Abstract

This study introduces an innovative multi-objective optimization method based on sequential approximation optimization (SAO) and radial basis function (RBF) networks to enhance the injection molding process for liquid silicone optical lenses. The method successfully minimizes residual stress and volume shrinkage, thereby improving product quality and manufacturing efficiency. By replacing finite element reanalysis with the RBF network, it constructs an approximate functional relationship between process conditions and quality. The novelty lies in simplifying multi-objective optimization into a single-objective problem and utilizing Pareto boundary analysis for precise parameter tuning. This approach not only reduces trial-and-error costs and material waste but also significantly decreases carbon emissions, showcasing extensive potential for application in various manufacturing processes. Simulations varying key parameters—filling time, melt temperature, mold temperature, curing pressure, and curing time—revealed optimal conditions: filling time of 1.57s, melt temperature of 27.18 °C, mold temperature of 150 °C, curing time of 20.02s, and curing pressure of 28.79 MPa. Experiments were conducted to validate the numerical results, employing nondestructive testing methods to assess residual stress and volume shrinkage. The results demonstrated significant reductions in these values, affirming the method’s reliability and practicality. This innovative and efficient optimization approach provides a robust solution for enhancing injection molding processes while contributing to sustainability and cost efficiency.

Similar content being viewed by others

Introduction

High brightness LEDs of the most recent generation can reach extremely high temperatures, which can put pressure on traditional polymers like PMMI, PMMA, and PC. Over a temperature range of -40 °C to 200 °C, silicones provide great temperature resistance, strong resistance to heat aging and high chemical resistance, purity, transparency, and stable mechanical qualities. Silicones significantly lessen the yellowing effect, making them perfect for usage in outdoor or severe environments. The silicone material for silicone lenses is a highly transparent two-component liquid silicone rubber with excellent injection molding process characteristics: providing fast cure, low viscosity, and high flow. These properties significantly increase productivity by reducing injection time and total cycle time. No additional protection is required, such as in the case of light poles or high grids, and no gaskets for IP insulation are required: no yellowing or heat shrinkage cracking in UV or high and low temperature environments, specifically for street, high pole, and high grill lighting applications. As an isotropic material, silicone offers a high degree of flexibility for silicone lenses that can easily fit into any hazardous and harsh environment. Due to its elastomeric nature, silicone offers ideal compensation for mechanical tolerances in construction, thereby contributing to a precise fit in the final application by virtue of its exceptional functionality.

Given its high productivity, cost-effectiveness, lightweight properties, and superior ability to accommodate intricate geometries, the manufacturing process that involves injecting plastic into molds has become an essential method for producing plastic items. The six-stage process involving clamping, filling, packing, cooling, opening, and ejection constitutes a critical cycle in the production of high-quality plastic components, with each stage contributing significantly to achieving the desired outcome. The material, component and mold design, as well as the manufacturing process factors, all affect the quality of plastic injection molded parts1. Product flaws like warpage, shrinkage, sink marks, and residual strains are caused by a range of production-related causes. Hence, a lot of study has been undertaken on the best design of plastic injection molding process parameters.

Literature and review

Given the significant attention this longstanding issue has garnered from researchers, recent years have seen a proliferation of advanced optimization theories and sophisticated techniques in design aimed at addressing the problem through enhanced understanding and resolution2. The conventional continuous modal testing methods have been replaced by CAE simulation approaches3. Integrating it with the idea of optimization design and using it to optimize the conditions of the injection molding process enhances the quality of the plastic parts while also speeding up the molding process4. R. Joseph Bensingh et al.5 investigated the effects of injection molding process parameters such as mold surface temperature, melt temperature, injection time, filling volume percentage V/P switching, filling pressure, and filling time on the volume shrinkage deformation of double aspheric lenses. The scientists used a mixture of computer numerical simulation and optimization approaches to determine the ideal molding parameters that resulted in the least variance of volume shrinkage deformation. Kuo-Ming Tsai et al. developed a lens shape accuracy prediction model using the artificial neural network (ANN) and response surface method in another study (RSM). Following experimental validation and accuracy comparison, the results showed that the injection molding process window obtained using the ANN for determining the cooling time and filling time had a high-order irregular shape, whereas the injection molding process window obtained using the RSM had an oblique ellipse shape. Furthermore, the findings demonstrated that the ANN model outperformed the RSM model in terms of lens shape accuracy6.

