Abstract

This paper, based on the node insertion algorithm for NURBS curves, explicitly defines the method for calculating the node coordinates and weights of subdivided element, without altering the geometric properties and parameter distribution of the RANCF elements. However, the diversity in the definition of RANCF elements can lead to uncontrollable subdivision in parameter space. To address the distortion in the subdivision process of non-uniformly parameterized elements, this paper introduces a distribution density function for the element parameter points and establishes a calculation method for the parameter space subdivision nodes corresponding to the arc length in physical space. This method enables precise subdivision of differently parameterized arc elements in the physical space. Ultimately, guided by numerical computation results, the subdivision criteria for RANCF elements were determined. The results indicate that local refinement in regions with denser parameter point distribution can both ensure computational accuracy and improve computational efficiency.

Similar content being viewed by others

Introduction

With the advancement of science and technology, research fields such as aerospace, automotive, and robotics are gradually evolving towards lightweight, flexible, high-speed, and precision designs, thereby imposing higher requirements on the accuracy and efficiency of numerical analysis. Consequently, the influence of flexible deformations of components on system dynamics has become a critical factor that can no longer be disregarded.

The Absolute Nodal Coordinate Formulation (ANCF) effectively overcomes the limitations of traditional methods in obtaining accurate numerical solutions for large deformations of flexible structures, and has become an effective method for analyzing flexible multibody dynamic systems. Since its introduction by Shabana in 1996, ANCF has matured significantly over more than two decades of development. ANCF utilizes the position and slope vectors of element nodes within a global coordinate system to describe the large deformations of flexible components. This modeling approach offers several advantages, including a constant mass matrix, the absence of Coriolis and centrifugal forces, and no need for coordinate transformations1,2,3. These characteristics make ANCF an effective method for studying systems with significant deformations4,5. As an advanced multibody dynamics analysis method, ANCF has been widely applied in the simulation of flexible dynamics in various fields, including vehicle systems, robotic arms, and spacecraft6,7,8. However, since ANCF elements employ polynomial shape functions, it is prone to introducing initial geometric errors when describing complex configurations such as circular arcs, cylinders, or free-form curves. As a result, it is still necessary to increase a large number of elements to achieve result convergence, which consequently reduces computational efficiency.

The Rational Absolute Nodal Coordinate Formulation (RANCF), as an extension of ANCF, improves the geometric accuracy of the initial model by introducing weights and denominator polynomials to construct rational shape functions for elements9. The introduction of weights provides greater flexibility in the description of element configurations, allowing for a precise representation of the analysis body with fewer elements, which notably reduces the computational burden and storage requirements of the model while ensuring high accuracy in the analysis results10,11,12,13. One important application area of efficient and accurate computational methods is uncertainty quantification in dynamic systems, especially for reliability analysis14,15,16. Such problems typically involve a large number of sampling-based computations, placing high demands on modeling and computational efficiency. The RANCF method has the potential to significantly reduce computational cost without sacrificing accuracy, making it a promising core simulation algorithm for tasks such as reliability-based design optimization. In addition, the dominant geometric modeling standard in industrial design is Non-Uniform Rational B-Splines (NURBS)17, which has a linear transformation relationship with RANCF elements18,19,20,21. The consistency in geometric descriptions can reduce errors caused by model conversion, significantly improving the efficiency and accuracy of product structural design and analysis22,23,24. Unlike isogeometric analysis (IGA) methods, which rely on global parameterization and utilize control points without explicit degrees of freedom, RANCF constructs shape functions based on rational Bézier curves by explicitly treating both nodal position coordinates and gradient coordinates as degrees of freedom. This parameterized representation in RANCF can be directly employed to derive mass matrices, stiffness matrices, and nonlinear force terms, thereby facilitating the direct integration of geometric modeling and dynamic analysis within the finite element framework. As a result, RANCF is particularly well suited for flexible multibody dynamic systems involving large deformations, where traditional IGA frameworks often require more complex coupling strategies with dynamic solvers. However, due to the adoption of rational interpolation shape functions in RANCF, the definition and refinement of the model have become more complex. Although the RANCF method has been proposed for more than a decade, its research is still in the early stages. The theory and application of the RANCF method require further exploration and optimization. RANCF method, similar to traditional finite element, discretizes the analysis domain into finite elements for computational analysis. Consequently, the number and quality of the elements will influence the efficiency and accuracy of the analysis results. It increases the freedom in describing the geometric configuration by introducing weights, enabling diverse definitions for elements with identical shapes. However, the diversity in the definition of RANCF elements can lead to subdivision distortions between the parameter space and physical space, making it difficult to subdivide the model according to the specified requirements. In addition, although the introduction of weights in RANCF improves the geometric accuracy of the initial model, it also presents certain difficulties in defining the subdivided elements.

