Abstract

Modular robots offer adaptability and reconfigurability, yet their application in aquatic environments and dynamic multi-tasking—particularly for manipulation—remains underexplored. We hypothesize that incorporating soft-bending capabilities into modular designs can significantly enhance versatility in such settings. In this work, we introduce a variable-stiffness soft modular robot that integrates rigid 3D-printed components, soft foam, a cable-driven actuation mechanism, and a propeller for aquatic propulsion. Permanent magnets enable fast, passive inter-module connections. This robot can bend, steer, and connect with others, supporting a variety of functions. It acts as a gripper to retrieve debris from water surfaces, assembles into a floating raft for drone landings, and forms a snake-like chain that transitions seamlessly between land and water. Additionally, multiple robots can collaborate in swarm-like behaviors to transport payloads. Our findings demonstrate that combining soft deformation with modularity enables a multifunctional robotic platform capable of navigating and interacting in complex, aquatic environments.

Similar content being viewed by others

Introduction

When we think about modular robots, we think that the robots can combine to do more complex tasks. Soft robots offer significant potential for complex, dynamic environments due to their compliance and mechanical intelligence, especially in aquatic scenarios where they can adapt to water flow and handle fragile objects. Their application in aquatic domains remains largely unexplored. To address this gap, we present SoftRafts, a robotic platform that seamlessly integrates softness and modularity for on-water operations. Our design combines rigid 3D-printed components with soft foam, featuring a cable-actuated mechanism and propeller for untethered aquatic locomotion. The robot modules can not only connect to form complex structures for collaborative tasks (Fig. 1i) but also switch between soft and rigid modes, enabling unprecedented versatility. The demonstrated capabilities of SoftRafts span from amphibious navigation and diverse object manipulation to constructing deformable, variable-stiffness lattices, showcasing the unique advantages of combining soft robotics with modular design in aquatic environments.

a Single module shape deformation. b Robots form “SMILE” shapes and structures. c Two chains of modules manipulate a ball using peristaltic manipulation. d A chain of modules locomotes from the ground and gets into the water. e A raft combined with multiple modules that can move in the water. f Multiple modules formed a rigid raft structure that allows a drone to land on it. g Caging manipulation. h Water flow contact-less manipulation. i Capability table between a single module and multiple modules comparison.

In nature, many species, such as ants and dolphins, work collectively to solve challenges related to locomotion, manipulation, or structure assembly1,2,3,4. For example, beavers collaborate to construct dams and lodges1, while ants work collectively to move heavy and large objects and build rafts from their bodies to survive floods2,3,5. Inspired by such natural swarm systems, robot swarms emulate collective behavior to tackle complex tasks beyond the capability of a single robot. Modular robotics builds on this concept by enabling individual units to assemble into larger lattices, forming robots in various configurations to accomplish diverse tasks6,7,8. Significant progress has been made in terrestrial modular robots9,10,11, such as SMORES11,12 and Sambot13. Recently, researchers have extended these concepts to outdoor environments, transitioning locomotion and manipulation tasks from indoor settings. Examples include snail-inspired robots14 and multi-legged robot swarms15.

Research on modular robots designed for aquatic applications remains limited8, particularly with few studies addressing surface robotics. Surface self-assembling modular robots, typically waterborne vehicles or boats8, excelling at tasks such as forming rigid floating platforms or enabling precise maneuverability. One notable example is a study from Yim’s group in 201516, which introduced the first aquatic modular reconfigurable robots. This work developed a swarm of boats, each equipped with four propellers for precise maneuverability, capable of autonomously connecting side-by-side to form larger, lattice-like structures. Another example comes from Rus’ group at MIT17, where a fleet of autonomous boats was designed to disconnect and reassemble into various configurations. These boats demonstrated the ability to form floating structures, such as rearranging three robots from a connected straight line into an “L” shape.

While research on surface modular robots remains limited, the majority of existing studies on aquatic modular robots focus primarily on underwater environments. Block-type modular robots are commonly used in aquatic environments18,19,20. Some of these robots mimic robotic arms by creating revolute joints and links21. Variations include different connection topologies, such as stacking cylinders and connecting spheres22,23. In addition to block-type robots, bio-inspired designs have emerged as a promising approach to enhance locomotion and adaptability in aquatic environments. Popular examples include snake robots24,25,26, eel-inspired robots27,28, and fish-inspired robots29. To support these configurations, various connection and detachment techniques, along with self-reconfiguration algorithms, have been developed to ensure reliable underwater operations. Furthermore, energy-efficient self-reconfiguration algorithms have been designed to optimize the movement and assembly of modular robots, reducing energy consumption during the reconfiguration process30. Active docking mechanisms and compliant connection interfaces further enhance adaptability in aquatic environments by compensating for hydrodynamic forces and ensuring stable connections31. These advancements are essential for enabling aquatic modular robots to form complex structures and perform a variety of tasks autonomously.

To expand the capabilities of modular robots, incorporating soft materials into modular robot designs introduces a new dimension of adaptability and versatility. Soft materials provide compliance32,33,34,35, enabling robots to conform to uneven surfaces, interact more effectively with fragile or irregular objects, and provide mechanical intelligence, which allows them to passively adapt to external stimuli, such as bending under pressure or flexing to reduce drag, thereby enhancing their ability to perform complex tasks in different aquatic environments36. When integrated with variable stiffness mechanisms, soft modular robots can transit between compliant states for flexibility and stiffened configurations for load-bearing or structural tasks. This dual capability enhances the functionality of existing designs, enabling new applications such as diverse manipulation tasks and merging multiple functionalities into a single platform. These robots can form adaptable floating platforms, construct deformable lattices for various manipulation tasks, perform different types of locomotion, and transform into various shapes to meet the demands of complex scenarios.

