Abstract

The Gold Ore Tailings (GOTs) are one of the major waste materials in the mining sector. The disposal of these tailings could be a problem for human health and a major environmental concern for several years. In this research work, the GOTs were used as an alternative material to the River Sand (RS) in the production of Geopolymer Concrete (GPC). Thus developed GPC samples were tested for its durability characteristics, such as resistance to sulphates and chlorides. The sulphate attack test was conducted by immersing the Conventional Concrete (CC) and GPC samples in 5% Magnesium Sulphate (MgSO4) solution for various curing periods. In this test, the GPC samples showed a reduction in compressive strength and weight, which is slightly more when compared to CC samples. The Rapid Chloride Penetration Test (RCPT) was also conducted to know the chloride ion penetration in which GPC samples exhibited less chloride penetration when compared to CC samples. Further, the Toxic Characteristic Leaching Procedure (TCLP) analysis showed that the GOTs have very high concentrations of hazardous metals. However, the concentration of Cyanide (CN−) was minimal in GOTs. In this regard, geopolymerization would be a better method for immobilizing the hazardous metals in GOTs.

Similar content being viewed by others

Introduction

The mining and construction industries generate the majority of the waste in the globe. Especially, the mining industry faces difficulty due to the generation of large volume of waste material and the associated problem in disposing this waste. These waste products contribute to environmental problems, such as soil contamination, acid mine drainage, and so on. Mining wastes, such as tailings of zinc, copper and gold have adverse effect on the environment1. Researchers have made numerous contributions to the reduction of these mine wastes. In India, the mining industry produces a large quantity of about 1.5 million tons of Gold Ore Tailings (GOTs) that have not been used for several years. The GOTs were obtained during the extraction of calaverite ore. Hence, an attempt should be made for the effective utilization of industrial waste in the construction industry in different forms. The GOTs can be used as filler material in the construction fields to make bricks, tiles, interlocks etc2,3,4,5,6. The GOTs can also be used as filler materials in the manufacture of concrete, especially in the Geopolymer Concrete (GPC), due to its more silica and aluminium7. The various researchers8,9,10,11,12,13,14,15,16,17,18,19,20,21,22used GOTs as replacement material in the production of various types of concrete and studied the mechanical properties of concrete. Some researchers7,23,24,25,26,27,28,29,30 utilized the mine ore tailings in the preparation of GPC and evaluated their mechanical properties. A few authors7,26,31,32,33,34 contributed their study towards utilization of GOTs in the production of geopolymer mortar and investigated the unconfined compressive strength and brazilian indirect tensile strength.

Shaikh36 presented a study on mechanical and durability properties of Fly Ash (FA) based GPC prepared using Recycled Coarse Aggregates (RCAs).The study revealed that the mechanical and durability characteristics of GPC were unfavourably affected due to the addition of RCAs.

A related research was carried out by Kurtoğlu et al.37 on mechanical and long-term durability characteristics of GPC which was prepared using fly-ash and slag. They prepared three types of specimens, such as FAGPC (100% FA), SGPC (100% GGBFS), and OPC (i.e. Ordinary Portland Cement) specimens. The outcome of their research demonstrated that the SGPC has better strength and more durable than FAGPC due to the presence of alumina-silicate materials in the GGBFS. The study also exhibited that the FAGPC has better resistance to the durability performance but lower mechanical properties when compared to OPC specimens. The decrease in strength in FAGPC was mainly due to low calcium content, less reactivity, and more porous structure in FA particles.

One more related work was conceded out by Manjunath et al.38 on performance GPC mixes subjected to aggressive environment, such as acids, sulphates and chlorides. Their study exhibited that there was reduction in compressive strength due to deterioration of GPC mixes exposed to 5% sulphuric acid solution to one year duration, which was in the range of 36.4–39.1%. Similarly, exposure to 10% MgSO4 solution showed that the deterioration of compressive strength was in the range of 15.5–20.5% to the end of one year.

Further, Waqas et al.39 have studied the influence of bentonite on mechanical and durability characteristics of GPC which was manufactured using high calcium fly ash (HCFA) along with natural and recycled aggregates. The study demonstrated that the addition of bentonite by 10% weight to HCFA gives better mechanical, durability, and rheological properties for both Geopolymeric Recycled Aggregate Concrete (GRAC) and Geopolymeric Natural Aggregate Concrete (GNAC).

