Abstract

Soft soil presents significant challenges for infrastructure development because of its high compressibility, low bearing capacity, and lateral deformation. Granular column techniques can reduce settlement in soft and weak soil by speeding up the dissipation of excess pore water pressure and enhancing bearing capacity. Furthermore, by stopping the lateral deformation of the clay particle, the use of reinforcing columns can greatly increase the shear strength of soft soil. The primary goal of this study is to find out how polypropylene columns can improve the soft reconstituted kaolin clay’s compressibility and shear strength. A number of factors, including the area replacement ratio, height penetration ratio, and volume replacement ratio, were analysed in order to look at the strength characteristics. This examination encompassed both single and grouped polypropylene columns. The reinforced kaolin samples were assessed using the Unconfined Compression Test. Based on the UCT results, it was observed that the undrained shear strength generally improved as the height penetrating ratio increased, however, once it reached 100% height penetrating ratio, it began to decrease. The undrained shear strength increment was also influenced by the polypropylene area replacement ratio. The shear strength of the soil sample did not change despite its high area replacement ratio. As the soil sample’s circumference was smaller than required, the column’s shearing strength needed to be increased. The ratio increased as the strength increased in the absence of restricting pressure. However, as the remaining width of the soil sample became insufficient to support the columns, excessive area replacement reduced the shear strength of the sample reinforced by group columns. In general, it can be concluded that the installation of polypropylene columns has the potential to improve the shear strength and compressibility characteristics of soft clay.

Similar content being viewed by others

Introduction

The fundamental requisite for the comprehensive progress of any country is the existence of an adequate infrastructure that includes residential buildings, highways, tunnels, bridges, and several other civil engineering projects. In the past, suitable land for construction sites abound, but nowadays, there is a drastic increase in land costs due to the rapid increase in infrastructure development, especially in metropolitan areas. The construction of clay soil has increased in prevalence mostly as a result of the limited availability of suitable land for infrastructure development and other improvements1. Construction is therefore now also being carried out on sites with extremely poor soil conditions, such as clays, which cover a large region in Malaysia.

Soft soil in Malaysia is often categorised as an quaternary sediment, which encompasses alluvial deposits and organic or peat soils2. According to the Quarterly Geological Map of Malaysia, significant areas of the western and eastern coastlines of Peninsular and East Malaysia are characterised by the presence of soft land; a common feature observed in the coastal plains of the country. The presence of a significant proportion of soft ground inside the country, along with the concentration of economic and social development in coastal areas, necessitates the undertaking of construction projects on these challenging deposits. In the past, several failures have been recorded either locally or internationally due to high soil compressibility and low shear strength, which had caused excessive settlement and structural deformation, such as embankment. The Public Works Department of Malaysia (PWD) has been actively engaged in several roadway and building projects on soft soil, owing to the nation’s significant and rapid expansion witnessed over the last few decades. The Public Works Department (PWD) plays a significant role as the primary technical agency for the Government of Malaysia. Its participation in development projects can occur in two main capacities: construction and forensic investigation. The summary of geotechnical forensic investigations conducted by JKR on problematic projects since 2010 is presented. Out of a total of 252 forensic instances, about 72% (182 cases) pertain to the matter of ground settlement. The remaining 28% of cases are attributed to other variables like vibration, erosion, foundation failures, and similar causes3. Therefore, it is apparent that the foremost technical obstacle encountered in the construction of soft soil is unquestionably the problem of soil settlement.

There is substantial potential for reusing waste materials to improve soil strength from a geotechnical and soil mechanics standpoint. Solid waste is widely recognised as one of the primary environmental issues in Malaysia, constituting a significant environmental challenge for the entire country. According to a study conducted by4, it was found that in 2013, the average daily solid waste generation per capita in Malaysia was approximately 800 g. Only approximately 5% of the waste is recycled, according to5, and the amount of waste created has increased as a result of growth and development. Nevertheless, Malaysia’s waste management standards continue to be insufficient in light of the substantial quantity and intricate nature of the trash generated. Engineering firms may utilise waste to create sustainable buildings. For instance, polypropylene is among the waste materials that have been generated for this purpose. Polypropylene, a thermoplastic polymer, possesses the characteristic of reusability. The use of this substance spans over a diverse array of items, encompassing textiles, plastics, food packaging, reusable containers, and tyres. Hence, this study aims to investigate the challenges associated with establishing infrastructure on soft soils and mitigate the scarcity of landfills in Malaysia due to increasing daily waste. It is expected that significant advancements in soil improvement techniques will be made as a result of this research. Furthermore, the utilisation of polypropylene as a waste product can lead to reduced expenses associated with soil improvement. Ideally, the insights derived from the study will provide valuable contributions to the ongoing progress of the field of clay soil development.

