Abstract

A new efficient synthesis of TRβ-selective thyromimetic GC-1 is described. The present strategy employs benzyl substituent as the exclusive protecting group, avoiding side reactions and simplifying the purification process in the last step. This paper reports 62% overall yield in six steps for total synthesis of GC-1 in multi-gram scale. The initial synthetic route is adaptable to analogue design and suitable for the preparation of other natural methylenebisphenols.

Similar content being viewed by others

It is well known that thyroid hormones regulate many different physiological processes in different tissues in mammals1,2,3,4,5,6. 3,5,3’-triiodo-L-thyronine (T3), which is derived from its precursor 3,5,3’,5’-tetraiodothyronine (T4), is the major active form of thyroid hormones. Most of the physiological actions of T3 result from transcriptional regulation T3-responsive genes that are mediated through thyroid hormone receptors (TRs), which have two major subtypes TRα and TRβ7,8,9. Most thyroid hormones do not distinguish these two TRs and bind both with similar affinity. However, researches show that α-form of the receptors contributed in a substantial way to cardiac stimulating effects, and β-selective agonist would be less likely to have these side effects10,11,12. GC-1, a high affinity TRβ-selective agonist ligand related to T3, was first designed and synthesized by T. S. Scanlan13,14 Biological activity studies showed a better triglyceride and cholesterol lowering effects than T3. GC-1 could decrease plasma levels of cholesterol, triglyceride and lipoprotein (a), and promote loss of fat without eliciting deleterious effects on heart rate and muscle15,16. These favorable results indicated that GC-1 could represent a prototype of new drugs for the treatment of hyperlipidemia and obesity17.

Structurally, GC-1 belongs to the analogue of 4,4’-methylenebisphenol. Most of the methylenebisphenol type natural products have interesting bioactivities, but few works focus on the total synthesis of methylenebisphenols based on the simple chemical structures18,19,20,21,22. Recently in our research programs, some amounts of GC-1 were needed for comparative studies. Unfortunately, the existing methods were found to be inappropriate for synthesis of GC-1 in multi-gram scale preparation due to hash purification conditions. It was necessary for us to optimize the synthetic route for producing GC-1 and other natural methylene-bisphenols conveniently. Herein, we report a concise process that starts from 4-hydoxy-3-isopropyl-benzaldehyde to allow for the efficient syntheses of GC-1. Moreover, the described new route was adapted to analogues design and suit for other natural methylenebisphenols (Fig. 1).

Results

Chemistry

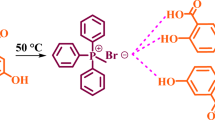

In the process of preparation GC-1 according the literature23, the major problem was encountered at the final stage. The purity of product is not enough for direct use. In further purification efforts for GC-1, we found that it is quite unstable to silica gel chromatography and HPLC. In addition, the following compounds 1, 2 and 3 were found to be unstable on TLC when placed in atmosphere over half an hour. Based on the structural characteristics of these compounds, we surmised an oxidation reaction occurred in purification process, leading to form para-quinone methide 4 (Fig. 2).

In order to overcome these disadvantageous factors for a convenient and large scale preparation, we devised an alternate synthetic route for the synthesis of GC-1. Initial synthetic plan for GC-1 is outlined in Fig. 3, which contained a key step of ketone reduction to form the biarylmethane skeleton. By treatment with benzyl bromide, 4-hydoxy-3-isopropyl-benzaldehyde 5 was easily converted to corresponding benzyl ether 6 in high yield. Compound 6 was coupled with lithiated 7 to give the biaryl alcohol 8 in 88% isolated yield. Oxidation of alcohol 8 provided the biarylketone, followed by treatment with tetrabutylammonium fluoride, the silyl ether protecting group was selectively removed to afford biaryl ketone 9 in 81% yield. Subsequent the compound 9 was alkylated by benzyl bromoacetate, giving ketone 10 in 92% isolated yield. It seems very easy to obtain the target compound GC-1 by a simple reduction of ketone 10 to provide mono-ester 11, and subsequently removal of hydroxyl and benzyl protecting groups by hydrogenolysis reaction. However, under various typical ketone reduction conditions, the expected product was not obtained (Table 1).

