Abstract

Unmanned aerial vehicles (UAVs) are increasingly deployed for high-voltage substation equipment inspection due to their superior flight flexibility, enhanced inspection efficiency, and capability for close-range observation. However, the electronic components of UAVs are susceptible to strong electromagnetic fields present in substations, necessitating careful consideration of safety distances during inspection route planning. This study establishes critical electromagnetic field thresholds for UAV operations, determining safety criteria of 320 kV/m for electric field intensity and 290 µT for magnetic flux density. A comprehensive safety distance calculation methodology is proposed, incorporating factors such as wind gust effects and UAV hovering accuracy. An inspection path planning algorithm is developed based on established safety thresholds and inspection requirements, with validation performed through simulation of a 220 kV substation bay. Simulation results demonstrate that the planned inspection paths maintain maximum electric field intensity and magnetic flux density values of 156 kV/m and 136 µT respectively, both below established safety thresholds. These findings contribute significantly to advancing the implementation of safe UAV-based inspection practices in high-voltage substation environments.

Similar content being viewed by others

Introduction

Substation inspection, as a crucial component of power system operation, enables timely detection of potential hazards, minimizes fault occurrence, and ensures the safe operation of power systems1. Multi-rotor UAVs, characterized by their enhanced flight flexibility, superior inspection efficiency, and capability for close-range observation, are widely deployed for inspecting high-voltage equipment in substations2,3. It is well-established in academic literature that the high density of equipment in substations creates a challenging electromagnetic environment4,5. Scholars have thoroughly investigated the spatial distribution of electric fields6 and the variability of magnetic fields under different load conditions7,8, confirming their strength and complexity. Building upon this foundational research9, it is clear that for UAV operations, maintaining an inadequate distance from energized equipment may result in discharge faults or flight control system failures due to this pervasive electromagnetic interference. Therefore, determining optimal safety distances and developing corresponding UAV inspection path planning strategies are crucial challenges in substation UAV inspection operations.

Extensive research has been conducted on UAV inspection path planning and safety distance assessment. In practical applications, Graz University of Technology indicates that flight missions are recommended to keep at least 15–20 m from the infrastructure10, while the United States and other regions indicate the safe distance is over 3 m11,12. In the context of UAV safety distance assessment, Chen D et al. developed a finite element model for electromagnetic field simulation of UAV inspection operations around 500 kV cat-head towers. Their study proposed a comprehensive methodology for calculating safe distances in UAV power inspection operations13. Li Y and Huang D.C et al. conducted safety distance testing, evaluating both measurement and control performance of Matrice 300 RTK and Mavic 2 enterprise advance UAVs, along with electric discharge observation experiments14,15. Through electromagnetic field simulations, they determined the upper tolerance limits for power frequency electric and magnetic fields affecting UAV operations. Cai H.Q et al. developed a three-dimensional simulation model incorporating actual UAV specifications and equipment configurations within the high-intensity electric field zones of 500 kV substations. Their results indicated a critical corona field strength threshold of 300 kV/m for UAV operations16. The study established minimum operational safety distances of 2.2 m and 2.1 m for UAV inspection of 500 kV pipe busbars and main transformer side bushings, respectively. Zhang Y et al. conducted three-dimensional electric field modeling of 220 kV substations, specifically focusing on the Genie 4 UAV platform. Their analysis, considering solely electric field effects, determined that maintaining a horizontal distance of 0.5 m from high-voltage equipment during traversing inspection ensures safe UAV operation17,18.

Various intelligent algorithms have been employed for UAV path planning, including genetic algorithm19, monte Carlo algorithm approaches20, and artificial potential field21. Elfe et al. proposed a grid-based method for path planning, where the operational space is discretized into cells, each assigned specific attributes indicating the presence or absence of obstacles22. Khatib et al. introduced an artificial potential field method for flight path planning, where obstacle avoidance and target reaching are achieved through force-driven navigation23. Liu Q.L et al. developed a hybrid path planning approach combining the Sparrow Search Algorithm with a Bioinspired Neural Network24. Their hybrid algorithm demonstrated superior performance in terms of path planning stability and path length optimization, while incorporating dynamic obstacle avoidance capabilities. Pan Z.H et al. introduced an enhanced artificial potential function-based approach for multi-UAV system path planning. Through the implementation of a rotating potential field, their method effectively addresses common challenges such as local minima and oscillatory behaviors in multi-UAV systems25.