Polypropylene is lightweight in nature, having a low density compared to other plastics. It has a relatively low cost and is energy saving in the manufacturing and transportation process. Polypropylene is used as a raw material for the granular column, and its performance is almost the same as the conventional stone column. The effectiveness in improving soil strength is dependent on the properties of polypropylene6. According to the result obtained by7, the maximum shear strength increment by reinforcing kaolin clay with polypropylene column is 91.24%, which proved that polypropylene is a suitable filler to be used in reinforcing soft clay. The two largest companies producing polypropylene are Polypropylene (M) Sdn. Bhd. and Titan Petchem (M) Sdn. Bhd., both with respective outstanding yearly production capabilities of 80,000 and 370,000 metric tons, respectively. Polypropylene is simple to process and is lightweight and rigid. It has a high average tensile strength of 330 kg/cm2, an average density of between 0.855 and 0.946 gm/cm3, and a range of densities.

On the contrary, it is well acknowledged that soft soil has notable compressibility and restricted bearing ability. In order to facilitate building on soft soil, it is imperative to employ a ground improvement approach that may efficiently improve bearing capacity while concurrently reducing settlement and consolidation time8. Sand drains, stone columns, prefabricated vertical drains, and many more methods have been selected over the years for this purpose. Choosing the right ground improvement method is essential to guarantee a safe and economical building. The stone column approach has gained significant popularity in recent times as a means to address building challenges encountered in soft soil conditions9. The stone column is commonly utilised in cohesive, soft soil to augment its capacity to carry loads, reduce settling, and aid in the dissipation of pore water pressure. Polypropylene exhibits characteristics that are analogous to those of sand, suggesting its potential viability as a substitute material for stone columns. The use of polypropylene as a substitute material in stone columns offers the possibility of reducing both the financial outlay of the project and the necessary space for disposing of any residual polypropylene. According to10, the utilisation of granular columns in engineering applications has been implemented to improve load-bearing capacity and mitigate settlement issues in soils that possess weak or soft properties. This process is thought to be among the most flexible and economical ways to deal with unstable ground conditions.

Granite residual soil (GRS) is a type of weathering soil that can decompose upon contact with water, potentially causing geological hazards11. In this study, cement, an alkaline solution, and glass fibre were used to reinforce GRS. The effects of cement content and the SiO₂/Na₂O ratio of the alkaline solution on the static and dynamic strengths of GRS were discussed. Microscopically, the reinforcement mechanism and coupling effect were examined using X-ray diffraction, micro-computed tomography, and scanning electron microscopy. The results indicated that the addition of 2% cement and an alkaline solution with an SiO₂/Na₂O ratio of 0.5 led to the densest matrix, lowest porosity, and highest static compressive strength after adding glass fibre. The compressive strength and dynamic impact resistance were a result of the coupling effect of cement hydration, a pozzolanic reaction of clay minerals in the GRS, and the alkali activation of clay minerals. Excessive cement addition or an excessively high SiO2/Na2O ratio in the alkaline solution can have negative effects, such as the destruction of C-(A)-S-H gels by the alkaline solution and hindering the production of N-A-S-H gels. The overall performance of the geopolymers was assessed via multiple influence indicator methods, and the optimal synthesis conditions for the geopolymers were a SiO2/Na2O ratio of 1.5 and a liquid–solid ratio of 0.75. The use of alkaline activation technology to transform EM into geopolymers has potential as a substitute for concrete, providing a new type of green material for geotechnical engineering12. This can result in damage to the matrix of reinforced GRS, leading to a decrease in both static and dynamic strengths. The findings indicate that cement and alkaline solution are appropriate for GRS and that the reinforced GRS can be used for high-strength foundation and embankment construction.

13reported that in controlled laboratory studies, the presence of a fully penetrating column within clay samples resulted in a notable 33% enhancement in strength as compared to those without a sand column. Furthermore, the research findings indicated that the observed augmentation in undrained shear strength observed in fully penetrated soil columns ranged from 13% to 19.5%. Moreover, the recorded increase in undrained shear strength showed a variation ranging from 67.5% to 75% when evaluating area replacement ratios of 7.9% and 17.8% respectively. The granular column can increase bearing capacity and provide a shorter drainage path, which can speed up the crucial process of consolidation14. suggested that the installation of granular material columns offers two distinct benefits. Firstly, due to the inherent stiffness and increased frictional strength of the granular material in comparison to soft clay, these columns function as piles. Consequently, these mechanisms efficiently transfer the applied stress to greater depths by means of both shaft resistance and end bearing. Furthermore, it is important to highlight that the material used for columns has a higher permeability when compared to clay. This results in the drainage channel being shorter, which speeds up the consolidation process and increases the strength overall.