As shown in Table 1, when NaBH4 was used as reductive reagent, instead of the expected biaryl alcohol 11, starting material 10 was recovered (Entry 1). Other stronger regents such as NaBH4/H+, NaBH4/CaCl2, NaBH4/LiCl and LiBH4 lead to the reduction of ester group occurring and the corresponding alcohol 12 was obtained. But the ketone reductions did not happen in all cases (Entries 2–5). If treated with the strongest reductive reagents such as B2H6 and LiAlH4, the reaction became very complex, respectively (Entries 6 and 7).

Consequently, we modified the synthetic route from biaryl alcohol 8 to finish the synthesis of GC-1. As shown in Fig. 4, biaryl alcohol 8 was converted to corresponding benzyl ether by treatment with benzyl bromide, and subsequent removal of the silyl ether protecting group to afford phenol 13 in 82% yield. The phenol was alkylated by benzyl bromoacetate to give the expected compound 14 in a high yield. Finally, by using an hydrogenolysis reaction under acid condition, all three benzyl protecting groups in compound 14 were reduced to give the intermediate, biaryl alcohol 15, which was subsequently removed of hydroxyl group in one pot and the target compound GC-1 was obtained in ~ 100% yield, together with the purity is high enough for direct use. It was worth noting that all the solvents used in last step should be fresh distilled to avoiding the purity cut down (Fig. 4).

Discussion

In summary, we have developed a novel and concise synthetic strategy to the high affinity TRβ-selective agonist ligand, GC-1, in six steps with 62% overall yield. The new synthetic route described here allows one to prepare of GC-1 in multi-gram quantities easily. Because of the perfect chemical stability, compound 14 could be easily purified by silica gel chromatography, leading to the purity of the product obtained in final hydrogenolysis step is higher enough for bioactive studies. A series of multi-substituted thyronine analogues could be synthesized conveniently by changing the substituents on 4-hydoxybenzaldehyde. In addition, the strategy is suitable for preparation of methylenebispenol type natural products and their analogues by changing the coupling fragments in step two. We are currently investigating this chemistry to produce interesting compounds.

Experimental section

Chemistry

Unless otherwise noted, all reagents were obtained from commercial sources and purified according to standard procedure. Thin-layer chromatography (TLC) was performed by using commercially prepared HP-TLC silica gel plates visualized with short-wavelength UV light (254 nm). Products were isolated by column chromatography on silica gel (200–300 mesh size) by using petroleum ether (PE; 60–90℃) and ethyl acetate as eluents. All compounds were characterized by1H, and13C NMR spectroscopic analysis1H and13C NMR spectra were recorded with an Avance 400 spectometer with an operating frequency of 400 and 100 MHz, respectively. Chemical shifts for1H NMR spectra are reported in ppm relative to TMS. The following abbreviations are used to indicate multiplicities: s = singlet, d = doublet, t = triplet, dd = doublet of doublets, m = multiplet. Coupling constants (J) are reported in hertz (Hz). High-resolution mass spectrometry (HRMS) data were performed with a Q-Tof MS instrument.

Methods

4-Benzyloxy-3-isopropyl-benzaldehyde (6)

A mixture of 4-hydoxy-3-iso- propyl benzaldehyde (64.5 g, 393.3 mmol), potassium carbonate (108.6 g, 786.9 mmol) and benzyl bromide (74.1 g, 433.3 mmol) in 800 mL of acetone was heated to reflux for 1.5 h. The reaction mixture was cooled to room temperature and the solid was filtered off. The filtrate was concentrated under reduced pressure and the residue was purified by flash chromatography (silica gel, 5–10% ethyl acetate in petroleum ether) to produce 6 as a yellow oil (94.8 g, 373.2 mmol, 95%).