The purpose of this study is to investigate the subdivision methods of RANCF elements and the defining method for the subdivided elements, providing a guidance for the rational discretization of RANCF elements to enhance their applicability in the dynamic analysis of complex geometries. This paper first clarifies the definition method for subdivided elements, ensuring that the geometric features, parameterization, and continuity of the elements remain unchanged after subdivision. Additionally, it addresses the issue of subdivision mapping distortions caused by the diversity in RANCF element definitions and provides a discretization algorithm for RANCF circular arc elements in physical space. In the simulation section, the paper analyzes the influence of RANCF element parameterization on subdivision strategies and presents subdivision principles that are distinct from those of ANCF elements.

Element displacement field function

Cubic rational Bézier curves are widely used in computer-aided design (CAD) to represent smooth and precise geometric entities. These curves are defined by a set of control points {Pi} i=0,1,2,3 and associated weights{ωi} i=0,1,2,3, allowing for the exact representation of conic sections and other complex shapes. However, while these curves provide a precise geometric description, they do not inherently possess mechanical meaning, such as mass or stiffness properties, which are essential for structural and dynamic analysis. To bridge this gap, we reconstruct the basics functions of rational Bézier curves as finite element shape functions and assign nodal coordinates (positions and slopes) to the control points, so that these curves become not merely geometric entities but finite elements with mechanical significance. Thus, the RANCF element not only possesses the freedom degrees and shape functions required for mechanical modeling, but also retains the geometric accuracy of rational Bézier curves, achieving an integration of geometric and mechanical modeling.

The traditional planar cable element consists of two nodes, each with four degrees of freedom: translational and rotational degrees of freedom along two coordinate axes. In contrast, RANCF uses the position coordinates rA rB of the two endpoints of the element in the global coordinate system and their gradient coordinates rxA rxB along the material axis x as the nodal degrees of freedom. By using rational displacement shape functions {Sri}i=0,1,2,3 to interpolate the nodal coordinates, the resulting RANCF element displacement function r(u) can accurately express the displacement of any point within the element25.

where, \({R_{i,3}}=\sum\limits_{{i=0}}^{3} {\frac{{{\omega _i}{B_{i,3}}}}{{\sum\nolimits_{{i=0}}^{3} {{\omega _i}{B_{i,3}}} }}} ,{B_{i,3}}=C_{3}^{i}{u^i}{\left( {1 - u} \right)^{3 - i}},i=0,1,2,3\)。

C3i is the binomial coefficient for the cubic Bernstein basis function. The displacement function of RANCF elements is derived from cubic rational Bézier curves based on the transformation relationship between Bézier curves and ANCF geometries, which represents an extension and generalization of ANCF displacement functions. As a result, RANCF retains the robust geometric representation capabilities of cubic rational Bézier curves while leveraging the advantages of ANCF in large deformation analysis. Figure 1 illustrates the equivalence between RANCF elements and cubic rational Bézier curves. Based on the geometric properties of cubic rational Bézier curves at endpoints, the transformation relationships between the nodal coordinates of RANCF elements and the control points of cubic rational Bézier curves can be derived as follows19:

In the displacement field function of RANCF elements, although the gradient coordinates rxA rxB and their corresponding shape functions Sr2 Sr4 both include the parameter l, they effectively cancel each other out in the displacement expression. Therefore, the parameter l only affects the numerical values of the gradient coordinates but does not alter the geometric shape or deformation behavior of the element. As such, the physical length l of the element in the reference configuration can be regarded as a scale mapping factor from the parametric domain to the physical space, and it can be assigned arbitrarily according to specific needs.

Element subdivision algorithm

To improve the convergence and accuracy of numerical solutions, the most direct and effective approach is the mesh discretization. It refers to the process of subdividing a larger RANCF element into several smaller elements as required, and using the nodal coordinates and weights of these small new elements to reconstruct the overall displacement field function. By inserting a parameter subdivision point uj (0<uj<1), the corresponding shape-value node r(uj) on the element splits the original element into two parts. Figure 2 illustrates the subdivision of a RANCF element. r1(u) and r2(u) are segments of the rational curve r(u) after splitting (knot insertion) at uj.

Assuming the original element is divided into n parts, n − 1 parameter subdivision points need to be inserted. In this case, the displacement field function of each subdivided element is given by Eq. (3). Comparing Eq. (1) with Eq. (3), it can be observed that the form of the displacement field function for the sub-elements remains consistent with that of the original element, with the differences lying in the node coordinates, weights and length.