Previous studies on UAV inspection safety distances in substations have predominantly focused on single voltage level equipment, while path planning research has primarily emphasized route optimization for minimizing inspection time and distance, neglecting the critical influence of safety distances on inspection path planning. This study conducts comprehensive electromagnetic field tolerance and discharge tests for UAVs operating in environments with voltage levels ranging from 110 kV to 500 kV. Through integration of experimental and simulation results, this paper establishes threshold values for average electric field strength and power frequency magnetic field tolerance concerning discharge phenomena between UAVs and high-voltage equipment. A three-dimensional model of a typical 220 kV substation bay is developed, facilitating UAV inspection path planning that incorporates varying safety distance requirements. Results demonstrate that the planned paths maintain maximum electric field intensity and magnetic flux density values of 156 kV/m and 136 µT, respectively, both remaining below established safety thresholds. Simulation results validate the effectiveness of the proposed methodology in enhancing the safety of UAV-based substation equipment inspection.

Simulation test of critical electromagnetic field distance of UAV

Electric field tolerance and electrical discharge test

Experimental investigations were conducted to evaluate UAV electric field tolerance thresholds and determine minimum discharge distances. Inspection experiments were performed using UAVs in simulated electromagnetic environments representative of 220 kV and 500 kV substations (see Figs. 1 and 2). This substation is a teaching substation, but its internal equipment is the same as that of an actual substation. UAV operational safety parameters and discharge phenomena were systematically monitored and analyzed.

The experimental setup comprises a high-voltage test transformer, voltage divider, 220 kV isolation switch, and 500 kV post insulator as primary components. The test environmental conditions are under temperature (26.6–27.9℃), relative humidity of air (80–83%), and environmental wind speed (0–1 m/s). UAVs were programmed to approach the energized conductor along predetermined trajectories at a controlled velocity of 2 m/s, each of experiments is calculated by taking the average of the results of three flights. Four UAV platforms were evaluated in this study: China Southern Power Grid Technology Smart Eye Pro26, DJI Mavic 2 Enterprise Advanced27, DJI Mavic 3 Enterprise Advanced28, and Autel Robotics EVO II29. The main parameters of each UAV are shown in Table 1, and the parameters of high voltage equipment are shown in Table 2. Discharge phenomena were monitored using an ultraviolet light imaging system, with critical discharge distances established when detected photon counts exceeded 100 between the UAV and high-voltage equipment, as shown in Fig. 3.

Experimental results indicate that initial weak corona discharge occurs between the UAV rotor and energized conductor during the approach phase. The electric field intensity in the air gap progressively increases with decreasing separation distance, ultimately leading to pronounced discharge activity between the rotor and high-voltage electrode. Due to the consistent use of non-conductive materials in rotor construction across all tested UAVs, the initial discharge critical distances exhibited minimal variation between platforms. The measured average critical distances were approximately 12 cm, 23 cm, and 61 cm for voltage levels of 110 kV, 220 kV, and 500 kV, respectively. A linear relationship was observed between critical discharge distance and applied voltage. Notably, the observed discharge phenomena had negligible impact on UAV control systems, with no instances of control system malfunction recorded.

Magnetic field tolerance test

Magnetic field tolerance testing was conducted using a bare conductor to simulate the magnetic field distribution of current-carrying equipment such as busbars (see Fig. 4). Critical magnetic field distances were determined based on observed anomalies in the UAV’s Real-Time Kinematic (RTK) positioning system and compass module alerts. Test results demonstrated that the Smart Eye Pro UAV exhibited a critical magnetic field distance of approximately 20 cm when exposed to a current of 300 A.