Designing waterproof, untethered, aquatic soft modular robots presents significant challenges due to the interplay of various factors.

i) Actuation is one of the primary considerations. Different actuation methods for soft robots, such as thermal-responsive systems9, cable-driven mechanisms37,38, pneumatics39, electrically-responsive methods40,41, and magnetically-responsive approaches42, among others, offer distinct advantages and trade-offs. Enabling untethered operations while achieving essential functionalities, such as bending, steering, locomotion, and variable stiffness, poses a significant challenge in selecting the appropriate actuation method. The chosen method must balance precision, efficiency, and compactness to meet the demands of an untethered aquatic modular system.

ii) Material selection is crucial, as the materials must provide softness for compliance and flexibility, and the ability to transition to a rigid state for load-bearing or structural tasks. Commonly used materials in soft robotics include silicone, foam, and other elastomers43,44, which offer a good balance between deformability and durability. However, for building multiple modules—particularly when scaling up to more than 20—the fabrication process becomes a significant factor. It must be efficient, consistent, and scalable to ensure uniformity and functionality across all modules while maintaining the desired material properties.

iii) Waterproofing and untethering present critical challenges45,46, particularly in cable-driven systems where delicate internal mechanisms must be safeguarded against water ingress. The direct exposure of cables to water necessitates the isolation of the winch and motor while simultaneously maintaining dynamic waterproofing to allow continuous operation. The design must ensure that actuators, cables, and electronic components remain securely sealed, providing robust protection without compromising the system’s motion or overall functionality.

iv) Interconnection methods between modules are a key challenge in the development of reconfigurable in-water systems. These connections must provide robust attachment while ensuring the seamless transmission of forces and motion between modules47. Reliable interconnections are particularly crucial for creating adaptable systems capable of forming larger structures or performing collaborative tasks. Existing methods, such as programmable magnets, which are a popular choice due to their customizable magnetic fields, offer flexibility for reconfiguration48. Some systems combine magnetic attachment with mechanical mechanisms for active detachment, providing a balance of strength and controlled release49. However, both programmable magnet-based connections and combined magnetic-mechanical systems require additional power for attachment and detachment, limiting robot size and operational longevity. Purely mechanical methods, such as latch-based connectors, provide robust and power-efficient attachment16, but their limited connection area decreases tolerance and reliability in dynamic underwater conditions. Furthermore, the placement and design of connectors play a significant role in determining the system’s assembly patterns and overall versatility36. To achieve all-directional connectivity, as demonstrated in StarBlocks10, connectors must be strategically positioned to facilitate flexible reconfiguration. This ensures compatibility with a variety of assembly geometries and operational demands, enhancing the adaptability and resilience of underwater modular robots.

In this work, we aim to advance the development of untethered, aquatic soft modular robots capable of reliable operation in dynamic environments. By enabling softness through aquatic modular robots, we address this critical gap and demonstrate the concept’s potential through various application scenarios. To address the identified design challenges, we drew inspiration from the principles of push puppets to develop a cable-driven system with two strings. Each module combines 3D-printed rigid components with soft foam components and incorporates a propeller for rapid locomotion on water. By shortening strings, the robot can deform into a curve or transition from a soft, compliant state to a fully rigid state, enabling a seamless switch between tasks that require flexibility or structural rigidity. To achieve waterproofing and untethered operation, we implemented wireless charging and developed a mechanism to isolate the winch from the motor to ensure reliable performance in submerged conditions. To enable inter-module attachment from all four directions, as a proof of concept, we designed a permanent magnet-based connection system that prioritizes simplicity and compactness. The connectors are mechanical only and do not support communication or power sharing, and do not support active detachment – these are important next steps in future work.

We evaluated the robot’s capabilities across three core functionalities: locomotion, manipulation, and formation (Fig. 1i). For locomotion, individual modules perform simple motions, while multi-module configurations, such as chains for amphibious movement on ground and water (Fig. 1d) and plus-sign structures for omnidirectional navigation (Fig. 7b), showcase versatility. Manipulation tasks leverage configurations like caging for transporting objects (Fig. 1g), contactless manipulation through water currents (Fig. 1h), and wave-phase strategies for non-prehensile operations (Fig. 1c). It is also able to manipulate objects collectively (Fig. 5c, d). For formation, individual modules perform simple motions (Fig. 1a), while multi-module configurations, such as (Fig. 1b), present the shape formation and structure formation to show the word “SMILE”. The robots assemble into rafts for drone landing platforms (Figs. 1f and 4c), bridges for moving small vehicles (Fig. 4d), or carriers supporting multiple decks for aircraft operations (Fig. 4e). These experimental results demonstrate the versatility of the design and its enhanced capabilities when multiple modules are combined, underlining the potential of this approach for addressing diverse tasks in complex aquatic environments.

Results

Mechanism overview

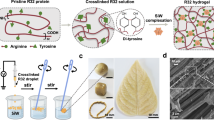

Each robot in the modular system is composed of four rigid components and a soft foam core, as depicted in Fig. 2. The front and rear rigid components (head and tail) house the controller (printed circuit board–PCB), power supply (battery), and actuators (motors). The two middle rigid components form a structural frame that securely holds the foam core, which is chosen for its buoyant and flexible properties. This design allows the foam to compress fully within the middle rigid frames, facilitating a smooth transition between soft and rigid states while maintaining a compact structure.

The robot features three primary controllers: two motors, located within the rigid head container, which control the left and right strings to enable precise bending movements. A propeller motor, housed in a 3D-printed component for protection attached to the rigid head part, drives a propeller for forward and backward motion. The combination of controlled bending and propeller thrust enables the robot to steer effectively. Although a second propeller would allow more versatile locomotion of individual modules, the minimalist single-propeller design is sufficient for our exploration of multi-modular configurations. The rear rigid container houses a sealed battery, a wireless charging module, a switch controller for power, and a power button for operation. The power cord runs from the rear components to the head components, passing through the middle of the soft foam, as depicted in Fig. 2c1, c2. This separation design balances the mass and buoyancy along the robot.

Waterproofing the cable-driven system was accomplished by isolating the winch from the motors using a combination of a shaft seal, waterproof grease, and an acrylic cover, as illustrated in Fig. 2c1. To ensure each robot is waterproof, two rubber plugs are used: one at the bottom of the rigid part of the head and the other at the tail part. Once all parts are sealed, the waterproofing is tested in two stages: static and dynamic tests. In the static test, air is injected into both containers using a syringe, and the system is observed to have approximately full rebound in the syringe, indicating a sealed environment. If the static test is successful, the robot is submerged in water and tested by visually observing if any bubbles appear when pushing air into the chamber. For the dynamic test, the propellers and motors are activated while the robot operates underwater to confirm the waterproofing under real-world conditions.

The configuration space of a single robot is determined by the lengths of two strings, s1 and s2, which control its deformation. The original width-to-length ratio of the robot is 1:2. The purpose of this design is to achieve symmetric attachment in both the original and compressed state. When both strings are shortened to half their original length, the robot transitions from a soft to a rigid state, allowing it to sustain a maximum load of 0.4 kg. In comparison, the original state can sustain up to 0.47 kg, as the internal foam is initially uncompressed and has a lower density. If only one string is shortened, the robot bends to one side, enabling shape formation and steering. As illustrated in Fig. 1a, the robot can achieve four primary states: the original state (s1 = s2 = s), bending to the left (\({s}_{1}=\frac{1}{2}s,{s}_{2}=s\)), bending to the right (\({s}_{1}=s,{s}_{2}=\frac{1}{2}s\)), and the compressed state (\({s}_{1}={s}_{2}=\frac{1}{2}s\)). Since the string lengths can vary continuously, the robot can achieve an infinite number of intermediate states, resulting in a highly versatile configuration space.

