Abstract

In response to emerging military tactics and technological advancements, this research investigates the ballistic and mechanical properties of cutting-edge defense-grade aluminum nickel phosphorus bronze (Al-NPB) metal matrix composites (MMCs), enhanced with 2, 4, and 6 weight percent titanium carbonitride (TiCN) coated yttrium oxide (Y₂O₃). The Y₂O₃ nanoparticles were initially synthesized through mechanical milling, followed by further milling with TiCN to produce TiCN + Y₂O₃ (TY) nanopowders, which were subsequently integrated into the Al-NPB matrix via stir-casting. Comprehensive characterization using X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), and scanning electron microscopy (SEM) confirmed the successful formation of the nanocomposite and MMC. Mechanical testing, encompassing tensile, impact, and compression evaluations, revealed that a 4 weight percent filler loading yielded optimal mechanical strength. Additionally, the MMCs were rigorously assessed for corrosion resistance and morphological attributes. Ballistic testing yielded promising outcomes, underscoring the potential applicability of these MMCs in armored fighting vehicles (AFVs). This study introduces a novel MMC that could significantly enhance the performance and durability of AFVs in challenging operational environments, contributing to the advancement of military defense technologies.

Similar content being viewed by others

Introduction

Armored fighting vehicles (AFVs) play a pivotal role in modern defense by combining advanced mobility with effective troop protection during critical operations such as counter-insurgency, surveillance, and combat missions in hostile and border regions1. These vehicles are engineered with a high power-to-weight ratio, enabling them to offer superior maneuverability without compromising on ballistic protection. Equipped with cutting-edge defensive technology, AFVs ensure a robust balance between agility and armor, essential for navigating complex combat scenarios with both speed and resilience. As contemporary warfare demands adaptability and efficiency, AFVs have become indispensable assets in military strategies, providing exceptional accessibility, operational security, and logistical flexibility2. These vehicles are designed to reduce the risk of collateral damage while enhancing stealth and cost-effectiveness, thus maximizing strategic value. Unlike traditional, heavier armored vehicles, AFVs are optimized to maintain a vital equilibrium between protective capabilities and mobility, making them versatile for a range of tactical situations. With ongoing advancements in military technology and evolving combat requirements, the relevance and deployment of AFVs are set to expand, solidifying their role as foundational components in the modern military arsenal3.

Aluminum’s low weight and strength-to-weight ratio make it an ideal material for armored vehicles and Armored Personnel Carriers (APCs), where minimizing mass without compromising protection is essential4. The Defense Research and Development Organisation (DRDO) in India have made significant strides in developing indigenous aluminum-based armor materials to meet these demands, along with upgrades for existing imported systems. While aluminum may not rival the strength of heavier metals, its combination of affordability, lightness, and sufficient resilience makes it well-suited for many armor applications5. In particular, DRDO has engineered specialized aluminum alloys designed for lightweight armor, such as aluminum alloy plates used in Infantry Combat Vehicles. Additionally, innovations like ultra-lightweight aluminum foams offer remarkable shock and vibration absorption, effectively mitigating blast forces. These materials have proven valuable in reducing the impact of explosive forces, and certain aluminum-based components have been optimized for use in anti-tank ordnance6,7. By harnessing aluminum’s properties, DRDO’s advancements support the development of armored systems that provide robust protection while enhancing mobility and efficiency in the field.

Metal matrix composites (MMCs) have revolutionized the construction of Armored Fighting Vehicles (AFVs) by providing a superior strength-to-weight ratio and exceptional durability in challenging operational environments1,3,8. These advanced materials offer a range of mechanical, chemical, and physical properties that make them ideal for modern AFV designs, far surpassing the performance of traditional metals3,9. MMCs are now widely utilized in critical components of AFVs, including the vehicle hull, armor plating, turret structures, support rails, engine parts, and protective shielding for sensitive elements. Each MMC is composed of a metal base matrix enhanced with reinforcing materials such as ceramics, metals, or carbon-based compounds, resulting in a composite structure with properties tailored for AFV applications10,11. This structure provides outstanding yield strength, modulus, and toughness, along with excellent resistance to wear, creep, and fatigue under both thermal and mechanical stress. Their remarkable strength-to-weight ratio makes MMCs a preferred choice over conventional armoring materials, enabling lighter designs without compromising protection12,13.

The distinctive properties of Metal Matrix Composites (MMCs) make them highly suitable for various demanding applications in Armored Fighting Vehicles (AFVs), including resistance to ballistic and blast impacts, reduced radar signature, enhanced mechanical strength, and high resilience to temperature and chemical exposure1. Among these, ballistic endurance is particularly critical, as MMCs must absorb, distribute, and dissipate the kinetic energy of incoming projectiles to protect the vehicle and its occupants. Achieving this requires the composite to be engineered with specialized features like high hardness, strength, multi-layered or laminated structures, and capabilities for rapid energy absorption and dissipation, as well as projectile deflection and resistance to fragmentation. In this context, aluminum-bronze-based MMCs, though relatively novel in AFV applications, demonstrate strong potential1,3. Bronze alloys, primarily composed of copper and tin, are renowned for their excellent casting properties, high corrosion resistance, and substantial hardness14. When reinforced with materials such as silicon carbide (SiC)1, titanium carbonitride (TiCN)1,3, aluminum oxide (Al₂O₃)15, yttrium oxide (Y₂O₃)14, graphene3, carbon nanotubes (CNTs), or carbon fibers16, these bronze-based composites exhibit significantly enhanced properties suited to the extreme demands of AFV environments. The addition of these secondary phase materials enables the aluminum-bronze MMCs to achieve greater strength, improved energy dissipation, and thermal stability qualities essential for ensuring robust ballistic performance and durability in high-stakes, combat-oriented applications.

In this study, we utilized defense-grade Aluminum Nickel Phosphorus Bronze (Al-NPB), developed by India’s Defense Research and Development Organization (DRDO) for application in lightweight armored vehicles. The full specifications and chemical composition of the Al-NPB alloy are detailed in Table 1. Al-NPB alloys stand out for their substantial hardness and durability, offering excellent wear resistance and high thermal stability qualities that make them suitable for operation in extreme temperatures and highly abrasive environments. The alloy’s aluminum content provides a beneficial strength-to-weight ratio, a crucial factor in applications where minimizing weight is essential, such as in aerospace and automotive sectors. However, Al-NPB is not without limitations. Despite its strength and thermal efficiency, it is susceptible to certain drawbacks, including limited wear resistance, relatively high thermal conductivity, some degree of porosity, and a lower melting point. These characteristics can undermine its performance in ballistic applications, where enhanced resistance to impact and heat is critical.

Titanium carbonitride (TiCN)1,3 and yttrium oxide (Y₂O₃)14 are ideal reinforcement materials for aluminum-based Al-NPB metal matrix composites due to their exceptional performance in enhancing material properties. TiCN, a highly wear-resistant ceramic, significantly increases the composite’s hardness and provides excellent thermal stability and corrosion resistance, making it well-suited for demanding conditions. With its high melting point, TiCN helps the composite retain its structural integrity and strength even under extreme temperatures. Y₂O₃, chosen for its remarkable strength, toughness, and thermal efficiency, is a stable, air-resistant powder that complements aluminum by enhancing the composite’s stability and resistance to both corrosion and wear. When combined in an Al-NPB matrix, TiCN and Y₂O₃ produce a composite with superior toughness, wear resistance, and thermal durability. These nano-scale reinforcements greatly enhance the composite’s performance, making it particularly suitable for the rigorous demands of military and aerospace applications where resilience and stability under severe conditions are paramount.

This study aims to assess the mechanical properties and performance of an Aluminum Nickel Phosphorus Bronze metal matrix composite (Al-NPB MMC) reinforced with TiCN and Y₂O₃ nanoparticles, specifically tailored for armored fighting vehicle applications. Previous work has investigated Al-NPB composites reinforced with TiCN and SiC or TiCN-decorated graphene nanoflakes1,3. Here, we developed TY NPs through mechanical milling of yttrium oxide powders with TiCN, which were then integrated as nanofillers into the Al-NPB matrix using stir-casting. The resulting TY-reinforced composite was subjected to comprehensive characterization, including spectroscopic analyses with X-ray diffraction (XRD), Fourier-transform infrared spectroscopy (FTIR), and scanning electron microscopy (SEM) to confirm the successful formation and distribution of the nanofillers within the matrix. We conducted mechanical testing to assess properties such as elasticity, toughness, and compression strength, while corrosion resistance was examined through specialized testing to gauge the composite’s chemical durability. Finally, the ballistic performance of the MMC was rigorously evaluated using finite element modeling to analyze its impact resistance and suitability for defense applications.