UAV safety distance simulation and determination

Simulation model

The electromagnetic field simulation model was developed to replicate the experimental test conditions. The following assumptions and simplifications were implemented in the modeling of UAVs and high-voltage equipment to optimize computational efficiency:

1) The model focuses on external electromagnetic fields generated by conductors and high-voltage equipment, allowing for simplification of internal equipment structures.

2) UAV geometry is represented by its primary structural dimensions while neglecting internal components with minimal influence on electromagnetic field distribution.

3) In the study of electric field distribution, the earth is regarded as an infinite plane with equal resistivity and zero potential. In the study of magnetic field distribution, the earth is regarded as an infinite plane with the same permeability as the air permeability.

The simulation model geometry (Fig. 5) was constructed based on actual measurements and manufacturer specifications for both UAVs and high-voltage equipment30. Regarding the material parameter settings of the simulation, the material properties of the four wings motors and the gimbal camera are set as conductor. The material properties of the UAV are set as polycarbonate composites. The relative permittivity is set to 7, the electric conductivity is set to 10− 12 S/m, and the relative permeability is set to 1. The insulator is made of epoxy resin with a relative permittivity of 3.45 and an electrical conductivity of 10− 17 S/m. The aluminum conductor conductivity is set to 3.5 × 107 S/m. In the simulation, the high voltage terminal voltage is set to the phase voltage of the corresponding voltage grade. The potential of the ground terminal is set to 0, and the motor potential of the UAV is set to suspension potential. The dimensions of the air domain all exceed three times the characteristic dimensions of the main components to reduce the influence of boundary effects. During the simulation, the tolerances were all set to 0.001, and the geometric center point of the main body of the UAV was taken as the detection point. When the change rate of the field strength calculation result at this point was less than 1%, it was considered to meet the requirements. The same method was adopted for all subsequent simulations to ensure that the calculation results were independent of the grid density.

Simulation model of UAV and test platform (a) 110 kV and 220 kV model (b) 500 kV model (c) Magnetic field simulation model. This image was created by the authors using MATLAB (Version R2022b, https://www.mathworks.com/products/matlab.html).

Simulation results

In the simulation, the UAV was positioned with its camera oriented towards the high-voltage equipment, maintaining separation distances consistent with experimental configurations. Figure 6. illustrates the potential and magnetic field distributions across the horizontal plane adjacent to the high-voltage equipment.

Surface electric field analysis revealed peak intensities in the vicinity of the UAV’s four rotor motors, with maximum field strength observed at the forward motor proximate to the isolation switch. Magnetic field distribution exhibited localized concentration at the wing tips, with comparatively lower intensities across the main body structure. Table 3 summarizes the maximum surface electric field intensities and motor surface potentials observed across all four UAV configurations at various voltage levels.

The maximum electric field intensity on the surface of the UAV is 1,650 kV/m, which is less than the corona control field intensity of general hardware 2,120 kV/m, so there is no corona discharge on the surface of the UAV, which is consistent with the observation results of the ultraviolet camera. Similarly, the average field strength (The spatial average at the phase angle.) between the UAV rotor motor and the high voltage end under different voltage levels is relatively close, with an average value of about 341 kV/m and a minimum value of 324 kV/m. Therefore, the 320 kV/m can be used as the criterion for the critical average electric field strength.

Since the 300 A current measured in the experiment is an effective value, when converted to peak conditions, the magnetic field tolerance intensity of the two UAVs should be 321 µT for the Smart Eye Pro and 293 µT for the Mavic 2 Enterprise advanced, which is consistent with the previous literature research results of over 200 µT. After rounded up, it can be considered that the maximum magnetic field tolerance value of the Smart Eye Pro is 320 µT. The Mavic 2 Enterprise advanced is 290 µT. Therefore, the 290 µT can be used as the criterion for the critical average magnetic field strength. The electromagnetic field limits of this paper are compared with relevant national standards and research papers in Table 4.

Due to the strong universality and relatively conservative nature of national standards, their limit values are relatively smaller. The research results of this paper are relatively close to those of15, with the main differences lying in the test environment and the methods of parameter selection.

