Abstract

Metamaterial sensors are gaining popularity for their numerous application possibilities, including sensing, imaging, energy harvesting, explosive detection, military radar, wavelength detection, and other sensor applications. This work presents a simple interconnected four-split rectangular ring resonator metamaterial (MTM) for microwave sensing applications. The novelty of the proposed MTM is reusability since it can detect sensitivity utilizing both of its sides in two distinct methods. It has an electrical size of approximately 0.178 λ0 × 0.178 λ0. The MTM unit cell demonstrates transmission resonance with Mu Negative (MNG) metamaterial properties for both the C and X-band. It has an excellent effective medium ratio (EMR) of 5.57 at 6.7 GHz and 4.33 at 8.6 GHz, which indicates its compactness and efficacy. Two sensing methods are investigated to determine which is more effective for sensitivity measurement and its potential in microwave sensing applications. The resonance frequency fluctuates based on the permittivity and refractive index changes. The MTM unit cell amplifies this resonance with the E-field intensity. The MTM demonstrates flexibility features for various bending degrees. The measured findings demonstrate that the proposed metamaterial has excellent sensitivity, high Q-factor (Q-factor > 10), and FoM for its first method. The sensitivity, Q-factor, FoM, flexibility and good EMR results suggested that the proposed MTM is a viable solution for microwave sensing applications.

Similar content being viewed by others

Introduction

Metamaterial-based microwave sensors have recently gained popularity due to their high sensitivity and precision in detecting the properties of compounds used in healthcare, industrial, pharmaceutical, and medical applications. Metamaterials (MTMs) have various advantages in sensing applications, including increased sensitivity, high accuracy, and the capability to work across a wide range of frequencies. In 2004, scientists established the use of metamaterials for sub-wavelength imaging, opening up new potentials for sensing applications1. Over the last decade, researchers in metamaterial sensing have developed novel structures for a wide range of real-world applications, including biosensing, material detection, and food safety. This sensing technology is quite established to overcome the traditional approaches2. MTMs are known as synthetic substances that have remarkable electromagnetic properties that are not seen in nature3. It also generates distinct resonance when capacitance changes because capacitance impacts the dielectric constant of the sample under test (SUT) in the sensing area. The resonance approach is more accurate than other procedures utilized for sensing, such as the transmission or reflection method. This characteristic makes metamaterials appropriate for sensing applications. In addition to these studies, MTMs have opened new opportunities in recent years for the development of next-generation sensing technologies. metamaterial sensor has been developed for a wide range of applications and purposes. Some of the applications, including absorbers4,5, energy harvesting6,7, biosensors8,9 microwave and THz sensors10 and antennas11,12.

Microwave metamaterial sensors have been widely employed in sensor applications throughout the past decade. As a possible sensing mechanism, metamaterial sensors have the potential to overcome the resolution limit of traditional sensors while offering the benefits of rapid response, high sensitivity, and straightforward measurement. There are several non-destructive, real-time sensing methods and approaches accessible in the previous works. Liang et al.13 presented a new metamaterial sensor with an ultrahigh Q-factor of 665.85 and 1883.3 at 5.46 GHz and 11.3 GHz. Han et al.14 proposed a metamaterial microwave sensor to determine the dielectric constants of liquid and solid materials. The sensor resonates at 2.45 GHz. In the solid state, the sensitivity and resolution were 4.12% and 102 MHz, respectively, in the liquid state, they were 0.78% and 8.4 MHz. Billa et al.1 proposed a new double negative (DNG) metamaterial sensor for textile fabric and moisture sensing. The design achieves high Q-factors and considerable resonance frequency shifting with a minimal 0.05 dielectric variation. Dewangan et al.15 presented a thin, polarization-insensitive, angularly stable, high Q-factor metamaterial absorber (MMA) for sensing applications in the C band. The design exhibits more than 90% absorptivity for both TE and TM polarized waves. Abdulkarim et al.16 proposed a novel hypersensitized liquid sensor based on metamaterials that integrates an omega-shaped resonator with a microstrip transmission line. The Q factor and the minimum value of S21 for the structure are compatible at frequencies from 1 to 20 GHz. Islam et al.17 proposed a unique-shaped metamaterial sensor that senses oils, fluids, and chemicals utilizing microwave frequencies. The resonance frequency moved to 100 MHz, 70 MHz, 80 MHz, and 90 MHz for different types of oils and fluid compounds. The sensor’s quality factor is 135, with a sensitivity of 0.56. Bazgir et al.18 developed a microwave sensor that measures permittivity and has a high Q-factor. The sensor is particularly designed to resonate at 3.36 GHz. The sensor’s measured average sensitivity is 4.68%. Zamel et al.19 described a one-port microwave sensor in the X-band with an effective method for classifying various power materials. This sensor can detect a variety of powder materials when the frequency shift range is between 30 and 60 MHz. Rabbani et al.20 developed an asymmetric square split-ring metamaterial for microwave absorbers. The SUT container contains the liquid or solid under test (SUT) positioned between the metamaterial structures. Also, the SUT might be placed at the metamaterial sensing front or back surface. Soffiatti et al.21 suggested a method based on metamaterial sensor antennas that can be used to assess impurities in chemicals based on the quality of transmission between the sensor antennas at different operating frequencies, such as 1.8 GHz, 2.4 GHz, 3.4 GHz, and 4.1 GHz, by producing varying sensitivity values. Abdulkarim et al.22 proposed an MTM sensor with a G-shape resonator that detects liquids in the 8–12 GHz band range. The sensor effectively uses frequency shift to identify different chemical liquids. Xie et al.23 showed a nested-complementary split ring resonator with outstanding sensitivity and good Q-factor values. It also demonstrated a flexible double-sided connected microwave sensor film for real-time detection of the liquid dielectric constant. Alsaif et al.24 proposed a metamaterial sensor for textile material identification that has a high quality factor, effective medium ratio (EMR) and sensitivity of 8.96, 14.57%, and 345. The sensor that detects textile materials which operates in the S and C bands.

