstrates its potential for advanced sensing technologies with promising practical implications. The transmission spectra of the non-defected PhC (GaN/air) for TE mode at incident angles 0°, 30°, 45°, 50°, and 65° respectively are shown in Fig. 2.

Structure with central defect

Figure 3 shows a schematic representation of the proposed finite size 1D PhC of structure periodic cells (GaN/air) with glycerin central defect material at periods repetitions N = 3 [(GaN-Air)3 (glycerin) (GaN-Air)3]. While Ddef. is the thickness of the glycerin defect layer. The glycerin was used as temperature sensing material because its reflective index decreases as temperature increases according to the equation55.

where, \({n}_{G}\) is the refractive index at temperature T, n₀ is the refractive index at the reference temperature and α is the thermo-optic coefficient (how much the refractive index changes with temperature).

Glycerin is commonly used as a temperature-sensitive material in PhC temperature sensors. It is known for its low thermal expansion coefficient, making it suitable for temperature sensing applications. Research has demonstrated the use of glycerin in various sensor configurations, such as selectively infiltrated PhC fibers, where it has shown compatibility with temperature sensing and polarization filtering. Additionally, glycerol microdroplets have been utilized as high-sensitivity whispering gallery mode humidity sensors, showcasing their potential for temperature-independent optical sensing. The unique properties of glycerin, including its low thermal expansion coefficient, make it a promising material for temperature sensing in PhC sensors56,57.

Theoretical considerations

Transfer matrix method (TMM)

In this study, we used the transfer matrix method (TMM) to simulate the optical spectra of the photonic structures in question. TMM is a numerical method based on Abeles’s approach that can extract the transmission and reflection spectra of a multilayer structure. Yeh58 introduced the transfer matrix method (TMM) as an appropriate numerical method to analyze electromagnetic wave transfer in multilayered media and extract the transmission and reflection spectra of a multilayer structure. This method is suitable for resolving standard problems in the photonic band structure transmission spectrum. It is based on Abele’s approach59, which lets us show how the amplitudes of the electric fields of the incident wave \({\varepsilon }_{0}^{+}\), the reflected wave \({\varepsilon }_{0}^{-}\), and the transmitted wave change after m layers \({\varepsilon }_{m+1}^{+}\). The following matrix for layered films within m layers was created to achieve this:

Cj is the propagation matrix with the matrix elements:

where \({\phi }_{j-1}\) indicate the change in the phase of the wave between the (j-1)th and the jth interfaces and are expressed in the following equations:

\(\lambda\) is the wavelength for the incident light in vacuum and \({d}_{j-1}\) is the thickness of the (j-1)th layer.

The values \(\tau\) j and \(\rho\) j are the Fresnel transmission and reflection coefficients, respectively, between the (j-1)th and the jth layers. These coefficients can be expressed using the complex refractive index \(\widehat{n}= {n}_{j}+{ik}_{j}\) and the complex refraction angle \({\Theta }_{j}\).

For TE polarization:

Besides, for the TM polarization:

The complex refractive indices and the complex angles of incidence obey Snell’s law, for j = 1,2, 3, . . . m + 1:

Since there is no reflection from the final phase, \({\varepsilon }_{m+1}^{-}\). Abele’s obtained then a conventional formula for the total reflection and transmission coefficients corresponding to the amplitude reflectance ρ and transmittance τ, respectively, as follows:

The quantities \({c}_{11}\) and \({c}_{21}\) are the matrix elements of the whole product \({c}_{j}\) matrix:

For TM and TE polarizations and the transmission T is:

While real indicates the real part.

Sensor’s characterizations

The sensitivity (S), quality factor (QF), figure of merits (FOM), signal-to-noise ratio (SNR), detection limit (δn) and sensor resolution (SR) are also important sensing parameters to evaluate sensor performance. These parameters can be found using the following expressions: The sensitivity (S) is defined as the ratio of the change in resonant wavelength (\(\Delta {\lambda }_{res})\) to the change in temperature (ΔT), it could be written as \(\left(S= \frac{{\Delta \lambda }_{res}}{\Delta \text{T}}\right)\), and it is measured in the unit of nm/℃. The quality factor (QF) of the suggested thermal sensor is calculated using the resonance wavelength \({\lambda }_{res}\) and the full width at the half maximum of the output transmission peak ΔλFWHM as given by \(\left(QF= \frac{{\lambda }_{res}}{{\Delta \lambda }_{FWHM}}\right)\)15. The figure of merit (FOM) is often calculated as the ratio of the sensitivity (S) to the bandwidth ΔλFWHM of the resonant peak30 and given by \(\left(\text{FOM}= \frac{S}{{\lambda }_{FWHM}}\right)\). FOM is used for the evaluation on sensing performance of RI sensors60. Moreover, FOM provides a measure of the sensor’s performance in detecting temperature variations and it is measured by inverse of the degrees Celsius (°C−1) or Kelvin (K−1). The signal-to-noise ratio (SNR) is defined as absolute of the change in resonant wavelength (Δλres) to change of the full width at the half maximum of the output transmission \(\Delta {\lambda }_{FWHM}\) as given by \(\left(\text{SNR}=\left|\frac{{\Delta \lambda }_{res}}{{\Delta \lambda }_{FWHM}}\right|\right)\). The detection limit (δn) of a one-dimensional photonic crystal (1D PhC) thermal sensor refers to the smallest detectable change in a temperature that the sensor can reliably measure30. The detection limit is determined by its sensitivity and the smallest temperature change it can accurately measure and given by \(\left(\updelta \text{n}= \frac{1}{S} \frac{{\Delta \lambda }_{FWHM}}{1.5 \left({SNR}^{0.25}\right)}\right)\) and it is measured by a temperature unit (ºC)61. Additionally, the detection limit (δn) is a crucial parameter that indicates the precision of the sensor in detecting the temperature variations. The measuring unit for the detection limit is typically degrees Celsius (°C) or Kelvin (K). The sensor resolution (SR) is defined as the minimal variation of the refractive index (RI) that can be detected by the sensor and it is given by multiply of the detection limit (δn) and the sensitivity (SR= \(\left|\updelta {\text{n}} \cdot \text{S})\right|\)62.

Results and discussions

Effect of change glycerin defect thickness (Ddef)

Figure 4a–f display TE transmission spectra of the suggested 1D PhC (GaN/air) thermal sensor at glycerin different defect thicknesses Ddef from 500 to 1000 nm with a step of 100 nm. With parameters as follows: an incident angle θ = 0º, GaN thickness dA = 100 nm, air thickness dB = 200 nm and number of GaN/air period repetitions N = 3. The figures show an overlap between the peaks at various temperatures which indicates to reduce the sensitivity. In addition, the broad peaks at different temperatures from 20 to 55 ºC indicate a reduction of the quality factor.