Currently, the industry mainly relies on the technical experience of designers to find a better solution to the quality problems of plastic products during the injection molding process by repeatedly testing and repairing the mold, and repeatedly adjusting the parameters of the injection molding process, but these methods not only increase the design cost and prolong the production cycle, but also make it difficult to obtain the best design results. Therefore, the optimization of injection molding process parameters plays a crucial role in the quality of products.

A approach to examine the impact of cavity pressure distribution on part quality using a neural network was put forth by Jinsu Gim et al. in 20217. The relationship between the mold internal pressure and the weight of the workpiece was determined by evaluating the mold internal pressure profile, and the fluctuation rule of the mold internal pressure was transformed into the quality index of the mold. The influence degree of each element on the injection process may be clarified by the analysis of numerous factors, and the injection process can be optimized in accordance with the influence degree of each component on the injection process. In 2020, Ming-Shyan Huang and colleagues8 proposed a unique method for predicting the geometry of manufactured parts using a multilayer perceptron (MLP) neural network model with quality indicators. Four factors were used as inputs to the model: the first-stage pressure retention index, pressure integral index, residual pressure drop index, and peak pressure index. Meanwhile, the output of the model was the geometry of the portion in question. The MLP model was trained and used to aid in learning and prediction. The MLP model correctly predicted the geometric width of the pieces, with over 92% accuracy in both training and testing outcomes. As a result, this technology has been demonstrated to be very successful and reliable, showing the potential for wider adoption in the manufacturing business. In 2022, Han-Jui Chang et al.9 used a non-explicit genetic algorithm with kriging response surface analysis to optimize the multi-objective design of UAV shells, considering various process parameters as model variables. After obtaining the warpage value, die stamping index, and mathematical relationship, a multi-objective genetic algorithm optimization program is employed to replace the experimental analysis. The model was optimized using the approach, and the model was then tested. The four critical points and mold index had a clear optimization effect, and the error was just 8.48%, which was within the acceptable range for production. Han-Jui Chang10 made the suggestion in 2021 that highlighting the product qualities is beneficial in the assessment of identifiability. However it is difficult to establish the reference value due to the influence of many causes, suggesting that one variable can be the dependent variable that is most affected. The information provided gives us a starting point for talking about how these phenomena occur. To create an independent injection molding quality control system that can be recognized and assessed, a novel technique for defect knowledge re-study and virtual measurement-based implementation is also suggested. Machines can now gather and store data throughout the production cycle in the era of information and technology, and with the help of big data management, this data can be processed to create efficient troubleshooting techniques.

In conclusion, a number of researchers have automated and intelligently predicted the quality of injection molded parts using artificial intelligence techniques11. The link between the process parameters and the molding quality objective is intricate, time-varying, nonlinear, and tightly connected12. Thus, identifying an acceptable set of optimal process parameters is very challenging. According to the conventional approach to optimization, the injection molded continually modifies the process settings in light of experience to find the ideal set of parameters. However, because the conventional approach is unable to produce the global ideal parameters, the test time, cost, and raw material waste are all significantly increased13,14. Hence, for high-precision and high-efficiency manufacturing, it is crucial to swiftly identify the ideal process parameters for microinjection molding on a scientific foundation. Advances in software computing have enabled more efficient determination of process parameters in recent years through the use of numerous methodologies such as evolutionary algorithms, fuzzy systems, expert systems, and artificial neural networks. Process parameter optimization can be divided into two categories: static process parameter optimization and dynamic optimization based on knowledge or previous cases. The former category uses an agent model to get globally optimal results, whereas the latter achieves optimization results gradually through interactions. The majority of research in this area has been on static process parameter optimization utilizing current methodologies, which typically entail three steps: collecting background data through experimental design, building an agent model, and using optimization algorithms. Other models for modeling the link between process parameters and quality indicators include response surface methodology (RSM)15, kriging, artificial neural network (ANN)16, and support vector regression (SVR). Jian Zhao et al.17 tackled the multi-objective optimization problem of injection molding plastic part quality by using a two-stage approach that combined an efficient global optimization algorithm and a genetic algorithm. For example, Gang Xu et al.18 proposed a comprehensive approach that integrated multiple optimization methods to achieve excellent performance. Both approaches demonstrated effective solutions in terms of quality and efficiency.