UAV inspection safe distance determination method

The combined experimental and simulation analyses establish a methodology for estimating critical electromagnetic field safety distances for UAV operations. However, additional operational factors beyond electromagnetic field effects can compromise the maintained separation distance between UAVs and energized equipment, potentially reducing it below the calculated critical threshold. Consequently, a safety margin must be incorporated into the final clearance distance specifications. At present, UAV inspection is mainly based on automatic flight31. Therefore, the main influencing factors considered in this paper are UAV hovering accuracy and gust effect.

UAV hovering accuracy characterizes the platform’s position-holding capability in both horizontal and vertical axes under nominal conditions without significant environmental perturbations. Implementation of RTK positioning systems enables position-holding accuracy of ± 10 cm. Wind gusts introduce positional offsets that degrade the baseline hovering performance. Operational protocols restrict UAV inspections to wind conditions below 8 m/s. Based on established UAV operational standards and empirical test data, a safety margin of 0.5 m is implemented to account for gust-induced displacement32. Based on the above analysis, the safe distance calculation method of UAV is as follows:

Where, dE and dB are the critical distances under the electric and magnetic field criteria, the uncertainty distance caused by hovering accuracy is d1, and the uncertainty distance generated by gust influence is d215.

Substation UAV inspection path planning with considering safe distance

The size of the UAV must meet the inspection requirements within narrow spaces. The magnification of its optical camera must meet the shooting requirements from a safe distance. Its hovering accuracy and wind resistance must ensure stable operation at different altitudes.

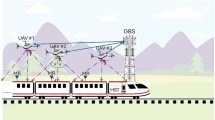

This study examines a typical 220 kV substation’s outdoor switchyard, specifically focusing on the main transformer feeder bay. Utilizing the developed model to determine spatial coordinates of target inspection equipment, electromagnetic field simulation analysis is then employed to establish safe clearance distances between the UAV and individual inspection targets, enabling the development of optimized inspection flight paths. The proposed flight paths undergo simulation-based validation to verify operational safety parameters.

Route planning method of UAV substation inspection based on safe distance

Based on the electromagnetic field impact analysis, simulation-derived minimum safety clearances can be established to facilitate inspection route planning. The methodology comprises the following key phases, as shown in Fig. 7.

-

(a)

Establish a three-dimensional substation model, load the operating voltage and current to the model, and obtain the minimum safe distance between the UAV and each equipment according to the simulation results;

-

(b)

Set the take-off and landing position of the UAV, and determine the coordinates of the UAV inspection site according to the equipment to be inspected;

-

(c)

Plan the inspection path of the UAV according to the minimum safety distance, so that the distance between the UAV and the equipment in the inspection process is greater than the corresponding minimum safety distance.

The following takes the typical 220 kV substation bay as an example to carry out the UAV inspection route planning and simulation.

220 kV substation bay model

220 kV substation bay equipment mainly includes arrester, isolation switch, circuit breaker, current transformer and tubular bus (see Fig. 8). The bay dimensions are 50 m × 14 m × 20 m (length × width × height). Some equipment is simplified without affecting the electromagnetic field distribution in the bay33. Temporal analysis of electromagnetic field calculations reveals peak field intensities near phase conductors coincide with voltage and current maximum. The spatial electromagnetic field distribution analysis focuses on conditions corresponding to maximum amplitude in phase A of the right-hand circuit.

Simulation and analysis of electromagnetic field distribution

The three-phase AC voltage and current with a phase difference of 120° are applied to the high-voltage bus bar and the equipment respectively, load current is 602 A, zero potential is applied to the gantry frame, and the ground and the low-voltage end fittings. Figure 9 illustrates the electric field intensity and magnetic flux density distributions at an elevation of 9.0 m above ground level.

According to the results in Fig. 9, the electric field at the substation bay is mainly concentrated in the vicinity of the high-voltage conductor and the adjacent frame, with a maximum of 1,160 kV/m. The magnetic field is mainly concentrated near the flow conductor, and the maximum magnetic flux density is 3,470 µT. The overall simulation results show that the magnetic field intensity near the devices with low current such as arrester is smaller, but the electric field intensity is larger, so the critical distance between the electric field and the magnetic field of each device is not the same. The calculated critical electric and magnetic field safety distances between the UAV and various high-voltage equipment are shown in Table 5.