Sikder and Saha40 reviewed the durability properties of GPC prepared using various types of waste materials, such as FA, GGBFS, Metakaolin (MK), Red Mud (RM), Ferrochrome Slag (FS), Rice Husk Ash (RHA), Sugarcane Bagasse Ash (SBA), and Palm Oil Fuel Ash (POFA) as binders. By referring to the various literatures, the authors concluded that the durability properties of GPC prepared with FA, and GGBFS shows better resistance when compared to other wastes.

Arpitha and Rajasekaran35 have carried out the research on durability properties of concrete of M40 grade, which was prepared using copper slag and GGBFS, as partial substitute to the fine aggregates. They conducted the Toxic Characteristics Leaching Procedure (TCLP) test to examine the concentration of sulphates, chlorides and sodium ions in the concrete. Their research study concluded that the developed concrete showed the better strength and durability against sulphate, chlorides and sodium ions up to one year of exposure condition.

However, no research has been published on the use of GOTs as finer materials in the production of GPC with RCAs. The current study emphasizes on the durability characteristics of GPC manufactured using GOTs along with RCAs. The laboratory tests were performed to determine the durability of GPC, such as resistance to sulphate and chloride attack. Since, cyanide is used during the process of extraction of gold it is mandatory to investigate its presence and heavy metals in GOTs before its commercial utilization. The leachability test was also carried out to assess the occurrence of hazardous metals in the GOTs.

Materials and methods

Raw materials

The GOTs were collected from gold mines in southern part of India. The geotechnical properties were determined, as per the ASTM Standards41,42. The GOTs results obtained from the laboratory study were within the allowable limits as per ASTM Standards43 which is indicated in Table 1. Further, the hydrometer analysis was performed to know the particle size distribution for GOTs as per ASTM 200744, in which more than 88.78% of particles were below 1.0 mm in size and remaining 11.32% of particles were above 1.0 mm in size which is depicted in Fig. 1. Hence it can be used only a partial replacement material to the RS in the production of GPC.

The locally available fine aggregates i.e., River Sand (RS) were used for the preparation of GPC. The physical properties of RS were investigated and obtained values43, were within the tolerable bounds as per Indian Standards (IS): 2386 − 1963 Part III45, which is shown in Table 1. The sieve analysis was conducted to know the particle size distribution for RS as per IS: 383–197046, which is shown in Fig. 1. The sieve analysis test indicated that 45.6% of sand particles were retained in the 0.6 mm sieve, more than 35% of particles were retained in the 0.3 mm sieve, 15% of particles were above 1.18 mm in size, and the remaining 4.4% of particles were retained by 0.15 mm sieve size. Hence, the sand particles were considered as well-graded, and it was used as a finer material in the preparation of GPC. The crushed old concrete cubes were utilized as Recycled Coarse Aggregates (RCAs) and their physical properties were determined. The tests conducted on RCAs shown that the obtained values43, were within the permissible limits as per BIS: 2386 - 42016; IS:2386 − 1963 1963; IS:2386 Part I 1963; IS: 2386- Part III 196345,47,48,49. The obtained physical properties of RCAs were shown in Table 1.

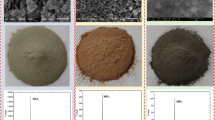

The Class F fly ash (FA) was utilized as a binding material which is collected from nearby power plant. The physical characteristics of FA were also investigated and the results were within the permissible bounds as per Bureau of Indian Standards (BIS) 200443, which is shown in Table 1. The GGBFS was used as a partial substitute material to the binding material (i.e., FA). The physical characteristics of GGBFS were assessed and obtained values were within the acceptable bounds as per BIS43 which is indicated in Table 1. The sodium hydroxide pellets (NaOH), sodium silicate (Na2SiO3) solutions, and naphthalene based super-plasticizers (SP 575) were obtained from the nearby chemical industries. The chemical properties of NaOH, Na2SiO3and SP 575 were determined51 in which obtained results are indicated in Table 1. The Fig. 2 exhibits the raw materials used for the preparation of GPC.

(f) RCAs, (g) NaoH pellets, (h) Na2SiO3 solution and (i) Super plasticizer (SP 575).