Beyond its deformation capabilities, the robot can perform locomotion and simple manipulation tasks using its propeller. The robot’s Cost of Transport (CoT) is approximately 6.84, calculated using the equation \(CoT=Power/(Weight\cdot Speed)\), where weight = 3.77 N, speed = 0.33 m/s (the robot’s maximum velocity when moving forward in calm water conditions), and power = 8.66 W represents the average energy consumption. The robot’s turning capabilities were also tested, showing a minimum turning radius of 185 mm at peak velocity (Supplementary Fig. 2).

Magnetic module connectors

Each robot is equipped with magnetic connectors on all four sides—front, back, left, and right—enabling versatile multi-robot configurations. The detailed magnet arrangement is shown in Fig. 3a–c, which supports connections between robots from various directions (Fig. 3d). When compressed, the robot forms a square from a top-down view, facilitating attachments in multiple orientations (Fig. 3e, f). This design allows the modules to assemble into various shapes tailored for specific tasks. For example, the modules can form snake-like chains for locomotion on both ground and water (Fig. 7a), a plus-sign shape with five modules for omnidirectional locomotion (Fig. 7b), or larger lattice structures for manipulation and the construction of movable platforms (Fig. 4d). The magnetic connectors exhibit significant strength, supporting approximately 2 kg before detachment; this was measured by connecting two modules vertically, gradually adding weight to the lower module, and recording the combined weight of the lower module and added mass at the point of separation. For simplicity, the current system does not include a mechanism for active detachment. In future work, we may draw inspiration from other connector systems that do permit active detachment50.

a Magnet arrangement on a single robot. b Magnet-based connection mechanism. c Example of a connection between two modules. d Four possible connection configurations when both modules are in their original state. e Four connection configurations when one module is in the original state and the other is compressed. f Four connection configurations when both modules are compressed.

a A chain of modules forms an “S” shape. b Three chains of modules form an “I” structure. c Multiple modules form a soft raft and then compress into a rigid raft, which allows a drone to land on it. d A lot of modules form a bridge, allowing a toy car to run on it. e Multiple modules form two platforms with a flat board on them. Perform as an aircraft carrier.

Shape and structure formation

Shape formation

Our modular robots can form various shapes and structures by deforming modules or through different assembly configurations (shown in Supplementary Movie 1). As shown in Fig. 4a, b, examples include forming letters such as “I” and “E” through specific arrangements and assembly methods. For a chain of robots, shapes like the letters “S” and “L” can be achieved by adjusting the string lengths of each module. The letter “M" combines both approaches: three chains are first assembled into a door-like shape, after which the middle chain deforms to complete the “M” shape.

For a chain of modules to deform into different shapes, an analytical relationship exists between the string lengths s1, s2, the angle θ, and the length L of the middle curve of the robotic structure. The structure comprises four rigid 3D-printed components, denoted as r1, r2, r3, and r4, each with a length lr. For more details, please see Supplementary Fig. 1, which illustrates the geometric configuration of the structure.

In the forward kinematics process, the resulting shape of the robot chain is calculated based on the given string lengths s1 and s2. The equations are as follows.

For s1 ≤ s2, we have:

For s1 > s2, the angle becomes negative:

At the initial state (s1 = s2 = L), the robot remains undeformed (θ = 0).

In the inverse kinematics process, the required string lengths s1 and s2 are determined to achieve a desired curve characterized by specific values of L and θ. The equations are:

where

If θ < 0, the values of s1 and s2 are swapped to reflect the negative angle.

These equations establish the relationship between the string lengths, the angle θ, and the middle curve length L, enabling precise control of the module’s shape. This analytical framework allows the chain of robots to adopt a wide range of shapes tailored to meet the demands of diverse tasks. The derivation of these equations is detailed in the Supplementary Note 1 under “Kinematics of Modular Robot”.

Structure formation

We explored the versatility of the system by forming various lattice structures for different applications (shown in Fig. 4 and Supplementary Movie 4). In one example, the modules were configured into a flat lattice structure to serve as a temporary, movable platform for drone landing, as shown in Fig. 4c. This lattice can move omnidirectionally and compress into a rigid platform, providing a stable and adaptable surface for drone operations. In another example, the robots were assembled into a larger lattice structure to form a bridge capable of supporting the movement of a small toy car, showing the robots’ ability to create structures for potential transportation tasks (Fig. 4d). Additionally, two separate movable platforms, each constructed with modular robots and topped with a rigid board, were joined together to simulate an aircraft carrier. This assembly, illustrated in Fig. 4e, demonstrates the potential of scalability and adaptability of the modular robots for larger, more complex structures.

We tested the maximum load of the robot in the rigid mode, which is designed to sustain weight. The load for a single module is about 400 g in compression and 470 g in the original state. We expect the load to scale linearly with the number of modules, based on Archimedes’ principle, i.e., the amount of water displaced will be a multiple of the number of modules, thus a multiple of the total buoyant force available.

Manipulation

Different configurations of modules are capable of various manipulation strategies to interact with and move objects. This section explores four key manipulation techniques: caging, grasping, non-prehensile manipulation, and contactless manipulation.

Caging: trash collection, transport, and enclosure

Our modular robots can form structures to surround and manipulate objects, enabling tasks such as trash collection, transport, and water enclosure. Caging stabilizes objects by forming a complete or partial enclosure. Once enclosed, the robots coordinate their movements to transport the object while maintaining the enclosure.

One example is a gripper-like caging configuration (shown in Fig. 5a and Supplementary Movie 3), where three chains of modules are connected into a door shape. We designed four control primitives that allow the gripper to move forward, left, right, and backward, enabling real-time operation for collecting and transporting trash. For the left-turn gait, the left chain’s propellers are set to run in reverse, while the right chain moves forward. For turning right, the left chain moves forward, and the right chain runs in reverse. For forward movement, both chains move forward, and for backward movement, both chains run in reverse. After the objects are collected, a fully enclosed caging mechanism ensures that all objects remain securely contained during transport.

a Caging manipulation. A robot cage formed with multiple blocks moving on the water, collecting objects floating on it, and then caging them securely. b Grasping manipulating. For large objects, the robot cage can act as a gripper and grasp the object to manipulate. c Pushing manipulation. A pile of modules deforms into the matching shape and pushes the object floating on the water. d Ant-like collaborative omnidirectional manipulation. For blocks to push the object together, by controlling the pushing force, the object can move in any direction.