[1]H NMR (CDCl3, 400 MHz): δ = 1.26 (d, J = 6.8 Hz, 6 H), 3.42 (hept, J = 6.8 Hz, 1 H), 5.16 (s, 2 H), 7.00 (d, J = 8.2 Hz, 1 H), 7.34 ~ 7.42 (m, 5 H), 7.68 (d, J = 8.2 Hz, 1 H), 7.80 (s, 1 H), 9.87 (s, 1 H)13C NMR (CDCl3, 100 MHz): δ = 22.32 (2 C), 26.79, 70.05, 111.17, 127.03 (2 C), 127.18, 128.04, 128.61(2 C), 129.74, 130.42, 136.25, 138.06, 160.92, 191.27.HR-MS (EI-TOF): m/z [M + H]+ calcd for C17H18O2: 254.1307; found: 254.1352.

(4-Benzyloxy-3-isopropyl-phenyl)-(2,6-dimehtyl-4-triisopropylsilanyloxy-phenyl)-methanol (8)

To a solution of 7 (58.8 g, 164.6 mmol) in 400 mL of tetrahydrofuran at − 78 °C was added 72 mL of n-butyllithium (2.5 M in pentane) and the reaction mixture was stirred for 30 min at − 78 ℃ under argon. The aldehyde 6 (38 g, 149.6 mmol) in 100 mL anhydrous tetrahydrofuran was added dropwise and the mixture was stirred for 2 h at − 78℃ and 1 h at room temperature. The reaction was diluted with 1 L of ethyl acetate, washed with 3 × 200 mL of water, 2 × 100 mL of brine. The extracts were dried over sodium sulfate, filtered and concentrated to give a residue, which was purified by flash chromatography (silica gel, 2–10% ethyl acetate in petroleum ether) to afford 8 as yellow oil (70 g, 131.6 mmol, 88%).

[1]H NMR (CDCl3, 400 MHz): δ = 1.10 ~ 1.29 (m, 27 H), 2.09 (s, 1 H), 2.21 (s, 6 H), 3.38 (hept, J = 6.8 Hz, 1 H), 5.05 (s, 2 H), 6.23 (s, 1 H), 6.56 (s, 2 H), 6.81 (d, J = 8.4 Hz, 1 H), 6.94 (d, J = 8.0 Hz, 1 H), 7.17 (s, 1 H), 7.30 ~ 7.44 (m, 5 H)13C NMR (CDCl3, 100 MHz): δ = 12.71 (3 C), 17.96 (6 C), 20.82 (2 C), 22.64, 22.67, 26.98, 70.07, 70.99, 111.30, 120.38 (2 C), 123.75, 123.78, 127.10 (2 C), 127.66, 128.46 (2 C), 132.25, 135.38, 137.00, 137.62, 138.41 (2 C), 154.64, 154.93. HR-MS (EI-TOF): m/z [M + Na]+ calcd for C34H48NaO3Si: 555.3270; found: 555.3243.

(4-Benzyloxy-3-isopropyl-phenyl)-(4-hydroxy-2,6-dimehtyl-phenyl)-methanone (9)

To a solution of biaryl alcohol 8 (25 g, 47 mmol) in tetrahydrofuran (200 mL), activated manganese dioxide (8.4 g, 94 mmol) was added and the mixture was stirred at room temperature for 16 h. The solid was filtered off and the filtrate was concentrated under reduced to give a residue. The crude product was used for next step without further purification.

To a solution of the crude product in 100 mL dichloromethane was added tetra-n-butylammonium fluoride (5.5 g, 21 mmol) and the mixture was stirred for 1 h at room temperature. The solution was diluted with dichloromethane (200 mL), washed with 3 × 50 mL of water and brine (50 mL), dried with sodium sulfate, filtered and concentrated under reduced pressure. The crude product was purified by flash chromatography (silica gel, 5–10% ethyl acetate in petroleum ether) to give 9 as white solid (14.3 g, 38.1 mmol, 81%, two steps).