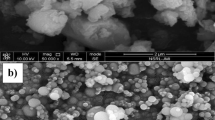

The chemical composition of GOTs, FA and GGBFS were ascertained by conducting X-ray florescence (XRF) analysis, which exhibited that the GOTs as well as FA has high silica and alumina content43, and the GGBFS has more calcium content51. The Field Emission Scanning Electron Microscopy (FESEM) analysis also performed to know the morphological view of raw materials (i.e., GOTs, FA and GGBFS). The morphology of FA is smooth spherical shape and, GOTs is looks like an uneven type of structure with small quartz particles were observed which is given in Fig. 3 (a) and, Fig. 3 (b) respectively. The morphology of GGBFS also looks like a crystalline type of structure and is depicted in Fig. 3 (c).

Experimental setup

For this research work, the 14 M NaOH solution was used (i.e., dissolving 404 gm of NaOH pellets in 596 gm of water to get 1 kg of NaOH soultion). Thus, prepared 14 M NaOH solution and Na2SiO3 solution were mixed for 5 min and kept for 24 h so as to get alkaline activator solution.

The GOTs, RS, FA, GGBFS, and RCAs were mixed in a dry manner for two minutes. After that, alkaline activator solution was added to the dry mixture. Further, mixing was continued to get homogenous mixture. The SP 575 was added to the wet mix to get required workability of geooplymer mix. The wet mix was poured in to the cubes (of size 150 mm × 150 mm × 150 mm). Totally, 21 cubes were prepared for determining the durability properties of GPC samples. In addition to above samples, for the purpose of comparison, M40 grade of conventional concrete (CC) of 21 cubes was also casted using OPC 43 grade cement with water - cement ratio (i.e., W/C) of 0.45.

Mix design

For this research work, the mix design was presumed with reference to the available literatures25,51. The mass of combined aggregates was taken as 75–80% of total weight of concrete. The 30% weight of concrete was occupied by RS and remaining 70% by RCAs. Further, 15% of RS was replaced by GOTs by weight (i.e., 15% GOTs and 85% RS). Similarly, the FA was replaced by 30% of GGBFS by weight and it was the optimum mix (i.e., 30% GGBFS and 70% FA). The main reason for adding GGBFS in to the FAs is that to speed up the setting time of GPC. The alkaline solution to the binder ratio (i.e., AL/B) was assumed as 0.45. The mix proportions of GPC and CC is given in Table 2.

Curing of GPC and CC samples

The prepared GPC samples were demoulded after 24 h and were cured in an ambient (i.e., in air) temperature for 28 days. Similarly, the CC samples were cured in water for 28 days.

Durability of concrete

The durability is defined as the concrete’s ability to endure the water pressure, chloride attack, acid attack, sulphate attack, and corrosion due to weathering action. In this research work, three types of tests were performed to determine the durability of GPC and CC samples, such as resistance to magnesium sulphate (i.e., magnesium sulphate attack test), resistance to chloride penetration (i.e., Rapid Chloride Permeability Test (RCPT) and bulk diffusion test) and leachability test.

Laboratory tests, results and discussions

Sulphate attack test

After 28 days of curing, 3 GPC and 3 CC cubes were taken and its compressive strength and weight were determined. The remaining 18 samples were immersed in 5% magnesium sulphate solution (i.e., 50 gm MgSO4 flakes were dissolved in 950 ml of distilled water) for different exposure conditions (i.e., curing period), such as 28 days, 56 days, 90 days, 180 days, 270 days and 365 days. For every exposure condition, 3 samples were tested for its compressive strength and weight. Figures 4 and 5 shows the test results of the compressive strength and weight, respectively. As shown in the figures, initially the compressive strength and weight or mass were slightly increasing up to 180 days curing condition. After 180 days there was a gradual decrease in their strength and weight i.e., for 270 days and 365 days exposure conditions. This increase in mass was because the magnesium sulphate solution reacted with cement hydration products, filling the material’s pores and increased its mass until 180 days. After 180 days of sulphate attack, the mass continued to decrease as hydration products such as C-S-H and calcium hydroxide gradually dissolved or decomposed from the surface, causing specimens to become severe loose and sanding. In case of compressive strength, initially, the hydration expansive products ettringite, gypsum, and sulphate crystals filled the pores to improve compressive strength. Then the expansion force of ettringite and gypsum and the crystallization pressure produced by the sulphate crystallization began to act on the pore walls. When the pressure of the pore wall exceeded the concrete tensile strength, many internal micro cracks appeared and decrease its compressive strength for 270 days and 365 days. The CC samples shown lesser loss in compressive strength and weight as compared to GPC samples.