This strategy is particularly effective for transporting irregularly shaped, fragile, or small objects that require a stable hold without direct physical contact. By maintaining the object within a stable formation, the caging approach ensures safe and efficient transport across dynamic aquatic environments.

Grasping for secure object transport

In the grasping strategy, the robots form a full loop around the object and contract inward to securely grip it. Unlike caging, grasping involves a tighter hold for greater control. Once grasped, the robots coordinate their movements to transport the object while maintaining a secure grip. Fig. 5b and Supplementary Movie 3 shows an example of a 2D gripper grasping a swim ring.

Non-prehensile manipulation

Non-prehensile manipulation involves interacting with objects without fully enclosing or grasping them. Instead, this approach relies on external forces or coordinated configurations to achieve desired tasks. Our modular robotic system demonstrates two distinct non-prehensile manipulation strategies:

Multi-robot collaboration for moving large objects. Inspired by the behavior of ants moving large objects3, multiple robots coordinate to apply synchronized forces to manipulate objects with physical contact but without physically attaching to them. This strategy enables the robots to collectively push or pull large objects, such as boxes or swim rings, by leveraging distributed force application. Fig. 5d and Supplementary Movie 3 illustrate an example where four modules work collaboratively to push a box in different directions. To maintain contact with the box without physically attaching to it, the propellers of all modules are carefully controlled. For instance, if robots A, B, C, and D are arranged clockwise, moving the box toward robot A requires the propellers of robots A, B, and D to operate at low speed to maintain contact, while robot C increases its propeller speed to generate the required net force toward robot A. Another example, shown in Fig. 5c and Supplementary Movie 3, involves a chain of modules connected side-by-side to push a swim ring. The modules deform to better fit the shape of the swim ring, and propeller control is used to steer and move the entire chain.

Peristaltic manipulation. This method uses two parallel chains of robots to generate wave-like contractions for moving objects. The motion is achieved by sequentially tightening and relaxing the string lengths of each module, producing a wave-like deformation similar to biological peristalsis. To implement this, one chain of robots is fitted to a sinusoidal curve, described mathematically as \(y=\sin (x+t)\), where t represents a phase shift over time. The second chain mirrors this curve symmetrically across the middle axis. The sinusoidal motion is discretized into six distinct stages per period, corresponding to evenly spaced phase shifts of \(\frac{\pi }{3}\). Each stage determines the desired string lengths s1 and s2 for each robot in the chain. These lengths are computed based on the required deformation to match the sinusoidal shape, as derived from the inverse kinematics equations. By iterating through these stages, the chains generate a traveling wave that applies periodic pressure to objects positioned between them, propelling the object forward.

The sequence of six stages ensures a continuous wave motion, with each robot transitioning smoothly between states to maintain a stable and consistent force on the object. This method is particularly effective for manipulating objects through narrow spaces or over uneven surfaces, as the wave motion dynamically adjusts to accommodate irregularities. Figure 6a and Supplementary Movie 3 illustrate the stages of the wave-like motion and the corresponding deformation of the robot chains.

Contactless manipulation

Contactless manipulation involves moving objects by generating water currents rather than through direct physical contact. As shown in Fig. 6b and Supplementary Movie 3, two chains of robots can form a tunnel to create a directed water current. This controlled flow transports objects without direct interaction, with each robot contributing to the stability and consistency of the current. The tunnel method operates similarly to the concept of a fish ladder, where a controlled current guides objects through the tunnel with precision and consistency.

Locomotion

Our modular robots can achieve diverse locomotion strategies by adopting different configurations and control approaches tailored to specific environments and tasks. The arrangement of modules determines the propulsion mechanism and the control strategy required for efficient movement. For example, chain configurations enable both amphibious locomotion and adaptability in transitioning between ground and water, while symmetrical arrangements like the plus-sign configuration allow for omnidirectional movement with precise control. Below, we present two examples illustrating how these configurations are optimized for distinct locomotion tasks.

Amphibious locomotion using a chain of modules

Inspired by the undulatory gait of snakes, we developed a gait for ground locomotion that achieves diagonal forward motion through coordinated and asymmetric lateral bending, similar to gaits used in other snake robots51,52. In this method, five modules are connected into a chain, as shown in Fig. 7a and Supplementary Movie 2. The gait alternates between bending modules 1, 2, and 5 in one direction (e.g., left) and modules 3 and 4 in the opposite direction (e.g., right), creating an unbalanced wave-like motion. This actuation sequence is then reversed, with modules 1, 2, and 5 bending to the right and modules 3 and 4 to the left. The asymmetric pattern introduces a mechanical imbalance, which propels the robot diagonally forward, even on surfaces with isotropic friction. Due to the placement of the propellers, the modules are inverted during ground locomotion, with the propellers positioned on the top side of the chain to avoid interference with the ground.

a Amphibious locomotion inspired by the undulation of a snake. The robot demonstrates snake-like movement on the ground (a1–a2) and utilizes a propeller for locomotion in water (a4). b Omni-directional locomotion demonstrated using a cross-shaped (+) configuration, enabling movement in all directions. c Lattice locomotion is achieved by actuating the propellers of modular units in different patterns, allowing coordinated movement of the entire structure.

When the chain of modules transitions into water, the center of mass causes the structure to self-right, flipping over so that the propellers are positioned underneath the body. Once in this orientation, the propellers are activated to provide efficient locomotion in the water, enabling smooth amphibious movement.

This dual locomotion strategy enables transition from ground to aquatic environments. The system leverages different mechanisms for propulsion in each domain, with a self-righting capability ensuring stability and functionality during the transition from ground to water. However, the reverse transition—from water to ground—has not yet been demonstrated and remains a potential area for future exploration.

Omni-directional locomotion in plus-sign configuration

When five modules are assembled into a plus-sign configuration, the middle module is compressed to serve as a connector, linking the four surrounding modules, as shown in Fig. 7b and Supplementary Movie 2. This configuration enables omnidirectional locomotion, allowing the robot to move in eight different directions by coordinating the actuation of the propellers on the modules, following a thruster-vectored configuration used in several classic underwater remotely operated vehicles. For instance, to move the robot diagonally toward the right-forward direction, the propellers on the left and back modules should rotate in the positive direction, while the propellers on the front and right modules should rotate in the negative direction. This coordinated actuation produces the desired net force to move the robot in the specified direction.