To subdivide elements without altering their original geometric properties, it is necessary to establish a precise method for calculating the new nodal coordinates and weights of the subdivided elements. Based on the standard knot insertion algorithm for NURBS curves, the original rational curve can be subdivided into two segments at a given knot value without altering the overall geometry. Inserting a new knot uj into the knot vector of a cubic NURBS curve without internal knots, and increasing its multiplicity to four, results in the curve being split into two independent segments of cubic rational Bézier curves. The new control points and weights after knot insertion can be computed using the knot insertion algorithm26. The parametric equation of a cubic NURBS curve without internal nodes is identical to that of a cubic rational Bézier curve. By treating the original element as a cubic NURBS curve without internal nodes, the control points and weights of the subdivided curve obtained through repeated knot insertion algorithm. Then, combining the linear transformation formula between cubic rational Bézier curves and RANCF geometries (Eq. (2)), the mapping relationship between the weights and node coordinates of the subdivided elements and the original element can be derived as follows:

Where,

\(\begin{gathered} a=1 - {u_j} \hfill \\ b={u_j} \hfill \\ c={a^3}{\omega _0}{\text{+}}3b{a^2}{\omega _1}+3{b^2}a{\omega _2}+{b^3}{\omega _3} \hfill \\ A= - {a^3}{\omega _1} - 2b{a^2}{\omega _2} - {b^2}a{\omega _3} \hfill \\ B={a^3}{\omega _0} - 3{b^2}a{\omega _2} - 2{b^3}{\omega _3} \hfill \\ C=2{a^3}{\omega _0}+3b{a^2}{\omega _1} - {b^3}{\omega _3} \hfill \\ D=b{a^2}{\omega _0}+2{b^2}a{\omega _1}+{b^3}{\omega _2} \hfill \\ \end{gathered}\)

l represents the length of the original element, while l1 and l2 represent the lengths of the left and right subdivided elements respectively. Since the element displacement field function is independent of the element length, to maintain continuity at the subdivision point, we set l1 = luj, l2 = l(1-uj). At this point, l1 and l2 are not the true lengths of the elements. Instead, they represent the discretized lengths of the original element l based on the subdivision ratio in the parameter space.

This chapter derives explicit expressions for the nodal parameters (including coordinates and weights) of the RANCF subdivided elements, based on the knot insertion algorithm for NURBS curves and the transformation relationships between the control points of cubic rational Bézier curves and the nodal coordinates of RANCF elements. This method enables element subdivision directly within the finite element framework while maintaining geometric continuity. This research fills a gap in the relevant field, providing a more precise and efficient element subdivision method, and promotes the application of RANCF in the analysis of complex structures.

Parameter space subdivision method

As shown in Sect. 3, the number and values of the subdivision parameter point directly determine the actual subdivision effect of the element. By substituting the point uj into Eq. (1), the position coordinates of the corresponding shape-value point r(uj) in physical space can be obtained, as shown below:

The introduction of weights in RANCF elements increases the degrees of freedom in element definition. Similar to rational Bézier curves, when the weights satisfy the condition that the shape-invariant factors k1 and k2 are equal, different weights can represent the same configuration. However, since the gradient coordinates of the RANCF element nodes are associated with the weights, any change in the weights will also alter their gradient coordinates. Therefore, the gradient coordinates of the nodes must also satisfy the equation of equal k3. It is important to note that in the shape-invariant factor Eq. (8) of the RANCF element, only two factors are independent.

When the shape-invariant factors are equal, the elements defined by different weights describe the same shape macroscopically. However, changes in the weights lead to variations in the correspondence between nodes on the curve and points in the parameter domain, as shown in Eq. (7), altering the distribution of parameter points on the element. Consequently, the positions of the corresponding shape-value node r(uj) at the same parameter division point will also change. To investigate the impact of different parameterizations on element subdivision, we define a set of uniformly and non-uniformly parameterized circular arc elements according to the circular arcs element definition method proposed by Zhang27. Defining parameters of these elements are shown in Table 1. The arc has a central angle of 120°, a radius of \(\:\text{2}\sqrt{\text{3}}\text{/3}\), and arc length l of \(\:4\pi\sqrt{\text{3}}\text{/9}\). Then, this set of elements is uniformly subdivided into 6 parts in the parameter space, respectively. Figure 3 presents a comparison of different parameterized elements uniformly subdivided in parameter space. For elements with evenly distributed parameter points, the subdivision rules between the parameter space and physical space follow a linear relationship. However, the definition of RANCF elements is diverse, and non-uniform parameterization is quite common. For elements with unevenly distributed parameter points, a “distortion” occurs during the subdivision process, meaning that uniform division in the parameter space does not correspond to uniformity in the physical space. Although directly discretizing the original element in the parameter space is the straightforward approach, the uncontrollability of subdivision for non-uniform parameterized elements in the parameter space prevents the element from being subdivided according to the intended rules.

Construction of the mapping relationship between parameter and physical space

To achieve accurate discretization in physical space, it is essential to clarify the influence of different parameterization on the mapping between the parameter space and physical space, providing the foundation for establishing the subdivision mapping relationship. In this study, parameter points u are treated as independent variables, with the corresponding element length x along the material coordinate axis as the dependent variable. A transformation rule is developed between the two to facilitate the collaborative discretization of both the parameter space and the physical space.