Soft clay is a soil formation that has low bearing capacity, high compressibility, and a tendency for lateral flow. It causes excessive displacement of structures15. Moreover, the process of disposing of soft soil is both costly and time-intensive. In addition, the establishment of infrastructure on soft soils may necessitate frequent post-construction maintenance activities aimed at decreasing the potential risks of structural problems16. The characteristics of soft clay make it very undrainable. These circumstances, particularly during the rainy season in Malaysia, cause serious havoc to structures. Thus, tackling this problem is of significant importance. Due to its effectiveness and positive economic impact, introducing a stone column or vertical column is a widely employed method for treating soft clay soils. The stone columns help reduce settlements, increase the bearing capacity, and accelerate the pre-consolidation of clay soil deposits.

Crushed stones and sand are the primary constituents of the stone column construction17. However, the uncontrollable usage of natural resources in granular columns like sand and stone is a matter of concern and calls for the crucial need to search for alternative substitutes for vertical column from renewable materials. To tackle these issues, the utilisation of renewable materials like polypropylene can be a potential solution. A stone column is normally installed in soft, cohesive soil to improve bearing capacity, reduce settlement, and accelerate pore water pressure dissipation14. On the other hand, Polypropylene is endowed with better crack resistance and stress absorption capability in comparison to sand18. Additionally, it can absorb stresses and movements without causing structural damage. The high friction angle value of polypropylene could increase soft clay’s bearing capacity, while the high permeability coefficient could accelerate the consolidation. Furthermore, the coefficient of the permeability of polypropylene is higher than that of sand, thus releasing extra pore water pressure from the sample19. Since the other functional attributes of polypropylene are similar to sand, it is anticipated that, using polypropylene as a substitute material in stone columns can replace the use of sand.

Soil stabilisation, as a cost-effective and environmentally friendly method, is used in the building of systems like roads, dams, canals and river levels. Various researchers have carried out research on the properties of soil, such as its compaction, compressibility, hydraulic conductivity, and strength characteristics20. Granular piles have been and are still widely employed to improve the ground in a number of ways, including reducing settlements, increasing load carrying capacity, facilitating the quick dissipation of pore pressures, reducing the impacts of liquefaction, etc. Determining the behaviour of granular piles in various soil conditions requires an understanding of the earth’s and the piles’ deformation characteristics in order to apply granular piles in soft ground effectively. The modular ratio of granular piles and the modulus of deformation of the surrounding in situ soil can be estimated using the load settlement response derived from compression experiments, as presented in this study. This study has taken into account the direct loading test situations, when the applied load is completely transferred onto the granular pile21.

Additionally, laboratory testing was highlighted in numerous research in the literature review. Therefore, a more comprehensive knowledge of the behavior of polypropylene columns in soft clay requires a closer look at the laboratory testing methods and outcomes, as well as how they relate to field performance. The development of sustainable and efficient soil reinforcing methods as well as a better comprehension of the mechanical and physical properties of soft clay reinforced with polypropylene columns can be achieved by filling in these knowledge gaps. The use of waste materials and products from different industries as reinforcing materials for soft soil is an innovative approach to a sustainable and financially sensible environment for the construction sector.

Methodology

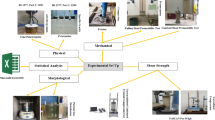

The study focuses on whether polypropylene can function as a suitable substitute for granular material in alternative soil reinforcing methods. The preparation and execution of the project methodology were accompanied by the study of previous experiments. The methodology encompasses a series of laboratory experiments aimed at assessing the mechanical, physical, and strength properties of polypropylene and kaolin clay, as well as the composite material formed by reinforcing kaolin with polypropylene columns. Cylindrical specimens, with a diameter of 50 mm and a height of 100 mm, were produced using kaolin as the clay element, and polypropylene provided the granular component. The studies were conducted at Universiti Malaysia Pahang’s Soil and Geotechnical Laboratory. The final selection of laboratory equipment for various tests was dependent on criteria such as suitability and financial considerations. This situation also led to the use of guiding frameworks like the British Standard (BS) and the American Society of Testing Materials (ASTM). This chapter presents a thorough examination of the process of setting up the model test, including the test content and the overall procedures involved.

Determination of properties of materials and laboratory tests standards

A comprehensive assessment of the mechanical and physical characteristics of soft kaolin and polypropylene was conducted via a series of experimental experiments. Soft kaolin clay was reinforced with polypropylene columns in a lab test to determine its shear strength. The American Society for Testing and Materials (ASTM) and the British Standard (BS) were frequently used as benchmarks, depending on the testing facilities at hand. The primary aim of this investigation was to comprehensively document all aspects of the experimental procedure, encompassing the equipment used, methodologies employed, and specifics on the undrained strength tests done on soft clay with polypropylene column reinforcements. The next part presents a comprehensive overview of the parameters under investigation, the materials utilised, the experimental setup, and the methods employed for testing. Table 1 presents the laboratory testing programme and the procedural criteria.