The plus-sign configuration demonstrates the versatility of the modular design, enabling precise control and movement across multiple directions, making it suitable for tasks requiring high maneuverability in dynamic environments.

Single module locomotion characteristic

To analyze and compare the robot’s performance across different gaits Fig. 8, we collected positional and orientational data using a setup involving an AprilTag attached to the top of the robot and a top-mounted camera for tracking. This setup enabled precise measurement of the robot’s x, y, and θ values.

The figure illustrates the global positions achieved by the robot under six different gaits: forward, backward, left front, right front, left back, and right back. The robot starts at an initial position and orientation of (0, 0, 0), with the initial orientation parallel to the x-axis. Cluster centers for each gait are marked with stars (*), indicating their corresponding positions (x, y) and orientations (θ). Dashed lines at each cluster center indicate the robot’s body orientation based on the average θ of the gait. The origin (0, 0) represents the robot’s starting position, and the dashed black line at the origin indicates its initial orientation. The robot achieved gait-specific speeds (in cm/s) and angular orientations (in degrees) as follows: forward (speed: 5.37, orientation: −2.19∘), backward (5.26, −8.76∘), left-front (5.03, 12.8∘), right-front (4.95, −17.68∘), left-back (4.64, −23.4∘), and right-back (5.36, 9.93∘).

Experiments were conducted in an open-loop control state, without feedback from sensors to adjust motion in real-time. Open-loop control offers a starting point for gait characterization, as it allows us to isolate and evaluate the robot’s intrinsic mechanical response and passive error-correcting behaviors without the confounding influence of feedback control. For each test, the robot was placed stationary in the water, minimizing disturbances from water flow and wall effects as much as possible. Each gait was executed for one second, during which displacement data was collected. We chose this short duration because longer-duration measurements would be excessively influenced by water currents, making them less reliable for characterizing the robot’s inherent motion capabilities.

For each gait, we conducted 35 trials. During these experiments, the robot started from various random initial positions and orientations. Using the recorded changes in distance (Δdistance) and orientation (Δθ), we transformed the data into a standardized local reference frame, assuming the robot’s initial position and orientation as (0, 0, 0), with the orientation aligned to the x-axis.

To ensure the analysis was robust and focused on typical gait behaviors, we filtered the data to remove outliers for each gait, retaining 30 data points that were representative of the robot’s performance. The cleaned data were then analyzed to determine cluster centers representing the robot’s average behavior for each gait, and these clusters were visualized to illustrate the motion patterns exhibited by the robot.

Discussion

This work demonstrates the versatility and adaptability of aquatic soft modular robots, highlighting their potential to address complex tasks in aquatic environments. The proposed design integrates modularity, softness, and amphibious capabilities, enabling the robots to perform locomotion, manipulation, and structure formation. The ability to transition between soft and rigid states through the combination of rigid and soft foam components allows the robots to adapt to a wide range of tasks, from forming stable structures to performing precise manipulations.

The locomotion strategies demonstrated by the modular robots, including the amphibious undulation gait and the omnidirectional plus-sign configuration, highlight their ability to operate effectively on both ground and water. In addition, manipulation techniques such as caging, grasping, peristaltic motion, and contactless methods showcase their versatility in interacting with objects without traditional grasping mechanisms, providing effective solutions for handling irregularly shaped or fragile items. Beyond locomotion and manipulation, the robots excel in structure formation, creating dynamic assemblies like flat lattices for temporary platforms, such as drone landing pads, or larger lattices for constructing structures like bridges. The ability to reconfigure into various shapes, including chains, plus-signs, and connected lattices, emphasizes the adaptability of the modular design, enabling a broad range of tasks and applications in aquatic environments.

While the results highlight the promise of the system, several limitations must be addressed in future work. The cable-driven actuation system, though lightweight and precise, relies on robust waterproofing measures, such as shaft seals and acrylic covers, which may face durability challenges during extended operation. Additionally, the reliance on propellers for aquatic locomotion introduces constraints in energy efficiency and speed, suggesting the need for alternative propulsion methods, such as bio-inspired fin mechanisms, to improve performance. Similarly, while the snake-like ground locomotion gait demonstrates proof-of-concept functionality, its forward speed remains limited. We are actively exploring strategies to improve ground mobility. Preliminary experiments with asymmetric friction elements, such as skates attached to the module base, have shown improved locomotion efficiency. Future work will further investigate the effect of mechanical enhancements and gait parameter tuning (e.g., phase lag adjustment) to increase speed and enable more practical deployment on land. Another potential enhancement involves improving the payload capacity of individual modules. Integrating air pockets or buoyant structures within the soft material could improve overall buoyancy and increase the effective payload without sacrificing mobility. For example, it is possible to integrate a programmable buoyancy mechanism 53 to enable a dynamic range of payload.

The connection mechanism, using permanent magnets, provides secure and reliable attachment between modules, unaffected by external forces. However, the current system does not support active detachment between individual modules, which constrains self-reconfiguration capability. Incorporating an active connection mechanism could enable more efficient attachment and detachment, allowing for greater flexibility in dynamic tasks. In addition to providing a mechanical connection, ideal inter-module connectors may also facilitate electrical communication and power sharing through conductive contacts or inductive coupling. This capability enables more centralized coordination and efficient energy distribution. For instance, Chen et al. presented a power-sharing mechanism integrated into SuperBot54, while the 3PAC system implemented both power sharing and communication capabilities55. There are a couple of considerations for implementing such mechanisms. First, wireless power transfer may suffer from high losses and limited capacity. Second, radio signals are ineffective, thus, communication through physical connectors is especially useful in environments like underwater.