Although previous studies demonstrated excellent sensitivity, they did not explain the sensing mechanism from both sides of the MTM. Additionally, the flexibility properties of the metamaterial are not demonstrated. According to some research25, flexible electromagnetic metamaterials offer considerable electromagnetic control properties in microwave, terahertz, infrared, and other frequency ranges. It has several applications in the areas of communication information, antennas and microwave sensing, electromagnetic wave absorption and stealth, and other areas. Metamaterials generate powerful localization and refinements of a strong electromagnetic (EM) field, resulting in an excellent sensing platform with high sensitivity, greater resolution, rapid response, and high accuracy with the ability to shift frequencies properly because of their engineered structures26. This allows them to respond significantly to even small changes in the surrounding environment, such as a slight shift in refractive index or dielectric properties, which results in a large observable signal change at the sensor’s resonant frequency. It is made to be very sensitive to small variations in their environment because of their unique subwavelength structures that precisely manipulate electromagnetic waves. Sensing methods based on an electric field with transmission resonance are more effective and efficient and provide better results than other approaches27,28.

This study investigated the detecting capabilities of our proposed MTM sensor and how the resonant frequencies are affected by changes of dielectric constant in the surrounding dielectric environment. Metamaterial-based sensors can increase the resolution limit of traditional sensors, and they are more sensitive. This MTM sensor utilizes two distinct sensitivity methods within its structure using transmission coefficient and E-field intensity. The proposed MTM sensor is designed to be reusable because the sensing can be performed from both sides. The SUT can be placed on the sensor’s front and back surfaces, allowing for fast examination of the sensitivity of liquid or solid samples in microwave frequencies. The high sensitivity and Q-factor make it a feasible option for microwave sensing applications.

Design methodology with design evolution

Design evolution steps

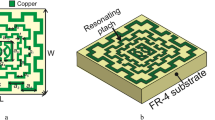

The designed structure was assessed step by step, as shown in Fig. 1a, until it reached the final design of the unit cell. Table 1 shows the effective EMR for various design phases of the proposed structure. The effective medium ratio (EMR) enables the development of an efficient, compact structure and extremely sensitive sensors, which is critical for real-world applications29,30. During the metamaterial development process, higher EMR can be attained. Figure 1b compares the transmission resonance (S21) of the unit cell structure for design steps. The transmission resonance shows dual band resonance in C and X band with a good transmission coefficient in the final design when compared to step 1 to step 4. In the first step, a single rectangular ring resonator (RR) with three slots is used to identify a resonance frequency. In step 2, a smaller rectangular RR inside the previous RR with a single slot was employed, and three resonance frequencies were identified within the frequency range. In the third and fourth steps, two rectangular RRs are used within those previous RR, resulting in a nearly similar resonance frequency as step 2. In steps 2, 3, and 4, the transmission coefficient at 4.6 GHz was less than − 10 dB. In the final step, the first three RR are connected using two connectors. The final proposed design has two resonance frequencies that cover the C and X frequency bands with transmission coefficients of − 41.40 dB and − 37.04 dB. Also, in the first step, the structure has a very little intensity in the E field within its conductive area, which will reduce the performance during sensing. So, the final design is appropriate when considering its overall results for sensing applications.

MTM structure with design parameters

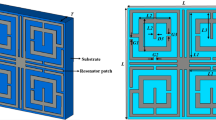

The proposed unit cell construction consists of three split rings that are mutually connected by slab resonator metal and a C-shaped resonator placed in the center of the unit cell. Figure 2 illustrates the proposed structure with parameters. The MTM design utilizes a Roger RT-5880 substrate with dimensions of (L) 8 × (W) 8 mm2 and thickness (h) of 0.254 mm. The material’s low dielectric constant of 2.2 makes it ideal for high-frequency sensing applications with low dielectric losses31. The isotropic structure of the Rogers 5880 PCB ensures consistent electrical properties in all directions, as well as a low thermal coefficient32. Also, the material is affordable and easily accessible. A resonator made of annealed copper has a conductivity of 5.8 × \({10}^{7}\) S/m. The copper is positioned on the top layer of the unit cell with a thickness (t) of 0.035 mm. Additionally, the design and assessment are developed using the EM simulation software CST, and the finite integration approach (FIT) is employed to enhance performance through the resonance of reflection and transmission coefficients. The proposed structure functions as frequency selective surfaces (FSS). In FSS, the electromagnetic response depends on the frequency and polarization of the electromagnetic waves33. The proposed MTM can reflect or transmit electromagnetic waves, allowing waves to travel through the structure while blocking undesired interference signals when SUT is applied. The unit cell was excited by the boundary conditions with a perfect magnetic conductor (PMC) and perfect electric conductor (PEC) to direct the magnetic and electric fields in the X and Y axis. EM waves are reflected and transmitted via waveguide ports 1 and 2 in the propagation of the Z-axis. The primary contributions of this study are the assessments of the transmission coefficient (S21) of sensing methods and simulation studies to validate the results. Table 2 shows the dimensions value of the MTM.

Parametric analysis

The structural characteristics also play a crucial part in improving the transmission coefficient. In Fig. 3, the transmission coefficient (S21) is investigated by changing the structural dimension values of the MTM. The physical parameters of the unit cell have a direct impact on the resonance frequency at which the MTM obtains a higher transmission coefficient value. Increasing the unit cell size often decreases the resonance frequency since it correlates to a lower frequency. On the other hand, the resonance frequency increases when the size is decreased. Similarly to this, changing the ring’s width has an impact on the permeability and effective permittivity. These geometric modifications improve the MTM’s performance over the target frequency range, resulting in an ideal transmission coefficient. In Fig. 3a, the S21 value is analyzed for various values of C1 at 0.1 mm intervals while the other parameters remain constant. There is a marginal variation in the C band frequency for the value of C1. Figure 3b depicts the S21 for various dielectric values of (C3). The value of C3 is varied between 0.15 and 0.35 mm with a 0.05 mm interval, and no significant changes are seen as C3 increases. In Fig. 3c, the width of the fourth ring resonator (W2) is changed from 1.4 to 1.8 mm, while all other parameters remain the same. Figure 3d depicts the response curve after adjusting the second ring resonator dimension (L1) from 5.6 to 6 mm. The frequency of the X band slightly fluctuates as L1 increases. A metamaterial dielectric thickness analysis shows how the dielectric layer thickness (h) within a metamaterial structure influences the interaction between the wave and the unit cell geometry of the metamaterial, thereby affecting its electromagnetic properties, specifically its resonant frequency and overall performance. For this analysis, the dielectric height is varied between 0.154 and 0.354 at a 0.05 interval. As the thickness of the dielectric layer increased, the resonance moved to lower frequencies. The effect of increasing the dielectric thickness was minimal, hence, h = 0.254 is chosen. This is because the transmission coefficient (S21) of electromagnetic (EM) waves in a metamaterial is essentially influenced by its features, such as composition, structure, and size. Figure 3f illustrates the differences of transmission coefficient (S21) for different materials such as Rogers RT-5880, Rogers RO4350B, FR-4, and Arlon DiClad 527. In comparison to Rogers RT-5880, the other three materials exhibit lower transmission coefficients and deflection in frequency bands.