[1]H NMR (CDCl3, 400 MHz): δ = 1.24 (d, J = 6.8 Hz, 6 H), 2.04 (s, 6 H), 3.38 (hept, J = 6.8 Hz, 1 H), 5.13 (s, 2 H), 6.56 (s, 2 H), 6.87 (d, J = 8.4 Hz, 1 H), 6.98 (d, J = 8.4 Hz, 1 H), 7.32 ~ 7.50 (m, 6 H), 7.91 (s, 1 H)13C NMR (CDCl3, 100 MHz): δ = 19.56 (2 C), 22.36 (2 C), 27.06, 70.11, 110.85, 114.52 (2 C), 127.12 (2 C), 127.43 (2 C), 128.03, 128.62 (2 C), 130.49, 132.11, 136.14 (2 C), 136.46, 137.85, 156.16, 160.66, 200.56. HR-MS (EI-TOF): m/z [M + H]+ calcd for C25H27O3: 375.1960; found: 375.1942.

[4-(4-Benzyloxy-3-isopropyl-benzoyl)-3,5-dimehtyl-phenoxy]-acetic acid benzyl ester (10)

To a solution of phenol 9 (14.25 g, 38.1 mmol) and caesium carbonate (24.76 g, 76 mmol) in dimethylformamide (30 mL). After stirred for 1.5 h at room temperature, the mixture was diluted with diethyl ether (500 mL) and washed with water (3 × 50 mL) and brine (50 mL). The organic phase was dried over sodium sulfate, filtered and concentrated under reduced pressure. The residue was purified by flash chromatography (silica gel, 4% ethyl acetate in petroleum ether) to afford 10 as colorless oil (18.3 g, 35.1 mmol, 92%).

[1]H NMR (CDCl3, 400 MHz): δ = 1.24 (d, J = 6.8 Hz, 6 H), 2.08 (s, 6 H), 3.39 (hept, J = 6.8 Hz, 1 H), 4.68 (s, 2 H), 5.13 (s, 2 H), 5.26 (s, 2 H), 6.59 (s, 2 H), 6.85 (d, J = 8.5 Hz, 1 H), 7.35 ~ 7.43 (m, 11 H), 7.89 (s, 1 H)13C NMR (CDCl3, 100 MHz): δ 19.72 (2 C), 22.37 (2 C), 27.05, 65.24, 66.96, 70.06, 110.72, 113.57 (2 C),127.09 (2 C), 128.03 (2 C), 128.43 (2 C), 128.52 (2 C), 128.61 (2 C), 130.26 (2 C), 130.35 (2 C), 133.89, 135.14, 136.22, 136.47, 137.84 (2 C), 157.49, 160.49, 168.78, 199.07. HR-MS (EI-TOF): m/z [M + H]+ calcd for C34H35O5: 523.2484; found: 523.2457.

(4-Benzyloxy-3-isopropyl-benzoyl)-[4-(2-hydroxy-ethoxy)-2,6-dimehtyl –pheny]-methanone (12)

To a solution of ketone 10 (5.23 g, 10 mmol) and lithium borohydride (0.44 g, 20 mmol) in tetrahydrofuran (30 mL). After stirred for 6 h at room temperature, washed with water (5 × 200 mL) and brine (100 mL). The organic phase was dried over sodium sulfate, filtered and concentrated under reduced pressure. The residue was purified by flash chromatography (silica gel, 4% ethyl acetate in petroleum ether) to afford 12 as colorless oil (3.34 g, 8 mmol, 80%).