Scalability is a critical consideration for advancing SoftRafts, and it can be understood along two axes: increasing the number of modules and increasing the physical size of each module. So far, we have demonstrated configurations with up to 24 modules. While this validates the feasibility of mid-sized assemblies, scaling further reveals both architectural and physical constraints. For scaling the number of modules, the current system uses a standard home Wi-Fi router (2.4 GHz), which in theory can support around 50–100 devices under stable conditions. However, in practice, the number of effectively connected modules is limited not just by the router’s device capacity, but also by radio interference and resource contention. As the number of active modules increases, radio noise, packet collision, and retries significantly reduce communication reliability. While the bandwidth itself may not yet be a bottleneck, real-time coordination degrades due to increased latency and jitter in control signals. Beyond 100 modules, we anticipate the need for alternative communication schemes, such as mesh networking or local broadcasting protocols. Additionally, coordination complexity becomes a central issue: synchronizing control among hundreds of modules introduces challenges in scheduling, fault handling, and distributed decision-making. To address these challenges, more advanced algorithms will be necessary to optimize coordination and performance. To scale the size of modules, larger units would need stronger connectors to maintain structural integrity under increased loads and hydrodynamic drag. The current magnetic connectors are rated to 2 kg of holding force, which is sufficient for the current module scale. However, larger modules would likely require mechanical latching systems or active connection mechanisms for reliable performance47. Disconnection mechanisms would also be needed to support selective detachment for reconfiguration or recovery. Furthermore, increasing module size reduces shape resolution and flexibility, which may constrain the system’s adaptability to fine-grained tasks. Thus, enabling large-scale deployment—whether by increasing number or size—will require rethinking communication architecture, control hierarchy, and physical interfaces. Future work will explore hybrid control schemes and scalable connector systems to support real-world applications with potentially hundreds of coordinated soft modular units.

Another significant challenge for future development lies in the comprehensive characterization of swarm configurations. The combinatorial explosion of possible arrangements and actuation modes creates an effectively unbounded test space that is impractical to explore experimentally. Future work could address this through physics-based simulations, which would allow for rapid evaluation of numerous configurations without the constraints of physical testing. Such simulations could potentially incorporate fluid dynamic approaches to identify optimal configurations for specific tasks, predict collective behaviors, and develop more sophisticated motion planning algorithms. Additionally, data-driven approaches may help establish generalizable principles governing the relationship between module configurations and resulting capabilities, enabling more systematic design of swarm arrangements for specific application requirements.

Currently, all modules are coordinated through a centralized terminal, with a human operator issuing commands based on visual observation. Most demonstrations were conducted in open-loop mode, with some tasks (e.g., trash collection and caging) involving real-time human-in-the-loop adjustments. We chose this centralized, open-loop control approach deliberately in the early development stage to focus on validating the mechanical design, connector reliability, and coordinated behaviors without adding the complexity of sensor feedback. Open-loop control also helps reveal the system’s passive error-correction properties, which are important to understand before introducing active feedback. While this setup simplifies coordination and debugging in experimental settings, it limits autonomy, scalability, and responsiveness to dynamic environments.

Transitioning toward more autonomous and distributed systems will require several key developments. For example, integrating onboard sensors—such as inertial measurement units (IMUs), low-resolution cameras, or proximity sensors—would allow modules to perceive their local state and surroundings. Decentralized control algorithms could then enable local decision-making, improving fault tolerance and adaptability. However, these enhancements would also increase system complexity, require more onboard energy and computational resources, and potentially increase module size and cost. As such, there is a fundamental tradeoff: centralized control remains suitable for certain tasks where coordination and simplicity are priorities, while decentralized architectures may be more effective for large-scale deployments or tasks requiring local autonomy. Future work will explore these tradeoffs in more depth to determine the most effective architecture for different application scenarios.

This research establishes a foundation for advancing aquatic soft modular robots by combining modularity, deformability, and amphibious functionality into a single system. Enhancements in durability, propulsion, and control, alongside rigorous field validation, will be crucial for realizing their full potential. These robots hold promise for applications in environmental monitoring, underwater exploration, and disaster relief, offering a modular and adaptable solution for aquatic environments.

Methods

Block fabrication and design

The fabrication of each SoftRaft module combines simplicity, functionality, and adaptability, utilizing lightweight materials and precise manufacturing techniques. The specifications of a single SoftRaft robot are provided in Supplementary Table 1, where the weight of a single module is 384 g. The rigid head and tail are 3D-printed using Resin, chosen for its high precision and waterproof feature. The rigid middle parts are 3D-printed using PETG. The acrylic cover is laser cut. The soft foam core has a Shore D hardness of 32, weighs 11 g, and is selected for its buoyancy and flexibility, enabling smooth deformation during transitions between soft and rigid states.

The cable-driven system is powered by an N20 DC motor equipped with a magnetic encoder (12 V, 50,000 rpm, 1:100 gear ratio), providing precise control over string lengths for deformation and steering. The propeller motor, used for aquatic locomotion, is model FC130BV-13215/42N-R. Each N20 motor weighs 10.9 g, while the whole propeller structure weighs 25.5 g. N35 magnets, embedded for modular connectivity, have a thickness of 3 mm and a diameter of 12 mm, ensuring robust and secure attachment between modules.

Waterproofing measures include silicone glue (TIAN MU®702) and waterproof grease (YIJIALIN®RUBBER SILICON) for sealing sensitive components. The total weight of the battery (27.5 g), PCB (13.2 g), and other electronic components ensures that each module maintains a lightweight design without compromising functionality. By distributing components between the head and tail sections, we achieve the robot’s optimal mass-buoyancy equilibrium.

The circuit and control flow, as shown in Fig. 9, highlight the modular integration of electronic components. The ESP32-S2 microcontroller is used for communication and control. The system is supplied with a 3.7 V 903052 1800 mAh Li-ion battery, converted to three 12 V and one 3.3 V for operation. The control flow design incorporates motor drivers, power monitors, and sensors, such as a Hall effect sensor encoder for precise actuation feedback. Wireless charging capabilities are integrated using a dedicated coil and charging module, allowing charging without breaking the waterproof sealing.

Experimental design and data analysis

To measure the maximum load capacity of a single robot, four modules are connected in a 2 × 2 compressed lattice configuration to ensure stability during the test. A rectangular container is placed on top of the structure, and sand is gradually added until the structure is submerged. This process is repeated across five trials, and the maximum load capacity is reported as the average of these experiments.

All application experiments were conducted in a swimming pool under uniform conditions without additional environmental preparation. Robots were connected to a centralized control terminal via Wi-Fi modules. This centralized terminal consisted of a custom-developed Python class library that served as a communication and control interface for all robot modules. The control interface was implemented in Jupyter Notebook, where different gait primitives—predefined based on shape analysis and kinematic models—were organized into separate code cells. Commands were issued by an operator using a laptop connected to the same Wi-Fi network as the robots. The control interface was implemented through Jupyter Notebook, where different functionalities were organized into separate code cells. For experimental control, we pre-programmed a series of movement gaits that the operator could activate by executing specific code cells. For tasks involving dynamic shape change (e.g., snake-like motion), we used inverse kinematics to compute string lengths. For tasks with fixed configurations (e.g., caging, plus-sign), primitives were designed using a differential-drive-inspired model. Depending on the application, the operator either executed control commands in real-time or ran pre-scripted sequences. This approach enabled precise control of individual modules and coordinated actions across multiple robots throughout our various experiments, from basic locomotion tests to complex manipulation tasks.