Results and discussion

Transmission and reflection coefficient of MTM

Based on S parameters, the simulation generated a complex frequency, with S11 representing the reflection coefficient and S21 representing the transmission coefficient, respectively \(\left( {{\text{T}} = \left| {S_{21} } \right|^{2} ,{\text{R}} = \left| {S_{11} } \right|^{2} } \right)\) of the MTM unit cell, which is shown in Fig. 4. With high magnitude and good EMR value, the transmission resonance curve becomes more sharply defined.

The EMR assesses the compactness of the MTM unit cell design. The unit cell’s effectiveness is demonstrated when the EMR value exceeds 4, indicating either a single negative (SNG) or double negative (DNG) metamaterial. By using the following equation30 the EMR can be computed.

Here, ‘λ’ and ‘D’ represent wavelength and dimension, respectively.

The resonance at 6.7 GHz has a maximum EMR of 5.57, whereas at 8.6 GHz, the EMR is 4.33, and the metamaterial is Mu negative (MNG). At 6.7 GHz, the proposed design exhibits good results with single negative (SNG) metamaterial features. The proposed design’s transmission coefficient (S21) has a response of − 41.40 dB at 6.7 GHz and − 37.04 dB at 8.6 GHz.

Metamaterial properties

The metamaterial unit cell structure displays MNG properties in the X and C-bands. The material properties simulation findings were discovered for the Z-axis field excitation. The metamaterial properties of this unit cell may be derived by calculating the reflection and transmission coefficients as follows34:

Figure 5a shows a frequency vs permittivity curve with a positive actual value for permittivity in TEM mode at the resonance frequencies of 6.7 GHz and 8.6 GHz. The effective permeability and the refractive index graph in Fig. 5b,c show that permeability and refractive index have negative and positive values at the resonance frequencies, respectively. The Nicolson-Ross-Weir approach35 was used to derive the actual MTM properties, which are extracted from S-parameter simulation data using CST post-processing.

Electromagnetic field distribution of the MTM

The proposed metamaterial has two resonant frequencies due to its structure. Various geometric features within the unit cell can interact with electromagnetic waves at different frequencies, effectively producing multiple resonance modes that can be excited independently. Furthermore, some metamaterials can provide a dual-band response by simultaneously exciting magnetic, electric, and surface current resonances at various frequencies. The distribution of the electric field, magnetic field, and surface current is fully demonstrated in Fig. 6a–c, respectively. Each field is represented at its corresponding resonance frequency. At resonance frequencies, the proposed MTM unit cell displays symmetric E-field and H-field resonances. The MTM sensor electromagnetic field distributions define the relationship between the H-field, E-field, and current distribution of the resonator as by Maxwell’s equation36,37. The E-field distributions for the transmission frequencies of 6.7 GHz and 8.6 GHz are mostly concentrated at the resonator capacitance surface area, as shown in Fig. 6a. Figure 6b shows that the H-field is more intense at 6.7 GHz than at 8.6 GHz in the gap between the first and second rings. At this frequency, the magnetic field’s intensity is greater than the intensity of the electric field. The copper layer’s antiparallel current leads to substantial magnetization between the first and second inner rings. At resonance frequencies, a higher concentration of surface current flows in both clockwise and counterclockwise directions. Figure 6c depicts the surface current for two resonance peaks, with greater concentrations flowing clockwise and counterclockwise at 6.7 GHz across the first to third rings. Although just a small number of current travels through the central ring, the current density there is comparatively low. The surface current direction at 8.6 GHz is close to 6.7 GHz, but the current density has changed on the right side of the first ring. The surface current is highly concentrated at the second ring edges.

Equivalent circuit model

The equivalent circuit model of the metamaterial usually consists of a basic RLC (resistor-inductor-capacitor) resonant circuit, in which the capacitor represents the electric response and the inductor represents the magnetic response of the metamaterial structure. This effectively simulates the metamaterial’s resonant behavior at a particular frequency. Based on the previous works38,39,40, a RLC circuit of the proposed MTM developed with ADS software is illustrated in Fig. 7a. The proposed MTM unit cell is separated into two segments, each of which functions as an RLC circuit Fig. 7a. Here, the two port is defined as Zo with 377 Ω, \({Z}_{TL}\) = 254 Ω, which represents the transmission line (substrate) and the 8.6 GHz frequency resonances for the R1L1C1 and 6.7 GHz frequency resonances for the R2L2C2 series. Different elements provide the inductance (L1 and L2), and the coupling capacitance (C) between the elements is calculated by Eqs. (6) and (7)40.

where L is the length of the ring resonator, W is the width of the ring resonator, D is the substrate height, and Ls is the total inductance (µH). The resonance frequencies (f) are mostly influenced by capacitance (C1 and C2), as determined using Eq. (7).

The coupling capacitance is determined using Eq. (8)40 where A represents the total area and d represents the spacing between the gaps. εo and εr represent the relative permittivity of free space and medium, respectively. The RLC circuit’s S11 and S21 simulation results are illustrated in Fig. 7b. The results of CST and ADS simulations for the proposed MTM are varied because of the fundamental differences in their simulation approaches. ADS frequently uses equivalent circuit models, whereas CST primarily analyzes electromagnetic fields using a full-wave, finite integration technique (FIT). For the resonance frequencies, a little bandwidth mismatch is seen in Fig. 7c. This is because the inductive effect of the metamaterial is dispersed evenly throughout the resonator in CST simulations. Furthermore, it is affected by coplanar capacitances between two neighboring metallic surfaces of the rings. However, in circuit modeling, the coplanar capacitor’s influence is ignored. Furthermore, circuit simulation regards components as lumped, resulting in a bandwidth difference from the CST simulation results41.