The parameter points distribution density function

By decomposing the displacement field function of the RANCF element in Eq. (1), the functional relationship between the parameter u and the natural coordinates X Y is derived as follows:

Where [e1 e2 e3 e4 e5 e6 e7]T = [rA rxA rB rxB]T. To facilitate the description of the transformation between the natural and the physical coordinate system, the Jacobian matrix J and its determinant |J| of the displacement field Eq. (9) are computed as follows:

Assuming the original element is subdivided into n segments, n − 1 material subdivision nodes r(uj)j=1, 2, …, n−1 need to be inserted along the material axis of the element. According to the arc length integral formula, the relationship between the arc length xj, from the starting node of the element to the subdivision node, and its corresponding parameter subdivision point uj is given as follows:

If the parameter points of the original element are uniformly distributed (for example, r1), the parameter u and the arc length x are positively correlated, and the mapping relationship between the two is given by x = u/LT (LT represents the total arc length from the starting node to the ending node). However, elements with non-uniform parameterization lose this uniform mapping relationship. To achieve synchronized subdivision between the parameter space and the physical space, it is necessary to clarify the impact of different parameterizations on the subdivision mapping relationship. A non-uniformly parameterized circular arc element (r2 from Sect. 4) was uniformly divided into 8 segments based on the equal arc-length principle. Subsequently, the numerical integration method described in Sect. 5.1 was employed to calculate the specific values of the parameter subdivision nodes (uj)j=1, 2, …, 7 corresponding to the arc lengths of the material subdivision points (xj)j=1, 2, …, 7. The positional correspondence between the material subdivision points and the parameter subdivision nodes is shown in Fig. 4(a).

Figure 4 (b) presents the mapping relationship curve between the material points and the parameter points. The x-u curve demonstrates a positive correlation between the parameter u and the arc length x. By calculating the first derivative of u with respect to x, the x-du curve is obtained, which shows that the rate of increase of u gradually decreases as x increases. This observation indicates that the distribution of parameter points within the element significantly influences the mapping relationship. Although Fig. 4 is a plot based solely on the data of r2, the conclusions drawn from this figure are consistent for elements with different parameterizations. The only difference lies in the rate of change of the parameter points. To describe the internal distribution of parameter points, a parameter distribution density function D is introduced and defined as follows:

Here, N(x) represents the number of parameter points assigned to the material points within the element, and NTotal denotes the total number of parameter points in the original element. In the Eq. (13), D (x = LT) = 1 indicates that the parameter point distribution density in the original element is 1. A larger value of D implies a denser distribution of parameter points, whereas a smaller value indicates a sparser distribution. Figure 5 illustrates the relationship between the arc length x and the parameter point distribution density D. It can be observed that the parameter point distribution density on the circular arc decreases progressively with increasing arc length, indicating a declining trend in the number of parameter points from the start to the end.

Relationship between parameter division points and material subdivision nodes

The original mapping relationship Eq. (12) from parameter space to physical space is defined between the parameter u and the arc length x. To directly reflect the impact of different parameterizations on the mapping function, this study considers to establish the relationship between the parameter u in parametric space and the parameter point density D in physical space. Figure 6 illustrates the relationship between the parameter point density ΔD and the corresponding proportion Δu in the parametric space for adjacent subdivided elements under equal arc-length subdivision.

As shown in the Fig. 6, for subdivided elements with equal arc length, the higher the parameter point density, the larger the proportion of the parameter space occupied. Conversely, a lower density results in a smaller proportion of the parameter space. Therefore, the distribution density of parameter points is positively correlated with the size of the parameter interval. It is assumed that the relationship between the two is given by:

For elements with equal arc length, the parameter density D is related to the number of parameter points N within the element. Assuming that the number of parameter points in the original element is NT=1e6, the relationship between the arc length x, the parameter u, and the number of parameter points N along the arc is illustrated in Fig. 7. It is particularly important to note that NT refers to the number of parameter points on the original element. A larger value of NT leads to higher accuracy in computing the parameter space insertion node values corresponding to the subdivided points in physical space. NT is not a fixed constant and can be adjusted according to the magnitude of the specific problem to maintain numerical stability. Since the arc length of the original element in this paper is relatively small, choosing 1e6 is sufficient to meet the required computational accuracy.