In all cases, coordination was handled centrally: the terminal synchronized commands across modules, controlling both cable motors and propellers based on the selected gait or sequence. Most demonstrations were run open-loop using predefined commands, while others (e.g., gripper-based trash collection) involved continuous human-in-the-loop control. Although the current system is centralized and relies on off-board sensing via human observation, future work will explore onboard sensing, distributed control, and autonomous planning.

All modules were fabricated identically to ensure consistency in experimental results. The control logic for the experiments and kinematic analyses was implemented in Python, while configuration space calculations were performed using MATLAB.

Data availability

The complete raw experimental dataset supporting the findings of this study has been deposited in Zenodo under the accession number "https://doi.org/10.5281/zenodo.17509126". This dataset includes all six gait recordings (forward, backward, left-front, right-front, left-back, and right-back) stored as JSON files in the "raw_gaits_data/" folder, together with accompanying metadata and documentation. All additional data required to evaluate the conclusions are available within the paper and its Supplementary Materials.

Code availability

All firmware, control software, MATLAB scripts, and CAD models used in this work are archived at Zenodo (https://doi.org/10.5281/zenodo.17509126) and are also accessible via the associated GitHub repository: https://github.com/luyangzhao/SoftRafts (release v1.1). The repository includes: (1) Python notebooks for robot control and gait data analysis (software/); (2) MATLAB scripts for workspace calculations (software/workspace/); and (3) complete CAD and firmware files for hardware reproduction. These resources collectively enable full reproducibility of the experiments and analyses presented in this study.

References

Bailey, D. R., Dittbrenner, B. J. & Yocom, K. P. Reintegrating the North American beaver (castor canadensis) in the urban landscape. WIREs Water 6, e1323 (2019).

Reid, C. R. et al. Army ants dynamically adjust living bridges in response to a cost–benefit trade-off. Proc. Natl. Acad. Sci. USA 112, 15113–15118 (2015).

Feinerman, O., Pinkoviezky, I., Gelblum, A., Fonio, E. & Gov, N. S. The physics of cooperative transport in groups of ants. Nat. Phys. 14, 683–693 (2018).

Delfour, F. Object manipulation and play behaviour in bottlenose dolphins (tursiops truncatus) under human care. Int. J. Comp. Psychol. 30, https://doi.org/10.46867/ijcp.2017.30.00.16 (2017).

Murata, S. & Kurokawa, H. Self-Organizing Robots Vol. 77 (Springer, 2012).

Parker, L. E., Rus, D. & Sukhatme, G. S. Multiple mobile robot systems. In Springer Handbook of Robotics 1335–1384 (Springer, 2016).

Yim, M. et al. Modular self-reconfigurable robot systems [grand challenges of robotics]. IEEE Robot. Autom. Mag. 14, 43–52 (2007).

Liang, G., Wu, D., Tu, Y. & Lam, T. L. Decoding modular reconfigurable robots: a survey on mechanisms and design. Int. J. Robot. Res. 44, 740–767 (2025).

Zhao, L. et al. Starblocks: soft actuated self-connecting blocks for building deformable lattice structures. IEEE Robot. Autom. Lett. 8, 4521–4528 (2023).

Zhao, L. et al. Soft lattice modules that behave independently and collectively. IEEE Robot. Autom. Lett. 7, 5942–5949 (2022).

Jing, G., Tosun, T., Yim, M. & Kress-Gazit, H. An end-to-end system for accomplishing tasks with modular robots: perspectives for the AI community. In Proc. Twenty-Sixth International Joint Conference on Artificial Intelligence, IJCAI-17 4879–4883 (ACM, 2017).

Liu, C., Whitzer, M. & Yim, M. A distributed reconfiguration planning algorithm for modular robots. IEEE Robot. Autom. Lett. 4, 4231–4238 (2019).

Wei, H., Cai, Y., Li, H., Li, D. & Wang, T. Sambot: a self-assembly modular robot for swarm robot. In Proc. International Conference on Robotics and Automation 66–71 (IEEE, 2010).

Zhao, D., Luo, H., Tu, Y., Meng, C. & Lam, T. L. Snail-inspired robotic swarms: a hybrid connector drives collective adaptation in unstructured outdoor environments. Nat. Commun. 15, 3647 (2024).

Ozkan-Aydin, Y. & Goldman, D. I. Self-reconfigurable multilegged robot swarms collectively accomplish challenging terradynamic tasks. Sci. Robot. 6, eabf1628 (2021).

Paulos, J. et al. Automated self-assembly of large maritime structures by a team of robotic boats. IEEE Trans. Autom. Sci. Eng. 12, 958–968 (2015).

Wang, W. et al. Roboat: an autonomous surface vehicle for urban waterways. In Proc. International Conference on Intelligent Robots and Systems (IROS) 6340–6347 (IEEE, 2019).

Yang, Z. et al. Design of a multi-environmentally adaptable modular self-reconfigurable robot. IEEE Robot. Autom. Lett. 9, 8627–8634 (2024).

Wang, D. et al. Miniature modular reconfigurable underwater robot based on synthetic jet. Adv. Sci. 11, 2406956 (2024).

Doyle, M. J. et al. Modular fluidic propulsion robots. IEEE Trans. Robot. 37, 532–549 (2020).

Bauschmann, N., Duecker, D. A., Alff, T. L., Hochdahl, R. C. & Seifried, R. Towards full actuation: reconfigurable micro underwater robots. In Proc. International Conference on Intelligent Robots and Systems (IROS) 6192–6199 (IEEE, 2023).

Vasilescu, I., Varshavskaya, P., Kotay, K. & Rus, D. Autonomous modular optical underwater robot (AMOUR) design, prototype and feasibility study. In Proc. International Conference on Robotics and Automation 1603–1609 (IEEE, 2005).

Nishikawa, K., Origane, Y. & Kurabayashi, D. Stroke synchronization of underwater modular robot through physical interaction. In Proc. International Conference on Robotics and Biomimetics (ROBIO) 1–6 (IEEE, 2023).

Bianchi, G., Lanzetti, L., Mariana, D. & Cinquemani, S. Bioinspired design and experimental validation of an aquatic snake robot. Biomimetics 9, 87 (2024).

Yang, B., Han, L., Li, G., Xu, W. & Hu, B. A modular amphibious snake-like robot: design, modeling and simulation. In Proc. International Conference on Robotics and Biomimetics (ROBIO) 1924–1929 (IEEE, 2015).