Materials and methods

Materials

Figure 1a shows that Al-NPB which was obtained from the Defence Metallurgical Research Laboratory (DMRL), DRDO Laboratory, Hyderabad, India. Powders of Yttrium Oxide (Y2O3) and Titanium Carbonitride (TiCN) were obtained from Sigma-Aldrich, USA. Deionized water is purchased from Merck Chemicals of India. All reagents with purity levels greater than 99% were utilized immediately, without any supplementary refinement.

Methods

Synthesis of TiCN + Y2O3 nanopowders

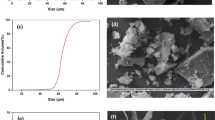

The synthesis of TiCN + Y₂O₃ (TY) nanopowders was achieved through a controlled mechanical milling process. Yttrium Oxide (Y₂O₃), initially sized at 25 ± 5 µm, underwent extensive milling for 6 h, achieving a final particle size below 100 nm. For the TY NPs synthesis, a blend of 10 g TiCN and Y₂O₃ was prepared, comprising TiCN at a volume fraction of 16.7%. This mixture was loaded into a 250 ml tungsten carbide-cobalt (WC–Co, YG8 grade) grinding jar, accompanied by 150 g of TiCN grinding media. To regulate milling conditions and prevent contamination, a 7:3 ethanol-distilled water solution (40 ml total volume) was used as the milling medium. The sealed jar was processed in a planetary ball mill at a rotational speed of 160 rpm for 50 h17. Following the milling procedure, the resulting powder was dried in a controlled drying oven to ensure stability1,3. This methodology produced ultrafine TYNPs with morphology confirmed by field emission scanning electron microscopy (FE-SEM), as depicted in Fig. 1b, confirming readiness for subsequent applications and material integration.

Fabrication TY reinforced AlNiPB MMC

Figure 1 showcases a comprehensive overview of the synthesis process for Al-NPB metal matrix composites (MMCs) reinforced with TY nanoparticles (TY NPs). The figure includes micrographs of the Al-NPB base material, FE-SEM images of TY NPs, the stir-casting setup, fabricated MMC specimens, and detailed microstructural images of Al-NPB MMCs reinforced with 2, 4, and 6 wt. % TY NPs. The MMC fabrication process involved a carefully controlled bottom-pour stir-casting technique, which ensured uniform distribution of TY NPs within the matrix and minimized defects. To achieve optimal results, several critical steps were employed. First, the EN8-3 steel mold was preheated to 300 °C to reduce the temperature gradient between the molten alloy and the mold, mitigating the risk of void formation and promoting smooth alloy flow. The Al-NPB alloy was melted in a high-temperature resistance furnace maintained at 1200 °C ± 5 °C, a temperature chosen to ensure complete melting of the alloy while preserving its intrinsic properties. TY NPs, pre-synthesized and characterized for uniformity as illustrated in Fig. 1, were preheated to 400 °C to eliminate moisture and enhance compatibility with the molten alloy.

During the stirring process, a four-blade stainless steel impeller coated with zirconia was used, designed with 45° inclined blades to maximize turbulence and ensure effective nanoparticle dispersion. Stirring was conducted at a speed of 300 RPM initially for gentle incorporation of nanoparticles, gradually increased to 700 RPM to achieve homogeneous mixing. The process lasted for 10 min, ensuring uniform nanoparticle distribution without agglomeration. An argon atmosphere was maintained throughout the process to prevent oxidation of both the molten alloy and the TY NPs, reducing the formation of undesirable oxides that could compromise the composite’s structural integrity. The molten alloy, reinforced with varying concentrations of TY NPs (2 wt.%, 4 wt.%, and 6 wt.%, corresponding to 20 g, 40 g, and 60 g additions for a 1000 g batch), was rapidly poured into the preheated mold under vacuum conditions. The vacuum environment was critical in eliminating gaseous impurities and minimizing oxidation, thereby enhancing the composite’s mechanical properties. The mold, preheated to 300 °C, facilitated uniform cooling and reduced thermal stresses. After holding for 45 min, the mold was carefully opened, and the solidified MMC specimens were allowed to cool at room temperature for 24 h1,3.

The precise methodology, including the Monte Carlo randomization technique for nanoparticle distribution, successfully yielded Al-NPB MMCs with superior structural and mechanical characteristics. These results highlight the efficacy of the stir-casting approach and the importance of carefully controlled parameters. The integration of TY NPs within the Al-NPB matrix, as visualized in Fig. 1, underscores the potential of this method for fabricating high-performance nanocomposites.

Characterization techniques

The synthesized TYNPs underwent rigorous spectroscopic analysis using a suite of advanced characterization techniques to gain detailed insights into their structural, morphological, and chemical properties, thereby confirming their suitability for high-performance applications. X-ray diffraction (XRD) analysis was conducted on a PANalytical XPert Pro Diffractometer utilizing Cu Kα radiation (λ = 1.5406 Å) across a 2θ range from 0° to 80° with a precision step of 0.05°. All measurements were carried out at stable room temperatures to minimize external variability. Surface morphology was examined with a high-resolution ZEISS Gemini SEM, providing detailed microstructural data, while elemental composition was assessed through energy-dispersive X-ray (EDS) spectroscopy using a ZEISS Smart EDX system, designed specifically for accurate EDS analysis in composite materials. High-resolution transmission electron microscopy (HR-TEM) was performed on a JEOL JEM-2100F and FEI Titan series microscopes, allowing for atomic-scale observation of TiCN distributions within the nanocomposite matrix. Fourier Transform Infrared Spectroscopy (FT-IR) analysis was conducted on a Shimadzu IRAffinity-1 spectrometer to identify molecular vibrations and functional groups. Potassium Bromide (KBr) pellets, pressed at 15 tons, ensured optical transparency and minimal spectral interference. FT-IR data were collected across a spectral range of 400–4000 cm⁻1, providing critical information on molecular bonding and chemical structure. This comprehensive characterization approach substantiates the TY NPs’ potential for advanced composite applications.

Experimental findings and outcomes

The experimental findings are systematically presented in three comprehensive sections. Section A provides an in-depth analysis of the spectroscopic properties and surface morphology of the synthesized TYNPs, detailing their structural and chemical characteristics. Section B rigorously examines the mechanical properties of the nanocomposites, including their surface morphology and environmental stability under various conditions. Finally, Section C assesses the ballistic performance of the reinforced composites, focusing on their impact resistance and energy dissipation capabilities. Together, these sections offer a robust evaluation of the material’s suitability for advanced defense applications.

X-ray diffraction analysis

The X-ray diffraction (XRD) analysis provides critical insights into the phase composition and crystalline structure of the synthesized TiCN, Y₂O₃, and TYNPs. Figure 2a shows the XRD patterns for each material. For TiCN, distinct diffraction peaks are observed at 2θ angles of 36.29°, 42.19°, 61.24°, 73.30°, and 77.12°, corresponding to the (111), (200), (220), (311), and (222) crystal planes, respectively1,3. These reflections confirm the face-centered cubic (FCC) structure of TiCN, consistent with the JCPDS references for TiN (Card No. 38–1420) and TiC (Card No. 32–1383)1,3, verifying the crystalline nature and phase purity of the material. The Y₂O₃ diffraction profile displays characteristic peaks at 20.42°, 28.16°, 33.81°, 35.91°, 39.88°, 43.44°, 48.47°, 57.57°, 59.13°, 60.49°, and 78.60°, which align with the (211), (222), (400), (411), (332), (134), (440), (622), (136), (444), and (662) planes, respectively14. These peaks confirm the cubic phase of yttrium oxide, in accordance with JCPDS Card No. 83–0927, indicating a stable and well-defined crystalline structure14.

In the TY NPs, the XRD pattern reveals a combination of both TiCN and Y₂O₃ crystalline structures. Peaks for TiCN in the composite appear at 36.29°, 42.19°, 61.24°, 73.30°, and 77.12°1,3, while Y₂O₃ peaks are noted at 20.49°, 29.23°, 33.88°, 35.76°, 40.01°, 43.33°, 48.41°, 57.50°, and 66.56°14. The prominent peak at 28.16°, attributed to the (222) plane of Y₂O₃, confirms the successful incorporation of Y₂O₃ into the TiCN matrix. This dual-phase configuration suggests a robust interfacial interaction between the TiCN and Y₂O₃ NPs, a factor likely contributing to the enhanced mechanical and thermal properties observed in the nanocomposite. The XRD profile analysis further allowed the calculation of crystallite size, lattice strain, and dislocation density of the TY NPs, providing essential parameters for evaluating structural integrity and phase stability at the nanoscale.