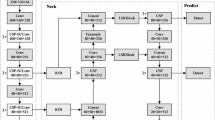

With the continuous development and popularity of computer-aided engineering, more and more fitting methods are being applied to optimization systems in various fields. These systems can be used to analyze and optimize various processes by building mathematical models to improve the quality and efficiency of products. Among the fitting methods, RBF neural networks are a commonly used method with the advantages of fast convergence and the ability to handle high-dimensional data. In addition, optimization systems based on fitting methods also include methods based on response surface methods and genetic algorithms. These methods can be applied in different scenarios, such as optimization of process parameters, design optimization, product performance prediction, etc. With these optimization systems, we can better understand and control complex processes and provide effective support for improving product quality and efficiency. Researchers examined the Kriging method19, radial basis function neural networks20, and sequential approximation optimization (SAO)21,22 to create high precision response surfaces and identify the global optimal solution. Satoshi Kitayama et al., for example, optimized plastic injection molding process parameters and holding pressure distribution using radial basis function neural networks and sequential approximation optimization (SAO) to reduce warpage and cycle time. Numerical studies and experimental findings confirmed the usefulness of this strategy in reducing warpage and cycle time. Gao and Wang constructed the approximation function of warpage versus process parameters using Kriging approach. Then, SAO was used to minimize warpage in the cell phone casing. However, the various parameters involved in the injection molding process are interdependent. An increase in melt temperature can result in a reduction in viscosity and shear stress, but a longer cooling time may also be required. Higher injection pressure and shorter injection time may decrease temperature differentials between different production areas but may also increase the temperature at the flow front. An increase in holding time can lead to a reduction in sink marks, but an increase in flash points. As the number of factors considered increases, so does the number of optimization targets. Therefore, multi-objective optimization is employed to balance these conflicting parameters. This study aims to perform multi-objective optimization of the holding curve and process parameters in order to minimize residual stress and volume shrinkage. This research focuses on a complete optimization technique for determining the best process parameters for minimizing residual stress and shrinkage. It is roughly separated into the following aspects, as indicated in Fig. 1: (1) carrying out experiments on residual stress and volume shrinkage in the lens molding process; (2) developing an RBF neural network model; (3) the effect of process parameters on molding quality; and (4) multi-objective optimization of minimum residual stress and minimum volume shrinkage and experimental verification.

Material and methodology

Liquid Silicone Rubber

Due to its high clarity and refractive index, LSR materials are well suited for optical applications such as LED lighting, camera lenses, and automotive headlight lenses. In addition, the excellent rheological properties and low viscosity of LSR materials make them suitable to produce high-precision, complex-shaped lenses through injection molding. The advantages of LSR materials over traditional glass or plastic lenses are their light weight, high strength and excellent optical properties that provide higher light transmission and better dispersion characteristics, resulting in improved quality and efficiency of optical components. the benefits of LSR materials include high precision, durability, biocompatibility and high productivity, making them suitable for a wide range of applications such as medical devices, prosthetics and other products requiring high precision and durability.

In this experiment, the LSR material with the model number of LSR-1 from the manufacturer CAE is used. Generally, the volume of LSR changes significantly with pressure and temperature. To calculate the shrinkage or warpage of the lens after vulcanization, it is necessary to describe the pressure-volume-temperature (PVT) relationship, as shown in Fig. 2. Viscosity is an indicator of LSR to flow resistance and depends on temperature, shear rate and pressure, as shown in Fig. 3.

In a complete injection molding cycle, it generally goes through the stages of melt-fill-recharge-shrink-pressure-hold-cooling-eject. As we all know, the filling stage of injection molding, VP switching point and pressure-holding process must be accurately controlled to get high quality and high precision products.

To avoid premature solidification of the material during the filling process, the filling rate of the plastic must be controlled. Likewise, the pressure applied to the material during the holding phase must be controlled to compensate for the shrinkage that occurs during cooling and to avoid material spillage. To ensure high quality, accuracy and repeatability in weight and dimensions of the molded product, the optimal pressure profile during the holding phase should be the one that varies isotropically during the cooling of the material.

During the injection molding process, the polymer material is heated into the molten state and injected into the mold cavity under high pressure, undergoing a process from high temperature and high pressure to rapid cooling and pressure drop, followed by a change from the molten state to the solid state, while the various physical parameters of the polymer material undergo a series of drastic changes, all of which are highly dependent on T, P and V. In particular, the V of the polymer determines the final weight and size of the product. The final molded product’s performance and quality are specifically determined by the polymer’s V: if the density is too low, it will result in insufficient strength; if the density is not uniform, it will produce internal residual stresses, causing warpage and deformation, etc.