[1]H NMR (CDCl3, 400 MHz): δ = 1.24 (d, J = 6.8 Hz, 6 H), 2.11 (s, 6 H), 2.16 (s, 1 H), 3.39 (hept, J = 6.8 Hz, 1 H), 3.97 (m, 2 H), 4.10 (m, 2 H), 5.14 (s, 2 H), 6.63 (s, 2 H), 6.86 (d, J = 8.4 Hz, 1 H), 7.34 ~ 7.48 (m, 6 H), 7.88 (s, 1 H)13C NMR (CDCl3, 100 MHz) δ: 19.74 (2 C), 22.39 (2 C), 27.06, 61.45, 69.07, 70.10, 110.80, 113.53 (2 C), 127.11 (2 C), 127.27, 128.03, 128.62 (2 C), 130.11, 130.28, 133.31, 136.16, 136.51, 137.83 (2 C), 158.44, 160.46, 199.22. HR-MS (EI-TOF): m/z [M + H]+ calcd for C27H30O4: 418.2144; found: 418.2138.

4-[Benzyloxy-(4-benzyloxy-3-isopropyl-benzoyl)-methyl]-3,5-dimehtyl –phenol (13)

To a solution of biaryl alcohol 8 (82 g, 154.1 mmol) and benzyl bromide (29 g, 169 mmol) in dimethylformamide (500 mL), sodium hydride (6 g, 200 mmol, 80% in mineral oil) was added in portions at 0℃. After stirred for 24 h at 35℃, the mixture was diluted with ethyl acetate (1 L), washed with water (3 × 100 mL) and brine (100 mL). The extracts were dried over sodium sulfate, filtered and concentrated to give a residue. The crude product was used for next step without further purification.

To a solution of the crude product in 300 mL dichloromethane was added tetra-n-butylammonium fluoride (16.5 g, 63 mmol) and the mixture was stirred for 1 h at room temperature. The solution was diluted with dichloromethane (500 mL), washed with 3 × 100 mL of water and brine (50 mL), dried with sodium sulfate, filtered and concentrated under reduced pressure. The residue was purified by flash chromatography (silica gel, 10% ethyl acetate in petroleum ether) to give 13 as colorless oil (58.9 g, 126.36 mmol, 82%, two steps).

[1]H NMR (CDCl3, 400 MHz): δ = 1.18 (d, J = 7.3 Hz, 6 H), 2.16 (s, 6 H), 3.36 (hept, J = 6.8 Hz, 1 H), 4.38 (d, J = 12.2 Hz,1 H), 4.60 (d, J = 12.2 Hz, 1 H), 4.79 (s, 1 H), 5.04 (s, 2 H), 5.85 (s, 2 H), 6.51 (s, 2 H), 6.78 (d, J = 8.4 Hz, 1 H), 6.93 (d, J = 8.0 Hz, 1 H), 7.23 ~ 7.43 (m, 10 H).HR-MS (EI-TOF): m/z [M + H]+ calcd for C32H34O3: 467.2508;found: 467.2457.

{4-[Benzyloxy-(4-benzyloxy-3-isopropyl-phenyl)-methyl]-3,5-dimehtyl –phenoxy}-acetic acid benzyl ester (14)

To a solution of phenol 13 (58 g, 124.46 mmol) and caesium carbonate (81.1 g, 248.92 mmol) in dimethylformamide (300 mL), benzyl bromoacetate (39.1 g, 170.33 mmol) was added dropwise. After stirred for 2 h at room temperature, the mixture was diluted with diethyl ether (1.5 L) and washed with water (5 × 200 mL) and brine (100 mL). The organic phase was dried over sodium sulfate, filtered and concentrated under reduced pressure. The residue was purified by flash chromatography (silica gel, 4% ethyl acetate in petroleum ether) to afford 14 as colorless oil (70.3 g, 114.5 mmol, 92%).