The two curves in the Fig. 7 completely overlap, indicating that the relationship between arc length x and parameter u can be equivalently transformed into the relationship between arc length x and the number of parameter points N within the element. The relationship between u and N is as follows:

The Eq. (15) indicates that the ratio of parameter points between the subdivided element and the original element corresponds to the parameter value u associated with the material node x. Therefore, the mapping relationship between the material subdivision nodes and the parameter subdivision points can be specifically represented as the probability value of the parameter point within the subdivided arc length relative to the total number of parameter points of the original element. This mapping relationship directly reflects the actual arc length in the physical space corresponding to any parameter point of the different parameterized elements, ensuring that the inserted subdivision parameter point uj accurately corresponds to the subdivision position r(uj) in the physical space. By solving the system of Eqs. (13–15), the calculation formula for E assumed in Eq. (14) can be derived as follows:

Subdivision method of RANCF Arc elements in physical space

For the arc element, the position of the material subdivision nodes xj on the arc can be determined by the relative central angle φj, as shown in Fig. 8. The relationship between them is given by xj =R φj. To divide an element with a total length of LT into n segments, ensuring that each subdivided segment length follows a fixed linear incremental distribution, the values of the n-1 material subdivision points xj to be inserted are determined as Eq. (17). Here, k represents the element discretization factor, which controls the distribution of the arc length in the subdivided elements. To prevent overlap or out-of-range material subdivision nodes, the constraint condition that k must satisfy is as Eq. (18).

The calculated material subdivision nodes are then substituted into Eq. (15), yielding the corresponding values of the subdivided points in the parameter space as Eq. (19). The non-uniformly parameterized arc element is divided into 5 sub-elements (n = 5) using different discretization factors k. Figure 9 shows the subdivision positions in the physical space of the element for five different values of k.

When k = 0, the length of each subdivided element is equal, resulting in an equal-arc-length uniform segmentation. For k > 0, the size of subdivision follows a linearly increasing pattern, where the earlier are smaller, and the subsequent gradually increase. Moreover, as the value of k increases, the growth rate also accelerates. Conversely, when k < 0, the length of the subdivided elements decreases linearly, with smaller k values leading to faster reduction rates. These findings highlight that the growth factor k governs the allocation pattern of subdivided element sizes. Therefore, by adjusting the value of k, the subdivision strategy for RANCF elements can be flexibly tailored.

Based on the above research, we can achieve accurate subdivision of RANCF circular arc elements in physical space according to specific needs. For an arbitrarily parameterized RANCF circular arc element, the appropriate subdivision scheme is first selected by considering the system’s structural and loading characteristics together with Eqs. (17–18), which determines the position of subdivision points in the physical space. Then, according to Eq. (19), parameter inversion is performed to obtain the parameter values of the nodes to be inserted in the parametric space corresponding to the subdivided arc lengths in physical space. Finally, these parameter values are substituted into Eqs. (4–6) to obtain the weights and nodal coordinates of the subdivided elements, providing accurate and reliable data for the subsequent construction of system dynamic equations. The geometry-preserving subdivision method for circular arc elements in physical space proposed in this paper enriches the theoretical framework of the RANCF method and lays a solid foundation for its further promotion and application in practical engineering scenarios.

Examples and result

The example used in this investigation is the curved beam pendulum shown in Fig. 10. The RANCF method is used to model the curved beam and analyze its motion under the effect of gravity. The motion of a flexible curved beam under its self-weight is analyzed using the RANCF method. The RANCF method offers multiple definition schemes, allowing diverse parameterizations for the same geometric configuration. To demonstrate the accuracy of the proposed subdivision method, a set of non-uniformly parameterized circular arc elements was defined for this structure. The nodal position coordinates are rA=(0, 0) rB=(0.433, 0.25), gradient coordinates rxA=(0.667185831, 0) rxB=(0.68333751, 1.18361), and the weights are [1, 1.08621103, 0.98905339, 1]. In this model, the O-end is subject to a hinged constraint, and initially, the tangent at point A of the curved beam is parallel to the x-axis. The beam begins to swing freely under the influence of gravity from rest. The radius of the arc curved beam is 0.5 m, with central angle of 60°, arc length of π/6 m, circular cross-section with a radius of 0.02 m. The material properties include density of 6000 kg/m³, and modulus of elasticity of 2 × 106 N/m².

To avoid matrix dimension mismatch issues in the subsequent equation derivations, we redefine the element displacement shape function matrix S and the element nodal coordinate vector e according to Eq. (1) as follows:

Here, I is the 3 × 3 identity matrix. According to the kinetic energy theorem, the expression for the mass matrix M of the RANCF cable element is obtained as follows28:

.

taking the partial derivative of the strain energy of the flexible cable element with respect to the generalized coordinates e29]– [30, thereby yielding the expression for the element elastic force as shown in Eq. (22).

The computation methods for the Green–Lagrange strain εa and the curvature κ are given in Eq. (23), where e0 and κ0 represent the initial nodal coordinate vector and the initial curvature of the element, respectively.

The only external force acting on the curved beam is gravity. Based on the virtual work done by gravity, the expression for the external force vector F is given as follows:

\({{\mathbf{F}}_e}=\int_{0}^{1} {Al \cdot {{\mathbf{S}}^T}\left[ {\begin{array}{*{20}{c}} 0&{ - \rho g}&0 \end{array}} \right]du}\)

Finally, based on the principle of virtual work in dynamics, the kinematic equation of the beam element is given as follows:

Where \({\mathbf{\ddot {e}}}\) is the acceleration displacement matrix of the element nodes, representing the second derivative of the generalized displacement vector e with respect to time t. In addition, the fourth-order Runge–Kutta (RK4) method is used in this study to solve the dynamic equations due to its high accuracy and good stability31. Thus, the dynamic model of the curved beam is established based on the RANCF finite element method. In this study, the simulation time is set to 1.0s, with a time step of 0.001s.