The presence of calcium hydroxide (Ca (OH)2) with C-A-S-H gel in the CC forms the brucite layer which act as a protective film to the CC38, which is observed from FESEM analysis as shown in Fig. 6. But the nonexistence of brucite layer in GPC, leads to direct environment attack on GPC, due to the presence of magnesium ions in the C-A-S-H structure resulting in the creation of magnesium–silicate-hydrate (M-S-H) and gypsum. These M-S-H and gypsum are generous in nature which cannot accommodate the pore spaces of GPC mixes, resulting in the formation of cracks in the concrete and hence reduction in their strengths. The corrosion of hydrated products in GPC also results in the reduction of strength and weight after 270 days, and 365 days exposure conditions.

Further, the FESEM analysis was performed to observe the micro structure view of GPC subjected to sulphate attack (i.e. immersion in MgSO4 solution) which is shown in Fig. 7. A close look at Fig. 7 exhibits plate-like structure, such as M-S-H gel and fibrous type of structure (gypsum). The morphology of the GPC looks like a rounded, angular and sometimes crystal shapes, with large voids and micro-cracks, after 365 days of exposure in the MgSO4 solution. From the FESEM analysis, it can be revealed that the decrease in compressive strength and weight were mainly due to the macro-cracks in the hydrated products, such as M-S-H and gypsum. The FESEM-EDAX analysis was also performed to know the trace elements present in the GPC as well as CC samples. The test results proved the presence of Si, Al, O2, Mg, Na, C, and S in the GPC mixes.

Resistance to chloride ion penetration test

The resistance of GPC and CC to chloride ion penetration was ascertained by conducting Rapid Chloride Permeability Test (RCPT) as per ASTM C 1202 - 12 Standards and the experimental setup for RCPT is shown in Fig. 8. For this test, 3 GPC and 3 CC cylindrical samples (of size 100 mm diameter and 50 mm height) were considered and the voltage was applied on these cylinders for 6 h. The current flowing in each cylinder was recorded to find coulombs of that particular cylinder. The voltage passed through the GPC and CC mixes were recorded to determine chloride ion penetration which is indicated in Table 3. These test results indicated that the chloride ion penetration is low in GPC mix (i.e., higher values of charge passed in terms of coulombs) as compared to CC mix.

Further, the resistance due to chloride ion penetration was ascertained by conducting bulk diffusion test as per ASTM C 1556 - 04. For determining depth of chloride ion penetration, 3 GPC and 3 CC cylindrical samples (of size 100 mm diameter and 200 mm height) was employed. After that the cylindrical samples were engrossed in 3.0% sodium chloride (NaCl) solution for a period of 35 days. After 35 days the samples were placed in air curing for 28 days. Then these specimens were halved longitudinally using compression testing machine and 0.1 M of AgNO3 (silver nitrate) solution was sprayed on its surface. The depth of the chloride ion penetration was determined as the colour of concrete turns to white due to AgCl2 as end product in the reaction mechanism. The cylindrical specimens (i.e., GPC and CC mixes) after halved into two equal parts to know the chloride ions which is shown in Fig. 9.

From the results of depth of penetration of chloride ion in the GPC and CC specimens, the bulk diffusion co-efficient can be determined using Eq. (1).

where, XD = depth of chloride penetration metres, D = diffusion co-efficient (in m2/s), and.

t = exposure time (in seconds).

The obtained bulk diffusion co-efficient values of GPC and CC mixes are given in Table 3. From the results, it can be seen that the average bulk diffusion co-efficient values of CC mixes were higher than the GPC mixes.

Leachability test

The leachability test was conducted as per the United States Environmental Protection Agency (USEPA) 1311 Toxicity Characteristics Leaching Procedure (TCLP) Standards to determine the toxic elements present in the GOTs as well as GPC. For this test 25 gm of GOTs which is passing through 9.5 mm sieve size was taken in four bottles. The GOTs sample was mixed with 0.57% of acetic acid (i.e., solid to liquid ratio 20: 1) and placed in rotary equipment which is shown in Fig. 10. After that the mixture was rotated at 30 ± 2 r.p.m for 18 h under room temperature. Thus, obtained mixture was poured on 0.45 μm membrane filter and extraction fluid (lechates) was collected.