Sequential approximation optimization

Sequential Approximation Optimization (SAO) is an optimization method usually used to solve complex multivariate optimization problems. SAO continuously optimizes the objective function to find the optimal solution through repeated iterations and stepwise approximation. This method has a wide range of applications in many fields, including engineering, machine learning, and optimization algorithms. In SAO, the value of the objective function is usually calculated based on the current parameter configuration, and the parameters are adjusted according to the calculation results. This process is repeated until a set termination condition is reached or converges to some local optimal solution. The core idea of SAO is to approximate the global optimal solution through repeated approximate optimization. This step-by-step optimization approach makes SAO robust and reliable in dealing with complex optimization problems. Overall, Sequential Approximation Optimization (SAO) is a commonly used optimization method for solving various complex multivariate optimization problems.

The schematic representation of the sequential steps involved in the implementation of the SAO optimization method is visually depicted in Fig. 4, showcasing the systematic flow and intricate details of this approach.

(Step 1) Initialize with number of sequences = 1.

(Step 2) Confirm the optimization objective, constraints, and design variable ranges.

(Step 3) A Latin hypercube design (LHD) is used to generate some initial sampling points.

(Step 4) Perform numerical simulation using Moldex3D software to numerically calculate the objective function for the sampling points.

(Step 5) Approximate all the functions as RBF networks. Here, the approximated objective function is expressed as

(Step 6) If convergence is satisfied, terminate the SAO algorithm and output the result. Otherwise, the number of sequences is added by one and the Pareto optimal solution will be added as a new sampling point and return to step 3.

Radial basis function neural network

Owing to their outstanding performance, RBF (Radial Basis Function) neural networks have been extensively employed in a diverse range of fields, including but not limited to pattern recognition, function approximation, system identification, and control. One of the major advantages of RBF neural networks is their fast-learning speed, which is achieved through a simple structure that requires fewer iterations to converge than other types of neural networks. Another advantage of RBF neural networks is their excellent approximation performance, which enables them to approximate complex functions with high accuracy. In addition, RBF neural networks have good generalization ability, which allows them to perform well on new, unseen data. A radial basis function is utilized in the hidden layer of RBF neural networks to transfer the input space into a higher dimensional space where linear separation is achievable. This enables the network to record nonlinear interactions between inputs and outputs, which is frequently required for difficult problem solving. The Gaussian function, which has a bell-shaped curve and is defined by a center and a width parameter, is the most often used radial basis function. Overall, the RBF neural network is an useful tool for handling difficult problems with nonlinear input-output relationships. Its straightforward structure, quick learning speed, high approximation performance, and generalization capabilities make it a popular choice for a wide range of applications in industry and academics. The topology of a radial-basis neural network with numerous inputs and multiple outputs is depicted in Fig. 5 below.

The complete interpolation method requires the interpolation function to pass through each sample point, i.e., \(\:F\left({X}^{n}\right)={d}^{n}\). There is a total of k sample points.

The RBF method is to choose k basis functions, each corresponding to a training data, each of which is of the form \(\:\phi\:(\parallel\:X-{X}^{k}\parallel\:)\), which is called radial basis function since the distance is radially homogeneous. \(\:\parallel\:X-{X}^{k}\parallel\:\) denotes the modulus of the difference vector, or called the 2-parametric number.

The interpolation function based on the radial basis function is

The following Gaussian kernel is generally used as the basis function: \(\:hi\left(x\right)=\text{e}\text{x}\text{p}(-\frac{{\left(x-xi\right)}^{T}(x-xi)}{{r}^{2}j})\)

where xi is the i-th sampling point and ri is the width of the i-th basis function. The response yi is computed at the sampling point xi. The learning of RBF networks is usually done by solving.

In Fig. 6, the horizontal coordinate is the design variable dimension, and the vertical coordinate is the solution vector dimension. For each design variable, the high precision numerical solution corresponds to a unique solution vector, as shown by the solid line in the figure. At each time when a new design variable *X needs to be calculated, the data of certain sample points, as shown by the solid dots in the figure, have been obtained in the previous period. Based on these sample points, the variation of the solution vector with the design variables can be predicted by approximate modeling, and the next sample point is sampled based on this prediction, as shown by the star-shaped point in the figure. The results in Fig. 6 demonstrate that, when the iteration format is left unchanged and the optimization is carried out, the distance between the predicted value and the converged value is significantly smaller than the distance between the initial value and the converged value, indicating that using the approximate model acceleration significantly decreases the total amount of iterative steps of the high-precision simulation.