(a–f) Shows the TE transmission spectra of the proposed 1D PC thermal sensor (GaN/air) with defect thicknesss Ddef from 500 to 1000 nm with a step of 100 nm. With parameters: an incident angle θ = 0º, GaN thickness dA = 100 nm, air thickness dB = 200 nm and number of GaN/air periods N = 3: (a) D = 500 nm, (b) D = 600 nm, (c) D = 700 nm, (d) D = 800 nm, (e) D = 900 nm, and (f) D = 1000 nm.

Table 1 shows the values of different sensing parameters of the proposed thermal sensor that were calculated at different central glycerin defect thicknesses. The sensitivity (S), quality factor (QF), figure of merit (FOM), signal-to-noise ratio (SNR), detection limit (δn), and sensor resolution (SR) are calculated of each thickness Ddef from 500 to 1000 nm with a step of 100 nm. The temperature range, wavelength range and shift direction also are identified for each thickness. According to Table 1's data, it seems that the values of sensitivity (S) and figure of merit (FOM) that follow an increase in defect thickness (Ddef) are positively correlated. As the thickness of the defect increases from 500 to 1000 nm, the sensitivity increases from 0.099 to 0.135 nm/°C. Also, FOM value rises from 0.116 to 0.219 °C−1 when the defect thickness increases from 500 to 900 nm. At 1000 nm defect thickness, FOM slightly decreases (0.169 °C−1). Although this slight decrease of the FOM’s value at Ddef 1000, it remains higher than the FOM values at lower thicknesses (Ddef) from 500 to 700 nm. Noteworthy, the quality factor (QF) of the proposed 1D PhC thermal sensor doesn’t follow a clear trend when increasing the glycerin defect thickness. Whereas it increases significantly Ddef from 500 to 600 nm and then decreases from Ddef 600 nm to 700 nm, which is the lowest value of 795.662 at Ddef 700 nm. After that, it increases again from Ddef 700 nm to 900 nm, which reaches the highest value of the QF of the proposed sensor 1539.678. At last, the quality factor drops a little between (Ddef) 900 and 1000 nm. Furthermore, there is no discernible correlation between the signal-to-noise ratio (SNR) and the defect thickness Ddef. Whereas SNR doesn’t consistently increase or decrease with increasing the glycerin defect thickness. It fluctuates significantly across the different thicknesses. It increases from Ddef 500 nm to 600 nm, then it decreases dramatically at Ddef 700, which represented the lowest value of SNR of 95.955 comparing with the other SNR’s values in the table. Then, it significantly increased from Ddef 700 nm to 800 nm, which reaches the highest value of SNR at Ddef = 800 nm of 671.001. Finally, SNR significantly decreased from Ddef = 800 nm to 1000 nm. Also, there appears a complex relationship between the increase in the defect thickness Ddef and the detection limit (δn) of the proposed 1D PhC thermal sensor. It fluctuates significantly across the different thicknesses by increasing and decreasing. It decreases from Ddef 500 nm to 600 nm, then it increases significantly at Ddef 700, which is the highest value of δn 1742.350 ºC. After that, it significantly decreased from Ddef 700 nm to 800 nm, to reach the lowest δn’s values in the table 906.304 ºC. Finally, δn significantly increased from Ddef 800 nm to 1000 nm. With respect to the relation of the glycerin defect thickness and the sensor resolution (SR) of the proposed sensor. It is noticed, SR’s values slightly increased from Ddef 500 nm to 600 nm, then it increases significantly at Ddef 700, which is the highest value of SR 206.555 nm compared with the other SR’s values in the table. After that, it decreased from Ddef 700 nm to 800 nm, to reach the lowest SR’s values in the table 107.442 nm. Finally, SR significantly increased from Ddef 800 nm to 1000 nm to reach the value 155.975 nm which is also higher than the SR values at lower thicknesses Ddef from 500 to 600 nm. All the TE transmission spectra occurred at a temperature range from 20 to 55 °C. Furthermore, all the resonances have a blue shift direction in the beginning of the near-infrared region from 780 to 980 nm. Thus, based on the interpretation of the effect of the change in the defect thickness Ddef in the sensing parameters of the suggested thermal sensor, Ddef 900 nm is an optimal glycerin defect thickness for maximizing the sensitivity and quality factor of this specific sensor design.

Figure 5 depicts the relationship between the glycerin central defect thickness Ddef, and both the sensitivity (in the black line) and the quality factor (QF, in the blue line) of the proposed 1D photonic crystal (PhC) thermal sensor at an incident angle of θ = 0°. The figure shows that the sensitivity generally increases as the defect thickness Ddef increases from 500 to 1000 nm, with some fluctuations. The sensitivity shows a gradual rise, reaching a peak around Ddef of 800 nm before experiencing a slight decline at higher thicknesses. The increase in sensitivity with an increase in defect thickness is likely due to the enhanced interaction between the photonic crystal structure and the temperature changes as the defect layer becomes thicker causing an increment of the optical path of the defect layer, which leads to a more pronounced shift in the transmission spectrum. At the same time, the QF remains relatively stable as Ddef increases, with minor fluctuations. It shows a slight increase from 500 to 800 nm, indicating improved resonance sharpness and fewer losses. After reaching its peak around Ddef of 800–900 nm, the QF begins to decline slightly at the highest thickness (1000 nm). The overall behavior of the QF suggests that while increasing the defect thickness can improve the resonance quality up to a point, further increases may lead to a reduction in performance, possibly due to excessive absorption or scattering within the thicker defect layer. Finally, the figure indicates an optimal range for the defect thickness Ddef, around 800–900 nm, where both sensitivity and QF are maximized. Beyond this range, further increases in thickness may diminish the quality factor while only marginally improving sensitivity.

Effect of incident angle (θ)

The proposed 1D PhC thermal sensor’s TE transmission spectra are displayed in Fig. 6a–f of the incidence angles of 0°, 15°, 30°, 45°, 50°, and 65°. The calculations are achieved for the defect thickness Ddef of 900 nm, GaN thickness dA of 100 nm, air thickness dB of 200 nm, and the number of GaN/air period repetitions N = 3. Notably, the angle of incidence θ could not increase further to 65º due to practical considerations. Since the maximum incident angle in a PhC thermal sensor is limited by practical considerations, such as the performance of the sensor26,47,48. It has been established that the change in incidence angle, which produces sharper peaks at different temperatures, is the basic cause of the increase in sensitivity. Furthermore, there is a large shift between the peaks, which suggests an increase in the quality factor. Some of the TE transmission spectra show a red shift, while others show a blue shift. Red-shifted TE transmission spectra are observed at the incidence angles of 45º and 65º. Although the blue-shifted TE transmission spectra are observed at the incidence angles of 0º, 15º, 30º, and 50º. Notably, all the transmission spectra exhibit a red or blue shift in the visible and near-infrared spectrums.