Preparation of Kaolin clay sample

In this study, the moisture content maintained in the reconstituted samples was 20%. This level was chosen as it is the ideal moisture level for kaolin clay, according to a reference from22. Moreover, the typical dry density range for kaolin clay at 20% MC, based on Proctor compaction, is approximately 1.3 to 1.6 gm/cm³. According to22, the compaction method was used to apply the soil to a defined compaction effort or to get the soil to a given dry density or void ratio. The moist soil was mixed by hand until it was evenly distributed, then poured into the specially designed mould and compacted into three layers. A 3.10 kg steel extruder was used to crush each layer with five free-fall strokes. The kaolin material which consisted of the specifically built mould underwent compaction to produce a specimen with a diameter of 50 mm and a height of 100 mm. Before introducing the soil into the mould, a thin coating of silicone grease was applied to the inside surface of the mould. Furthermore, a smooth polyethylene sheet was strategically positioned over the coated surface to reduce the level of friction that occurs between the soil and the wall of the mould.

According to initial predictions of negligible mass reductions during the operation, the applied approach effectively preserved the integrity of each specimen. Complete adherence to a roughly equal distribution of soil mass and mould volume allowed for the accomplishment. The “controlled sample” specimens did not have a polypropylene column attachment. For kaolin samples reinforced with polypropylene columns, drill bits with diameters of 10–16 mm were used to make a hole for the column to reduce the specimen’s expansion while it was within the mould. The columns were specifically intended to have a height of 100 mm for completely penetrating columns, while partially penetrating columns were created with lengths of 60 mm and 80 mm. The specimen was then taken out of the moulds and placed in an appropriate container. To encourage the stabilisation of pore pressure, the container was left undisturbed for at least 24 h after that. The geographical distribution of the places utilised for measuring the moisture content of the samples is depicted.

Installation of polypropylene columns

The investigation involved the production of specimens to assess the shear strength of kaolin clay that had been reinforced with polypropylene columns. The control sample consisted of three produced samples, each lacking polypropylene reinforcement and exhibiting a 0-penetration ratio. The provided samples were used to determine the unmodified sample’s shear strength. Every individual kaolin sample has a uniform penetration ratio, namely 0.6, 0.8, and 1.0. However, the area replacement ratio differs across specimens. Subsequently, perforations were created with a drill bit with a suitable diameter, while the specimens remained enclosed within the mould to impede any expansion. This was done in preparation for the fabrication of the polypropylene column for the reinforced specimens. Installation of the 16 mm group polypropylene column requires very careful work. The space around the 16 mm column is very small, so if it is not installed properly, the 16 mm sample breaks during installation. On the other hand, the installation of the 10 mm group polypropylene column did not break because of sufficient area around the 10 mm group column.

The penetration ratios (Hc/Hs) for each batch of kaolin specimens were consistent, with values of 0.0, 0.6, 0.8, and 1.0. The column diameter was seen to have two distinct measurements, specifically 10 mm and 16 mm. These measurements corresponded to area displacement ratios of 4.00% and 10.24%, respectively, denoted as the column area to sample area ratio (Ac/As). Figure 1 shows the photograph of specimens reinforced with singular and group polypropylene columns respectively. The specimen apertures were subsequently substituted with polypropylene material, as depicted in Fig. 1. For the installation of the group column, the centre-to-centre distance between the columns is 22 mm, and the clear spacing between the columns is 6 mm for a 16 mm polypropylene column and 12 mm for a 10 mm polypropylene column. The distance between the outer surface of the sample and the outer surface of the 10 mm polypropylene column is 7.5 mm, and the distance between the outer surface of the sample and the outer surface of the 16 mm polypropylene column is 4.5 mm. The determination and production of the mass of polypropylene necessary to fill each pre-drilled hole were conducted to ensure constant density throughout all polypropylene columns.

The diameter of the polypropylene column (D) and also the particle size of granular material (d) played an important role in choosing the appropriate size of the column to be used in the model tests. The diameters of polypropylene columns used in this study were 10 mm and 16 mm, while the particle size of polypropylene was between 1.08 mm and 3.35 mm. The ratio D/d in the model tests therefore had the values between 4 and 17. Although the lower range D/d values of model tests were slightly smaller than those typical in practice, it was unavoidable as there was a limitation on the diameter of the column to be used to avoid boundary effects. Figure 2 shows the preparation and installation of polypropylene columns for both single and group columns.