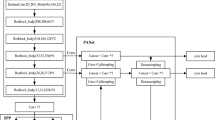

The subdivision method presented in Sect. 6 is applied to uniformly subdivide this non-uniformly parameterized circular arc element into equal arc-length segments in the physical space. By setting k = 0 in Eq. (17), the material subdivision nodes xj = j·LT / n (j = 1, 2, …, n-1). Assuming the original element contains NT = 1e6 parameter points, the number of parameter points N(xj) within each subdivided arc-length segment is determined. According to Eq. (19), the parameter division nodes (uj)j=1, 2, …, n−1 corresponding to the material subdivision points are obtained. These parameter division points are inserted sequentially, and the defining parameters of each subdivided element, including position coordinates, gradient coordinates, and weights, are computed by Eqs. (4–6) in Sect. 3. Figure 11 illustrates the uniform arc-length subdivision in the physical space for n = 2 ~ 7 sub-elements.

Figure 12 shows the shape of the curved beam at different time instances under numerical convergence. The absolute displacement in the y-direction at the end varies with time t, as shown in Fig. 13. Figure 14 presents the change in the length of the curved beam during the motion. It can be observed that as the flexible curved beam begins to fall from the initial position under the influence of gravity, the deformation of the beam continuously increases. Under the effect of gravity and elasticity, the curved beam elongates and reaches its maximum extension at the lowest point. After passing the lowest point at approximately 0.35s, the beam starts to decelerate due to the gravity. The curved beam begins to fall back after reaching its highest point at 0.8s. This demonstrates that the RANCF method can accurately describe the motion and deformation of flexible curved beams under large rotations and deformations.

Figure 15 shows the variation in the distance between nodes A and B. The results indicate that as the number of elements increases, the deformation of the curved beam tends to stabilize, which demonstrates that the model has achieved convergence. The analysis results indicate that the model reaches convergence when the number of subdivided elements is 6. To verify the correctness of the RANCF element subdivision method proposed in this paper, we compared the numerical results with those obtained using the ANCF and ABAQUS B31 finite element model. Figures 16 and 17 show the convergence results obtained using the ANCF and ABAQUS B31 finite element model, respectively. The comparison indicates that the convergence results of the three types of elements are consistent, and the RANCF method requires the fewest elements to achieve convergence. This is because RANCF finite elements can accurately represent the geometry in the reference configuration, allowing higher computational accuracy to be achieved with fewer elements.

In the framework of the finite element method, to enhance computational efficiency, the subdivision strategies should comprehensively account for accuracy requirements, computational efficiency, geometric and physical characteristics, boundary conditions, and load distribution. However, the definition of RANCF elements exhibits diversity. A series of elements representing the same configuration under different weights differ in their parameterization. Therefore, when discretizing RANCF elements, in addition to considering the aforementioned factors, it is essential to clarify the impact of different parameterizations of the elements. To investigate the influence of different subdivision methods for non-uniformly parameterized RANCF elements on numerical results, we selected a relatively extreme definition approach for the model shown in Fig. 10. The specific definition parameters are listed in Table 2.

Using the data from Table 2, the three sets of arc elements with different parameterizations (r1, r2, r3) are plotted, as shown in Fig. 18. Taking the example of dividing the original element into two parts (n = 2), the value range of the element discretization factor k is derived from Eq. (19) as -LT<k<LT (LT = π/6). Within this range, the method presented in Sect. 6 is applied to discretize r1, r2, r3, respectively, to evaluate the impact of different subdivision positions r(uj) on the numerical calculation results. Figure 19 shows the variation of the distance between points A and B at different subdivision locations for three sets of differently parameterized arc elements. It can be observed that the optimal subdivision points for r1, r2, and r3 differ. In this example, the configuration and loading conditions are identical, with the only difference being the distribution of parameter points on the elements. Therefore, in the refinement of RANCF elements, in addition to considering the structure and loading conditions, the distribution of parameter points on the elements should also be taken into account.

By comparing Fig. 19 a–c, it can be observed that uniformly parameterized elements inherently possess good numerical properties, and the location of the subdivision points has little impact on the computational results. However, for non-uniformly parameterized elements, the optimal subdivision point is located in areas where the parameter points are more densely distributed. This indicates that the distribution of parameter points on the element influences the selection of subdivision strategy. Therefore, when discretizing RANCF elements, in order to improve the quality of the subdivided elements, finer discretization should be applied to regions with dense parameter point distribution, while avoiding unnecessary over-refinement in sparsely distributed regions.