(i) Average crystalline size (D).

The average crystallite size of the synthesized TY NPs was determined using the Debye–Scherrer formula, as shown in Eq. (1)17,18. This calculation relies on peak broadening data from the XRD patterns, yielding an estimated crystallite size of 28.5 ± 5 nm.

where ‘D’ represents the crystallite size, ‘K’ is the shape factor (typically taken as 0.9), λ is the wavelength of the X-ray source (Cu Kα, 1.5406 Å), ‘β’ is the full width at half maximum (FWHM) of the diffraction peak in radians, and ‘θ’ is the Bragg angle.

This precise crystallite size estimation, based on XRD peak broadening, provides insights into the nanoscale structure of the TY NPs, which is crucial for evaluating their potential impact on the mechanical properties of the composite. The calculated size suggests a fine crystalline structure, which is instrumental in enhancing the interfacial bonding and overall structural stability within the Al-NPB matrix. The fine scale of these nanoparticles is expected to contribute significantly to the composite’s mechanical robustness and thermal stability.

(ii) Lattice strain (ε)

The lattice strain within the synthesized TY NPs was calculated from XRD peak broadening, yielding a value of 0.1218 using the equation derived from Bragg’s Law as given in Eq. (2).16

where ‘β’ represents the full width at half maximum (FWHM) of the diffraction peak, and ‘θ’ is the Bragg angle.

This lattice strain measurement reflects a considerable level of microstructural distortion in the TY NPs. The observed strain is likely a result of lattice parameter mismatches between the TiCN and Y₂O₃ phases, compounded by the mechanical stresses introduced during the milling and synthesis process. Such high lattice strain indicates an increased density of defects and dislocations within the TY NPs, which can act as barriers to dislocation motion, thereby contributing to enhanced hardness and strength. In the context of TY NPs formation, the presence of lattice strain is a critical factor, as it suggests sufficient deformation to establish strong interfacial bonding between the TiCN and Y₂O₃ phases. This robust interfacial interaction is essential for efficient load transfer across the composite matrix, which is beneficial when these NPs are incorporated as fillers in the Al-NPB metal matrix composite (MMC). The intrinsic lattice strain within the TY NPs can enhance the overall mechanical performance of the composite by introducing additional strengthening mechanisms, such as strain hardening and grain boundary strengthening. These effects contribute to the composite’s improved wear resistance, hardness, and tensile strength, making it highly suitable for applications demanding superior mechanical resilience.

(iii) Dislocation density (δ)

Dislocation density is a crucial parameter that quantifies the number of dislocations within a unit volume of the crystal lattice. For the synthesized TY NPs, it was calculated to be 0.1235 nm⁻2 using Eq. (3):17

where ‘D’ is the average crystalline size obtained from Debye–Scherrer’s formula.

A high dislocation density signifies a substantial number of dislocations within the crystalline structure, which has a profound impact on the material’s mechanical properties. Dislocations, which are line defects in the lattice, typically allow for plastic deformation under stress. However, when dislocation density is high, the movement of these defects is restricted, thereby increasing the yield strength and hardness of the material. In the context of TY NPs synthesis, the elevated dislocation density indicates that the particles have undergone considerable mechanical deformation during milling, resulting in the introduction of numerous dislocations. This high dislocation density raises the internal energy of the NPs, promoting better dispersion and stronger interfacial bonding when these particles are incorporated as nanofillers within the Al-NPB matrix. Such an increase in dislocation density enhances load transfer and stress distribution across the composite, leading to improved mechanical performance, including higher strength and wear resistance. Additionally, the presence of dislocations can serve as nucleation sites for phase transformations or the development of secondary phases, further stabilizing the microstructure and contributing to the composite’s mechanical robustness. This characteristic is essential for applications where mechanical durability and stability under stress are paramount.

FT-IR studies

The Fourier Transform Infrared Spectroscopy (FTIR) spectra displayed in Fig. 2b provide detailed insights into the molecular structures of TiCN, Y₂O₃, and their TYNPs. FTIR is an essential characterization method, allowing for precise identification of molecular vibrations by examining the interaction of molecular bonds with infrared light. This technique is particularly useful for observing changes in dipole moments, which appear as specific IR absorption bands. The FTIR spectrum for TiCN reveals several distinct peaks. A prominent absorption band in the 2100–2300 cm⁻1 range is indicative of the cyanide (C≡N) stretching vibrations, while peaks in the 700–800 cm⁻1 range correspond to titanium-carbon (Ti–C) stretching modes1,3. Additional bands in the 1100–1300 cm⁻1 and 500–700 cm⁻1 regions can be attributed to nitrogen (N) and carbon (C) stretching vibrations, respectively. These vibrational modes confirm the molecular composition of TiCN, highlighting the presence of Ti–C, C–N, and N–C bonds, consistent with its expected chemical structure1,3.

In the FTIR spectrum of Y₂O₃, characteristic peaks appear at 498 cm⁻1 and 561 cm⁻1, corresponding to yttrium-oxygen (Y–O) stretching vibrations. Other observed peaks around 1446 cm⁻1 and 1626 cm⁻1 may represent carbon–oxygen (C–O) bonds, likely due to minor surface contamination or residual compounds from synthesis. A broad absorption band near 3450 cm⁻1 suggests the presence of hydroxyl (O–H) groups, possibly from adsorbed moisture or surface hydroxyls, which is common in synthesized oxides. These features validate the cubic structure of Y₂O₃ and confirm its molecular integrity14,20.

The FTIR spectrum for the TY NPs combines characteristics of both TiCN and Y₂O₃, though certain expected peaks are diminished or absent. This alteration is likely due to structural integration effects and the impact of mechanical milling, which can modify vibrational signatures by influencing molecular dipole moments20. Some peaks appear with lower intensity, possibly due to interactions between TiCN and Y₂O₃ at the nanoscale that alter the vibrational properties, while the milling process may introduce further changes in molecular structure. Despite these variations, the spectrum retains features of both components, demonstrating the successful formation of the TY NPs. The observed combined vibrational bands indicate a cohesive interaction between TiCN and Y₂O₃, suggesting effective integration at the molecular level. This structural coherence is essential for the nanocomposite’s intended advanced applications, as it enhances mechanical stability and ensures robust performance. The FTIR analysis, supported by the spectral data in Fig. 2b, verifies the molecular structure and successful synthesis of a stable, well-integrated TY NPs, aligning with the requirements for high-performance materials in advanced applications.

Morphological analysis

The morphological and structural characteristics of the TY NPs were thoroughly examined using Field Emission Scanning Electron Microscopy (FE-SEM), High-Resolution Transmission Electron Microscopy (HR-TEM), and Energy Dispersive X-ray Spectroscopy (EDS), as shown in Fig. 3. These analytical methods provide detailed insights into the distribution, attachment, and elemental composition of TiCN and Y₂O₃ within the nanocomposite, which are crucial for understanding the material’s properties at a microstructural level. The FE-SEM images Fig. 3a–d) reveal the distribution and morphological features of the TiCN and Y₂O₃ particles in the composite. In Fig. 3a, Y₂O₃ particles appear as distinct bright granules adhered to the TiCN particles, indicating a robust interfacial bonding between the two phases. This attachment is critical, as it facilitates efficient load transfer from the matrix TiCN to the reinforcement Y₂O₃, enhancing the composite’s mechanical performance. The dispersed Y₂O₃ particles do not show any signs of agglomeration, implying a uniform distribution achieved through the synthesis process. Such homogeneity in dispersion is essential, as it prevents weak points that could lead to structural failure under mechanical stress.