The collected extraction fluid was tested using Inductively Coupled Plasma (ICP-MS) analysis to know the presence of toxic elements, such as As, Pb, Cd, Cr, Fe, Hg, Zn etc. The results of the ICP-MS analysis are depicted in Table 4. As indicated in Table 4, except Pb the concentration of all the other elements under consideration were above the permissible limits. Further, As, Zn, Fe, and Hg metals may be considered as hazardous materials as their concentration is high. The presence of cyanides (CN−) was 2.36 mg/L, which is considered as low31. The negative concentration of Hg in the GPC indicates that the sample was analyzed but the concentration was below the USEPA limits of analytical method. The negative concentration may also due to the instrumental error, sample matrix, not matching calibration standards etc. In those cases errors must be corrected and considered the negative values as zero. Hence these metals can be immobilized in the process of geopolymerization. These results encourage to utilize GOTs for production of GPC in the construction sector.

Conclusions

In this research work attempt has been made to utilize GOTs in the manufacturing of GPC. The raw materials used for the preparation of GPC were tested for its physical properties and it was found that all the ingredients were within the allowable limits as per BIS. The GOTs were used as a partial replacement to the RS. The cube and cylindrical samples were prepared and were tested for its durability properties. The following conclusions are drawn from the various tests conducted on both GPC and CC samples:

-

The magnesium sulphate attack test results confirmed that the compressive strength and weight of GPC samples were increasing for the initial exposure period of 28 days, 56 days, 90 days, and 180 days. But there was a loss in compressive strength and weight for270 days and 365 days exposure, and this loss was more when compared to CC samples. The study demonstrated that the GPC has M-S-H gel and gypsum, which are expansive in nature and hence cannot accommodate the pore spaces of GPC mixes. This results in the formation of cracks in the concrete, which leads to loss in the strength and weight. The deterioration of hydrated products in the GPC also facilitates the decrease in the strength and weight of GPC after 270 days, and 365 days of exposure conditions.

-

The rapid chloride penetration test as well as bulk diffusion test results proved that the chloride penetration rate is less in GPC mixes as compared to CC mixes. The lower diffusion co-efficient values of GPC mixes safeguard against corrosion of rebar’s in the concrete structures.

-

The leachability test revealed that the GOTs comprises high concentration of As, Zn, Fe, and Hg, and hence these metals can be considered as hazardous metals present in GOTs. However, these toxic metals can be effectively immobilized in the process of geopolymerization during the manufacturing of GPC, which was proved by ICP-MS analysis. Further, this analysis also exhibited that the GOTs contains CN- of 2.36 mg/L, which is considered as within the safe limit.

-

Finally, this study concluded that the GPC showing the better durability properties in terms of alkalis and acids. The utilization of GOTs in the preparation of GPC promotes the natural resources and thus reduces the consumption of CO2 gases which leads to the eco-friendly environment. Further, the GOTs would be used as 100% replacement material to RS along with suitable additives in the production of various types of concretes, such as Light Weight Concrete (LWC), Ultra High-Performance Concrete (UHPC), Self-Compacting Concrete (SCC) etc. The thermal conductivity test and fatigue behaviour analysis can also be performed on GPC prepared using GOTs.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Rai, A. & Rao, D. B. N. Utilisation potentials of industrial/mining rejects and tailings as Building materials. Manag Environ. Qual. Int. J. 16 (6), 605–614. https://doi.org/10.1108/14777830510623673 (2005).

Roy, S., Adhikari, G. R. & Gupta, R. N. Use of gold mill tailings in making bricks: A feasibility study. Waste Manag Res. 25 (5), 475–482. https://doi.org/10.1177/0734242X07076944 (2007).

Malatse, M. & Ndlovu, S. The viability of using the Witwatersrand gold mine tailings for brickmaking. J. South. Afr. Inst. Min. Metall. 115 (4), 321–327. https://doi.org/10.17159/2411-9717/2015/v115n4a8 (2015).