Case study

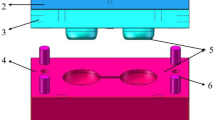

A company’s selection of liquid silicone lenses for a car lamp is shown in Fig. 7. The object has a maximum flesh thickness of approximately 22.483 mm, a minimum flesh thickness of approximately 0.101 mm, and a volume of approximately 53,972.35 mm3. We model it using modeling software, and the model that is created will be used in the test’s mold flow analysis.

The essential parameters linked to injection molding allows users to set in this inquiry are shown in Table 1. Based on the literature analysis, five process factors were chosen and experimentally analyzed: melt temperature (°C), mold temperature (°C), filling time (s), maturation time (s), and maturation pressure (MPa), all of which are substantially connected with the density of residual stress values.

Among them, the residual stress detection methods for injection molded parts can be basically categorized as lossy testing and nondestructive testing. The principle of lossy testing is to destroy the original structure of the product, break the original stress equilibrium state to make the product appear deformation or appearance changes, so as to calculate the size and distribution of residual stress. The common methods of lossy stress detection include drilling, layer peeling, solvent method, etc. Non-destructive testing is the use of instrumentation to detect changes in the physical properties of the product due to the presence of stress, and thus calculate the stress distribution. The common polarized stress test is one in which, according to the law of stress optics, the refractive index of a transparent plastic material changes when the material is subjected to stress. This is reflected under the stress polarization equipment by the color distribution presented on the product. Through the color distribution state, it is possible to simply observe the residual stress distribution on the product. It is characterized by a simple method, easy operation and inexpensive equipment, and is a widely used nondestructive stress detection method. The disadvantage is that the results are generally measured qualitatively and cannot be calibrated in quantitative terms.

Table 2 demonstrates the injection molding experimental data, i.e., the effect of variations of five factors on residual stress and volume shrinkage. These data contain a large amount of feature and label information that can be used to train and validate the performance of the model. The data need to be pre-processed and cleaned to ensure the accuracy and consistency of the data before proceeding to modeling, and finally they will be used for the building of RBF networks for LSR lens injection molding. The pre-processed and cleaned data will serve as the foundation for constructing RBF networks for LSR lens injection molding, which constitutes a crucial step in our experimental process.

A multilayer radial basis neural network with three network topologies (i.e., input, hidden, and output) was used to map the injection molding process of liquid silicone rubber lenses. The mapping process was performed using MATLAB 2020 software and a neural network toolbox. The hidden layer neurons use Gaussian activation functions, while the output layer neurons use pure linear functions.

The input layer of the neural network consists of five neurons corresponding to the number of independent variables, while the output layer has two neurons matching the number of dependent variables. Figure 8 shows the multilayer LSR neural network developed in the MATLAB 2020 environment, which was used to predict process parameters and evaluate the quality of the molded LSR lenses.

Result and discussion

The energy used in mass production cannot be overlooked, despite the fact that the cost of energy consumption during injection molding is very modest. Up to 30 billion kWh of energy are used annually by the global injection molding industry, which accounts for 10% of all energy used globally and generates a significant amount of carbon emissions. Thus, it is essential to maximize energy efficiency to ensure product quality. The main piece of machinery used in the injection molding process is the injection molding machine. Using high-tech tools like servo motors with high precision and energy-efficient injection molding machines can drastically save energy usage. Using low-energy LSR materials can also significantly reduce the amount of energy needed to heat plastic in the injection molding machine, leading to a more environmentally friendly and energy-efficient manufacturing process. Consequently, it is possible to increase energy efficiency and reduce emissions in the injection molding process while maintaining the quality of the final product by upgrading equipment and employing high-quality materials.

When a substance undergoes cooling from a state of high temperature and high pressure to a state of low temperature and low pressure, its volume changes. This change is known as volume shrinkage, which is defined as the percentage difference in volume before and after cooling. Volume shrinkage is positive when the substance undergoes a reduction in volume and negative when the substance expands due to excessive holding pressure.

The shrinkage rate of the entire plastic part differs from that of its profile, leading to the formation of internal residual stresses that mimic the effects of external forces. The distribution of residual stress is closely related to the optical properties of the product, and the presence of residual stress can significantly impact its optical performance. Areas of the product with higher residual stress tend to exhibit poorer optical performance than areas with lower residual stress. If the volume shrinkage of a product is uneven, it can compromise not only the dimensional accuracy of the product but also indirectly impact its optical performance. This is due to the potential irregularities in the product’s shape caused by the uneven shrinkage, which may result in deviations on the surface of optical components and ultimately affect their optical performance.