(a–f) Shows the TE transmission spectra of the proposed 1D PC thermal sensor at incident angles θ from 0 to 65º, With parameters: defect thickness Ddef = 900 nm, GaN thickness dA = 100 nm, air thickness dB = 200nm and number of GaN/air periods repetitions N = 3; (a) θ = 0º, (b) θ = 15º, (c) θ = 30º, (d) θ = 45º, (e) θ = 50º, and (f) θ = 65º.

Table 2 shows the sensing parameters sensitivity (S), quality factor (QF), figure of merit (FOM), signal-to-noise ratio (SNR), detection limit (δn), and sensor resolution (SR) for the proposed thermal sensor by increasing the incident angle θ from 0º to 65º. The data is calculated for the defect thickness Ddef of 900 nm, the GaN thickness dA = 100 nm, the air thickness dB of 200 nm, and the number of GaN/air period repetitions N = 3. Also, the temperature range, wavelength range, and shift direction are detected for each angle. The data in the table suggests that there is a fluctuation between the calculated sensing parameters and an increase in the incident angle θ for the suggested 1D PhC thermal sensor. This is consistent with the general understanding that the performance of PhC sensors can be affected by the angle of incidence26,47,48. There isn’t a clear relationship between the incident angle (θ) and the calculated sensing parameters across the data points provided. However, there is no consistent increase or decrease in the sensing parameters as the incident angle increases. Notably, the sensing parameters are not allowed (NA) and cannot be calculated at some incident angles, such as θ = 10°, 40°, 55°, and 60°. These missing data points make it difficult to understand how the calculated sensing parameters change across the entire range of incident angles. For example, the sensitivity (S) increases when the incidence angle θ increases from 0° (0.125 nm/ºC) to 5° (0.297 nm/ºC). After that, it decreases from 15° (1.606 nm/ºC) to 20° (0.108 nm/ºC).

Then it significantly increases from 25° (2.309 nm/ºC) to 30° (10.088 nm/ºC), which is the second highest value of sensitivity in the table. After that, it was at 35° (2.497 nm/ºC). Finally, it increases from 45° (6.648 nm/ºC) to 65° (20.075 nm/°C) which is the highest value of the sensitivity in the table. The quality factor (QF) also fluctuates in an inverse manner across the entire range of incident angles, comparing the sensitivity. The QF decreases from the angle 0° (1539.678) to the angle 5° (1252.071). Then it decreases from the angle of 15° (1427.766) to 20° (13,816.943). Then it significantly increases from the angle 25º (254.881) to 30º (35,443.258), which is the highest value of the quality factor in the table. After that, it dramatically decreases at the angle 35º (1550.879). Then it decreases again from the angle 45° (4464.783) to the angle 50° (1535.228), and finally it significantly increases at 65° (14,723.294), which is the second highest value of the quality factor in the table. With respect to the relationship between the increase in incident angles and the signal-to-noise ratio (SNR), It fluctuates significantly between different angles. It decreases from 453.342 at the angle 0° to 92.508 at the angle 5°. Then, there’s an increase at angle 15° (118.820) and again at angle 20° (455.307). After that, it decreases again at angle 25° (4024.852), but then it shows a significant increase at angle 30° (12,030.150). The trend continues with an increase in the incident angle from 35° (1691.867) to 45° (4024.852), then it shows a dramatic decrease at angle 50° (333.752), and finally it shows another increase at angle 65° (2174.234). Also, the detection limit (δn) shows a fluctuation with an increase in the incident angle as follows: It has a significant decrease in the detection limit from (1016.438 ºC) at the angle 0° to (119.618 ºC) at the angle 15°. Then it significantly increases at angle 20° (1435.123 ºC), which follows by a dramatic decrease at angle 30° (5.691 ºC). Generally, a lower detection limit (δn) is desirable for a sensor as it indicates higher sensitivity. Then it increases at angle 35° (35.854 ºC), but then decreases again at higher angles (45°, 50°, and 65°). Unfortunately, the missing data points at the angles 10°, 40°, 55°, and 60° make it difficult to say for certain about the trend at those intermediate angles. Noteworthy, the sensor resolution (SR) of the proposed 1D PhC thermal sensor has the same behavior as the detection limit (δn). However, SR dramatically decreases from (120.498 nm) at 0º to (14.180 nm) at the angle 15º. Then, it significantly increases at 20° (170.133 nm), which follows by dramatically decreasing to 30° (0.674 nm). Again, it significantly increases at the angle 35° (89.534 nm), which is followed by a decrease at 45° (37.468 nm). Finally, SR increases at 50° (150.986 nm), which follows another decrease at 65° (136.946 nm). The temperature range for the TE transmission spectra ranges from 20º to 55º. A red shift is observed in some TE transmission spectra, while a blue shift is observed in others. red-shifted TE transmission is detected at incident angles of 5º, 20º, 25º, 45º, and 65º. Despite this, the incidence angles of 0º, 15º, 30º, 35º, and 50º of the blue-shift TE transmission spectra are detected. It is important to note that the TE transmission spectra exhibit a red and blue shift in the visible light and near-infrared spectrums from 420 to 1110 nm. Interestingly, electromagnetic radiation possesses a low wavelength with a red shift and a high wavelength with a blue shift. Thus, based on the interpretation of the effect of the change in the incident angle (θ) in the sensing parameters of the suggested thermal sensor, θ = 65º is an optimal angle to attain the maximum sensitivity and quality factor of this specific sensor design.

Effect of change of GaN thickness (dA)