Application as sensor at microwave frequency

Sensitivity analysis of the metamaterial

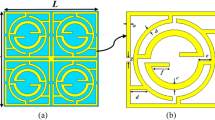

The proposed unit cell is developed for two sensing methods to detect the sensitivity of liquid or solid materials in an electromagnetic simulation environment for the C-band frequency response of 6.7 GHz. Figure 8a shows the simulation setup for sensitivity measurement in which an SUT is positioned on the resonator of the MTM. Additionally, the proposed MTM can be used for another method of sensing where the SUT will be placed on the opposite side of the resonator. Figure 8b shows the simulated setup of this method. Based on earlier research42,43 the method of sensing is performed in a simulated environment to measure the solid or liquid substance with frequency shifts based on permittivity changes.

For the first method, a 0.5 mm thick SUT material is used with the same length and width as the sensor unit cell’s dielectric substrate. To investigate the sensitivity of the unit cell, an analysis is included of the SUT’s permittivity (εr) changes from 2 to 12 with a step size of 2. For the initial steps, the resonant frequency was at 6.7 GHz and 8.7 GHz when no sensing layer (ε = 0) was implemented to the MTM. When the sensing layer is applied with a permittivity of 2, a change in the resonant frequency is observed in the transmission coefficient. A red shift occurred in the resonant response with four resonant frequencies at 5.8 GHz, 7.5 GHz, 8.5 GHz, and 8.96 GHz. The reason for this frequency shift depends on the characteristics of the SUT. When the SUT is positioned on top of the MTM sensor, the number of detected resonant frequencies exceeds the expected two frequencies. This occurs when the SUT interact with the MTM, changing the sensor’s electromagnetic characteristics. The presence of the SUT alters the effective permittivity of the surrounding medium, resulting in shifts in resonance frequencies. Furthermore, the SUT causes coupling effects inside the MTM, resulting in the stimulation of various resonance modes44. As a result of the SUT’s dielectric sensitivity and its interaction with the electromagnetic properties of the metamaterial, the sensor has more than two resonant frequencies. In Fig. 9a, the simulation of transmission resonance S21 shows how the resonant frequency of the sensor shifts when the permittivity (ε) changes. The transmission resonance shifting in Fig. 9b,c demonstrates an inversely proportional relationship; when the permittivity of the SUT’s permittivity increases, the resonance frequency decreases. In simulations, the MTM unit cell exhibits an average frequency shift of 0.26 GHz for C band and 0.33 GHz for X band. However, to calculate the linear fit, the first two resonant frequency shifts were considered. Linear fitting functions (R2) are used to determine the fit of the resonance shift and permittivity change data of the sensor. The slope of the linear fit is calculated to obtain the sensitivity value from each plot. The obtained R2 value is 0.9249 for C band, and the R2 value is 0.9321 for X band frequency, which suggests excellent linear performance. The ideal curve fit is obtained by determining the R2 value. It also explains the degree of correlation between the dependent variable (ε) and the independent variable (f)45.

The transmission intensity for second sensing method is demonstrated in Fig. 10a where, the permittivity (ε) is increased as the first method from 2 to 12 with a thickness of 0.5 mm. The interval of the permittivity (ε) is 2. For the increased permittivity of the SUT, the frequency shifting shows minimal differences in Fig. 10b,c. From the simulated results, the average frequency shift is obtained at 0.08 GHz for C band and 0.12 GHz for X band resonant frequency. In this method, the obtained R2 value is 0.9312 when fo = 6.36 GHz and R2 is 0.9375 when fo = 8.7 GHz.

To understand the sensor’s operation, the E-field intensity behavior of the proposed sensor for various modes is demonstrated in Fig. 11. It shows the E-field response at 5.83 GHz for ε = 2 and a thickness of 0.50 mm of the SUT in Fig. 11a. It has a higher sensitivity in the corner side of the first two rings in transparent mode. Still, when a sensor layer is applied in the top layer of the MTM for the changes of testing material’s permittivity, the similar intensity of E-field is attained on the SUT region. In terms of method 2, the E-field intensity response is shown in Fig. 11b at 6.47 GHz for ε = 2 and a SUT thickness of 0.50 mm. The E-field intensity is very low in the sensing region compared to method 1. For that reason, the frequency shift shows a minimal effect in this method.

The two most important metrics for assessing a sensor’s performance are its sensitivity (S) and quality factor (Q). One traditional approach uses for frequency shift, which is expressed as \({f}_{s}\) = \({f}_{r}\)−\({f}_{0}\), where \({f}_{0}\) is the resonance frequency without any load and \({f}_{r}\) is the resonance frequency when the SUT is present. The sensor’s sensitivity is evaluated by Eq. (9). Where it compares the changes in resonant frequency (∆f) to changes in permittivity (∆ε)46.

The Eq. (9) can be elaborated to Eq. (9.1) where \({f}_{l}\) stands for the frequency deviation at the lowest permittivity, and \({f}_{h}\) indicates the frequency deviation at the maximum permittivity. This method considers the impact of permittivity. This study assumes that the unloaded situation (\({\varepsilon }_{l}\) = 1) has the lowest permittivity. A more effective approach for comparing sensor sensitivity is the normalized average sensitivity (\({S}_{av}\), f) by Eq. (10).

The quality factor is the vital significant feature of an MTM sensor that investigates dielectric properties. A primary concern is that most MTM sensors have a low q-factor and substantial measurement errors, limiting their use in many applications. Higher Q factors improve sensing performance by indicating sharper resonant peaks. It also reflects the sensor’s resolution and sensitivity. The Q factor is evaluated by using Eq. (11)47.

The figure of merit (FoM) of a metamaterial sensor is an indicator of its sensing performance. A higher FoM suggests improved sensing performance. As a quantifiable representation of the sensing performance characteristic, the figure of merit (FoM) may be determined using Eq. (12)48. Where S represents the sensitivity and Q represents the quality factor.

From Table 3, the MTM exhibits an almost similar Q-factor for both methods, while method 1 demonstrates higher sensitivity and FoM than method 1. This indicates that method 1 will be more effective than method 2 for microwave sensing.