LSR material is characterized by low shrinkage and warpage, which makes it an ideal material for applications where dimensional accuracy and optical performance are critical. The volume change of a product before and after V/P switching is a reliable indicator of the injection molding process’s carbon footprint. Failure to adjust the process parameters correctly can result in higher shrinkage and a subsequent increase in the carbon footprint of the product.

To gain a better understanding of the interaction between different factors, response surface plots were employed to visualize the effect of each factor on the residual stress in the plastic part. In this study, five influential factors were considered, including melt temperature, maturation pressure, maturation time, filling time, and mold temperature.

Figure 9 displays a 3D surface that demonstrates how different factors influence the residual stress in the plastic part. Figure 9(a) shows the interaction between melt temperature and maturation pressure on the residual stress values. The results reveal that the residual stress value of the lens is at its minimum at a melt temperature of 25–30 °C and a maturation pressure of approximately 40 MPa. Similarly, Fig. 9(b) illustrates the relationship between maturation time and maturation pressure on the residual stress values. The results demonstrate that the residual stress values decrease as the maturation time increases at a constant maturation pressure. Figure 9(c) shows the effect of filling time and maturation pressure on the residual stresses, where the effect of filling time is comparatively minor compared to the significant impact of maturation pressure on the residual stresses. Furthermore, Fig. 9(d) displays the response surface plots of filling time and maturation time on the residual stress values. The results show that the residual stress values of the lenses gradually decrease with increasing curing time. In Fig. 9(e), the interaction between melt temperature and maturation time on the residual stress values is demonstrated. The results indicate that the residual stress values of the lenses are at their minimum when the maturation time is 18–20 s, and the melt temperature is higher. Finally, Fig. 9(f) presents the effect of melt temperature and mold temperature on residual stresses. The results show that the lenses have the smallest residual stress values when the mold temperature is 150 °C and the melt temperature is approximately 30 °C. Overall, these response surface plots provide valuable insight into the effects of different factors on residual stress values in plastic parts.

To optimize these parameters and improve the efficiency and quality of injection molding, the optimal Latin hypercube sampling method was used to obtain samples in this study. We selected five input parameters as the input layer of the model, namely melt temperature, mold temperature, holding time, holding pressure and filling time, while a radial basis (RBF) neural network model was constructed with minimum volume shrinkage and minimum residual stress as the output layer. The model has strong nonlinear approximation capability and good accuracy and can effectively perform prediction and optimization with a large amount of data.

Through numerical calculations, we determined the Pareto boundary between residual stress and volume shrinkage to obtain the best combination of parameters. As shown in Fig. 10, we compared three different points on the Pareto boundary and found that point I had a larger value of residual stress and a smaller volume shrinkage, while point II had more average values of residual stress and volume shrinkage. The distribution of stress values at point III was improved and was similar to points I and II. By analyzing the results in Table 3, we conclude that by constructing the RBF neural network model, the best combination of parameters can be obtained, thus reducing the cost of production trial and error and saving production time and material.

It is important to note that there must be some trade-offs between the optimization objectives. In practice, optimizing one objective may lead to the sacrifice of another, so the best balance needs to be found. In injection molding, the balance between the two objectives, minimum residual stress and minimum volume shrinkage, requires careful trade-offs and considerations. In actual production, choosing the best injection molding parameters can not only improve production efficiency and quality, but also significantly reduce production costs.

Conclusion

-

A.

Multi-objective Optimization and Experimental Validation: This study successfully reduced residual stress and density through multi-objective optimization of the ripening pressure distribution and process parameters. The optimization of the ripening pressure distribution was adjusted during the ripening stage as needed, while melt temperature, injection time, holding pressure, and holding time were used as optimization parameters. Due to the high computational intensity of PIM numerical simulations, a sequential approximation optimization method based on radial basis functions was adopted. Numerical calculations determined the Pareto boundary between residual stress and density, and the results were validated through experiments, showing a high degree of consistency between experimental and numerical results. However, critically, the consistency between numerical calculations and experimental results does not necessarily imply the universality of the method. For instance, the book Statistical and Computational Techniques in Manufacturing (Springer)23 highlights that data applicability and assumptions of simulation models can affect result accuracy. Therefore, future research needs to further evaluate the applicability of simulation models under different materials and process conditions.

-

B.