The data in Table 5 show that the magnetic field generated by the current has a greater impact on the safety distance than the electric field, and the critical distance of each device is different to some extent, with a maximum difference of 23 cm. Therefore, it is necessary to consider the impact of the safety distance on UAV inspection. According to the Biot-savart’s Law, any electric current generates a magnetic field around it, and the strength of this field is directly proportional to the magnitude of the current. Therefore, as the load grows and causes the current to rise, the strength of the magnetic field around the conductors increases linearly in direct proportion. Thus, the magnetic field intensity under other load currents can be obtained based on the proportional coefficient.

Inspection path planning and simulation

The UAV inspection trajectory was developed in compliance with industry standard DL/T 96934, encompassing comprehensive equipment inspection requirements. The UAV takes off from the bottom of the arrester (Point 1) and inspects devices such as the arrester, isolation switch, circuit breaker, tubular bus, and current transformer after rising to the inspection height, and finally landed at point 19, as shown in Fig. 10. In addition to point 1, points 2, 4, 5, 8, 9, 12, 13, 16, 17, 18 represent the live part of the inspection equipment, and the remaining points are the non-live part of the inspection insulator, meter, etc.

Figures 11 and 12 present the average electric field intensity between UAV and energized components along the inspection path, and the magnetic flux density distribution on the UAV fuselage surface. The observed variations in electric field intensity and magnetic flux density correlate with specific equipment operational characteristics. Near surge arresters, measurements indicate elevated electric field intensities coupled with reduced magnetic flux densities. Simulation results confirm that along the safety-distance-constrained inspection path, the maximum average electric field intensity between UAV and energized components reaches 156 kV/m, remaining below the threshold limit of 320 kV/m. The peak magnetic flux density measured at the UAV surface attains 136 µT, maintaining compliance with established safety thresholds. These results validate the operational safety of the designed inspection trajectory. This analysis substantiates the efficacy of the proposed safety-distance-based UAV inspection path planning methodology.

Verification of safety distance for UAV inspection

Based on the UAV trajectory planning method considering safe distance proposed in this paper, the Smart Eye Pro UAV completed three automatic flights at a 110 kV substation, as shown in Fig. 13. Considering that the loss of control of UAV would pose a significant threat to the safety of power transformation equipment and cause safety accidents, no further critical verification tests were carried out. The above-mentioned tests initially verified the effectiveness of the method proposed in this paper, and further tests will be conducted through other methods in the future.

Conclusion

This study presents simulation tests for UAV inspection of substation equipment across 110 kV-500 kV voltage levels, combined with high-current proximity tests, to establish critical distance criteria for both electric and magnetic fields. A safety distance-based inspection path planning methodology is proposed and validated within a typical 220 kV substation bay. The key findings of this study are summarized as follows:

-

(a)

The established average critical distances are approximately 12 cm, 23 cm, and 61 cm for voltage levels of 110 kV, 220 kV, and 500 kV, respectively. A linear relationship is observed between critical distance and applied voltage. Simulation results establish threshold values of 320 kV/m for critical average electric field strength and 290 µT for maximum allowable magnetic flux density.

-

(b)

A comprehensive safety distance-based route planning methodology is developed for UAV substation inspection. The methodology initially determines safety distance criteria for various UAV platforms, followed by critical distance calculations based on equipment operating parameters (voltage and current). Comprehensive safety distances are established for each piece of equipment after accounting for additional influencing factors. The path planning algorithm ensures that UAV trajectories maintain minimum safety distance constraints from all equipment.

-

(c)

The methodology was validated through simulation using a 220 kV substation bay as a case study. Simulation results demonstrate maximum values of 156 kV/m for electric field intensity and 136 µT for magnetic flux density along the planned path, both remaining below established safety thresholds. These findings provide significant insights for enhancing both the implementation of UAV-based substation inspections and the safety assurance of high-voltage equipment operations.