Fabrication process and experimental analysis

To analyze the simulation results the proposed metamaterial sensor is fabricated using the LPKF ProtoMat S103 on a laminated Rogers RT5880 dielectric substrate material49,50. A simple experimental setup and manufacturing of the MTM unit cell is illustrated in Fig. 12. The scattering parameter can be calculated using the SUT as a stand-in MTM unit cell. Figure 12a shows the unit cell’s fabricated model, whereas Fig. 12b shows the experimental configuration used to measure the transmission coefficient (S21) of the proposed MTM between the two waveguide ports. The electronic calibrator Keysight N4692A MW was used. After Ecal calibration, adapters were used to connect the coaxial cables to P/N:137WCAS waveguide ports. A vector network analyzer (VNA) was utilized to calculate the S-parameter result for the whole setup. The vector network analyzer probe connects to two waveguide ports, with the constructed prototype located in the center. Figure 12c shows the prototype’s measured data during measurement. Figure 12d shows the difference between CST simulation outputs and measured resonance data of maximum amplitudes. The results demonstrate that the simulated and measured resonances are nearly identical. However, there are slight changes in the C band peak occurrence. The frequency shifted from 6.7 to 7.0 GHz. At 7.0 and 8.6 GHz, the unit cell shows strong peak transmission coefficients of − 44.86 dB and − 43.12 dB, respectively. The measured results align closely with the modeling outputs. There are some discrepancies between the simulated and measured results in the C band resonance, with a slight difference in the lower frequency range on measurement result. This disparity may have resulted from RF feeding cable, manufacturing tolerance, and measurement tolerance51. The dielectric loss also has a significant impact on the results52,53,54. Microwave metamaterial sensors offer numerous advantages, but several practical challenges, such as electromagnetic noise, signal stability, and compatibility with commercial systems, must be resolved for real-world applications. The performance of sensors can be harmed by external electromagnetic interference (EMI). This can be minimized by using shielding enclosures and noise-cancelling devices like Helmholtz resonators to reduce interference29,55. Signal stability is another issue, particularly in the presence of environmental conditions like temperature and humidity. This may be reduced by utilizing temperature-compensated designs, using stable reference materials, and choosing substrates with low dielectric loss and minimum temperature dependency, such as Rogers RT-588034,56. Furthermore, maintaining compatibility with commercial systems may be accomplished by using commonly utilized frequency bands (C and X-bands) and standard interfaces for easy integration15,44.

Flexibility test of the metamaterial

The metamaterial array’s flexibility is shown in Fig. 13a,b. Flexible electromagnetic metamaterials in many frequency ranges improve the electromagnetic characteristics of traditional materials, opening up new possibilities for technologies that are compatible with microwave, terahertz, infrared, and multiband frequencies. Metamaterials made with flexible materials produced a significant dip at the resonance frequency, and flexible substrates provide better sensitivity and an increase in linear response as compared to nonflexible substrates. It is developed with specialized qualities to interact with certain wavelengths of light, sound, or other waves, as well as conform to uneven surfaces or adapt to movement, making it perfect for wearable and implantable sensors57. It has several applications, including electromagnetic wave absorption and stealth, microwave devices, antennas, wireless communication, and wearable sensors58. There are several previous studies on flexible metamaterials59,60,61,62. This research also proposes a flexible MTM that works well with curved surfaces. The flexible material is made up of tiny repeating structures that can bend and change shape, giving it the ability to detect changes in its surroundings with high sensitivity. MTM bending may be needed to varying degrees depending on the application, such as environmental sensing or wearable technology. This expands the sensor application scenario by examining how bending affects the sensor’s transmission frequency. The resonant frequency shifts decrease when it changes its bending degree from 0° to − 5°. When the bending degree increases from 0° to 5°, it shows similar characteristics as − 5°, where the frequency decreased at 5.8 GHz. However, as the bending degree increases gradually from 5° to 20°, the transmitted peak frequency shifts blue, as indicated in Fig. 13c. Although the transmission response has shifted as a result of varied bending degrees, it will not affect the sensor performance. For each different degree, the transmission response will show characteristics according to that bending MTM. To detect the sensitivity of the liquid, it can be placed in a curvature shape, e.g., jar, beaker, or funnel, where the MTM will be placed alongside the outer space of that curvature shape as Fig. 13d.

Table 4 presents a comparison analysis with previous works in microwave sensing based on several important factors. The proposed MTM demonstrates better results in comparison to the previous works.

-

I.

The proposed MTM sensor has higher sensitivity (0.26% and 0.33%) compared to previous works. Also, the quality factor (Q-factor) values are almost double those of the works referenced in39,40,41,42,43,44,56,63. The results indicate that the proposed MTM could be a viable solution during the microwave sensing application with its method 1 and 2.

-

II.

Based on the dimensions, the MTM sensor is compact than prior work64,65,66,67,68,69,70,71, low-cost, and easy to fabricate.

-

III.

The metamaterial sensor’s flexibility was not discussed or analyzed in any of the research studies of64,65,66,67,68,69,70. Flexibility is necessary to assess liquid sensitivity in flat or curvature-shaped sample holders. The suggested MTM sensor’s flexibility properties are also investigated.

-

IV.

This MTM sensor can be utilized in different industrial applications, such as adulterated fuel detection72, edible oil dielectric measurement73, chemical sensing22, and water quality measurement74 for its flexibility, sensitivity, and Q-factor results. Because of its high sensitivity, the proposed microwave metamaterial sensor has potential for use in medical diagnostics and healthcare monitoring75.

Conclusion

In this article, the proposed MTM unit cell is investigated for microwave sensing applications by utilizing two methods. The proposed design demonstrates MNG properties for the C and X-band with EMR of 5.57 and 4.33. The electric and magnetic fields with surface current distributions of the MTM sensor are also analyzed. By simulating the first method, the sensitivity for the permittivity (ε) shift is observed 0.26% and 0.33% with a Q-factor of 58.88 and 80.39, respectively. For the second method, 0.08% and 0.12% sensitivity are observed for both of the bands with a very minimal frequency shift. In this method, the Q-factor is obtained at 66.04 and 73.28. The E-field sensing intensity is higher in the first method. The flexibility has also been assessed from − 5° to 20°, which proposed that it can be implemented in curvature sensing. Finally, the sensitivity, Q-factor, and FoM reveal that the first method is more capable than the second method in terms of sensing liquid and solid samples in the C and X-band microwave frequency.

Data availability

All data generated or analysed during this study are included in this published article.

References

Billa, M. B. et al. High quality factor double negative metamaterial for textile fabric and fabric moisture sensing applications. J. Ind. Text. 54, 15280837231225828. https://doi.org/10.1177/15280837231225828 (2024).