[1]H NMR (CDCl3, 400 MHz): δ = 1.18 (d, J = 7.4 Hz, 6 H), 2.16 (s, 6 H), 3.36 (hept, J = 6.8 Hz, 1 H), 4.37 (d, J = 12.2 Hz, 1 H), 4.58 (d, J = 12.2 Hz, 1 H), 4.66 (s, 2 H), 5.03 (s, 2 H), 5.25 (s, 2 H), 5.85 (s, 1 H), 6.57 (s, 2 H), 6.77 (d, J = 8.4 Hz, 1 H), 6.90 (d, J = 8.0 Hz, 1 H), 7.21 ~ 7.43 (m, 16 H)13C NMR (CDCl3, 100 MHz): δ = 20.92 (2 C), 22.57 (2 C), 27.15, 65.14, 66.89, 69.81, 69.93, 111.09, 114.81 (2 C), 124.18, 124.39, 127.03, 127.36 (2 C), 127.52, 127.61 (2 C), 128.30 (2 C), 128.39 (2 C), 128.43 (2 C), 128.47 (2 C), 128.58 (2 C), 130.14 (2 C), 133.78, 135.20, 136.72, 137.56, 138.92, 139.70, 154.73, 156.52, 168.99. HR-MS (EI-TOF): m/z [M + Na]+ calcd for C41H42O5 + Na: 637.2930, found: 637.2899.

[4-(4-Hydroxy-3-isopropyl-benzyl)-3,5-dimehtyl–phenoxy]-acetic acid (GC-1)

A solution of 14 (88 g, 143.3 mmol) in 1 L of fresh distilled 10% (v/v) AcOH in MeOH containing 10% Pd/C (16 g) was hydrogenated at 2 atm at room temperature. When hydrogen uptake was complete (~ 15 h), the catalyst was filtered off and the filtrate was evaporated under reduce pressure. The residue was azeotroped with fresh distilled toluene three times and dried under high vacuum to yield GC-1 as a slight yellow solid (46.8 g, 142.7 mmol, 99.6%).

[1]H NMR (CDCl3, 400 MHz): δ = 1.18 (d, J = 6.8 Hz, 6 H), 2.16 (s, 6 H), 3.15 (hept, J = 6.8 Hz, 1 H), 3.86 (s, 2 H), 4.60 (s, 2 H), 6.49 (d, J = 7.7 Hz, 1 H), 6.55 (d, J = 8.2 Hz, 1 H), 6.60 (s, 2 H), 6.91 (s, 1 H), 7.0 ~ 7.5 (m, 2 H)13C NMR (CDCl3, 100 MHz): δ = 20.41 (2 C), 22.54 (2 C), 26.99, 33.67, 64.94, 114.04 (2 C), 115.20, 125.22, 126.10, 131.09, 131.92, 134.28 (2 C), 138.62, 150.69, 155.27, 174.35. HR-MS (EI-TOF): m/z [M + K]+ calcd for C20H24O4 + K: 367.1312, found: 367.1204.

Data availability

Supporting Information for this article is available online at “ https://pan.baidu.com/s/16YzhPIlhOUKkcVFaj_MFWQ? pwd=3um7.” Included are copies of 1 H NMR and 13 C NMR spectra for all new compounds.

References

Hansson, P., Valdemarsson, S. & Nilsson-Ehle Experimental hyperthyroidism in man: effects on plasma lipoproteins, lipoprotein lipase and hepatic lipase. Horm. Metabol Res. 15, 449–452 (1983).

Elisabetta, P. & Qian, M. Thyroid hormone receptor-β agonist GC-1 inhibits Met-β-Catenin–Driven hepatocellular cancer. J. Med. Res. 18, 72473–72485 (2017).

Li, B. et al. Inhibition of macrophage inflammasome assembly and pyroptosis with GC-1 ameliorates acute lung injury. Theranostics 15, 2360–2374 (2025).

Giacomo, B. et al. Efficacy of sustained delivery of GC-1 from a nanofluidic system in a spontaneously obese non-human primate: a case study. Biomed. Microdevices. 20, 49 (2018).

Bokyung, K., Ho, Y. K. & Massimiliano, R. Diphenyl-methane based thyromimetic inhibitors for transthyretin amyloidosis. Int. J. Mol. Sci. 22, 3488–3488 (2021).