Yang, Y., Zhu, S., Li, Q., Yang, B. & Chen, Y. Research on making fired bricks with gold tailings, Proc. - Int. Conf. Comput. Distrib. Control Intell. Environ. Monit. CDCIEM 2011, pp. 1687–1690, (2011). https://doi.org/10.1109/CDCIEM.2011.411

Wei, Z. et al. Utilizing gold mine tailings to produce sintered bricks. Constr. Build. Mater. 282, 122655. https://doi.org/10.1016/j.conbuildmat.2021.122655 (2021).

Shreekant, R. L., Aruna, M. & Vardhan, H. Utilisation of mine waste in the construction industry - A critical review. Int. J. Earth Sci. Eng. 9 (1), 182–195 (2016).

Aseniero, J. P. J., Opiso, E. M., Banda, M. H. T. & Tabelin, C. B. Potential utilization of artisanal gold-mine tailings as geopolymeric source material: preliminary investigation. SN Appl. Sci. 1 (1), 1–9. https://doi.org/10.1007/s42452-018-0045-4 (2019).

Reddy, B. M. R. Use of gold mine tailings in production of Concrete-A feasibility study. Int. J. Earth Sci. Eng. 9 (3), 197–202 (2016).

Parthasarathi, N., Ramalinga Reddy, B. M. & Satyanarayanan, K. S. Effect on workability of concrete due to partial replacement of natural sand with gold mine tailings. Indian J. Sci. Technol. 9 (35). https://doi.org/10.17485/ijst/2016/v9i35/99052 (2016).

Wang, Q. et al. Approach to the management of gold ore tailings via its application in cement production. J. Clean. Prod. 269, 122303. https://doi.org/10.1016/j.jclepro.2020.122303 (2020).

Wang, J. N. et al. A novel design of low carbon footprint Ultra-High performance concrete (UHPC) based on full scale recycling of gold tailings. Constr. Build. Mater. 304, no. https://doi.org/10.1016/j.conbuildmat.2021.124664 (August, 2021).

Ahmed, T. et al. Development of ECO-UHPC utilizing gold mine tailings as quartz sand alternative. Clean. Eng. Technol. 4, 100176. https://doi.org/10.1016/j.clet.2021.100176 (2021).

Luo, B. & Luo, Z. Influence of curing regimes on the mechanical properties and microstructure of ultra-high-performance concrete blended with gold mine tailings, Mater. Lett., vol. 311, no. December p. 131527, 2022, (2021). https://doi.org/10.1016/j.matlet.2021.131527

Chen, B. et al. Effect of activated gold tailings replacing fly Ash on the properties of Cement-Based grouting material. J. Mater. Civ. Eng. 34 (5), 1–11. https://doi.org/10.1061/(asce)mt.1943-5533.0004209 (2022).

Preethi, A. V., Rajendra, S., Navneeth & Pawan Kumar, L. P. Studies on Gold Ore Tailings as Partial Replacement of Fine Aggregates in Concrete, Int. J. Latest Technol. Eng. Manag. Appl. Sci., vol. VI, no. Iv, pp. 30–32, (2017).

Consoli, N. C., Nierwinski, H. P., Peccin da Silva, A. & Sosnoski, J. Durability and strength of fiber-reinforced compacted gold tailings-cement blends. Geotext. Geomembranes. 45 (2), 98–102. https://doi.org/10.1016/j.geotexmem.2017.01.001 (2017).

Li, Q., Li, K., Ni, W., Li, D. & Chen, W. The effect of grinding time on the performance of gold tailings aerated concrete. Chem. Eng. Trans. 59 (4), 349–354. https://doi.org/10.3303/CET1759059 (2017).

Pyo, S., Tafesse, M., Kim, B. J. & Kim, H. K. Effects of quartz-based mine tailings on characteristics and leaching behavior of ultra-high performance concrete. Constr. Build. Mater. 166, 110–117. https://doi.org/10.1016/j.conbuildmat.2018.01.087 (2018).

Yao, G., Liu, Q., Wang, J., Wu, P. & Lyu, X. Effect of mechanical grinding on pozzolanic activity and hydration properties of siliceous gold ore tailings. J. Clean. Prod. 217, 12–21. https://doi.org/10.1016/j.jclepro.2019.01.175 (2019).