At incident angle 30 º

Table 3 displays the calculations for sensitivity (S), quality factor (QF), figure of merit (FOM), signal-to-noise ratio (SNR), detection limit (δn), and sensor resolution (SR) at different GaN dA thicknesses ranging from 100 to 900 nm. The data is calculated for defect thickness Ddef of 900 nm, air thickness dB of 200 nm, an incident angle of 30º and the number of GaN/air period repetitions N = 3. For each thickness of GaN, the temperature range, wavelength range, and shift direction are determined. Based on the data in Table 3, there is an inverse relationship between the increase in GaN thickness (dA) and the sensitivity (S) of the proposed 1D PhC thermal sensor. As GaN thickness (dA) increases from 100 to 900 nm, the sensitivity (S) generally decreases. The decreasing relationship is not perfectly linear. While the other calculated sensing parameters appear fluctuation whether increasing or decreasing across the different GaN thicknesses (dA) without a clear trend. For instance, the quality factor (QF) varies significantly across different GaN thicknesses. QF increases from 35,443.258 at 100 nm to 96,101.415 at 200 nm, then it drops significantly to 18,100.882 at 300 nm. Then, it increases again to 72,411.983 at 500 nm which follows by decrease to 42,374.683 at 600 nm. Then, it increases again to reach 76,593.859 at 800 nm and finally it decreases to 59,342.563 at 1000 nm. In the same manner, FOM fluctuates throughout the range of GaN thicknesses. It increases from 621.462 ºC−1 at 100 nm to 1590.882 ºC−1 at 200 nm, then dramatically drops to 177.159 ºC−1 at 300 nm. Then it increases again to attain 656.275 ºC−1 at 400 nm, which follows a decrease to 306.792 ºC−1 at 600 nm. Then, it increases again to 465.465 ºC−1 at 800 nm, and finally, it decreases to 334.081 ºC−1. Also, SNR shows a significant fluctuation between the increasing and decreasing across the increase GaN thickness. It significantly decreases from 12,030.150 at 100 nm to 2212.286 at 600 nm. Then, it increases to attain the highest value of SNR of 134,814.539 at 700 nm which dramatically decreases to 1240.809 at 800 nm which follows by slight increase to 1386.438 at 1000 nm. In the same way, the detection limit (δn) has the same behavior. It rises from 5.691 ºC at 100 nm to 13.242 ºC at 300 nm, then drops to 11.875 ºC at 400 nm. After that, it increases again to 24.954 ºC at 800 nm, which is the highest value of (δn), then slightly decreases to 22.617 ºC at 1000 nm. Also, sensor resolution (SR) significantly increases from 0.674 nm at 100 nm to 90.022 nm at 300 nm, then decreases to 70.080 nm at 400 nm. After that, it increases to 86.220 nm at 800 nm, and finally, it slightly decreases to 81.223 nm at 1000 nm. Notably, a higher signal-to-noise ratio (SNR) could result from a higher quality factor (QF). Likewise, a smaller detection limit may result in a higher sensitivity (S). Noteworthy, all TE transmission spectra occurred in the temperature range of 20º to 50º. Furthermore, all the resonances have a blue shift direction in the visible light region of 400 to 725 nm. Thus, based on the interpretation of the effect of the change in the GaN thickness on the sensing parameters of the suggested thermal sensor, (dA)100 is an optimal GaN thickness for maximizing the sensitivity (10.088 nm/ºC) of this specific sensor design.

Figure 7 displays the relation between the sensitivity and the quality factor with increase the GaN thickness at incident angle of 30º. The figure shows beyond GaN thickness (dA) 100 nm the sensitivity begins to decline steadily, while the quality factor fluctuates but remains relatively high. Also, the figure shows the inverse relationship between the sensitivity and the GaN thickness. Whereas the sensitivity decreases with increased GaN thickness this is due to the multireflection processes between the whole layers of photonic crystal increases. Thus, the rate of the destructive interference process inside the photonic crystal increases. This leads to a reduction of sensitivity. At the same time, the quality factor increases initially, then it fluctuates with several peaks and troughs, and remains relatively high despite the increase in defect thickness. This indicates that while increasing GaN thickness reduces sensitivity, it helps in maintaining or improving the quality factor up to a certain extent.

At incident angle 65º

Table 4 displays the calculations for sensitivity (S), quality factor (QF), figure of merit (FOM), signal-to-noise ratio (SNR), detection limit (δn), and sensor resolution (SR) at different GaN dA thicknesses ranging from 100 to 900 nm. The data is calculated for defect thickness Ddef 900 nm, air thickness dB 200 nm, an incident angle of 65º and the number of GaN/air period repetitions N = 3. For each thickness of GaN, the temperature range, wavelength range, and shift direction are determined. Table 4 shows that the sensitivity (S) of the suggested 1D PhC thermal sensor seems to be inversely correlated with the increase in GaN thickness (dA). Generally speaking, when GaN thickness (dA) increases from 100 to 900 nm, the sensitivity (S) drops; however, this decreasing relationship is not perfectly linear. Since the sensitivity increases slightly between 400 nm (10.827 nm/ºC) and 500 nm (11.186 nm/ºC). The data together imply that a thicker GaN layer may not always enhance the sensitivity of the sensor. This data set suggests that a GaN layer that is thinner—roughly 100 nm—might be better. While the relationship between the quality factor (QF) and the increase in GaN thickness (dA) of the proposed 1D PhC thermal sensor is difficult to describe. Since there isn’t simply an increase or decrease trend, and there is a variance in the quality factor (QF) with varying GaN thicknesses dA. Table 4 shows results showing a large variation in the quality factor (QF) for different GaN thicknesses. For example, it decreases to 2295.369 at 200 nm from 14,723.296 at 100 nm, followed by a rise sharply to 13,568.691 at 300 nm. At 500 nm, it again falls sharply to 3028.869 and then rises to 8914.900 at 600 nm. Eventually, it drops to 3725.620 at 800 nm, and then rises dramatically to 7029.010 at 900 nm. Also, the relationship between the increase in GaN thickness (dA) and the figure of merit (FOM) of the proposed 1D PhC thermal sensor appears complex. FOM also fluctuates throughout the increase in GaN thickness. It dramatically decreases from 397.187 ºC−1 at 100 nm to 32.355 ºC−1 at 200 nm, then significantly increases to 224.994 at 300 nm. It continues to fluctuate across the different GaN thicknesses. Since it significantly decreases again at 500 nm to 25.210 ºC−1, which follows by increasing another time to 83.504 ºC−1 at 600 nm, Finally, it decreases again to 22.146 ºC−1 at 800 nm, followed by another increase to 42.701 at 900 nm. SNR also fluctuates between increasing and decreasing as GaN thickness increases. It significantly drops from 2174.223 at 100 nm to 583.197 at 200 nm, followed by an increase to 1197.744 at 300 nm. Then, it decreases to 593.212 at 400 nm, followed by increasing to 680.414 at 500 nm. Then, it decreases again to 478.833 at 600 nm, followed by increasing to 1379.108 at 700 nm. Subsequently, it experienced another decrease, reaching 291.838 at 800 nm. Finally, it attained the highest value of 2308.629 at 900 nm. This suggests that a thicker GaN layer generally leads to a higher SNR in this sensor design. Similarly, there is not an apparent trend in the values of δn, which sometimes rises or decreases as the GaN thickness increases. It is 6.821 ºC at thickness 100 nm, while it is 11.260 ºC at thickness 200 nm. Then, it drops to 9.670 ºC at 300 nm, while it rises sharply to 21.063 ºC at 400 nm. Then, at 600 nm, it drops to 17.814 ºC, and at 800 nm, it dramatically increases to 30.496 ºC. At 900 nm, it finally drops significantly to 30.181 ºC nm. Furthermore, the relationship between SR and the increase in GaN thickness does not show a simple increase or decrease pattern. Since the sensor’s resolution values fluctuate as GaN thickness increases. According to the data in Table 4, SR value increases from 136.945 nm to 203.271 nm when GaN thickness increases from 100 to 200 nm. Then it decreases to 136.016 nm at 300 nm, followed by an increase again to 228.078 nm at 400 nm. After that, SR’s value decreases dramatically to attain the lowest value of SR in the table 2.111 nm at 600 nm. Then, it was followed by a large increase to 245.470 nm at 800 nm, which is the highest value of SR, followed by a significant decrease to 205.982 nm at 900 nm. It is important to note that all TE transmission spectra occurred in the temperature range of 20º to 50º and exhibit a red shift in the visible light and near-infrared spectrums from 593 to 1063 nm.