Figure 3b and c offer a broader perspective, highlighting the even distribution of Y₂O₃ across the TiCN matrix. This distribution ensures that the reinforcing particles are well-integrated within the matrix, contributing to uniform mechanical properties across the composite. The image in Fig. 3d further confirms the lack of particle clustering, showcasing the successful synthesis of a homogenous structure. This uniformity minimizes stress concentrations, thereby reducing the potential for localized failure and improving the composite’s overall structural integrity. The HR-TEM image Fig. 3g provides a nanoscale view of the TY NPs, where Y₂O₃ particles are clearly visible as dark spots attached to the edges of the TiCN matrix. This high-resolution observation confirms the strong interfacial bonding suggested by the FE-SEM images. The TiCN particles serve as a robust host matrix for Y₂O₃, ensuring that the reinforcement particles are well-anchored. The clear attachment of Y₂O₃ to TiCN seen in the HR-TEM image is crucial for effective stress transfer and contributes to the composite’s enhanced durability. This nanoscale integration is essential for optimizing the mechanical and thermal properties of the composite, as it allows for even load distribution and improved resistance to thermal expansion mismatches.

The EDS spectra, derived from the FE-SEM image shown in Fig. 3e and f, confirm the elemental composition of the TY NPs, indicating the presence of Ti, C, N, O, and Y. This elemental mapping validates the successful incorporation of both TiCN and Y₂O₃ phases within the composite. The detected elements align with the expected composition, corroborating the uniform distribution observed in the FE-SEM and HR-TEM images. The presence of Ti and Y in specific regions further supports the idea of a well-dispersed composite structure, with each component maintaining its integrity and location within the matrix. Together, these findings from FE-SEM, HR-TEM, and EDS provide comprehensive evidence of the structural cohesion and elemental uniformity of the TY NPs. The strong interfacial bonding, homogeneous dispersion, and robust structural integration of Y₂O₃ within the TiCN matrix are critical for the composite’s superior mechanical properties. These characteristics enhance load-bearing capacity, improve wear resistance, and contribute to the thermal stability of the material, making the TY composite a promising candidate for advanced engineering applications requiring high mechanical performance and durability.

XRD analysis

The XRD patterns reveal the successful formation of a multi-phase, nanocomposite structure with well-defined CuSn, TiCN, and Y₂O₃ peaks. The variation in peak intensities with increasing TY-NP content underscores the influence of nanoparticle concentration on the crystalline characteristics of the composite. The findings highlight both the strengths of the material’s design such as uniform reinforcement and crystallinity and areas that require further control, particularly the stability of Y₂O₃ at higher loadings, to optimize the composite for demanding engineering applications. The X-ray Diffraction (XRD) analysis in Fig. 4a provides crucial insights into the crystalline structure of the AlNiPB metal matrix composite (MMC) reinforced with TY NPs at varying loadings of 2, 4, and 6 wt.%. This analysis offers a comprehensive understanding of the distribution, phase formation, and stability of constituent elements within the composite, reflecting both the quality of synthesis and the structural attributes of the final material.

Distinct diffraction peaks corresponding to CuSn, Y₂O₃, TiCN, and Ni are observed, indicating the effective incorporation and phase presence of these components in the AlNiPB MMC. Peaks associated with CuSn align with the reference PDF No. 03–065-682121, while copper peaks match PDF No. 01–070-3030, confirming the phase identity within the matrix. The identification of CuSn and Ni phases at prominent angles (2θ values) of 43.34°, 50.35°, and 73.96° highlights the fundamental roles of copper and nickel in the structural framework of the AlNiPB alloy. These peaks also confirm the alloy’s integrity and provide a benchmark for evaluating the influence of the TiCN and Y₂O₃ reinforcements. The XRD patterns reveal subtle differences between the 2, 4, and 6 wt. % loadings of TY NPs. With increasing nanoparticle content, there is an enhancement in the intensity of peaks associated with TiCN and Y₂O₃ phases, indicating improved crystalline alignment and distribution within the AlNiPB matrix. Notable peaks for TiCN and Y₂O₃ appear at 31.26°, 36.53°, and 62.30°, reflecting their uniform dispersion and successful incorporation22,23. The consistency of these peaks with those previously identified in Fig. 2a reinforces the reproducibility of the composite’s crystalline structure across varying compositions.

For the 6 wt. % loading, peak intensities associated with TiCN and Y₂O₃ are more pronounced, suggesting a higher degree of crystallinity and phase presence compared to the 2 and 4 wt. % loadings. However, the data also hint at potential challenges. The brittle nature of Y₂O₃, especially at higher concentrations, may lead to structural degradation under processing conditions, which could compromise the composite’s overall stability. This potential brittleness is critical to consider, as it may affect the mechanical robustness and durability of the MMC, particularly in applications requiring high wear resistance and thermal stability. The XRD analysis confirms a strong interaction between the AlNiPB matrix and the reinforcing nanoparticles during the stir-casting process. This interaction ensures that the desirable properties of each phase are retained and contribute synergistically to the composite’s performance. However, the risk of Y₂O₃ degradation suggests a need to optimize processing parameters, especially for higher nanoparticle loadings, to preserve the structural integrity and functional properties of the composite.

FT-IR analysis

The FTIR spectra shown in Fig. 4b provide valuable information on the functional groups and bonding characteristics of the TY NPs reinforced Al-NPB metal matrix composite (MMC) at loadings of 2, 4, and 6 wt.%. FTIR spectroscopy serves as a crucial tool for identifying molecular vibrations and bonding modes, especially in the reinforcement phases, as metals like copper and aluminum, which form the primary structure of Al-NPB, generally exhibit broad, featureless spectra due to their free electron cloud17,18,19. This featureless profile arises from the absence of distinct vibrational transitions in metals, as they lack covalent bonds that would typically interact with IR radiation. In the context of the composite, distinct peaks associated with the reinforcing materials, TiCN and Y₂O₃, are observed. For TiCN, several characteristic bands are identified. Strong absorption peaks between 400 and 800 cm⁻1 are attributed to Ti–N stretching vibrations, confirming the presence of titanium nitride within the composite. Additionally, peaks corresponding to C–N stretching modes are visible between 1200 and 1600 cm⁻1, and a significant peak around 2350 cm⁻1 is attributed to the C≡N stretching vibration. These distinct bands indicate that TiCN retains its molecular structure within the composite, contributing to the overall stability and mechanical resilience of the MMC1,3.

The FTIR spectrum for Y₂O₃ also reveals specific vibrational bands that reflect its molecular structure. Yttrium-oxygen (Y–O) stretching vibrations are observed at 498 cm⁻1 and 561 cm⁻1, consistent with Y₂O₃’s cubic phase structure. Additional peaks at 1446 cm⁻1 and 1626 cm⁻1 are likely due to C–O stretching, possibly arising from surface contamination or residual synthesis by-products. A broad peak around 3450 cm⁻1 corresponds to O–H stretching, suggesting the presence of surface-adsorbed water or hydroxyl groups, a common occurrence in oxide materials14,24,25. These features validate the structural integrity of Y₂O₃ within the composite, indicating that it contributes effectively to the composite’s overall properties. In comparing the spectra for the 2, 4, and 6 wt. % loadings, several trends can be observed. As the weight percentage of TY NPs increases, the intensity of the characteristic peaks for TiCN and Y₂O₃ also increases. This trend suggests a higher concentration of these reinforcing phases, which correlates with enhanced mechanical reinforcement due to improved phase presence and bonding. The absence of additional peaks across all loadings confirms the high purity of the Al-NPB MMC, as no significant impurities or unanticipated by-products are detected in the spectrum. This purity is essential for the composite’s performance, ensuring that only the intended reinforcement materials contribute to the material’s structural and mechanical characteristics. The FTIR analysis substantiates the presence and distribution of TiCN and Y₂O₃ within the Al-NPB matrix. The observed molecular vibrations confirm that the TiCN and Y₂O₃ phases are well-integrated within the composite and contribute to the material’s enhanced mechanical and thermal properties. This integration is especially beneficial for applications requiring materials with high hardness, wear resistance, and thermal stability, as the reinforcement phases effectively augment these characteristics in the Al-NPB MMC3,25.