Based on the above, three different discretization factors were applied to the non-uniformly parameterized curved beam element initially defined in this paper, and the beam was re-discretized into three elements according to the method in Sect. 6 (as shown in Fig. 20). Figure 21 presents the variation of element AB distance under these three different discretization methods. It shows that when k = 0.1, the results are closer to numerical convergence. This indicates that matching appropriate subdivision strategies for non-uniform parameterized elements can further improve the efficiency of numerical analysis. However, the development of the optimal subdivision scheme for RANCF elements with different parameterizations requires further in-depth investigation.

By comparing Fig. 19 a–c, it is evident that the convergence results differ significantly among the three parameterization methods. Figure 22 presents a comparison of these results with the numerical convergence obtained from the ANCF and traditional finite element models. It can be observed that the RANCF model with uniform parameterization shows good consistency with the ANCF and ABAQUS models. This indicates that the use of highly non-uniform RANCF elements can negatively impact the accuracy of numerical results in flexible large deformation dynamic simulations, leading to the discrepancies on the convergence results in Fig. 19. Therefore, for flexible structures undergoing large deformations, the use of uniformly parameterized RANCF elements helps maintain the accuracy of numerical simulations.

Conclusion

This paper defines the subdivision method and principles for RANCF elements. Without altering the original geometric properties and parameter distribution of the element, the formulas for calculating the coordinates and weights of the subdivided element nodes are derived. This subdivision algorithm is consistent with the NURBS node insertion algorithm, facilitating the integration of CAD and CAA systems.

By introducing a parameter point distribution density function, a subdivision mapping relationship between parameter space and physical space is established. This mapping allows for the rapid identification of subdivision nodes in the parameter space according to the specific subdivision requirements, achieving accurate subdivision of different parameterized elements. This method effectively resolves the issue of subdivision mapping distortion in the parameter space of non-uniform RANCF elements.

A flexible and controllable subdivision method for RANCF arc elements in the physical space is proposed. This algorithm allows for the active control of the distribution of subdivision element sizes. By adjusting the values of the element discretization factors, different subdivision schemes for RANCF elements are demonstrated, catering to the accuracy requirements of various application scenarios.

The influence of element parameterization on subdivision strategies is validated through numerical simulations, leading to the establishment of subdivision criteria for RANCF elements. It is demonstrated that, when discretizing a geometry using RANCF elements, the distribution of parameters on the elements must also be comprehensively considered. This provides a theoretical foundation for the development of optimal subdivision strategies and adaptive mesh refinement for RANCF elements.

Data availability

All the data in the current study are available from the author Manyu Shi on reasonable request via e-mail manyu.shi@outlook.com.

References

Shabana, A. A., Hussien, H. A. & Escalona, J. L. Application of the absolute nodal coordinate formulation to large rotation and large deformation problems. J. Mech. Des. 120 (2), 188–195 (1998).

Sun, J. L., Tian, Q. & Hu, H. Y. Advances in dynamic modeling and optimization of flexible multibody systems. Chin. J. Theoretical Appl. Mech. 51 (6), 1565–1586 (2019).

Nachbagauer, K. State of the Art of ANCF elements regarding geometric description, interpolation strategies, definition of elastic forces, validation and the locking phenomenon in comparison with proposed beam finite elements. Arch. Computat Methods Eng. 21, 293–319 (2014).

Xu, Q. P. & Liu, J. Y. An improved dynamic model for a silicone material beam with large deformation. Acta Mech. Sin. 34, 744–753 (2018).

Wang, Q. T., Tian, Q. & Hu, H. Y. Contact dynamics of elasto-plastic thin beams simulated via absolute nodal coordinate formulation. Acta Mech. Sin. 32 (03), 525–534 (2016).

Yu, Z. Q., Liu, Y. G., Tinsley, B. & Shabana, A. A. Integration of geometry and analysis for vehicle system applications: Continuum-Based leaf spring and tire assembly. J. Comput. Nonlinear Dynam. 11 (3), 031011 (2015).

Shabana, A. A. Integration of computer-aided design and analysis: application to multibody vehicle systems. Int. J. Veh. Perform. 5 (3), 300–327 (2019).

Li, Y. Y., Wang, C. & Huang, W. H. Dynamics analysis of planar rigid-flexible coupling deployable solar array system with multiple revolute clearance joints. Mech. Syst. Sig Process. 117, 188–209 (2019).

Han, L., Su, G. L. & Yang, B. A new procedure for the integration of computer aided design and analysis. Proc. 2011 Int. Conf. Comput. Sci. Netw. Technol. 4, 2460–2464 (2011).

Ding, Z. S. & Ouyang, B. A. Variable-length rational finite element based on the absolute nodal coordinate formulation. Machines 10 (3), 174 (2022).