Figure 8 presents the relation between the sensitivity and the quality factor with an increase in the GaN thickness at incident angle of 65º. The figure shows the sensitivity decreases with increase the GaN thickness. This is also due to the multireflection processes between the whole layers of photonic crystal increases which leads to a reduction of the sensitivity value. However, the rate of the destructive interference processes inside the photonic crystal at incident angle 65º increases than the incident angle 30º. At the same time, the quality factor is almost constant with increasing the GaN thickness as the same in the incident angle 30º.

Effect of change number GaN/air periods repetitions (N)

At incident angle 30º

Figure 9a–d shows TE transmission spectra of the proposed 1D PhC thermal sensor at different temperatures, with the following parameters: incident angle θ = 30°, defect thickness Ddef = 900 nm, GaN thickness dA = 100 nm, air thickness dB = 200 nm, and different GaN/air period repetitions (N) from 3 to 6. The different lines on the graph represent the transmission spectra at different temperatures: black line: 20 °C, red line: 25 °C, green line: 30°C and blue line: 35 °C. Each colored line (black, red, green, blue) exhibits a peak at a specific wavelength, indicating the resonant wavelength where maximum transmission occurs. The figure shows as the temperature increases the TE transmission peaks shift towards shorter wavelengths (blue shift). This behavior indicates a direct relationship between temperature and the position of the transmission peak: as the temperature rises, the resonant wavelength decreases. The shift in transmission peaks with temperature is likely due to the temperature dependence of the refractive index of the materials (GaN and air) used in the photonic crystal structure, causing changes in the photonic band gap. The figure also shows the TE transmission spectra shows a blue shift as the number of GaN/air period repetitions (N) increases from 3 to 6. With fewer period repetitions (N = 3), the resonance peaks are well-separated, indicating higher sensitivity to temperature changes. As the number of period repetitions increases (N = 4, N = 5, N = 6), the peaks move closer together, indicating reduced sensitivity to temperature changes. The wavelength range shifts from a broader range (570–670 nm for N = 3) to a narrower range (395–430 nm for N = 4, N = 5, and N = 6). The separation between the peaks at different temperatures decreases with increasing N, suggesting that a lower number of period repetitions might be more advantageous for achieving higher sensitivity in this thermal sensor design.

Table 5 shows the sensing parameters that are calculated of the proposed 1D PhC thermal sensor for different numbers of GaN/air period repetitions N = 3, 4, 5 and 6 at incident angle 30º. The table contains different values of sensing parameters of the proposed sensor: sensitivity (S), quality factor (QF), figure of merit (FOM), signal-to-noise ratio (SNR), detection limit (δn) and sensor resolution (SR). Also, the table shows the temperature range, wavelength range, and shift direction for each number of GaN/air period repetitions. According to the data in the table, the number of period repetitions (N) is inversely correlated with the sensitivity (S). Whereas by increasing the number of GaN/air period repetitions (N) from 3 to 6 the sensitivity (S) decreases significantly. Since the most considerable drop occurs between N = 3 and N = 4, with sensitivity dropping from 10.088 nm/°C to 2.004 nm/°C. while from N = 4 to N = 6, the sensitivity continues to decrease but at a much smaller rate. This suggests that increasing the number of GaN/air period repetitions reduces the sensor’s sensitivity to temperature changes, with the most significant reduction happening between number of period repetitions N = 3 and 4. While the data in the table indicates a non-linear relationship between the quality factor and the number of GaN/air period repetitions. Initially, the increase of the number of period repetitions from 3 to 4 reduces the value of the quality factor sharply from 35,443.258 to 7419.528, but further increases in the number of period repetitions from 4 to 6 result in a substantial improvement in the quality factor, with the highest value of the quality factor achieved at N = 6 which is 250,132.271. By the same way, the data in the table indicates a non-linear relationship between the figure of merit and the number of GaN/air period repetitions. Initially, increasing the number of period repetitions from 3 to 4 results in a significant drop in the value of FOM from 621.462 to 35.066 °C−1. However, further increasing the number of period repetitions from 4 to 6 results in a significant increase in the FOM, with the highest FOM observed at N = 6 which is 1148.198 °C−1. Also, the data provided in the table indicates a non-linear relationship between the signal-to-noise ratio and the number of GaN/air period repetitions. Initially, increasing the number of period repetitions from 3 to 4 results in a substantial decrease in the SNR value from 12,030.150 to 93.567. However, further increasing the number of period repetitions from 4 to 6 leads to a significant increase in the SNR value. Also, the data provided in the table indicates a non-linear relationship between the number of GaN/air period repetitions and the detection limit. Initially, increasing the number of period repetitions from 3 to 4 results in a substantial increase in the detection limit value from 5.691 to 47.588 °C indicating to reduced sensitivity. However, further increasing the number of period repetitions from 4 to 6 leads to a decrease in the detection limit, though it does not reach the low level observed at N = 3 which indicates to increase sensitivity at this number of GaN/air period repetitions. Besides, the data in the table indicates a non-linear relationship between the sensor resolution and the number of GaN/air period repetitions. Initially, increasing the number of period repetitions from 3 to 4 results in a substantial increase in the sensor resolution from 0.674 to 95.367 nm. This sharp increase in the sensor resolution means that the sensor becomes less precise and indicates a decrease in resolution quality. However, further increasing the number of period repetitions from 4 to 6 leads to a decrease in the sensor resolution, thereby improving the precision, although it does not reach the high precision observed at N = 3. With respect to the operating temperature range of the proposed sensor. The data in the table indicates that as the number of GaN/air period repetitions increases from 3 to 4, the temperature range of the sensor narrows significantly. For N = 3, the sensor operates over a broader temperature range (20–50 °C). While beyond N = 4, increasing the number of period repetitions to 5 and 6 does not further affect the temperature range, which remains at temperature range narrows to 20–30 °C. Finally, the data in the table shows as the number of GaN/air period repetitions increases from 3 to 4, the wavelength range narrows significantly from a broad range (400–700 nm) to a much narrower range (405–428 nm). This range is included in the visible light spectrum (approximately 380–750 nm). While further increasing the number of period repetitions to 5 and 6 results in a slight additional narrowing of the wavelength range (405–427) which are within the blue to green region of the visible spectrum. Therefore, the sensor’s wavelength range covers the visible light spectrum, with narrower ranges focused more specifically within the blue to green light spectrum as the number of period repetitions increases and the shift direction remains consistently blue across all the different numbers of GaN/air period repetitions.