Result and discussion

The primary materials employed in this study were kaolin and polypropylene. The engineering characteristics of kaolin were assessed using various laboratory examinations, such as the Atterberg limit test, particle size distribution analysis, compaction test, specific gravity measurement, permeability test, unconfined compression test, and consolidated undrained triaxial test. Several tests were performed on the polypropylene in the laboratory, including the vane shear test, the consolidated undrained triaxial test, the particle size distribution test, the relative density test, the compaction test, the permeability test, the direct shear test, the scanning electron microscope test, and the unconfined compression test.

The results of the consolidated undrained triaxial test and the unconfined compression test are also included in this research. The cylindrical specimens, measuring 50 mm in diameter and 100 mm in height, were made of soft kaolin clay and used for experimental research. Both reinforced and unreinforced samples were included in the study. These tests aimed to determine the engineering qualities of the materials investigated in the study. In order to assess the enhancement in shear strength observed at a specific location, an experimental study was conducted by employing polypropylene columns with varying diameters and penetration ratios to reinforce the soft kaolin clay (Table 2).

Undrained shear strength for UCT test

Unconfined compression tests were performed on samples of soft clay reinforced with polypropylene columns to determine their shear strength. In order to calculate the average values of shear strength, a total of four sets of tests were conducted for each penetration ratio. Average max. shear strength equal to maximum corrected deviator stress divided into two (Su = qu/2). The findings of the average max. shear strength are presented in Table 3. Additionally, there was no polypropylene column reinforcement used in the control sample.

The effect of area replacement ratio

The results shown in Fig. 3 demonstrate that increasing the width of a polypropylene column can result in greater shear strengths. The mentioned relationship shows that the shear strength demonstrates improvement with an increase in the area replacement ratio (Ac/As). The research showed that the polypropylene columns, which had a height of 80 mm, demonstrated a much greater shear strength of 10.24% for the area replacement ratio compared to the lower value of 4.00%. This observation shows the possibility of improving shear strength by increasing the area replacement ratio. At a column height of 80 mm, it was observed that the shear strength of the polypropylene column was comparatively lower for the area replacement ratio of 4.00% as compared to the column with an area replacement ratio of 10.24%. This is a result of the high particle size and gaps in polypropylene, which makes the material less resistant to compression. The 10.24% area replacement ratio exhibited superior performance compared to the 4.00% area replacement ratio for an 80 mm column height, owing to its higher compactness and reduced inter-particle spacing. The value of axial strain varies from 2.43 to 2.86 for the varieties of shear strength. The maximum shear strength obtained was 74.50% at axial strain 2.54. Moreover, the compressive strength experienced a significant increase due to the large surface area of the polypropylene pellets that made contact with the upper conical plate.

The correlation between the area replacement ratio (Ac/As) and an increase in shear strength is shown in Fig. 3. It also suggests that the polypropylene column’s shear strength could improve with respect to an increase in its diameter. At a column height of only 80 mm, the polypropylene columns’ shear strength for the area of 12.00% was higher than the shear strength for the area replacement ratio of 30.72%, which might potentially increase the shear strength. This finding indicates the potential of improving the shear strength. This is a result of the high particle size and gaps in polypropylene, which makes the material less resistant to compression. The improvement in the area replacement ratio of 12.00% was more significant compared to the 30.72% area replacement ratio for an 80 mm column height due to denser packing of particles and reduced intermediate spaces. In addition, the large contact area between the polypropylene pellets and the upper conical plate resulted in a significant increase in the compression strength.

This was due to the fact that the area replacement ratio of the column was too small. When the vertical load was distributed inside the column, there was a bulge in the column as the remaining width of the soil sample was too thick to hold the column. The circular periphery area of the soil sample was as much as the column needed to increase the shearing strength. That is why the shear strength has increased even though the area replacement ratio of the soil sample is high.

The results show that the trend is in line with previous studies by23 and9, which described how the decline in performance is caused by the mobilization of greater confining stress in smaller SDC. A higher stiffness of smaller diameter results from the columns’ higher value of confining stresses. The results support research studies by6, which employed a sand column to find that the height of the column over column diameter ratio and the area of the replacement ratio affected the improvement of soft clay.

The effect of column penetration ratio

The potential influence of the column’s height to diameter ratio on undrained shear strength has been examined using Fig. 4. This was achieved by visualising how these two variables relate to one another. This was accomplished by graphically representing the relationship between these two variables. A variety of results from the study conducted by24 are illustrated on one graph for easier comparison. According to previous research, the dark grey area in the image is known as “the critical column length” and it is four to eight times the column’s diameter (Dc).

The findings are consistent with the hypothesis that there is a critical column length over which there is very little increase in undrained shear strength. Based on all the area ratios, the grey area showed the most gain. Higher increases were often observed in single columns instead of in group columns. When it reached 8Dc, the undrained shear strength increased the most with area replacement ratios of 4% and 12%. The area replacement ratios at 5Dc, which were 10.24% and 30.76%, showed the greatest improvement.