Pappalardo, C. M., Yu, Z. Q., Zhang, X. S. & Shabana, A. A. Rational ANCF thin plate finite element. J. Comput. Nonlinear Dyn. 11 (5), 051009 (2015).

Ma, C., Wei, C., Sun, J. & Liu, B. Modeling method and application of rational finite element based on absolute nodal coordinate formulation. Acta Mech. Solida Sin. 31, 207–228 (2018).

Ma, L., Wei, C., Ma, C. & Yang, Z. Modeling and verification of a RANCF fluid element based on cubic rational Bezier volume. J. Comput. Nonlinear Dynam. 15 (4), 041005 (2020).

Jiang, Y. B., Zhang, X. Y. & Beer, M. First excursion probability of dynamical systems: A review on computational methods. Mech. Syst. Sig Process. 323, 112751 (2025).

Jiang, Y. B., Zhang, X. Y. & Beer, M. An efficient method for reliability-based design optimization of structures under random excitation by mapping between reliability and operator norm. Reliab. Eng. Syst. Saf. 245, 109972 (2024).

Jiang, Y. B., Zhao, L. J. & Beer, M. Dominant failure mode analysis using representative samples obtained by multiple response surfaces method. Probab. Eng. Mech. 59, 103005 (2020).

Cheng, Y. M., Liu, H. T. & Wei, W. B. Location of critical three-dimensional non-spherical failure surface by NURBS functions and ellipsoid with applications to highway slopes. Comput. Geotech. 32 (6), 387–399 (2005).

Lan, P. & Shabana, A. A. Integration of B-spline geometry and ANCF finite element analysis. Nonlinear Dyn. 61, 193–206 (2010).

Lan, P. & Shabana, A. A. Rational finite elements and flexible body dynamics. J. Vib. Acoust. 132 (4), 041007 (2010).

Lan, P., Yu, Z. Q. & Du, L. Integration of Non-UniformRational B-Spline geometry and rational absolute nodal coordinates formulation finite element analysis. Acta Mech. Solida Sin. 27 (5), 486–495 (2014).

Zienkiewicz, O. C. & Taylor, R. L. The Finite Element Method for Solid and Structural Mechanics 6th edn (Butterworth Heinemann, 2005).

Lan, P. & Liu, M. L. Integration of computer aided design and analysis using the absolute nodal coordinate formulation. 2011 Fourth Int. Conf. Intell. Comput. Technol. Autom. (ICICTA). 1, 159–162 (2011).

Sanborn, G. G. & Shabana, A. A. On the integration of computer aided design and analysis using the finite element absolute nodal coordinate formulation. Multibody Syst. Dyn. 22 (2), 181–197 (2009).

Chang, H. J., Cheng, L. & Tian, Q. Three new triangular shell elements of ANCF represented by Bezier triangles. Multibody Syst. Dyn. 35 (4), 321–351 (2015).

Sanborn, G. G. & Shabana, A. A. A rational finite element method based on the absolute nodal coordinate formulation. Nonlinear Dyn. 58, 565–572 (2009).

Shi, F. Z. Computer Aided Geometric Design and non-uniform Rational b-splines (Beijing Aeronautics and Astronautics University, 2013).

Zhang, W. S., Liu, M. L., Shi, M. Y. & Lan, P. Construction method for circular Arc elements in rational absolute nodal coordinate formulation. Mech. Mach. Theory. 203 (15), 105811 (2014).

Shabana, A. A. Computer implementation of the absolute nodal coordinate formulation for flexible multibody dynamics. Nonlinear Dyn. 16 (3), 293–306 (1998).

Li, L., Wang, Y. & Guo, Y. Large deformations of hyperelastic curved beams based on the absolute nodal coordinate formulation. Nonlinear Dyn. 111, 4191–4204 (2023).

Fan, J. H., Bai, H. L., Wang, M. Q. & Fang, H. F. Research on cable dynamic response of a catenary anchor leg mooring system based on ANCF[J]. Ocean. Eng. 305, 117916 (2024).

Fotland, G. & Hauge, B. Numerical integration algorithms and constraint formulations for an ALE-ANCF cable element. Mech. Mach. Theory. 170, 104659 (2022).

Funding

The research supported by Henan Provincial R & D Plan Joint Fund, grant number 225,101,610,072; and the Independent Research and Development project of State Key Laboratory of Green Building, grant number LSZZ202209.

Author information

Authors and Affiliations

Contributions

Manyu Shi: Writing – original draft, Conceptualization, Methodology, Validation, Software, Resources, Data curation. Manlan Liu: Writing – review & editing, Conceptualization.Yaxiong Liu: Software writing. Peng Lan: Funding acquisition, Supervision, Visualization.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shi, M., Liu, M., Liu, Y. et al. Subdivision method for rational ANCF circular elements. Sci Rep 15, 21872 (2025). https://doi.org/10.1038/s41598-025-05729-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-05729-z