Ince, C. Reusing gold-mine tailings in cement mortars: mechanical properties and socio-economic developments for the Lefke-Xeros area of Cyprus. J. Clean. Prod. 238, 117871. https://doi.org/10.1016/j.jclepro.2019.117871 (2019).

Kiventerä, J. et al. Solidification/stabilization of gold mine tailings using calcium sulfoaluminate-belite cement. J. Clean. Prod. 239 https://doi.org/10.1016/j.jclepro.2019.118008 (2019).

Li, Q. et al. Analysis on gold tailings-based aerated concrete in different phases of autoclave curing based on nuclear magnetic resonance. Rev. Des. Compos. Des. Mater. Av. 29 (6), 381–387. https://doi.org/10.18280/rcma.290607 (2019).

Rangan, B. V. Geopolymer concrete for environmental protection. Indian Concr J. 88 (4), 41–59 (2014).

Hardjito, D. & Rangan, B. V. Development and properties of low-calcium fly ash-based geopolymer concrete, Res. Rep. GC, p. 94, [Online]. (2005). Available: http://www.geopolymer.org/fichiers_pdf/curtin-flyash-GP-concrete-report.pdf

Lloyd, N. A. & Rangan, B. V. Geopolymer concrete with fly ash, 2nd Int. Conf. Sustain. Constr. Mater. Technol., vol. 7, pp. 1493–1504, (2010).

Kiventerä, J. et al. Utilization of sulphidic tailings from gold mine as a Raw material in geopolymerization. Int. J. Min. Process. 149, 104–110. https://doi.org/10.1016/j.minpro.2016.02.012 (2016).

Moukannaa, S. et al. Alkaline fused phosphate mine tailings for geopolymer mortar synthesis: Thermal stability, mechanical and microstructural properties, J. Non. Cryst. Solids, vol. 511, no. December pp. 76–85, 2019, (2018). https://doi.org/10.1016/j.jnoncrysol.2018.12.031

Manjarrez, L., Nikvar-Hassani, A., Shadnia, R. & Zhang, L. Experimental study of geopolymer binder synthesized with copper mine tailings and Low-Calcium copper slag. J. Mater. Civ. Eng. 31 (8), 04019156. https://doi.org/10.1061/(asce)mt.1943-5533.0002808 (2019).

Burduhos Nergis, D. D., Vizureanu, P., Sandu, A. V., Burduhos Nergis, D. P. & Bejinariu, C. Xrd and tg-dta study of new phosphate-based geopolymers with coal Ash or Metakaolin as aluminosilicate source and mine tailings addition. Mater. (Basel). 15 (1). https://doi.org/10.3390/ma15010202 (2022).

Abdila, S. R. et al. Potential of soil stabilization using ground granulated blast furnace slag (GGBFS) and fly Ash via geopolymerization method: A review. Mater. (Basel). 15 (1). https://doi.org/10.3390/ma15010375 (2022).

Opiso, E. M. et al. Synthesis and characterization of coal fly Ash and palm oil fuel Ash modified artisanal and small-scale gold mine (ASGM) tailings based geopolymer using sugar mill lime sludge as Ca-based activator. Heliyon 7 (4), e06654. https://doi.org/10.1016/j.heliyon.2021.e06654 (2021).

Zhang, N. et al. On the incorporation of class F fly-ash to enhance the geopolymerization effects and splitting tensile strength of the gold mine tailings-based geopolymer. Constr. Build. Mater. 308, no. https://doi.org/10.1016/j.conbuildmat.2021.125112 (October, 2021).

Zhang, N. et al. Fracture properties of the gold mine tailings-based geopolymer under mode I loading condition through semi-circular Bend tests with digital image correlation. Theor. Appl. Fract. Mech. 116, no. https://doi.org/10.1016/j.tafmec.2021.103116 (June, 2021).

Liu, Q., Li, X., Cui, M., Wang, J. & Lyu, X. Preparation of eco-friendly one-part geopolymers from gold mine tailings by alkaline hydrothermal activation. J. Clean. Prod. 298, 126806. https://doi.org/10.1016/j.jclepro.2021.126806 (2021).

Arpitha, D. & Rajasekaran, C. Study on durability properties of sustainable alternatives for natural fine aggregate. J. Inst. Eng. Ser. A. 102 (4), 1105–1112. https://doi.org/10.1007/s40030-021-00580-7 (2021).