An unconfined compression test was used to increase the shear strength to height penetration ratio for both single and grouped polypropylene columns, shown in Fig. 5. The height penetrating ratio (Hc/Hs) indicated consistency, with the most significant enhancement seen at Hc/Hs = 0.8 across all samples. The findings of the investigation suggest that the height penetration ratio had a greater influence on the improvement of undrained shear strength in clay soil in comparison to the height-to-diameter ratio of the column.

This suggests that deeper penetration of the columns enhances their reinforcing effects on the soil. The results are analogous to the study on the encasement of a sand column conducted by25, which discovered that the undrained shear strength was raised by encasing the sand column. As per the studies by26 and27, the enhancement of soft clay’s shear strength relies upon the area replacement ratio and the penetrating proportion when paired with either SDC or sand columns.

The effect of volume replacement ratio

The results illustrated demonstrate an increased undrained shear strength in a relationship with the volume ratio (Vc/Vs). The table presents data that demonstrates an increase in the undrained shear strength of the kaolin sample following the installation of the polypropylene column. The undrained shear strength indicated substantial improvements of 44.95%, 51.94%, and 40.90% for specimens with a single column diameter of 10 mm and heights of 60 mm, 80 mm, and 100 mm, respectively. Similarly, samples with a single column diameter of 16 mm had comparable percentage increases of 51.75%, 74.50%, and 49.20%. However, the advancement became more apparent as the volume replacement ratio increased.

The results presented in Table 3 indicate that the presence of the polypropylene column leads to a significant enhancement in the undrained shear strength of the kaolin specimen. The undrained shear strength of the samples increased by 48.50%, 68.50%, and 43.50% for samples with group column diameters of 10 mm and heights of 60 mm, 80 mm, and 100 mm, respectively. Conversely, samples with group column diameters of 16 mm had comparatively lower improvements of 18.00%, 22.20%, and 17.00%. However, as the volume replacement ratio was raised, there was a corresponding increase in the level of improvement observed. Figure 6 shows a graph of the volume penetration ratio vs. the rise in shear strength. The column with a diameter of 16 mm showed the highest improvement percentage, reaching 74.50%. In comparison, the group of columns with a diameter of 10 mm had a slightly lower improvement percentage of 68.50%.

28proposed that the enhancement in undrained shear strength could rely upon this column volume penetration ratio as well as the volume proportion (Vc/Vs). In their study of this relationship29, suggested critical column length, above which the columns is unlikely to have any favorable impacts upon efficiency gains.

Morphological properties

The Field Emission Scanning Electron Microscope (FESEM) images demonstrated the texture, roughness, and topology of the polypropylene (Figs. 7 and 8). During the initial investigation, it was seen that the polypropylene particles within the pellets exhibited both cylindrical and spherical shapes, characterized by smooth surface textures. In regions where the pellets had been through the cutting process, it was observed that the texture tended to be comparatively rougher. Referring to Fig. 7 (A, B, C), three specific areas were marked to show the difference between the cutting areas, and referring to Fig. 8, three areas were marked areas as D, E and F to differentiate between the process areas. The experimental findings indicated that the cutting area exhibited a higher degree of surface roughness compared to the normal surface area of the polypropylene particle.

The variability of testing findings between polypropylene columns may be attributed to the smoothness and lack of voids observed on the particle surfaces. The polypropylene pellets were rigid enough to withstand its shape after compaction. As a result, even under compression, the stacking of polypropylene particles formed more voids inside the column, leading to more space. Subsequently, these spaces aided in speeding up the release of extra pore water pressure from the samples. Thus, by reducing the consolidation time, the process progress accelerated faster.

The increased polypropylene content of the stabilised tertiary clay caused microstructural development in the stabilised soil. The micrograph reveals an entirely novel mineral crystal formation within the pore spaces, believed to be the result of a pozzolanic reaction. The addition of polypropylene to soft kaolin clay led to a decrease in the coefficient of permeability compared to the coefficient of permeability of soft kaolin clay itself. The soft kaolin clay and the stabilised mixtures showed an impervious degree of permeability and generally corresponded to clay soil, indicating a poor drainage characteristic. Based on the results, it can be concluded that polypropylene was an effective stabiliser for improving the geotechnical properties of clayey soil samples to be suitable for engineering projects.

The interlocking mechanism arises from the arrangement of the polypropylene granules within the polymer matrix. During the processing of the composite material, the polypropylene granules are dispersed and distributed evenly within the polymer matrix. As the polymer matrix solidifies, the granules become embedded within it, forming a network of reinforcing columns. These columns act as barriers against external forces, effectively increasing the material’s resistance to deformation and improving its overall strength. As a result, the composite material exhibits improved mechanical properties such as higher tensile strength, modulus, and impact resistance.