-

(d)

Future research will focus on deploying and validating the proposed path planning method in real substation environments. The core objective is to leverage intelligent algorithms to generate highly consistent and repeatable UAV inspection paths, thereby significantly enhancing the efficiency and reliability of automated inspections. Moreover, the safety distance proposed in this study does not take into account the directional differences caused by the structure of the UAV itself and the antenna layout. Exploring the directional safety margin of UAVs from multiple angles and in various postures will also be the focus of the next research.

Discussion

A key consideration in this paper is that the derived safety distances are based on steady-state electromagnetic field conditions. Operations during switching operations or fault occurrences fall into the category of “abnormal operating conditions” or “emergency responses,” which necessitate a distinct and more complex risk assessment framework that is beyond the scope of this paper. The characterization of safety during transient events constitutes a separate and important research problem for future investigation.

Another important consideration is the influence of environmental factors, which were not explicitly modeled in this study, such as rain, humidity, and corona discharge. The analysis in this paper was conducted under “standard operating conditions,” typically corresponding to fair weather, which aligns with the baseline requirements stipulated in most UAV operational manuals for any flight mission. In non-standard weather, it is imperative for operators to apply an additional safety margin to this baseline value to account for the prevailing environmental conditions.

Data availability

The datasets generated and/or analysed during the current study are not publicly available due to funding agency requirements, but are available from the corresponding author on reasonable request.

References

Dukanac, D. Extraction of partial discharge signal in predominant VHF range in the presence of strong noise in power transformer. Electr. Eng. 105, 3001–3018 (2023).

Ergün, E. Artificial intelligence approaches for accurate assessment of insulator cleanliness in high-voltage electrical systems. Electr. Eng. 107 (3), 2969–2982 (2024).

Suh, U. S. et al. Passive IR-UWB localization system for UAV-Based electric facility inspection during GPS outage. IEEE Access. 11, 39597–39608 (2023).

Borisov, R. K. et al. An electromagnetic environment monitoring system at electric substations. Russ Electr. Engin. 92, 442–446 (2021).

Safigianni, A. S. Tsompanidou. electric- and magnetic-field measurements in an outdoor electric power substation. IEEE Trans. Power Delivery. 24 (1), 38–42 (2009).

Li, N., Yang, X. & Peng, Z. Measurement of electric fields around a 1000 kV UHV substation. IEEE Trans. Power Delivery. 28 (4), 2356–2362 (2013).

Vilacha, C. et al. Magnetic-field evaluation in the vicinity of high-voltage electric systems. IEEE Trans. Power Delivery. 27 (2), 980–985 (2012).

Tanaka, K. Mizuno, Y. & Naito, K. Measurement of power frequency electric and magnetic fields near power facilities in several countries. IEEE Trans. Power Delivery. 26 (3), 1508–1513 (2011).

Yang, L. et al. A review on state-of-the-art power line inspection techniques. IEEE Trans. Instrum. Meas. 69 (12), 9350–9365 (2020).

Komar, G. et al. Automatic UAV-based inspection of overhead lines and substations: beyond visible spectrum. 8th Int. Conf. Condition Monit. Diagnosis (CMD). Phuket, Thailand (210–213), 2020 (2020).

Lekidis, A., Anastasiadis, A. G. & Vokas, G. A. Electricity infrastructure inspection using AI and edge platform-based UAVs. Energy Rep. 8, 9, 1394–1411 (2022).

Ogan, R. T., Lott, D. & Paden, W. Electrical Transmission Line Inspection Using Unmanned Aircraft. 1–7 (Southeast Con, 2019).

Chen, D. et al. Safety distance analysis of 500 kV transmission line tower UAV patrol inspection. IEEE Lett. Electromagn. Compat. Pract. Appl. 4 (2), 124–128 (2020).

Li, Y. et al. Study on safety distance determination method of UAV inspection of high voltage equipment in substation. Adv. Technol. Electr. Eng. Energy. 42 (3), 76–84 (2023). (in Chinese).

Huang, D., Wang, Y. & Li, H. Study on UAV inspection safety distance of substation high-voltage and current-carrying equipment based on power-frequency magnetic field. IEEE Trans. Instrum. Meas. 73, 1–8 (2024).