FE-SEM analysis of Al-NPB-MMCs with varying TY NP loadings

The morphology and structural characteristics of the Al-NPB metal matrix composites (MMCs) reinforced with TYNPs at various concentrations (0%, 2%, 4%, and 6% by weight) were examined using Field Emission Scanning Electron Microscopy (FE-SEM), as shown in Fig. 5a–d. The stir-casting method employed in the fabrication process played a pivotal role in determining the dispersion quality and interfacial interaction of the nanoparticles within the Al-NPB matrix, which, in turn, significantly impacted the mechanical and structural integrity of the composite. As illustrated in Fig. 5a, the pristine Al-NPB matrix without TY NP reinforcement provides a baseline for assessing the structural modifications induced by nanoparticle additions. The SEM image reveals a relatively smooth, continuous surface with minimal defects or irregularities. The absence of nanofillers results in a homogenous but less fortified matrix structure, lacking the mechanical reinforcement typically introduced by nanoparticle additions25. This uniform, defect-free baseline is critical for understanding the incremental improvements in structural integrity and mechanical performance as TY NPs loadings are introduced. Figure 1d–g also show FE-SEM images of Al-NPB-MMCs with different proportions of weight of TY-NPs. These photos present a good visual representation of the MMCs, confirming the lack of visible production flaws in all samples. Figure 1e shows 2 weight% TY-NPs disseminated as white granules through these Al-NPB matrices, with no obvious defects or abnormalities, showing that the nanofillers were successfully formed and distributed uniformly.

At 2 wt. % loading of TY NPs, shown in Fig. 5b, the SEM image indicates a uniform and well-dispersed distribution of nanoparticles across the matrix. The TY NPs are evenly scattered as fine white granules, with no visible signs of clustering or agglomeration. This homogenous dispersion is essential for enhancing load transfer between the matrix and reinforcement, as it minimizes localized stress concentrations. The smooth surface morphology suggests that the nanoparticle integration is effective, allowing the TY NPs to improve the mechanical properties of the composite without introducing structural disruptions. This well-integrated structure implies that the 2 wt.% loading successfully contributes to hardness and wear resistance without compromising the uniformity of the Al-NPB matrix.

Figure 1f shows a consistent reinforcement of 4 weight% TY-NPs over the Al-NPB framework. The nanofillers are equally dispersed, indicating a good distribution within the MMC. This uniformity is credited to the optimal lattice strain and dislocation density, which facilitate effective stress transfer and enhance the mechanical properties of the composite. Figure 5c presents the SEM image of the Al-NPB MMC with a 4 wt. % loading of TY NPs, which appears to represent the optimal concentration for reinforcing the matrix. The TY NPs are uniformly dispersed throughout the matrix, maintaining an even distribution that prevents particle clustering. This configuration ensures efficient stress transfer and promotes structural integrity, as uniformly distributed nanoparticles reduce the likelihood of crack initiation and propagation. At this concentration, the TY NPs are well-incorporated within the Al-NPB matrix, achieving a balance between reinforcement and structural coherence. The lack of agglomeration and the uniform dispersion of nanoparticles suggest optimal lattice strain and dislocation density, factors that contributes to the composite’s enhanced mechanical properties, including increased tensile strength, hardness, and durability.

Figure 1g depicts a SEM picture of the Al-NPB-MMC containing 6 weight% TY-NPs, which shows aggregates and clusters scattered within the matrix. The formation of this clustering pattern indicates that that the distribution of TY-NPs in the Al-NPB framework is not equally distributed as in earlier situations. Considering the existence of these aggregates, the matrix itself appears to be free of defects. The high loading of TY-NPs leads to increased lattice strain and dislocation density, which can result in stress concentrations and weak points within the composite. In Fig. 5d also a significant shift in morphology at the 6 wt.% TY NP loading, where excessive nanoparticle concentration leads to visible clustering and agglomeration. Unlike the lower concentrations, the TY NPs here are distributed unevenly, forming concentrated pockets within the matrix26,27. These agglomerates act as stress risers, creating weak points where cracks are likely to initiate under mechanical load. The high concentration of nanoparticles at this level results in increased lattice strain and dislocation density, which can compromise the structural integrity of the composite. The clustering of TY NPs disrupts the uniform distribution, leading to inconsistent mechanical properties across different regions of the composite. Consequently, the 6 wt. % loading, while increasing the overall amount of reinforcement, detracts from the composite’s reliability and performance due to the non-uniform dispersion of particles and the formation of stress concentration zones.

The lattice strain and dislocation density play critical roles in determining the morphology and mechanical properties of the MMCs28. At 4 weight% TY-NPs, the optimal lattice strain and dislocation density contribute to a homogeneous dispersion of the nanoparticles, enhancing the composite’s structural integrity and mechanical performance. The well-distributed nanoparticles prevent agglomeration and ensure effective load transfer, improving the overall strength and durability of the composite. In contrast, at 6 weight% TY-NPs, the excessive addition of nanofillers leads to increased lattice strain and dislocation density, causing the nanoparticles to agglomerate and form clusters29. These agglomerates act as stress risers, creating weak points within the composite3. When exposed to external influences, these locations encounter larger tension concentrations, which make them more prone to fracture genesis and propagation. As a result, the composite material’s ultimate mechanical performance and dependability are affected.

Mechanical analysis

In this study, the mechanical properties of Al-NPB-MMC samples were systematically examined through comprehensive tensile, hardness and compression testing. While the mechanical attributes of unreinforced Al-NPB have been well-documented, limited research exists on Al-NPB composites reinforced with Y₂O₃ or TiCN. Although TiCN is commonly employed as reinforcement in various hybrid composites, the combined use of TiCN and Y₂O₃ (TY-NPs) as dual-phase reinforcement in Al-NPB to produce an advanced MMC represents a novel approach that remains unexplored1,3. The mechanical performance of MMCs is profoundly influenced by the fabrication process, matrix characteristics, and the properties of the reinforcing materials. One of the inherent challenges in developing MMCs lies in managing the trade-off between the hardness imparted by ceramic reinforcements and the natural ductility and toughness of the metal matrix. High-hardness ceramic additives can often lead to a decrease in ductility, thereby compromising the matrix’s flexibility. To address this, TiCN and Y₂O₃ NPs known for their ultra-high temperature stability and ceramic robustness were selected as reinforcements, aiming to enhance mechanical strength while maintaining the composite’s essential ductility and toughness.

For this investigation, samples with varying nanoparticle concentrations (2%, 4%, and 6% by weight) were prepared following ASTM standards, ensuring consistency across tensile, hardness and compression tests. A series of five samples per concentration were tested, and the average values were calculated to provide reliable data. The analysis focused on understanding how the unique combination of TiCN and Y₂O₃ influences the composite’s mechanical behavior under load, aiming to achieve a balanced enhancement in strength and resilience. By integrating these reinforcements, the study seeks to significantly improve the mechanical performance of Al-NPB-MMCs, particularly in applications requiring both strength and durability, such as armored fighting vehicles (AFVs). This pioneering use of TY-NPs as a dual-phase reinforcement in Al-NPB opens a new pathway for the development of advanced materials with optimized mechanical properties, offering potential breakthroughs in lightweight, high-strength armor materials. The detailed findings and their implications are discussed in the subsequent sections, highlighting the potential of TY-NPs to advance MMC technology.

Tensile test

The tensile properties of the fabricated Al-NPB and Al-NPB-MMC specimens reinforced with TY-NPs were assessed in accordance with ASTM E08, the standard protocol for tensile testing of metallic materials. Testing was performed on a Tinius Olsen H50KL universal testing machine, equipped with a load capacity of 400 kN, which is ideal for evaluating the tensile strength and behavior of the MMC specimens under high stress. The samples were precisely machined to a uniform width of 10 mm and a length of 100 mm to maintain consistency and accuracy across all tests. Each specimen was carefully mounted in the tensometer, and a gradually increasing load was applied until fracture occurred, allowing for a precise assessment of tensile strength and deformation resistance. Tensile strength, a fundamental property in materials science, is especially relevant for MMCs in applications where substantial tensile loads are encountered, such as structural components in demanding environments3.

The study included four variations of Al-NPB specimens, each reinforced with different weight percentages of TY NPs (0%, 2%, 4%, and 6%), to analyze the impact of reinforcement on tensile behavior. Five samples of each type were tested to ensure statistical reliability, with the results summarized in Table 2. This testing approach provides a comprehensive understanding of how TY-NPs enhance the tensile properties of the Al-NPB matrix, contributing insights into the material’s performance and suitability for advanced applications where high tensile strength is crucial. The findings highlight the potential of TY NPs reinforcement to improve the structural resilience of Al-NPB-based MMCs.