Figure 10 presents a line graph illustrating the relationship between sensitivity (S) and quality factor (QF) with respect to the number of GaN/air period repetitions at the incident angle 30°. The figure shows a significant decrease in the sensitivity value from 3 to 4 period repetitions, then it remains stabilizing at a low value from 4 to 6 period repetitions. While the figure shows a clear positive correlation between the number of period repetitions and the quality factor, since it shows a steady increase of the quality factor with increase of the number of period repetitions. Finally, the figure demonstrates a clear inverse relationship between the sensitivity and the number of GaN/air period repetitions, while the quality factor shows a direct correlation.

At incident angle 65º

The suggested 1D PhC thermal sensor’s TE transmission spectra are displayed in Fig. 11 (a-d) for different period repetitions ranging from 3 to 6 at angle θ = 65º, defect thickness Ddef = 900 nm, GaN thickness dA = 100 nm, and air thickness dB = 200 nm. It is observed that the temperature range’s upper limit rises to 50ºC as the number of period repetitions increases from 3 to 6. Furthermore, the resonances of all N values exhibit a red shift direction in the visible and at the beginning of the near-infrared wavelength range (from 593 to 1110 nm). This implies that the peak of the response curve of the sensor might be shifting towards longer wavelengths.

Table 6 displays the values of different sensing parameters that are calculated of the proposed 1D PhC thermal sensor for different numbers of GaN/air period repetitions N = 3, 4, 5 and 6 at incident angle 65º. The table contains different values of sensing parameters as follows: sensitivity (S), quality factor (QF), figure of merit (FOM), signal-to-noise ratio (SNR), detection limit (δn), and sensor resolution (SR). Also, the table shows the temperature range, wavelength range, and shift direction for each number of period repetitions. Based on the data in the table, the number of period repetitions (N), sensitivity (S), and sensor resolution (SR) are inversely correlated. Based on the data in the table it is noticed that the number of period repetitions (N) increases from 3 to 6, the sensitivity (S) drops from 20.074 nm/°C to 17.868 nm/°C and the sensor resolution (SR) drops from 136.946 to 97.696 nm. Although the quality factor (QF) and the figure of merit (FOM) are directly correlated with the number of period repetitions (N). The quality factor (QF) increases dramatically from 14,723.294 to 13,824,513.53 and FOM increases significantly from 397.18 °C−1 to 3.39 × 105 °C−1 as the number of period repetitions (N) increases from 3 to 6. While the signal-to-noise ratio (SNR) fluctuates across increasing numbers of period repetitions (N). Notably, it seems that the detection limit (δn) has a complicated relationship with the increase of the number of period repetitions (N). The values of the detection limit (δn) are very close at N = 4 and 5 whereas the lower detection limit (δn) for N = 6 is 5.467 ºC. Lastly, its lowest detection limit (δn) of 5.467 ºC is reached at N = 6. Thus, based on the interpretation of the effect of the number of GaN/Air period repetitions in the sensing parameters of the suggested thermal sensor, dA = 100 nm is an optimal GaN thickness to attain the maximum sensitivity of this specific sensor design.

Figure 12, the black line illustrates how little the impact of the number of GaN/Air period repetitions on the suggested 1D PhC’s sensitivity. Since there is a small drop in sensitivity value from 20.074 nm/ºC for N = 3 to 17.868 nm/ºC for N = 6. However, the quality factor (blue line) shows a high increase from 14,723.294 for N = 3 to 13,824,513.53 for N = 6 with temperature range 20-50ºC.

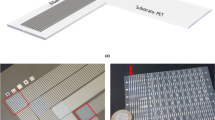

Experimental approach

In this study, the structure of the proposed 1D PhC thermal sensor is established using the GaN dielectric material. Moreover, Glycerin is introduced into the faulty area for thermal sensing purposes. Dry and wet etching methods can be used to fabricate this stracture63,66,67,68,67. The photolithography technique can be used to open up the grooved GaN structure68. The photolithography method is used to create 1D PhC systems by opening the air gaps between the GaN walls. T.S. Perova et.al69 applied the optofluidic microsystem (OFM) technique to infiltrate a NLC of type E7 into the air spaces between the Si walls70. Based on the research by S. Surdo et.al70, the proposed current 1D PhC thermal sensor system can infiltrate glycerin into the central defect region of the 1D PhC system using the OFM technique.

Conclusion

In conclusion, the transfer matrix (TMM) approach was used to investigate the thermal characteristics of the suggested construction. The proposed structure is made up of a defective one-dimensional photonic crystal thermal sensor composed of gallium nitride (GaN), glycerin, and air layers. The effect of defect thickness Ddef, incident angle θ, the GaN thickness dA, and the number of GaN/air period repetitions (N) are investigated on the different sensing parameters of the proposed sensor. The study suggests that the optimal glycerin defect thickness for a thermal sensor is 900 nm, as it enhances sensitivity and quality factors. The proposed thermal sensor’s TE transmission spectra were analyzed at angles from 0° to 65°, with a maximum angle of incidence of 65° due to practical performance issues. Spectra shows redshifts at higher angles and blueshifts at lower angles. The sensitivity fluctuates with angle changes, peaking at 65° with the highest value recorded. The sensing parameters like sensitivity, quality factor, and signal-to-noise ratio fluctuate with angle changes, with the optimal angle being 65° for maximum sensitivity and quality factor. The study explores the impact of GaN thickness on thermal sensor performance at different incident angles. It reveals a relationship between temperature and resonant wavelength, and a decrease in sensitivity as GaN thickness increases. The optimal GaN thickness is 100 nm. The study also explores the impact of GaN/air period repetitions on a thermal sensor’s performance at the incident angles. As the temperature increases, transmission peaks shift to shorter wavelengths, indicating a blue shift. Fewer GaN/air period repetitions (N = 3) show better temperature sensitivity. Sensitivity decreases with an increase of GaN/air, the quality factor and figure of merit also improve. The operating temperature range narrows, focusing more on the blue-to-green light spectrum. The optimal number of GaN/air period repetitions is N = 3. The small number of period repetitions helps to create a compactable sensor. Our findings indicate that the suggested sensor structure has a sensitivity of 20 nm/°C, a high-quality factor of 14,723, the figure of merit of 397 ºC−1, a signal-to-noise ratio of 2174, a detection limit of 7 °C, and a sensor resolution of 137 nm. Finally, by comparison of the present work results with the previous thermal sensor studies as shown in Table 7, our findings represented the highest values of sensitivity, quality factor and figure of merit. Thus, the present work suggests a sensor that more helpful in the creation of cheap and practical thermal sensors.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Joannopoulos, J. D., Villeneuve, P. R. & Fan, S. Photonic crystals. Solid State Commun. 102, 165–173 (1997).

Nair, R. V. & Vijaya, R. Photonic crystal sensors: An overview. Prog. Quantum Electron. 34, 89–134 (2010).

Maskaly, K. R., Maskaly, G. R., Carter, W. C. & Maxwell, J. L. Diminished normal reflectivity of one-dimensional photonic crystals due to dielectric interfacial roughness. Opt. Lett. 29, 2791–2793 (2004).