Conclusions

The major focus of this study is to check out whether there is any improvement on the undrained shear strength of soft kaolin soil after reinforced with polypropylene column with two different column diameters and different length of penetration. Based on laboratory test results analysis, the following conclusions can be made:

-

The plasticity chart indicates that kaolin has an LL of 36.60% and PI of 11.50%, which may be classed as low plasticity silt, organic silt of medium compressibility, or organic silt (ML). Furthermore, based on the AASHTO table, kaolin was classified under Group A-6. With a specific gravity of 2.63, kaolin was found to be within the range of inorganic silt. Additionally, the standard compaction test produced maximum dry density and optimum moisture content values of 1.63 gm/cm3 and 20%, respectively.

-

The plasticity chart classifies polypropylene into three groups: well-graded gravels (SW), little or no fines, and gravel-sand mixtures. Furthermore, according to the AASHTO chart, polypropylene was classified under Group A-1-a. Furthermore, utilising a vibratory table, the maximum density of polypropylene at 100% and 0% compaction was found to be 0.74 gm/cm3 and 0.57 g/cm3, respectively.

-

The shear strength of both single and group polypropylene columns was improved by implementing an unconfined compression test, resulting in an improvement in shear strength by area replacement ratio. The polypropylene column with maximum shear strength at an 80 mm column height and an area replacement ratio (Ac/As) of 10.24% could also improve the shear strength. The shear strength improvements by height penetration ratio were observed with a 16 mm penetrating single column with Hc/Hs = 0.8. The undrained shear strength showed the highest increments at an area replacement ratio of 10.24% when it reached a value of five times the diameter of the column (5Dc). The observed increases in strength for single columns were found to be larger compared to those for group columns.

-

The undrained shear strength improved in relation to the volume replacement ratio (Vc/Vs). The insertion of the polypropylene column increased the undrained shear strength of the kaolin specimen. Shear strength was improved by 74.50% in samples that were 80 mm high and had a single column diameter of 16 mm. But as the volume replacement ratio approached nearer to 0.082, shear strength increased.

Polypropylene is an urgent need to identify building materials that can replace sand in light of the worldwide push towards sustainable development goals and low-carbon emissions. In tropical areas, foundation pit engineering produces engineering muck (EM), which is rich in clay minerals and can be used to prepare low-carbon geotechnical materials. Eco-friendly recycling of engineering muck for the creation of low-carbon geopolymers assessed by life cycle assessment should include the required life cycle assessment comparisons, as well as an investigation into how synthesis conditions affect performance and the use of polypropylene (PP) columns for reinforcement. According to this study, converting electromagnetic fields into geopolymers using alkaline activation technology may be a viable alternative to foundations, offering a novel green material for geotechnical engineering.

Data availability

The data related to this study is not accessible in any public repository; however, it will be supplied upon request.

References

Michael, F. et al. Geotechnical characteristics and management of clay soil for enhanced road construction. Jurnal Mekintek. 15, 58–66 (2024).

Khajeh, A., Nazari, Z., Movahedrad, M. & Vakili, A. H. A state-of-the-art review on the application of lignosulfonate as a green alternative in soil stabilization. Sci. Total Environ. 943, 173500 (2024).

Mohamad, N. O. et al. Challenges in construction over soft soil-case studies in Malaysia. in IOP conference series: materials science and engineering vol. 136 12002 (2016).

Ismail, N. & Ani, F. N. Solid waste management and treatment in Malaysia. Appl. Mech. Mater. 699, 969–974 (2015).

Salah, M., Elbeltagi, E., Almoshaogeh, M., Alharbi, F. & Elnabwy, M. T. Identifying root causes and sustainable solutions for reducing construction waste using social network analysis. Sustainability 17, 7638 (2025).

Hoque, M. I., Hasan, M. & Datta, S. D. Undrained shear strength of soft clay reinforced with encapsulated stone dust columns. International J. Building Pathol. Adaptation (2024).

Zaini, M. S. I., Hasan, M. & Almuaythir, S. Experimental study on the use of polyoxymethylene plastic waste as a granular column to improve the strength of soft clay soil. Sci. Rep. 14, 22558 (2024).

Hoque, M. I., Hasan, M. & Datta, S. D. Effect of waste plastic strip on the shear strength and permeability characteristics of black cotton soil. J. Appl. Sci. Eng. 27, 2019–2028 (2023).

Hoque, M. I., Hasan, M. & Mim, N. J. Shear strength of soft clay reinforced with single encased stone dust columns. Jurnal Teknologi. 85, 27–34 (2023).

Hasan, M. & Samadhiya, N. K. Experimental and numerical analysis of geosynthetic-reinforced floating granular piles in soft clays. Int. J. Geosynthetics Ground Eng. 2, 1–13 (2016).