Shaikh, F. U. A. Mechanical and durability properties of fly Ash geopolymer concrete containing recycled coarse aggregates. Int. J. Sustain. Built Environ. 5 (2), 277–287. https://doi.org/10.1016/j.ijsbe.2016.05.009 (2016).

Kurtoğlu, A. E. et al. Mechanical and durability properties of fly Ash and slag based geopolymer concrete. Adv. Concr Constr. 6 (4), 345–362. https://doi.org/10.12989/acc.2018.6.4.345 (2018).

Manjunath, R., Narasimhan, M. C. & Umesha, K. M. Studies on high performance alkali activated slag concrete mixes subjected to aggressive environments and sustained elevated temperatures. Constr. Build. Mater. 229, 116887. https://doi.org/10.1016/j.conbuildmat.2019.116887 (2019).

Waqas, R. M. et al. Influence of bentonite on mechanical and durability properties of high-calcium fly Ash geopolymer concrete with natural and recycled aggregates. Mater. (Basel). 14 (24). https://doi.org/10.3390/ma14247790 (2021).

Sikder, A. & Saha, P. Effect of different types of waste as binder on durability properties of geopolymer concrete: A review. IOP Conf. Ser. Earth Environ. Sci. 796 (1). https://doi.org/10.1088/1755-1315/796/1/012018 (2021).

ASTM & D4318–00. Standards,for liquid limit, plastic limit, and plasticity index of soils this C of soils, ASTM D 4318-00. ASTM Int. 04, 1–14 (2000).

ASTM, D. - Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer, Astm D854, vol. 2458000, no. C, pp. 1–7, (2000). https://doi.org/10.1520/D0854-14

Lokesha, E. B., Aruna, M., Reddy, S. K. & Srinivasa, A. S. Physicomechanical properties and characterization of gold ore tailings and the utilization in manufacturing of geopolymer concrete with class F fly Ash and recycled coarse aggregates. J. Hazard. Toxic. Radioact Waste. 27 (4), 1–12. https://doi.org/10.1061/jhtrbp.hzeng-1248 (2023).

ASTM, D. Particle Size Analysis of Soils_, Astm, vol. D422-63, no. Reapproved, pp. 1–8, [Online]. (2007). Available: http://papers2://publication/uuid/32E2AE22-8555-4A27-B8B6-F7217202A1F2

IS 2386- Part III. Method of Test for aggregate for concrete. Part III- Specific gravity, density, voids, absorption and bulking, Bur. Indian Stand. New Delhi, p. 1963.Reaffirmed (2002).

IS:383. Specification for coarse and fine aggregates from natural sources for concrete. Indian Stand., pp. 1–24, (1970).

IS:2386 (Part I). Method of test for aggregate for concrete (Particle size and shape), Indian Stand., p. 1963.Reaffirmed (2002).

BIS: 2386-4. Indian Standards: 2386-4:1963 Method of test for aggregates for concrete-mechanical properties. Bureau of Indian Standards, New Delhi, India. 2016.Reaffirmed (2016).

IS:2386 – 1963. Methods of test for aggregates for concrete. Bur Indian Stand. 5, 1–14 (1963).

Bureau of Indian Standards (BIS). Methods of physical tests for hydraulic cement, Part 2: Determination of fineness by specific surface by Blaine air permeability method, IS 4031 (Part 2) 1999, New Delhi, pp. 1–13, (2004).

Lokesha, E. B., Aruna, M., Reddy, S. K. & Srinivasa, A. S. Development of Regression Model and Optimization of Mechanical Properties of Geopolymer Concrete Prepared Using Gold Ore Tailings, J. Hazardous, Toxic, Radioact. Waste, vol. 27, no. 4, pp. 1–14, (2023). https://doi.org/10.1061/jhtrbp.hzeng-1259

Author information

Authors and Affiliations

Contributions

E.B. Lokesha: Conceptualization, methodology, investigation, validation, writing - original draft preparation. M. Aruna: Writing - review and editing. S.K. Reddy: Review.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent for publication

All authors confirm the consent for publication.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lokesha, E.B., Aruna, M. & Reddy, S.K. Durability characteristics of geopolymer concrete produced using gold ore tailings along with recycled coarse aggregates. Sci Rep 15, 12051 (2025). https://doi.org/10.1038/s41598-025-97056-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-97056-6