Ranjan, S. K. & Sahoo, S. A review of metamaterial-based microwave absorbers and sensors. J. Electron. Mater. 53(2), 571–595. https://doi.org/10.1007/s11664-023-10809-9 (2024).

Schmidt, R. & Webb, A. Metamaterial combining electric- and magnetic-dipole-based configurations for unique dual-band signal enhancement in ultrahigh-field magnetic resonance imaging. ACS Appl. Mater. Interfaces 9(40), 34618–34624. https://doi.org/10.1021/acsami.7b06949 (2017).

Islam, M. S. et al. A gap coupled hexagonal split ring resonator based metamaterial for S-band and X-band microwave applications. IEEE Access 8, 68239–68253 (2020).

Zhang, Y., Yang, W., Li, X. & Liu, G. Design and analysis of a broadband microwave metamaterial absorber. IEEE Photon. J. 15(3), 1–10 (2023).

Mizeraczyk, J. & Budnarowska, M. Microwave metamaterial absorber with radio frequency/direct current converter for electromagnetic harvesting system. Electronics 13(5), 833. https://doi.org/10.3390/electronics13050833 (2024).

Bağmancı, M. et al. Wide band fractal‐based perfect energy absorber and power harvester. Int. J. RF Microw. Comput.-Aided Eng. 29(7), e21597. https://doi.org/10.1002/mmce.21597 (2019).

Wang, J. et al. Microwave biosensors utilizing metamaterial enhancement: Design and application. Nanotechnol. Precis.Eng. https://doi.org/10.1063/10.0028757 (2025).

Vafapour, Z., Hajati, Y., Hajati, M. & Ghahraloud, H. Graphene-based mid-infrared biosensor. JOSA B 34(12), 2586–2592 (2017).

Chuma, E. L., Iano, Y., Fontgalland, G. & Roger, L. L. B. Microwave sensor for liquid dielectric characterization based on metamaterial complementary split ring resonator. IEEE Sens. J. 18(24), 9978–9983 (2018).

Andrews, C. J. M., Narayanan, A. S. K. & Sunil, A. M. Compact metamaterial based antenna for 5G applications. Results Eng. 24, 103269 (2024).

Esmail, B. A. F. & Koziel, S. Design and optimization of metamaterial-based highly-isolated MIMO antenna with high gain and beam tilting ability for 5G millimeter wave applications. Sci. Rep. 14(1), 3203. https://doi.org/10.1038/s41598-024-53723-8 (2024).

Liang, J. et al. Metamaterial microwave sensor with ultrahigh Q-factor based on narrow-band absorption. Sens. Actuators Phys. 364, 114779 (2023).

Han, X. et al. CSRR metamaterial microwave sensor for measuring dielectric constants of solids and liquids. IEEE Sens. J. (2024) Accessed: 25 Sep 2024. [Online]. Available: https://ieeexplore.ieee.org/abstract/document/10472886/

Dewangan, L., Mishra, N. K. & Ghosh, S. Angularly stable high-Q factor metamaterial absorber for bio-medical sensing applications. IEEE Sens. Lett. (2024), Accessed: 26 Sep 2024. [Online]. Available: https://ieeexplore.ieee.org/abstract/document/10556627/

Abdulkarim, Y. I. et al. Novel metamaterials-based hypersensitized liquid sensor integrating omega-shaped resonator with microstrip transmission line. Sensors 20(3), 943 (2020).

Islam, M. R. et al. Metamaterial sensor based on rectangular enclosed adjacent triple circle split ring resonator with good quality factor for microwave sensing application. Sci. Rep. 12(1), 6792 (2022).

Bazgir, M. & Sheikhi, A. High Q-factor compact permittivity sensor based on coupled SRR-ELC metamaterial element and metasurfaces shield. IEEE Sens. J. (2024) Accessed: 25 Sep 2024. [Online]. Available: https://ieeexplore.ieee.org/abstract/document/10379005/

Zamel, H. M., El-Rahman, S. I. A. & Attiya, A. M. Metamaterial enhanced sensor for powder material classification. Sci. Rep. 14(1), 21316. https://doi.org/10.1038/s41598-024-71175-y (2024).

Rabbani, Md. G. et al. Orthogonal centre ring field optimization triple-band metamaterial absorber with sensing application. Eng. Sci. Technol. Int. J. 49, 101588. https://doi.org/10.1016/j.jestch.2023.101588 (2024).

Soffiatti, A., Max, Y., Silva, S. G. & de Mendonça, L. M. Microwave metamaterial-based sensor for dielectric characterization of liquids. Sensors 18(5), 1513 (2018).

Abdulkarim, Y. I. et al. Design and study of a metamaterial based sensor for the application of liquid chemicals detection. J. Mater. Res. Technol. 9(5), 10291–10304. https://doi.org/10.1016/j.jmrt.2020.07.034 (2020).

Xie, J., Chen, J., Li, Z. & Yuan, W. Flexible microwave sensor films based on nested-complementary split ring resonator for liquid dielectric constant detection. Sens. Actuators Phys. 359, 114461. https://doi.org/10.1016/j.sna.2023.114461 (2023).

Alsaif, H. et al. Dual circular complementary split ring resonator based metamaterial sensor with high sensitivity and quality factor for textile material detection. APL Mater. 12(3), 031136. https://doi.org/10.1063/5.0196472 (2024).

Feng, Y., Liang, M., Zhao, X. & You, R. Fabrication and modulation of flexible electromagnetic metamaterials. Microsyst. Nanoeng. 11(1), 1–20. https://doi.org/10.1038/s41378-024-00806-1 (2025).

Cao, Y., Ruan, C., Chen, K. & Zhang, X. Research on a high-sensitivity asymmetric metamaterial structure and its application as microwave sensor. Sci. Rep. 12(1), 1255. https://doi.org/10.1038/s41598-022-05255-2 (2022).

Hakim, M. L. et al. Corrigendum to ‘Intensified electric field based highly sensitive backbone-shaped C and X band microwave metamaterial sensor for permittivity characterization applications’ [Eng. Sci. Technol. Int. J. 60 (2024) 101877]. Eng. Sci. Technol. Int. J. 63, 101984. https://doi.org/10.1016/j.jestch.2025.101984 (2025).

Lin, F. et al. High-frequency electric field intensity measurement based on frequency shift with high gain and wide frequency range. Opt. Commun. 545, 129682 (2023).