Advantages of the Sequential Approximation Optimization Method: This study demonstrated the numerous advantages of the sequential approximation optimization method in optimizing injection molding process parameters. The method can efficiently and quickly find the optimal solution, reduce the number of trials, and simultaneously optimize multiple parameters, significantly lowering costs and time. However, the book Computational Methods and Production Engineering (Elsevier)24 emphasizes that the computational cost of such optimization methods may grow non-linearly with problem complexity, and there could be limitations in interpreting non-linear phenomena. Hence, in practical applications, the balance between computational load and accuracy needs to be considered.

-

C.

Improved Method Based on RBF Neural Networks: This study proposed a novel optimization method that combines sequential approximation optimization with multi-objective optimization, simplifying the original multi-objective optimization problem into a single-objective optimization problem, thereby greatly enhancing optimization efficiency. Experimental results show that this method effectively reduces the residual stress (by 27.4%) and volume shrinkage rate (by 10.3%) of plastic parts while shortening the time required for process parameter optimization. However, according to the book Industrial Optimization (Springer)25, such methods may face overfitting risks, especially when sample data are insufficient or the number of parameters is excessive. Future research should consider introducing more comprehensive validation mechanisms to mitigate overfitting risks.

-

D.

Broad Application Prospects of the Method: The proposed optimization method not only holds potential applications in plastic injection molding but can also be extended to other manufacturing fields to optimize complex systems and processes. However, the article Sustainable and Smart Manufacturing: Perspectives in Line with the 2030 Agenda for Sustainable Development (Bioresources, 2024)26 emphasizes that sustainability should become a core consideration in future manufacturing process optimizations. Although this study focuses on improving product quality and production efficiency, it shows insufficient attention to sustainable manufacturing. Future research should integrate environmental impact assessments and include energy consumption and waste reduction in optimization objectives to better support the 2030 Sustainable Development Goals(Table 4).

The optimization method proposed in this study performs exceptionally well in enhancing the quality and production efficiency of plastic parts, providing a new technical tool for the manufacturing industry. However, drawing from the observations in the literature, issues such as model applicability, computational cost, overfitting risks, and sustainability require further exploration. Future studies should conduct extensive testing under various materials and process conditions and incorporate environmental sustainability into the optimization framework to achieve more comprehensive process improvements.

Data availability

Data Availability Statement: The authors declare that the data supporting the results of this study are available in the paper. If any raw data files in other formats are required, they can be obtained from the corresponding author upon reasonable request.

References

Chen, W. C., Nguyen, M. H., Chiu, W. H., Chen, T. N. & Tai, P. H. Optimization of the plastic injection molding process using the Taguchi method, RSM, and hybrid GA-PSO. Int. J. Adv. Manuf. Technol. 83 (9–12), 1873–1886 (2015).

Lin, W. C., Fan, F. Y., Huang, C. F., Shen, Y. K. & Wang, H. Analysis of the Warpage Phenomenon of Micro-sized Parts with Precision Injection Molding by Experiment, Numerical Simulation, and Grey Theory. Polym. (Basel) (2022). 14, (9).

Huang, C. T., Xu, R. T., Chen, P. H., Jong, W. R. & Chen, S. C. Investigation on the machine calibration effect on the optimization through design of experiments (DOE) in injection molding parts. Polym. Test. 90. (2020).

Huang, H. Y. et al. Optimal Processing Parameters of Transmission Parts of a Flapping-Wing Micro-Aerial Vehicle Using Precision Injection Molding. Polymers (Basel) 14, (7). (2022).

Bensingh, R. J., Boopathy, S. R. & Jebaraj, C. Minimization of variation in volumetric shrinkage and deflection on injection molding of bi-aspheric lens using numerical simulation. J. Mech. Sci. Technol. 30 (11), 5143–5152 (2016).

Tsai, K. M. & Luo, H. J. Comparison of injection molding process windows for plastic lens established by artificial neural network and response surface methodology. Int. J. Adv. Manuf. Technol. 77 (9–12), 1599–1611 (2014).

Gim, J. & Rhee, B. Novel Analysis Methodology of Cavity Pressure Profiles in Injection-Molding Processes Using Interpretation of Machine Learning Model. Polymers (Basel) 13, (19). (2021).

Ke, K. C. & Huang, M. S. Quality Prediction for Injection Molding by using a Multilayer Perceptron neural network. Polym. (Basel). 12, 8 (2020).

Chang, H., Zhang, G., Sun, Y. & Lu, S. Non-dominant genetic algorithm for multi-objective optimization design of unmanned aerial vehicle Shell process. Polym. (Basel). 14, 14 (2022).