Wang, J.-L. et al. Design and architecture of a slender and flexible underwater robot. Intell. Serv. Robot. 17, 445–464 (2024).

Hall, R., Espinosa, G., Chiang, S.-S. & Onal, C. D. Design and testing of a multi-module, tetherless, soft robotic eel. In Proc. International Conference on Robotics and Automation (ICRA) 8821–8827 (IEEE, 2024).

Wright, M. et al. Design and development of modular magnetic bio-inspired autonomous underwater robot–mmbauv. Ocean Eng. 273, 113968 (2023).

Hu, Y., Wang, L., Zhao, W., Wang, Q. & Zhang, L. Modular design and motion control of reconfigurable robotic fish. In Proc. Conference on Decision and Control 5156–5161 (IEEE, 2007).

Furno, L., Blanke, M., Galeazzi, R. & Christensen, D. J. Self-reconfiguration of modular underwater robots using an energy heuristic. In Proc. International Conference on Intelligent Robots and Systems (IROS) 6277–6284 (IEEE, 2017).

Mintchev, S. et al. An underwater reconfigurable robot with bioinspired electric sense. In Proc. International Conference on Robotics and Automation 1149–1154 (IEEE, 2012).

Lee, C. et al. Soft robot review. Int. J. Control, Autom. Syst. 15, 3–15 (2017).

Parra Rubio, A. et al. Modular morphing lattices for large-scale underwater continuum robotic structures. Soft Robot. 10, 724–736 (2023).

Fang, Q. et al. Reconfigurable transparent variable-stiffness soft robot for underwater operations. Adv. Intell. Syst. 6, 2300688 (2024).

Liu, B. & Hammond, F. L. Modular platform for the exploration of form-function relationships in soft swimming robots. In Proc. 3rd IEEE International Conference on Soft Robotics (RoboSoft) 772–778 (IEEE, 2020).

Zhang, C., Zhu, P., Lin, Y., Jiao, Z. & Zou, J. Modular soft robotics: modular units, connection mechanisms, and applications. Adv. Intell. Syst. 2, 1900166 (2020).

Chen, M. et al. Analysis of clustered cable-actuation strategies of v-expander tensegrity structures. Eng. Struct. 296, 116868 (2023).

Zhao, L., Jiang, Y., She, C.-Y., Chen, M. & Balkcom, D. Softsnap: rapid prototyping of untethered soft robots using snap-together modules. Soft Robot. 12, 698–707 (2025).

Zhai, Y. et al. Desktop fabrication of monolithic soft robotic devices with embedded fluidic control circuits. Sci. Robot. 8, eadg3792 (2023).

Mao, Z. et al. Soft computing-based predictive modeling of flexible electrohydrodynamic pumps. Biomim. Intell. Robot. 3, 100114 (2023).

Miriyev, A., Stack, K. & Lipson, H. Soft material for soft actuators. Nat. Commun. 8, 596 (2017).

Chung, H.-J., Parsons, A. M. & Zheng, L. Magnetically controlled soft robotics utilizing elastomers and gels in actuation: a review. Adv. Intell. Syst. 3, 2000186 (2021).

Coyle, S., Majidi, C., LeDuc, P. & Hsia, K. J. Bio-inspired soft robotics: material selection, actuation, and design. Extrem. Mech. Lett. 22, 51–59 (2018).

Li, G. et al. Bioinspired soft robots for deep-sea exploration. Nat. Commun. 14, 7097 (2023).

Qu, J. et al. Recent advances on underwater soft robots. Adv. Intell. Syst. 6, 2300299 (2024).

Rich, S. I., Wood, R. J. & Majidi, C. Untethered soft robotics. Nat. Electron. 1, 102–112 (2018).

Yim, M., White, P., Park, M. & Sastra, J. Modular Self-Reconfigurable Robots 5618–5631 (Springer New York, 2009).

Hauser, S., Mutlu, M. & Ijspeert, A. J. Kubits: solid-state self-reconfiguration with programmable magnets. IEEE Robot. Autom. Lett. 5, 6443–6450 (2020).

Knizhnik, G. & Yim, M. Design and experiments with a low-cost single-motor modular aquatic robot. In Proc. 17th International Conference on Ubiquitous Robots (UR) 233–240 (IEEE, 2020).

Zhao, L., Jiang, Y., Chen, M., Bekris, K. & Balkcom, D. Modular shape-changing tensegrity-blocks enable self-assembling robotic structures. Nat. Commun. 16, 5888 (2025).

Liljebäck, P., Pettersen, K. Y., Stavdahl, Ø. & Gravdahl, J. T. Snake Robots: Modelling, Mechatronics, and Control (Springer, 2013).

Wright, C. et al. Design of a modular snake robot. In Proc. International Conference on Intelligent Robots and Systems 2609–2614 (IEEE, 2007).

Lensgraf, S., Balkcom, D. & Li, A. Q. Buoyancy enabled autonomous underwater construction with cement blocks. In Proc. International Conference on Robotics and Automation (ICRA) 5207–5213 (IEEE, 2023).

Chen, C.-A., Collins, T. & Shen, W.-M. A near-optimal dynamic power sharing scheme for self-reconfigurable modular robots. In Proc. International Conference on Robotics and Automation (ICRA) 5183–5188 (IEEE, 2016).

A. Holdcroft, K., H. Belke, C., Bennani, S. & Paik, J. 3pac: a plug-and-play system for distributed power sharing and communication in modular robots. IEEE/ASME Trans. Mechatron. 27, 858–867 (2022).

Author information

Authors and Affiliations

Contributions

Conceptualization: L.Z., Y.J., A.Q., M.C., and D.B.; Methodology: L.Z., Y.J., C.S., A.Q., M.C., and D.B.; Investigation: L.Z., Y.J., C.S., A.Q., M.C., and D.B.; Visualization: L.Z. and Y.J.; Experiments design and implementation: L.Z., Y.J., C.S., A.Q., M.C., and D.B.; System design and implementation: L.Z., Y.J., M.C., and D.B.; Algorithm design and implementation: L.Z., Y.J., M.C., and D.B.; Project administration: L.Z., M.C., and D.B.; Supervision: D.B., M.C., and A.Q.; Writing: original draft: L.Z.; Writing: review and editing: L.Z., Y.J., M.C., C.S., D.B., and A.Q.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhao, L., Jiang, Y., She, CY. et al. SoftRafts: floating and adaptive soft modular robots. npj Robot 4, 8 (2026). https://doi.org/10.1038/s44182-025-00070-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44182-025-00070-z