The addition of TY-NPs had a profound impact on the tensile strength of the Al-NPB alloy, introducing a balance between enhanced strength and ductility. Initially, the unreinforced Al-NPB exhibited a tensile strength of 554 MPa. With the incorporation of 2 wt. % TY-NPs, the tensile strength rose to 571 MPa, signaling the reinforcing effect of the nanocomposite. The strength increase was even more pronounced at 4 wt. % TY-NPs, where tensile strength reached 590 MPa. This enhancement can be attributed to the well-dispersed TiCN and Y₂O₃ particles within the softer bronze matrix, which improve load distribution and inhibit dislocation motion. The chemically stable TiCN provides hardness and thermal stability, while Y₂O₃ contributes to corrosion resistance and bonding at the nanoscale, ensuring effective particle–matrix adhesion. These reinforcements restrict dislocation mobility and absorb applied stresses, strengthening the overall composite.

However, increasing the TY-NP concentration to 6 wt. % led to a decline in tensile strength to 561 MPa. This reduction is primarily due to the formation of agglomerates, as excessive nanoparticle concentration leads to clustering. These clusters act as stress concentrators within the matrix, weakening the composite’s integrity and reducing tensile strength. Additionally, the high nanoparticle content increases matrix porosity, further compromising the material’s structural cohesion. This behavior underscores the importance of balancing the matrix and reinforcement materials, with 4 wt. % TY-NPs representing the optimal concentration for maximizing tensile strength without sacrificing ductility.

The fracture surface analysis, presented in Fig. 6, provides valuable insights into the failure mechanisms across different reinforcement levels. Figure 6a and b, corresponding to unreinforced Al-NPB and the 2 wt.% TY-NPs reinforced composite, exhibit a network-like pattern with numerous dimples marked by yellow arrows, indicative of a primarily ductile fracture mode. The presence of these dimples, which are characteristic of plastic deformation, suggests that the material can withstand significant stress before failure, maintaining the matrix’s intrinsic ductility despite the low reinforcement concentration.

This ductile behavior is essential for applications where impact resistance and energy absorption are crucial. In Fig. 6c–e, representing the 4 wt. % TY-NPs reinforced composite, the fracture morphology remains predominantly ductile, although the dimples are noticeably smaller. This reduction in dimple size is likely due to the increased volume of reinforcement particles, which constrains the matrix’s capacity for extensive plastic deformation. Nonetheless, the smaller dimple size indicates efficient load transfer between the matrix and reinforcement particles, thereby enhancing the composite’s strength while retaining adequate ductility.

The fracture surfaces of the 6 wt. % TY-NPs reinforced composite, shown in Fig. 6f, g, and h, display a markedly different morphology. While dimples indicative of ductile fracture are still present, distinct cleavage planes, highlighted by yellow arrows, are evident, suggesting the presence of brittle fracture mechanisms. This shift in fracture mode is attributed to the high concentration of reinforcements, which promotes particle agglomeration. These clusters create localized stress concentration zones, initiating cracks and leading to cleavage fractures. The presence of these brittle features compromises the composite’s mechanical performance, as stress concentrators weaken the material’s structural integrity and reduce its capacity to absorb impact energy.

The introduction of TY-NPs into the Al-NPB alloy not only enhanced its mechanical properties, particularly tensile strength, but also affected its fracture behavior. The 4 wt. % TY-NPs reinforcement emerged as the optimal composition, balancing strength and ductility, as evidenced by the relatively small dimples and the absence of significant cleavage planes. This balance is critical for applications requiring high impact resistance and energy absorption, such as in armored fighting vehicles (AFVs). The 6 wt. % TY-NPs reinforcement, however, illustrates the detrimental effects of excessive nanoparticle loading, where agglomeration leads to a mixed fracture mode with both ductile and brittle characteristics, reducing impact resistance and durability.

The pristine Al-NPB and 2 wt. % reinforced specimens, in contrast, show more ductile features, suggesting that lower reinforcement levels retain higher porosity and result in lower ultimate tensile strength. These fractographic analyses highlight the necessity of optimizing reinforcement levels to achieve a desirable balance between strength and plastic deformation in the composite material. The interaction between matrix and nanoparticles at an optimal concentration enhances load distribution, while excessive reinforcement concentration detracts from the mechanical stability, as illustrated by the observed mixed fracture modes in high-concentration samples.

Impact analysis

Impact testing is an essential method for determining a material’s ability to withstand sudden, high-strain-rate loading conditions, which are typical in defense applications, such as armor for Light Armored Vehicles (AFVs)1,3. These tests measure the material’s capacity to absorb energy until failure, directly reflecting its toughness and resilience under impact stresses29. For defense materials, the ability to absorb and dissipate energy on impact is crucial for ensuring protection against ballistic threats, as it prevents penetration and minimizes shock transmission to underlying structures30. Among the samples tested, the Al-NPB MMC reinforced with 4 wt. % TY-NPs exhibited the highest impact toughness, indicating superior energy absorption capability. This enhancement is primarily attributed to the synergistic interaction of TiCN and Y₂O₃ nanoparticles within the composite matrix, which strengthens the material’s robustness under impact conditions.

The unreinforced Al-NPB MMC demonstrates a desirable combination of strength and corrosion resistance but lacks sufficient impact resistance due to its relatively coarse grain structure and the inherent tendency for stress concentration at grain boundaries. This characteristic can lead to brittle fracture under high-velocity impacts, a common failure mode in ballistic environments. The addition of TiCN NPs contributes significantly to toughness improvement through various mechanisms31. TiCN’s high hardness and elastic modulus restrict plastic deformation, while its ceramic nature provides exceptional wear resistance, reducing material degradation upon impact. The inclusion of TiCN also results in grain refinement, which introduces additional grain boundaries that can absorb and dissipate impact energy effectively32. This grain boundary strengthening mechanism is crucial for preventing crack initiation and propagation, thereby enhancing the material’s structural integrity under impact loads33.

Y₂O₃ nanoparticles, known for their outstanding mechanical properties, including high strength and thermal stability, further enhance the impact resistance of the Al-NPB matrix when incorporated as reinforcement34. The high surface area of Y₂O₃ allows for efficient load transfer between the matrix and the reinforcement, increasing the composite’s overall energy absorption capacity35. Additionally, Y₂O₃ particles located along crack paths serve to deflect and impede crack growth, thereby contributing to the composite’s overall toughness36. Together, TiCN and Y₂O₃ create a balanced reinforcement within the Al-NPB matrix, with TiCN providing strength and hardness while Y₂O₃ enhances ductility and flexibility. This balance, particularly at the 4 wt. % reinforcement level, prevents the formation of brittle phases and enables the composite to undergo substantial deformation before failure, which is essential for absorbing and dissipating impact energy.

The improved impact toughness of the 4 wt. % TY-NP reinforced Al-NPB MMC directly translates to enhanced ballistic performance. Composites with superior impact resistance are better able to absorb and distribute the kinetic energy from ballistic threats, reducing the risk of penetration and minimizing shock transfer to protected structures. The absorbed energy disperses the impact force over a broader area, thereby decreasing localized stress and injury potential. This characteristic is crucial in defense applications, where the ability to mitigate the effects of ballistic impacts determines the level of protection for both AFVs and their occupants. The integration of TY-NPs thus represents a significant advancement in the development of resilient, high-performance materials for defense applications, combining the strengths of TiCN and Y₂O₃ to achieve an optimal balance between strength, toughness, and durability.

Hardness test analysis

Hardness testing serves as a straightforward, cost-effective approach to assessing a material’s strength by measuring its resistance to both elastic and plastic deformation under an applied load19. This method offers valuable insights into the material’s stress–strain behavior within the deformation zone. Various hardness tests, including Rockwell, Brinell, and Vickers, operate on the principle of determining the size or depth of an indentation produced by a specific indenter under a controlled load1,19. In this study, the Krystal Tech KAB Rockwell hardness tester was employed to evaluate the hardness of Al-NPB MMCs reinforced with TY-NPs. The procedure involves applying an initial minor load followed by a larger load, after which the depth of the resulting indentation is measured. This method yields reliable hardness values that are essential for assessing the material’s durability and structural robustness. Analyzing the hardness values across varying TY-NPs concentrations provides valuable insights into the effects of reinforcement on the composite’s mechanical performance.