Sifat, R. et al. Development of double-layer metamaterial with high effective medium ratio values for S- and C-band applications. Heliyon 10(1), e23851. https://doi.org/10.1016/j.heliyon.2023.e23851 (2024).

Moniruzzaman, M. et al. Gap coupled symmetric split ring resonator based near zero index ENG metamaterial for gain improvement of monopole antenna. Sci. Rep. 12(1), 7406. https://doi.org/10.1038/s41598-022-11029-7 (2022).

Cai, L., Jiang, Z. H., Wu, J.-B., Chen, H. & Hong, W. Low-loss and flexible terahertz bandpass frequency selective surface based on cyclic olefin copolymer substrate via solvent-free synthesis. Opt. Express 31(13), 21706–21720. https://doi.org/10.1364/OE.488787 (2023).

Rahman, A. A. M. et al. H-shaped modifiers loaded mirror symmetric resonator based double negative metamaterial for multi-band wireless communications. Sci. Rep. 13, 15943. https://doi.org/10.1038/s41598-023-43182-y (2023).

Anwar, R., Mao, L. & Ning, H. Frequency selective surfaces: A review. Appl. Sci. 8(9), 1689. https://doi.org/10.3390/app8091689 (2018).

Soliman, M. M. et al. Rectangular ring resonator-based symmetrically engineered metamaterial absorber for electromagnetic interference shielding in the S and C bands. J. Phys. Conf. Ser. 2922(1), 012001. https://doi.org/10.1088/1742-6596/2922/1/012001 (2024).

Barroso, J. J. & De Paula, A. L. Retrieval of permittivity and permeability of homogeneous materials from scattering parameters. J. Electromagn. Waves Appl. 24(11–12), 1563–1574. https://doi.org/10.1163/156939310792149759 (2010).

Hakim, M. L., Alam, T., Almutairi, A. F., Mansor, M. F. & Islam, M. T. Polarization insensitivity characterization of dual-band perfect metamaterial absorber for K band sensing applications. Sci. Rep. 11(1), 17829 (2021).

Hakim, M. L. et al. Intensified electric field based highly sensitive backbone-shaped C and X band microwave metamaterial sensor for permittivity characterization applications. Eng. Sci. Technol. Int. J. 60, 101877 (2024).

Hannan, S. et al. A co-polarization-insensitive metamaterial absorber for 5G n78 mobile devices at 3.5 GHz to reduce the specific absorption rate. Sci. Rep. 12(1), 11193. https://doi.org/10.1038/s41598-022-15221-7 (2022).

Joseph, C. H., Mencarelli, D., Pierantoni, L., Russo, P. & Zappelli, L. Identification of compact equivalent circuit model for metamaterial structures. IEEE Trans. Antennas Propag. 71(7), 5850–5864 (2023).

Amiri, M., Tofigh, F., Shariati, N., Lipman, J. & Abolhasan, M. Review on metamaterial perfect absorbers and their applications to IoT. IEEE Internet Things J. 8(6), 4105–4131 (2020).

Hasan, M. M. et al. Polarization insensitive dual band metamaterial with absorptance for 5G sub-6 GHz applications. Sci. Rep. 12, 8495. https://doi.org/10.1038/s41598-022-12106-7 (2022).

Raj, A., KumarJha, A., Ansari, M. A. H., Akhtar, M. J. & Panda, S. Metamaterial-inspired microwave sensor for measurement of complex permittivity of materials. Microw. Opt. Technol. Lett. 58(11), 2577–2581 (2016).

Misran, N., Yusop, S. H., Islam, M. T. & Ismail, M. Y. Analysis of parameterization substrate thickness and permittivity for concentric split ring square reflectarray element. J. Kejuruter. 23, 11–15 (2011).

Prakash, D. & Gupta, N. Applications of metamaterial sensors: A review. Int. J. Microw. Wirel. Technol. 14(1), 19–33 (2022).

Chowdhury, N. M., Soliman, M. M., Islam, M. T., Alam, T. & Soliman, M. S. Star shape symmetric engineered meta surface to sense food additives (benzoic acid/copper sulfate) at terahertz spectrum. Optik 312, 171954 (2024).

Chowdhury, N. M. et al. Sensitivity detection of imidacloprid pesticide using a metasurface sensor in THz spectrum regime. Eng. Sci. Technol. Int. J. 57, 101801 (2024).

Hakim, M. L. et al. Quad-band polarization-insensitive square split-ring resonator (SSRR) with an inner Jerusalem cross metamaterial absorber for Ku-and K-Band sensing applications. Sensors 22(12), 4489 (2022).

Cong, L. et al. Experimental demonstration of ultrasensitive sensing with terahertz metamaterial absorbers: A comparison with the metasurfaces. Appl. Phys. Lett. https://doi.org/10.1063/1.4906109 (2015).

Zerrad, F. et al. Multilayered metamaterials array antenna based on artificial magnetic conductor’s structure for the application diagnostic breast cancer detection with microwave imaging. Med. Eng. Phys. 99, 103737 (2022).

Hakim, M. L. et al. Physical analysis of high refractive index metamaterial-based radiation aggregation engineering of planar dipole antenna for gain enhancement of mm-wave applications. Sci. Rep. 14(1), 22074. https://doi.org/10.1038/s41598-024-72100-z (2024).

Hakim, M. L. et al. Polarization insensitive symmetrical structured double negative (DNG) metamaterial absorber for Ku-band sensing applications. Sci. Rep. 12(1), 479. https://doi.org/10.1038/s41598-021-04236-1 (2022).

Gong, F., Li, Q., Xiao, Z. & Liu, S. Experimental verification of latticed acoustic metamaterials with pentamode to bandgap characteristics. Eur. Phys. J. B 97(12), 192. https://doi.org/10.1140/epjb/s10051-024-00834-w (2024).

Hu, C., Li, X., Feng, Q., Chen, X. & Luo, X. Investigation on the role of the dielectric loss in metamaterial absorber. Opt. Express 18(7), 6598–6603. https://doi.org/10.1364/OE.18.006598 (2010).

Koziel, S. & Haq, T. Uncertainty quantification of additive manufacturing post-fabrication tuning of resonator-based microwave sensors. Measurement 216, 112952 (2023).