Amedeo, C., Grazia, C. & Anna, M. K. GC-1: A thyromimetic with multiple therapeutic applications in liver disease. Gene Expr Patterns. 17, 265–275 (2017).

Mangelsdorf, D. J. & Evans, R. M. The RXR heterodimers and orphan receptors. Cell 83, 841–850 (1995).

Manglesdorf, D. J. et al. Nuclear Receptor Superfamily: Cell 83, 835–839 (1995).

Estefanía, R. et al. Effect of thyromimetic GC-1 selective signaling on reproductive and lactational performance in the hypothyroid rat. Eur. Thyroid J. 10, 425–433 (2021).

Wikstrom, L. et al. Abnormal heart rate and body temperature in mice lacking thyroid hormone receptor alpha 1. EMBO J. 17, 455 (1998).

Estefanía, R. et al. Effect of thyromimetic GC-1 selective signaling on reproductive and lactational performance in the hypothyroid Tat. Eur. Thyroid J. 10, 425–433 (2021).

Fatima, R. S. F. et al. The thyroid hormone receptor beta-specific agonist GC-1 selectively affects the bone development of hypothyroid rats. J. Bone Min. Res. 20, 294–304 (2005).

Chiellini, G. et al. A high-affinity subtype-selective agonist ligand for the thyroid hormone receptor. Chem. Biol. 5, 299 (1998).

Chiellini, G., Nguyen, N-H. & Yoshihara, H. A. I. improved synthesis of the iodine-free thyromimetic GC-1. Med. Chem. Lett. 10, 2607 (2000).

Chiellini, G. et al. Synthesis and biological activity of novel thyroid hormone analogues: 5’-aryl substituted GC-1 derivatives. Bioorg. Med. Chem. 10, 333 (2002).

Trost, S. U. et al. The thyroid hormone receptor-beta-selective agonist GC-1 differentially affects plasma lipids and cardiac activity. Endocrinology 141, 3057 (2000).

Baxter, J. D. & Webb, P. Thyroid hormone mimetics: potential applications in atherosclerosis, obesity and type 2 diabetes. Nat. Rev. Drug Disc. 8, 308 (2009).

Li, B. & Xia, C. The thyroid hormone analog GC-1 mitigates acute lung injury by inhibiting M1 macrophage polarization. Adv. Sci. 26, 2401931 (2024).

Li, K., Li, X. M., Wang, B. G. & Gloer, J. B. New nitrogen-containing bromophenols from the marine red Alga Rhodomela confervoides and their radical scavenging activity. Food Chem. 135, 868 (2012).

Lee, C. L. et al. –)-Xanthienopyran, a new inhibitor of superoxide anion generation by activated neutrophils, and further constituents of the seeds ofxanthium strumarium. Planta Med. 74, 1276 (2008).

Na, M. K. et al. Inhibition of protein tyrosine phosphatase 1B by diterpenoids isolated from Acanthopanax Koreanum. Bioorg. Med. Chem. Lett. 16, 4738 (2006).

Fan, X., Xu, N. J. & Shi, J. G. J. Bromophenols from the red Alga Rhodomela confervoides. Nat. Prod. 66, 455 (2003).

Hassan, A. Q. & Koh, T. J. A functionally orthogonal ligand – receptor pair created by targeting the allosteric mechanism of the thyroid hormone receptor. J. Am. Chem. Soc. 128, 8868–8874 (2006).

Funding

This work was supported by the National Science Foundation of China (grant no. 21272048).

Author information

Authors and Affiliations

Contributions

C.X.H : Synthesis, Experiments, Data curation, Analysis, Manuscript Original draff.W.J.J: Resources, Formal analysis, Validation.L. Y.Z: Design, Supervision, Review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval

This study is not applicable because it does not involve the use of animals or humans.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chu, X., Wang, J. & Li, Y. An improved synthesis of TRβ-selective thyromimetic GC-1. Sci Rep 15, 26779 (2025). https://doi.org/10.1038/s41598-025-12379-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-12379-8