The unreinforced Al-NPB MMC exhibited a hardness of 312 HBW. Upon the addition of 2 wt.% TY-NPs, the hardness increased significantly to 364 HBW. This improvement is due to the inherent toughness of TY-NPs, which enhances the composite’s overall durability by resisting indentation and deformation. At this concentration, the TY-NPs effectively strengthen the aluminum-bronze matrix, reducing the ease of plastic deformation under stress and thereby increasing hardness. Further reinforcing with 4 wt. % TY-NPs resulted in an even higher hardness of 423 HBW, likely due to optimal dispersion of the nanoparticles within the matrix, facilitating stronger particle–matrix interaction. The dispersed TY-NPs impede dislocation movement, enhancing the composite’s resistance to deformation and boosting hardness. However, increasing the concentration to 6 wt. % TY-NPs led to a reduction in hardness to 394 HBW, which, although still greater than the unreinforced material, is lower than the 4 wt.% reinforced sample37. This decrease is likely attributed to excessive reinforcement, which can result in particle agglomeration and stress concentration within the composite. The clustering of particles creates localized zones of deformation, reducing overall hardness and highlighting the importance of achieving an optimal balance of reinforcement in MMCs38.

The FE-SEM images provide visual evidence to support these findings, offering detailed insights into the surface characteristics of the Al-NPB MMC under varying reinforcement levels39. The SEM images of the 4 wt. % TY-NP reinforced composite, shown in Fig. 7a and b, reveal distinct indentation marks, indicating the material’s high hardness and its ability to resist plastic deformation. These indents demonstrate that the composite can withstand significant localized stress, aligning with the enhanced hardness values observed. The underlying chemistry of these results is related to the material’s increased resistance to dislocation movement under stress. At 4 wt. % TY-NPs, the reinforcement particles create barriers that hinder dislocation motion, which is essential in resisting plastic deformation. This impediment to dislocation mobility results in higher hardness and enhanced resistance to permanent deformation.

In contrast, the FE-SEM images of the 2 wt.% and 6 wt.% TY-NP reinforced composites, shown in Fig. 7c and d, exhibit different surface characteristics. The 2 wt. % reinforced composite shows fewer indentation marks, indicating reduced resistance to plastic deformation. This is likely due to an insufficient number of reinforcement particles to effectively impede dislocations, allowing the matrix to undergo more pronounced deformation. On the other hand, the 6 wt.% sample exhibits signs of particle agglomeration, resulting in heterogeneous stress distribution and localized stress concentration zones. These regions can facilitate crack initiation and propagation, compromising hardness and structural integrity. The hardness testing and SEM analysis underscore the importance of an optimal TY-NP concentration in enhancing the mechanical properties of Al-NPB MMCs. The 4 wt. % TY-NP reinforcement provides the most effective balance, as it maximizes hardness by strengthening the matrix without introducing the drawbacks associated with excessive reinforcement, such as particle clustering and stress concentration. This optimized reinforcement level improves the composite’s resistance to deformation and makes it a suitable candidate for applications demanding high durability and structural resilience.

Compression test

The mechanical performance of Al-NPB MMCs enhanced with TY-NPs nanofillers offers valuable insights for potential applications in Armored Fighting Vehicles (AFVs). The baseline Al-NPB MMC exhibits an energy absorption capacity of 54.6 Joules (J), which serves as a reference point for evaluating the effect of TY-NP reinforcement. Introducing 2 wt. % TY-NPs increases the energy absorption to 68.2 J, attributed to the mechanical properties of TiCN and Y₂O₃ NPs. TiCN’s ceramic toughness enhances the rigidity of the composite, while Y₂O₃’s high surface area allows for better stress distribution, thereby improving compressive resistance. This combination fortifies the MMC, enabling it to withstand higher compressive loads and enhancing structural resilience.

The optimal reinforcement level is observed at 4 wt. % TY-NPs, where the composite achieves energy absorption of 75.4 J. At this concentration, TY-NPs are uniformly distributed within the Al-NPB matrix, facilitating effective stress dissipation under compressive loads. This uniform distribution prevents localized deformation and enhances the load-bearing capacity of the composite. Such a configuration is ideal for AFV armor, which requires materials capable of withstanding extreme impact and compressive forces. However, increasing the reinforcement to 6 wt.% leads to a slight decline in energy absorption, down to 70.5 J. Although this is still higher than the base material, the decrease from the peak performance at 4 wt. % can be attributed to nanoparticle agglomeration, which causes stress concentrations that diminish compressive strength.

The 4 wt.% TY-NP loading in Al-NPB MMCs appears optimal for enhancing mechanical properties in AFV armor applications. This reinforcement level achieves a balanced composite with superior energy absorption, offering better protection against mechanical failure under high-stress conditions. These findings are significant for material selection and design in future AFVs, emphasizing the need for precise engineering to achieve optimal nanofiller distribution for superior mechanical performance. This research demonstrates that MMCs, when carefully designed, can provide a unique combination of lightweight, high strength, and resilience, meeting the rigorous demands of military applications.

The FE-SEM images provide further evidence of the impact of different TY-NP loadings on the microstructural characteristics of Al-NPB MMCs under compressive loading. Figure 8a shows the pristine Al-NPB MMC, which exhibits high porosity, a rough surface texture, and visible cleavage planes. These features are indicative of significant plastic deformation, suggesting that the base material undergoes ductile fracture with substantial strain before failure. Figure 8b and c show the Al-NPB MMC with 2 wt. % TY-NPs, revealing a reduction in surface roughness and extrusion, indicating improved durability and resistance to deformation. The addition of nanofillers begins to enhance the material’s toughness, as the TY-NPs act as obstacles to dislocation movement, resulting in higher yield strength and less plastic deformation.

The microstructure of the 4 wt. % TY-NP reinforced MMC, shown in Fig. 8d and e, exhibits minimal deformation with a relatively smooth and intact surface. The uniform distribution of TY-NPs at this optimal concentration facilitates even stress distribution, enhancing the composite’s strength and toughness. The nanofillers provide structural support to the matrix, increasing load-bearing capacity and energy absorption. However, Fig. 8f reveals the microstructure of the 6 wt. % TY-NP reinforced MMC, where surface imperfections such as cracks and cavities become apparent. These defects suggest that excessive nanofiller content leads to agglomeration and clustering, which in turn creates stress concentration zones that undermine structural integrity. These areas act as initiation points for failure mechanisms under compressive loads, reducing the composite’s mechanical performance compared to the 4 wt.% reinforcement level.

Corrosion analysis

Tafel plot analysis of corrosion susceptibility (Ecorr) and corrosion current density (Icorr) provides a robust empirical framework for evaluating the corrosion resistance of Al-NPB MMCs reinforced with various weight percentages of TY-NPs. The corrosion potential (Ecorr) indicates a material’s tendency to corrode; a less negative Ecorr value signifies reduced susceptibility to corrosion. In parallel, corrosion current density (Icorr) correlates with the corrosion rate; a lower Icorr suggests a slower degradation rate. The 4 wt. % TY-NPs reinforced Al-NPB MMC exhibits the most favorable corrosion characteristics, with an Ecorr of -201 V and an Icorr of 6.516 μA/cm2, as shown in Table 3. This enhancement stems from the synergistic effects of TiCN and Y₂O₃ nanoparticles. The inherent hardness, high melting point, and corrosion resistance of TiCN form an efficient nanoscale barrier, limiting the penetration of corrosive agents. The TiCN encasement on Y₂O₃ nanoparticles further fortifies the MMC’s surface, creating a protective shield that inhibits the diffusion of corrosive species, thus slowing down the corrosion process.

Y₂O₃, known for its exceptional thermal stability and chemical inertness, acts as an additional physical barrier, further preventing corrosive elements from breaching the surface35. The robust lattice structure of Y₂O₃ enhances the composite’s resistance to corrosion by providing a layer that is difficult for corrosive agents to penetrate. Together, TiCN and Y₂O₃ deliver a dual-protection mechanism: TiCN serves as a primary corrosion-resistant layer, while Y₂O₃ reinforces this defense by providing a secondary layer of protection. The combined presence of these reinforcements leads to a marked reduction in corrosion rate, with the 4 wt. % TY-NPs concentration yielding optimal corrosion resistance among the studied samples.

The 6 weight% TY-NPs augmented MMC had a lower Ecorr (-276 V) and greater Icorr (7.183 μA/cm2) than the 4 weight% specimen, as shown in Table 3. This might be attributed to particle agglomeration or clustering at higher concentrations, which creates weak places in the matrix and allows corrosive species to enter. As a result, this reduces the composite capacity for corrosion resistance. A proportionate incorporation of TiCN-coated Y₂O₃ NPs, as demonstrated in the 4 weight% TY-NPs augmented AINPB MMC, may significantly enhance corrosion resistance. This is critical for materials utilized in extreme atmospheric conditions like those experienced by AFVs. Evaluation of MMC samples containing 2% and 6% TiCN-coated Y₂O₃, depicted in the SEM pictures of Fig. 9, demonstrates critical properties. The photos show a high surface roughness, representative the existence of porosity or voids in the material. This porosity can be caused by corrosion processes that lead to the accumulation of corrosion products such as oxides or rusted deposits. These deposits arise when the substance reacts with caustic agents, producing new compounds. Their presence frequently indicates continuing corrosion, which can degrade the material’s mechanical qualities and corrosion resistance.