Inouye, H. et al. Optical properties of a total-reflection-type one-dimensional photonic crystal. IEEE J. Quantum Electron. 38, 867–871 (2002).

John, S. Strong localization of photons in certain disordered dielectric superlattices. Phys. Rev. Lett. 58, 2486 (1987).

Notomi, M. Manipulating light with strongly modulated photonic crystals. Rep. Prog. Phys. 73, 96501 (2010).

Yablonovitch, E. Inhibited spontaneous emission in solid-state physics and electronics. Phys. Rev. Lett. 58, 2059 (1987).

Fenzl, C., Hirsch, T. & Wolfbeis, O. S. Photonic crystals for chemical sensing and biosensing. Angew. Chem. Int. Ed. 53, 3318–3335 (2014).

Zheng, S., Zhu, Y. & Krishnaswamy, S. Nanofilm-coated photonic crystal fiber long-period gratings with modal transition for high chemical sensitivity and selectivity. In Smart Sensor Phenomena, Technology, Networks, and Systems Integration 2012 Vol. 8346, 70–78 (SPIE, 2012).

Ramanujam, N. R. et al. Enhanced sensitivity of cancer cell using one dimensional nano composite material coated photonic crystal. Microsyst. Technol. 25, 189–196 (2019).

Mohebzadeh Bahabady, A., Olyaee, S. & Arman, H. Optical biochemical sensor using photonic crystal nano-ring resonators for the detection of protein concentration. Curr. Nanosci. 13, 421–425 (2017).

Zhang, Y., Zhao, Y. & Lv, R. A review for optical sensors based on photonic crystal cavities. Sens. Actuators A Phys. 233, 374–389 (2015).

Chang, Y.-H., Jhu, Y.-Y. & Wu, C.-J. Temperature dependence of defect mode in a defective photonic crystal. Opt. Commun. 285, 1501–1504 (2012).

El-Ghany, S.-S.A. Temperature sensors based on one dimensional photonic crystals with different double defects. J. Nanoelectron. Optoelectron. 13, 221–228 (2018).

Elmahdy, N. A., Esmail, M. S. & Mohamed, M. Characterization of a thermal sensor based on one-dimensional photonic crystal with central liquid crystal defect. Optik 170, 444–451 (2018).

Olyaee, S., Seifouri, M., Karami, R. & Mohebzadeh-Bahabady, A. Designing a high sensitivity hexagonal nano-cavity photonic crystal resonator for the purpose of seawater salinity sensing. Opt. Quantum Electron. 51, 1–9 (2019).

Liu, Y. & Salemink, H. W. M. All-optical on-chip sensor for high refractive index sensing in photonic crystals. Europhys. Lett. 107, 34008 (2014).

Zheng, S., Shan, B., Ghandehari, M. & Ou, J. Sensitivity characterization of cladding modes in long-period gratings photonic crystal fiber for structural health monitoring. Measurement 72, 43–51 (2015).

Lai, W.-C., Chakravarty, S., Wang, X., Lin, C. & Chen, R. T. On-chip methane sensing by near-IR absorption signatures in a photonic crystal slot waveguide. Opt. Lett. 36, 984–986 (2011).

Zhang, Y., Zhao, Y. & Wang, Q. Measurement of methane concentration with cryptophane E infiltrated photonic crystal microcavity. Sens. Actuators B Chem. 209, 431–437 (2015).

Singh, A., Thapa, K. B. & Kumar, N. Analysis and design of optical biosensors using one-dimensional photonic crystals. Optik 126, 244–250 (2015).

Scalora, M. et al. Transparent, metallo-dielectric, one-dimensional, photonic band-gap structures. J. Appl. Phys. 83, 2377–2383 (1998).

Gong, Q. & Hu, X. Ultrafast photonic crystal optical switching. Front. Phys. China 1, 171–177 (2006).

Jakšić, Z., Maksimović, M. & Sarajlić, M. Silver–silica transparent metal structures as bandpass filters for the ultraviolet range. J. Opt. A Pure Appl. Opt. 7, 51 (2004).

Mohammadi, M., Olyaee, S. & Seifouri, M. Passive integrated optical gyroscope based on photonic crystal ring resonator for angular velocity sensing. Silicon 11, 2531–2538 (2019).

Lu, T.-W., Wu, C.-C. & Lee, P.-T. 1D photonic crystal strain sensors. Acs Photonics 5, 2767–2772 (2018).

Han, L. 1D photonic crystals: principles and applications in silicon photonics. Theor. Found. Appl. Photonic Cryst 159–180 (2018).

Panyaev, I. S., Sannikov, D. G., Dadoenkova, N. N. & Dadoenkova, Y. S. Three-periodic 1D photonic crystals for designing the photonic optical devices operating in the infrared regime. Appl. Opt. 60, 1943–1952 (2021).

Dinodiya, S., Suthar, B. & Bhargava, A. Temperature sensor based on 1D SiN/air photonic crystal. In 2020 IEEE 8th International Conference on Photonics (ICP) 111–112 (IEEE, 2020).

Aly, A. H., Mohamed, B. A., Al-Dossari, M. & Mohamed, D. A temperature sensor based on Si/PS/SiO2 photonic crystals. Sci. Rep. 13, 21560 (2023).

Starczewska, A. & Kępińska, M. Photonic crystal structures for photovoltaic applications. Materials 17, 1196 (2024).

Shen, H., Wang, Z., Wu, Y. & Yang, B. One-dimensional photonic crystals: fabrication, responsiveness and emerging applications in 3D construction. RSC Adv. 6, 4505–4520 (2016).

Kumar, A. et al. Wide range temperature sensors based on one-dimensional photonic crystal with a single defect. Int. J. Microw. Sci. Technol. 2012, 1–5 (2012).

Zhang, Y. et al. High sensitivity temperature sensor based on cascaded silicon photonic crystal nanobeam cavities. Opt. Express 24, 23037–23043 (2016).

El-Amassi, D. M., Taya, S. A. & Vigneswaran, D. Temperature sensor utilizing a ternary photonic crystal with a polymer layer sandwiched between Si and SiO2 layers. J. Theor. Appl. Phys. 12, 293–298 (2018).

Chen, Y.-H., Shi, W.-H., Feng, L., Xu, X.-Y. & Shang-Guan, M.-Y. Study on simultaneous sensing of gas concentration and temperature in one-dimensional photonic crystal. Superlattices Microstruct. 131, 53–58 (2019).

El-Naggar, S. A., Nguyen, T. K. & Dhasarathan, V. Numerical analysis of tunable defect mode in cylindrical photonic crystals configuration. Microw. Opt. Technol. Lett. 62, 3351–3358 (2020).