Mir, F., Mandal, D. & Banerjee, S. Metamaterials for acoustic noise filtering and energy harvesting. Sensors 23(9), 4227. https://doi.org/10.3390/s23094227 (2023).

Faruque, M. R. I., Siddiky, A. M., Ahamed, E., Islam, M. T. & Abdullah, S. Parallel LC shaped metamaterial resonator for C and X band satellite applications with wider bandwidth. Sci. Rep. 11(1), 16247. https://doi.org/10.1038/s41598-021-95468-8 (2021).

Chen, T., Li, S. & Sun, H. Metamaterials Application in Sensing. Sensors 12(3), 2742–2765. https://doi.org/10.3390/s120302742 (2012).

Gao, B., Yuen, M. M. F. & Ye, T. T. Flexible frequency selective metamaterials for microwave applications. Sci. Rep. 7(1), 45108. https://doi.org/10.1038/srep45108 (2017).

Lang, T., Zhang, J., Qiu, Y., Hong, Z. & Liu, J. Flexible terahertz Metamaterial sensor for sensitive detection of imidacloprid. Opt. Commun. 537, 129430. https://doi.org/10.1016/j.optcom.2023.129430 (2023).

Melik, R., Unal, E., Perkgoz, N. K., Puttlitz, C. & Demir, H. V. Flexible metamaterials for wireless strain sensing. Appl. Phys. Lett. 95(18), 181105. https://doi.org/10.1063/1.3250175 (2009).

Li, Y. et al. Flexible terahertz metamaterial biosensor for ultra-sensitive detection of hepatitis B viral DNA based on the metal-enhanced sandwich assay. Front. Bioeng. Biotechnol. https://doi.org/10.3389/fbioe.2022.930800 (2022).

Xiao, M. et al. Flexible graphene-based metamaterial sensor for highly sensitive detection of bovine serum albumin. Appl. Opt. 61(35), 10574–10581 (2022).

Li, D. et al. A generalized equivalent circuit model for composite metamaterial absorbers: From isotropic to anisotropic substrate. Compos. Sci. Technol. 257, 110832. https://doi.org/10.1016/j.compscitech.2024.110832 (2024).

Kaur, K. P., Upadhyaya, T., Pandya, K. & Patel, U. Ultrathin high Q-factor perfect metamaterial absorber for sensing applications. in 2023 IEEE Wireless Antenna and Microwave Symposium (WAMS) 1–5 (IEEE, 2023). Accessed: 26 Sep 2024. [Online]. Available: https://ieeexplore.ieee.org/abstract/document/10242878/

Han, X. et al. Microfluidic microwave sensor loaded with star-slotted patch for edible oil quality inspection. Sensors 22(17), 6410. https://doi.org/10.3390/s22176410 (2022).

Navaei, M., Rezaei, P. & Kiani, S. Microwave split ring resonator sensor for determination of the fluids permittivity with measurement of human milk samples. Radio Sci. 57(7), 1–11 (2022).

Zhao, W.-S. et al. Swarm intelligence algorithm-based optimal design of microwave microfluidic sensors. IEEE Trans. Ind. Electron. 69(2), 2077–2087 (2021).

Rahman, N. A. et al. Liquid permittivity sensing using teeth gear-circular substrate integrated waveguide. IEEE Sens. J. 22(12), 11690–11697. https://doi.org/10.1109/JSEN.2022.3166561 (2022).

Gargari, A. M., Zarifi, M. H. & Markley, L. Passive matched mushroom structure for a high sensitivity low profile antenna-based material detection system. IEEE Sens. J. 19(15), 6154–6162. https://doi.org/10.1109/JSEN.2019.2908687 (2019).

Rezeg, M., Hlali, A. & Zairi, H. Metamaterial microwave biosensor based on CSRR for monitoring of leukemia blood cancer. in 2024 IEEE International Conference on Advanced Systems and Emergent Technologies (IC_ASET) 1–6 (IEEE, 2024). Accessed: 28 Sep 2024. [Online]. Available: https://ieeexplore.ieee.org/abstract/document/10596170/

Al-Gburi, A. J. A., Zakaria, Z., Ibrahim, I. M., Aswir, R. S. & Alam, S. Solid characterization utilizing planar microwave resonator sensor. Appl. Comput. Electromagn. Soc. J. https://doi.org/10.13052/2022.ACES.J.370211 (2022).

Chowdhury, M. Z. B., Islam, M. T., Hossain, I., Alzamil, A. & Samsuzzaman, M. A tunable hexa-band SRR metamaterial for microwave sensing application. Ain Shams Eng. J. 15(12), 103121 (2024).

Islam, M. R. et al. Tri circle split ring resonator shaped metamaterial with mathematical modeling for oil concentration sensing. IEEE Access 9, 161087–161102 (2021).

Amineh, R. K., Ravan, M. & Tandel, D. Detection of water pollutants with a nonuniform array of microwave sensors. IEEE Trans. Instrum. Meas. 72, 1–11 (2023).

Baghelani, M., Abbasi, Z., Daneshmand, M. & Light, P. E. Non-invasive continuous-time glucose monitoring system using a chipless printable sensor based on split ring microwave resonators. Sci. Rep. 10(1), 12980. https://doi.org/10.1038/s41598-020-69547-1 (2020).

Acknowledgements

The authors would like to acknowledge to the Universiti Kebangsaan Malaysia research grant Dana Impak Perdana 2.0 (DIP 2.0) through the grant number: DIP-2023-021. Also, the authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2025-59)

Funding

This research was funded by the Universiti Kebangsaan Malaysia research grant Dana Impak Perdana 2.0 (DIP 2.0) through the Grant Number: DIP-2023-021. Also, this research was funded by Taif University, Saudi Arabia, Project No. (TU-DSPP-2025-59).

Author information

Authors and Affiliations

Contributions

N.M.C, M.L.H,. made substantial contributions to this research work regarding the conception, design, analysis, measurement, and writing of the manuscript. T.A, M.S.J.S, M.S.S, M.S.I and A.A.M, made substantial contributions to this research work regarding conception, analysis, and revising the manuscript. M.T.I. supervised the entire project and acquired the portion of the funding. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chowdhury, N.M., Hakim, M.L., Alam, T. et al. Interconnected four split rectangular ring resonator flexible metamaterial for microwave sensing application. Sci Rep 15, 21230 (2025). https://doi.org/10.1038/s41598-025-00040-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-00040-3