Furthermore, holes on the substrate’s interface may indicate surface deterioration. Erosion, pitting, or local material loss can all cause these voids, and significant ruggedness can indicate inadequate distribution of reinforcing nanofillers or inadequate interfacial bonding. These locations are susceptible to corrosion sites, and favored corrosion may occur, particularly in multi-phase materials such as MMCs, where distinct phases have contradictory corrosion resistances. Galvanic corrosion may be contributing to this problem, as the MMC matrix and augmenting nanofillers establish a galvanic pair, speeding up the corrosion of the less noble constituent.

In contrast, SEM pictures of the 4% augmented MMC sample exhibit lesser ruggedness and fewer dendrites and grains. A finer appearance, as evidenced by decreased roughness, could suggest an improved dispersion of augmenting nanofillers and a more powerful reinforcement-matrix bond, hence improving protection against corrosion and overall resistance. Dendrites and grains formed during consolidation indicate a more sophisticated morphology with superior crystallographic equilibrium, which may contribute to superior mechanical and corrosion resistance qualities.

Figure 9 depicts the variation in morphology among MMCs augmented using 2%, 4%, and 6% TY-NPs. These variations might be ascribed to considerations that include the type of electrolytes employed and the voltage supplied over time. These variables can affect the development of corrosion products as well as the quantity of surface deterioration. The corrosion resistant qualities of these elements have important consequences for latent relevance such as armored fighter vehicles (AFVs). The MMC sample contains 4% TY-NPs, with its enhanced microstructure, material dispersion, and more robust reinforcement-matrix bonding, may improve the ballistic properties of AFV. It outperforms MMC specimens reinforced with 2% and 6% TY-NPs in terms of distortion and piercing resistance, as well as corrosion resistance.

Comprehensive ballistic evaluation of MMC

The findings of this research highlight the substantial advantages of TY-NP-reinforced Al-NPB MMC as a versatile alternative to traditional rolled homogeneous armor (RHA) carbon steel in armored fighting vehicles (AFVs). This superiority is attributed to the composite’s unique material properties, process stability, precision in dimensional control, and its inherent capacity to meet stringent functional requirements. The TY-NP-reinforced Al-NPB MMC demonstrates impressive toughness and wear resistance, enabling effective dispersion and absorption of impact energy. The inclusion of Y₂O₃ nanoparticles in the composite further enhances its resilience by providing a robust barrier against projectile penetration, ensuring the armor’s structural integrity under ballistic conditions. Additionally, Y₂O₃’s exceptional thermal properties allow it to absorb and dissipate heat generated from ballistic impacts, reducing the risk of thermal damage to the armor and enhancing overall survivability.

The strategic combination of TiCN and Y₂O₃ within the metal matrix contributes to a composite that significantly mitigates impact energy, prevents projectile penetration, and elevates ballistic resistance energy not only enhances mechanical strength but also optimizes the composite’s energy absorption and thermal management, which are critical in high-stress environments40. Importantly, the Al-NPB MMC offers a significant reduction in density compared to RHA steel, achieving similar or superior protection levels at a reduced weight. This translates to a potential 35–45% decrease in weight for AFVs, which can greatly enhance vehicle maneuverability and fuel efficiency without compromising protective performance.

To meet DRDO specifications, TY-NPs are incorporated at reinforcement levels of 2%, 4%, and 6%, with armor plates fabricated in thicknesses ranging from 10 to 14 mm. This controlled integration of nanofillers allows for precise tuning of the material’s mechanical and ballistic properties, ensuring optimal performance across various threat scenarios. The resulting Al-NPB MMC with TY-NP reinforcement emerges as a promising, lightweight, high-strength alternative to traditional steel armor, offering improved protective capabilities for advanced defense applications while meeting the rigorous standards of modern AFVs.

Simulation for assessment

(a) Material substitution in MMCs:

In the production of plates for ballistic evaluation, the principle of mass equivalence is often applied to ensure that introducing nanofillers into the composite does not significantly alter the overall mass of the plate. However, due to the differing densities of nanofillers and the base material, such substitutions can affect the plate’s shape factor, defined as its unique geometry and mass distribution. Altering the shape factor has the potential to influence ballistic performance by modifying how stress disperses and deformation patterns develop under impact. To address this, any reduction in the composite volume caused by the removal of a specific mass of base material is carefully calculated. An equivalent volume of nanofillers is then introduced to replace the removed material, ensuring that the composite’s volume and shape factor remain consistent, despite the density differences between the TY-NPs and the MMC matrix.

The application of varied nanofiller weight percentages (2%, 4%, and 6%) requires maintaining stability in the composite’s form across different reinforcement levels. For each specified percentage, the exact volume of nanofillers needed to replace the extracted base material is meticulously calculated and incorporated into the composite. These calculations are foundational for creating plates with consistent volume and shape factor, which are essential for meaningful ballistic analysis. When substituting 2% of the composite with nanofillers, the concept of mass equivalence is challenged due to the density differences between the TY-NPs and the base MMC material, resulting in changes to the shape factor. To address this potential distortion, the lost volume is accurately measured, and an equivalent volume of nanofillers is added to ensure consistency. This methodology is repeated for 4% and 6% weight fractions, as detailed in Table 4.

Ensuring volume consistency across composite plates is paramount to the accuracy of finite element analysis for ballistic testing41. The values derived from these calculations enable the construction of plates that maintain consistent volume and shape factors across varying nanofiller concentrations. By doing so, the influence of changes in stress distribution and deformation patterns on ballistic performance is minimized. This approach is crucial for the development of advanced materials for ballistic protection, as it allows for the precise assessment and optimization of mechanical properties and ballistic efficacy in composite plates. By maintaining a stable shape factor and volume despite nanofiller incorporation, this methodology supports a reliable framework for integrating advanced reinforcements, such as TiCN and Y₂O₃, into Al-NPB-MMCs, enhancing their resistance to ballistic impacts42,43.

(b) Distribution of TY-NPs in Al-NPB-MMC

Utilizing MATLAB software, a Monte Carlo algorithm was employed to stochastically distribute spherical nanoparticles within the composite matrix1,3, a process detailed in Supplemental Code S1. This method ensures a truly random distribution of TY-NPs within the Al-NPB-MMCs, accurately replicating the heterogeneous structure of the reinforced material. The samples produced with this protocol underwent rigorous ballistic testing, with results documented in Table 5.To validate the model and assess the endurance of the composite material in modern combat scenarios, testing adhered to STANAG (Standardization Agreement) guidelines44. These NATO standards provide comprehensive criteria for evaluating armor resistance against various ballistic threats, including small arms fire and shell splinters44. By adhering to these well-defined parameters, the study aims to position the MMCs as a viable and modular alternative to traditional Rolled Homogeneous Armor (RHA) steel commonly used in armored fighting vehicles (AFVs).

RHA (Rolled Homogeneous Armor) steel is renowned for its robustness and effectiveness in providing ballistic protection45 however, its substantial weight significantly restricts vehicle maneuverability and reduces fuel efficiency46. This study evaluates Al-NPB-MMCs reinforced with TY NPs, aiming to meet or exceed ballistic performance benchmarks traditionally achieved with RHA steel, yet without the associated weight burden. This approach aligns with NATO STANAG 4569 standards, which set stringent requirements for combat vehicle armor. Demonstrating that the Al-NPB-MMC composite achieves comparable or superior ballistic resistance paves the way for a paradigm shift toward advanced composite materials in defense applications.

The compliance of these enhanced composites with recognized defense standards emphasizes their tactical significance. Meeting the STANAG criteria not only verifies the material’s ability to withstand prescribed ballistic threats but also highlights its strategic advantage by providing enhanced protection with reduced weight. This weight reduction is critical in modern armored vehicle design, where mobility and operational range are just as vital as protection. These findings indicate that Al-NPB-MMCs fortified with TY nanoparticles have the potential to become a viable alternative to conventional RHA steel in armored vehicles, improving mobility without compromising on safety.