Abadla, M. M., Elsayed, H. A. & Mehaney, A. Sensitivity enhancement of annular one dimensional photonic crystals temperature sensors with nematic liquid crystals. Phys. Scr. 95, 85508 (2020).

Abadla, M. M., Elsayed, H. A. & Mehaney, A. Novel design for the temperature sensing using annular photonic crystals. Silicon 13, 4737–4745 (2021).

Elsayed, H. A., Sayed, F. A. & Aly, A. H. Graphene deposited liquid crystal and thermal sensitivity using photonic crystals. Phys. Scr. 96, 35503 (2021).

Zaky, Z. A. & Aly, A. H. Highly sensitive salinity and temperature sensor using Tamm resonance. Plasmonics 16, 2315–2325 (2021).

Thara, R. L., Priya, P. A. & Nayak, C. Enhanced temperature sensing based on the randomness in the multilayered 1D photonic crystals. In Journal of Physics: Conference Series, Vol. 2357, 12020 (IOP Publishing, 2022).

Kumar, M. & Prasad, S. High performance mid infrared temperature sensor based on resonance excitation of hybrid Tamm surface states. Opt. Mater. 131, 112586 (2022).

Srivastava, S. K. design of temperature sensor based on one-dimensional photonic crystal containing Si–BGO layer. Mater. Open 1, 2350003 (2023).

Bouazzi, Y., Esmail, M. S. M., Touahmia, M., Ahmad, A. & Soliman, S. E. High-Q coupled topological edge state in 1D photonic crystal mirror heterostructure for ultrasensitive thermal sensing. Opt. Commun. 574, 131198 (2025).

Barker, A. S. Jr. & Ilegems, M. Infrared lattice vibrations and free-electron dispersion in GaN. Phys. Rev. B 7, 743 (1973).

Furqan, C. M. et al. Humidity sensor based on gallium nitride for real time monitoring applications. Sci. Rep. 11, 11088 (2021).

Abedi, M., Hempel, L., Sadeghi, S. & Kirsten, T. GAN-based approaches for generating structured data in the medical domain. Appl. Sci. 12, 7075 (2022).

Yang, A. et al. Highly reliable temperature sensor based on p-GaN/AlGaN/GaN hybrid anode diode with wide operation temperature from 73 K to 573 K. Crystals 13, 620 (2023).

Khan, M. A. H. & Rao, M. V. Gallium nitride (GaN) nanostructures and their gas sensing properties: a review. Sensors 20, 3889 (2020).

Reddeppa, M., Nguyen, T. K. P., Park, B.-G., Kim, S.-G. & Kim, M.-D. Low operating temperature NO gas sensors based hydrogen peroxide treated GaN nanorods. Phys. E Low-dimensional Syst. Nanostructures 116, 113725 (2020).

Peyrade, D. et al. Fabrication of GaN photonic crystals for 400 nm wavelength. Microelectron. Eng. 57, 843–849 (2001).

Tompkins, R. P. Polarity Inverted Gallium Nitride for Photonic Crystal Biosensors (West Virginia University, 2009).

Bin, J., Feng, K., Shen, W., Meng, M. & Liu, Q. Investigation on GaN-based membrane photonic crystal surface emitting lasers. Materials 15, 1479 (2022).

Bing, P. B., Li, Z. Y., Yao, J. Q., Lu, Y. & Di, Z. G. A photonic crystal fiber based on surface plasmon resonance temperature sensor with liquid core. Mod. Phys. Lett. B 26, 1250082 (2012).

Cheng, T. et al. Microstructured optical fiber filled with glycerin for temperature measurement based on dispersive wave and soliton. Opt. Express 29, 42355–42368 (2021).

Reinis, P. K. et al. High-sensitivity whispering gallery mode humidity sensor based on glycerol microdroplet volumetric expansion. Sensors 21, 1746 (2021).

Yeh, P. & Hendry, M. Optical waves in layered media. Phys. Today 43, 77 (1990).

Abelés, F. Recherches sur la propagation des ondes électromagnétiques sinusoïdales dans les milieux stratifiés. Annales de physique 12, 706–782 (1950).

Qiao, Q., Xia, J., Lee, C. & Zhou, G. Applications of photonic crystal nanobeam cavities for sensing. Micromachines 9, 541 (2018).

Shaban, M., Ahmed, A. M., Abdel-Rahman, E. & Hamdy, H. Tunability and sensing properties of plasmonic/1D photonic crystal. Sci. Rep. 7, 41983 (2017).

Rahman-Zadeh, F., Danaie, M. & Kaatuzian, H. Design of a highly sensitive photonic crystal refractive index sensor incorporating ring-shaped GaAs cavity. Opto-Electron. Rev. 27, 369–377 (2019).

Elwenspoek, M., Elwenspoek, M. & Jansen, H. V. Silicon Micromachining Vol. 7 (Cambridge University Press, 2004).

Gotra, Z. Y. Technology of microelectronic devices. (1991).

Kendall, D. L. Vertical etching of silicon at very high aspect ratios. Annu. Rev. Mater. Sci. 9, 373–403 (1979).

Barillaro, G., Nannini, A. & Pieri, F. Dimensional constraints on high aspect ratio silicon microstructures fabricated by HF photoelectrochemical etching. J. Electrochem. Soc. 149, C180 (2002).

Astrova, E. V. & Fedulova, G. V. Formation of deep periodic trenches in photo-electrochemical etching of n-type silicon. J. Micromech. Microeng. 19, 95009 (2009).

Tolmachev, V. A. et al. 1D photonic crystal fabricated by wet etching of silicon. Opt. Mater. 27, 831–835 (2005).

Perova, T. S., Tolmachev, V. A., Astrova, E. V., Zharova, Y. A. & O’Neill, S. M. Tunable one-dimensional photonic crystal structures based on grooved Si infiltrated with liquid crystal E7. Phys. Status Solidi C 4, 1961–1965 (2007).

Surdo, S. et al. Optofluidic microsystems with integrated vertical one-dimensional photonic crystals for chemical analysis. Lab Chip 12, 4403–4415 (2012).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

M.M. and M.S. conceived the main idea and the designed structure. M.M.; A.H.A.; M.S.E.; & S.E.S. designed and conducted the analyses and software. M.M.; M.S.E., and A.H.A. analyzed the results. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Maher, M.A., Aly, A.H., Esmail, M.S. et al. Maximizing temperature sensitivity in a one-dimensional photonic crystal thermal sensor. Sci Rep 15, 4105 (2025). https://doi.org/10.1038/s41598-024-82889-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-82889-4

Keywords

This article is cited by

-

Tunable 1-D photonic crystal sensor for high temperature measurement by introducing double defect mode within successive layers of gallium nitride and silicon nitride

Optical and Quantum Electronics (2026)

-

Highly sensitive salinity sensing using annular one-dimensional photonic crystals

Scientific Reports (2025)

-

A novel approach to salinity monitoring using two dimensional hexagonal photonic crystals

Scientific Reports (2025)