Yuan, B. et al. Optimized reinforcement of granite residual soil using a cement and alkaline solution: A coupling effect. J. Rock Mech. Geotech. Eng. 17, 509–523 (2025).

Yuan, B. et al. Eco-efficient recycling of engineering muck for manufacturing low-carbon geopolymers assessed through LCA: exploring the impact of synthesis conditions on performance. Acta Geotech. https://doi.org/10.1007/s11440-024-02395-9 (2024).

Srijan, S. & Gupta, A. K. Vertically and horizontally reinforced End-Bearing stone column: an experimental and numerical investigation. Appl. Sci. 13, 11016 (2023).

Abdelhamid, M., Ali, N. & Abdelaziz, T. A. Literature review of factors affecting the behavior of encased stone columns. Geotech. Geol. Eng. 41, 3253–3288 (2023).

Tsige, D., Korita, M. & Beyene, A. Deformation analysis of cement modified soft clay soil using finite element method (FEM). Heliyon 8, e09613 (2022).

Mirzababaei, M., Arulrajah, A., Haque, A., Nimbalkar, S. & Mohajerani, A. Effect of fiber reinforcement on shear strength and void ratio of soft clay. Geosynthetics Int. 25, 471–480 (2018).

Choudhury, D., Reang, R. & Paul, S. An experimental study to determine the best aggregate mix for stone columns. in 125–134 (2023). https://doi.org/10.1007/978-981-19-6727-6_12

Saberian, M. et al. Mechanical properties of polypropylene fibre reinforced recycled concrete aggregate for sustainable road base and subbase applications. Constr. Build. Mater. 405, 133352 (2023).

Wang, H., Ni, W. & Yuan, K. Improvement of strength and impermeability of fiber-reinforced loess by bentonite and polypropylene fibers: a response surface analysis. Environ. Earth Sci. 82, 252 (2023).

Hoque, M. I., Hasan, M. & Khondoker, M. T. H. Laboratory tests based strength evaluation of alluvial soil: a case study. J. Adv. Geotech. Eng. 6, 46–63 (2023).

Najamuddin, M., Madhav, M. R. & Padmavathi, V. Estimation of modular ratio and modulus of deformation of granular piles from in situ compression tests under direct loading. in 463–472 (2023). https://doi.org/10.1007/978-3-031-20172-1_45

Head, K. H. Manual of Soil Laboratory Testing (Volume 1 Soil Classification. (1982).

Almuaythir, S., Zaini, M. S. I., Hasan, M. & Hoque, M. I. Sustainable soil stabilization using industrial waste ash: enhancing expansive clay properties. Heliyon 10, e39124 (2024).

Maakaroun, T., Najjar, S. S. & Sadek, S. Effect of Sand Columns on the Load Response of Soft Clays. in Contemporary Topics in Ground Modification, Problem Soils, and Geo-Support 217–224American Society of Civil Engineers, Reston, VA, (2009). https://doi.org/10.1061/41023(337)28

Najjar, S. S., Sadek, S. & Maakaroun, T. Effect of sand columns on the undrained load response of soft clays. J. Geotech. GeoEnviron. Eng. 136, 1263–1277 (2010).

Hasan, M., Yee, K. H., Pahrol, M. F. H. A. J. & Hyodo, M. Shear strength of soft clay reinforced with encased lime bottom Ash column (ELBAC). Int. J. GEOMATE. 16, 62–66 (2019).

Almuaythir, S., Zaini, M. S. I., Hasan, M. & Hoque, M. I. Stabilization of expansive clay soil using shells based agricultural waste Ash. Sci. Rep. 15, 10186 (2025).

Najjar, S. S. A State-of-the-Art review of Stone/Sand-Column reinforced clay systems. Geotech. Geol. Eng. 31, 355–386 (2013).

Hoque, M. I. et al. Machine learning methods to predict and analyse unconfined compressive strength of stabilised soft soil with polypropylene columns. Cogent Engineering 10, (2023).

Acknowledgements

The authors would like to acknowledge the Universiti Malaysia Pahang Al-Sultan Abdullah for financing this research through the UMPSA International Matching Grant Scheme, Project Number RDU 252702. We also extend our gratitude to Hokoku Engineering Ltd. (Japan) for funding this research under the International Grant Scheme, specifically Project Number UIC251503. We greatly acknowledge the cooperation from all parties involved in this research.

Funding

This research did not receive any specific funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hoque, M.I., Hasan, M., Zaini, M.S.I. et al. Analyzing the shear strength of Kaolin clay stabilized with polypropylene columns. Sci Rep 16, 611 (2026). https://doi.org/10.1038/s41598-025-30118-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-30118-x