Cai, H. Q. et al. Safe distance of inspection operation by unmanned aerial vehicles in 500 kV substation. High. Voltage Eng. 50 (7), 3199–3208 (2024). (in Chinese).

Zhang, Y. et al. Research on electric field safety distance of high-voltage equipment in substations inspected by UAV. In The Proceedings of 2023 4th International Symposium on Insulation and Discharge Computation for Power Equipment (IDCOMPU2023). IDCOMPU 2023. Lecture Notes in Electrical Engineering. Vol. 1103 (Springer, 2024).

Zhang, Y. et al. Calculation of electric field for UAV cross-inspection in 220 kV substation. In The Proceedings of the 18th Annual Conference of China Electrotechnical Society. ACCES 2023. Lecture Notes in Electrical Engineering. Vol. 1169 (Springer, 2024).

Singh, B. & Dubey, P.K. Distributed power generation planning for distribution networks using electric vehicles: Systematic attention to challenges and opportunities. J. Energy Storage. 48, 104030 (2022).

Dubey, P. K. et al. A novel approach for comparative analysis of distributed generations and electric vehicles in distribution systems. Electr. Eng. 106 (3), 2371–2390 (2024).

Dubey, P. K., Singh, B. & Singh, D. Integration of distributed generation and electric vehicles in the distribution system. Eng. Application Artif. Intell. 137, 109036 (2024).

Moravec, H. & Elfes, A. High resolution maps from wide angle sonar. In Proceedings of the IEEE International Conference on Robotics and Automation, St. Louis, MO, USA. 116–121 (1985).

Khatib, O. Real-time obstacle avoidance for manipulators and mobile robots. In Proceedings of the 1985 IEEE International Conference on Robotics and Automation, St. Louis, MO, USA. 500–505 (1985).

Liu, Q. et al. Multi-UAV path planning based on fusion of sparrow search algorithm and improved bioinspired neural network. IEEE Access. 9, 124670–124681 (2020).

Pan, Z. et al. An improved artificial potential field method for path planning and formation control of the multi-UAV systems. IEEE Trans. Circuits Syst. II Express Briefs. 69 (3), 1129–1133 (2022).

China Southern Power Grid Technology Co., Ltd. Smart Eys Unmanned Aerial Vehicle User Manual. 1–10. (China, 2024).

Dajiang Innovation. Mavic 2 Enterprise Advanced User Manual. 1–68. (China, 2024).

Dajiang Innovation. DJI Mavic 3E 3T User Manual, 1-100 (China, 2024).

Autel Robotics. EVO-II-RTK & Series V3 Multi-rotor Unmanned Aerial Vehicle User Manual 1–125 (China, 2024).

Wuhan University. 220 kV Test Substation. (2025). https://gxpt.whu.edu.cn/genee02/equipment/3322

Jialin, L. et al. Multi-spectral characteristics of metal conductor floating potential discharge in SF6 gas. Insulating Mater. 52 (8), 77–83 (2019). (in Chinese).

State Administration for Market Regulation. Standardization Administration of the People’s Republic of China. Test Methods for Civil Multi-Rotor Unmanned Aircraft System. 1–32 (Chinese Standard GB/T 38058–019, 2019).

Shen, J. et al. Analysis of power frequency electromagnetic field in outdoor AIS and indoor GIS substations. In 2024 IEEE 7th International Electrical and (CIEEC), Harbin, China. 1219–1224 (2024).

National Development and Reform Commission. Guideline of Substation Operation. Chinese Standard DL/T 969–2005. 1–10 (2005).

Acknowledgements

This work was financially supported by the China Southern Power Grid Corp funded science and technology project (GDKJXM20220879).

Author information

Authors and Affiliations

Contributions

Wensheng Li participated in the UAV experiments, Huaqing Wang wrote the main manuscript text and revised the paper, and all other authors, including Duanjiao Li, Ying Zhang, Hao Wu, and Yun Chen, reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, D., Wang, H., Zhang, Y. et al. A method for UAV inspection path planning based on safety distance in substation. Sci Rep 15, 43688 (2025). https://doi.org/10.1038/s41598-025-27525-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-27525-5