Chang, H. J., Zhang, G. Y., Su, Z. M. & Mao, Z. F. Process prediction for compound screws by using virtual measurement and recognizable performance evaluation. Appl. Sci. 11, 4 (2021).

Chang, H., Su, Z., Lu, S. & Zhang, G. Intelligent Predicting of Product Quality of Injection Molding recycled materials based on Tie-Bar Elongation. Polym. (Basel) 14, (4). (2022).

Alvarado-Iniesta, A., Cuate, O. & Schütze, O. Multi-objective and many objective design of plastic injection molding process. Int. J. Adv. Manuf. Technol. 102 (9–12), 3165–3180 (2019).

Hriberšek, M. & Kulovec, S. Preliminary study of void influence on polyamide 66 spur gears durability. Journal of Polymer Research 29, (6). (2022).

Lee, J., Yang, D., Yoon, K. & Kim, J. Effects of Input Parameter Range on the Accuracy of Artificial neural network prediction for the injection molding process. Polym. (Basel) (2022). 14, (9).

Miza, A. T. N. A. et al. Optimization of warpage on plastic injection molding part using response surface methodology (RSM) and particle swarm optimization (PSO). AIP Conf. Proc. 2030(1), 020155. https://doi.org/10.1063/1.5066796 (2018).

Everett, S. E. & Dubay, R. A sub-space artificial neural network for mold cooling in injection molding. Expert Syst. Appl. 79, 358–371 (2017).

Zhao, J., Cheng, G., Ruan, S. & Li, Z. Multi-objective optimization design of injection molding process parameters based on the improved efficient global optimization algorithm and non-dominated sorting-based genetic algorithm. Int. J. Adv. Manuf. Technol. 78 (9–12), 1813–1826 (2015).

Xu, G. & Yang, Z. Multiobjective optimization of process parameters for plastic injection molding via soft computing and grey correlation analysis. Int. J. Adv. Manuf. Technol. 78 (1–4), 525–536 (2014).

Liu, J., Chen, X., Lin, Z. & Diao, S. Multiobjective Optimization of Injection Molding Process Parameters for the Precision Manufacturing of Plastic Optical Lens. Mathematical Problems in Engineering 2017, 1–13. (2017).

Kitayama, S., Yokoyama, M., Takano, M. & Aiba, S. Multi-objective optimization of variable packing pressure profile and process parameters in plastic injection molding for minimizing warpage and cycle time. Int. J. Adv. Manuf. Technol. 92 (9–12), 3991–3999 (2017).

Kitayama, S. et al. Multi-objective optimization for minimizing weldline and cycle time using variable injection velocity and variable pressure profile in plastic injection molding. Int. J. Adv. Manuf. Technol. 107 (7–8), 3351–3361 (2020).

Chang, H., Zhang, G., Sun, Y. & Lu, S. Using sequence-approximation optimization and radial-basis-function network for Brake-Pedal Multi-target Warping and cooling. Polym. (Basel). 14, 13 (2022).

Book Statistical and Computational Techniques in Manufacturing (Springer, 2012). https://link.springer.com/book/10.1007/9783-642-25859-6.

Book Optimization in Industry (Springer, 2019). https://link.springer.com/book/10.1007/978-3-030-01641-8.

Book Computational Methods and Production Engineering (Elsevier, 2017). https://www.sciencedirect.com/book/9780857094810/computational-methods-and-production-engineering

Article Sustainable and Intelligent Manufacturing: perceptions in line with 2030 agenda of Sustainable Development. Bio Resour. 19 (1), 4–5 (2024).

Acknowledgements

Acknowledgments: This research was funded by the 2023 Guangdong Science and Technology Program (2024A0505050013) and Technical Support by Xuying Biomedicine Co., Ltd., and Software Support by CoreTech System Co., Ltd., which are gratefully acknowledged.

Funding

This research was funded by the 2023 Guangdong Science and Technology Program (2024A0505050013).

Author information

Authors and Affiliations

Contributions

Conceptualization, H.C.; Data curation, Y.L.; Methodology, S.L.; Project administration, Y.S.; Writing—original draft, H. C.All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chang, H., Lu, S., Sun, Y. et al. Quality optimization of liquid silicon lenses based on sequential approximation optimization and radial basis function networks. Sci Rep 15, 4092 (2025). https://doi.org/10.1038/s41598-025-87753-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-87753-7

Keywords

This article is cited by

-

Optimizing EDM performance of aluminum matrix composites using a temporal inductive path neural network with starfish algorithm

International Journal of Mechanics and Materials in Design (2026)