Abstract

Bubble acoustics offers a powerful window into the complex physics of liquid-vapor phase-change phenomena such as boiling. Advancing this field requires a synergistic convergence of improved physical understanding, rigorous experimental standardization with optimized acoustic sensing, and integration of interpretable data-driven modeling. This perspective outlines a unified roadmap emphasizing experimental fidelity, open standardized datasets, and explainable machine learning for intelligent, real-time diagnostics in next-generation multiphase thermal systems.

Similar content being viewed by others

Introduction

Boiling is a complex heat and mass transfer phenomenon that plays a critical role in large-scale multiphase systems such as boilers in thermal and nuclear power plants, chemical and food processing industries, petroleum refining, and industrial manufacturing1. It involves at least two phases and is highly sensitive to numerous parameters, including surface superheat, roughness, wettability, orientation, liquid subcooling, dissolved gas concentration, system pressure, and the specific heating and/or quenching strategies employed2. The use of advanced diagnostic techniques, such as high-speed visualization, infrared thermography, and computational fluid dynamics (CFD), has significantly enhanced our mechanistic understanding of bubble dynamics and phase-change heat transfer. In particular, the ebullition cycle -comprising bubble nucleation, growth, departure, and subsequent liquid rewetting of the surface - serves as a simplified yet informative model of actual boiling behavior and is relatively well understood for predicting key parameters such as heat flux, surface superheat, and the onset of boiling3. However, predicting critical events such as the boiling crisis (or the critical heat flux, CHF) and regime transitions remains a significant challenge due to inherent uncertainties and system complexities4.

While thermal diagnostics are limited by high latency, and optical characterization methods by two-dimensional spatial insight, acoustic emissions provide statistically rich, temporally resolved information that captures the inherently three-dimensional and global nature of bubble activity5. Boiling acoustics is therefore gaining recognition as a powerful, non-invasive diagnostic tool for probing the multiscale dynamics of vapor bubbles, with promising potential to predict critical events such as onset of nucleate boiling (ONB), boiling crisis - CHF, and regime transitions6. Studies7 have shown that acoustic signals generated during boiling arise from various processes, including nucleation, growth, departure, coalescence, and collapse of vapor bubbles. These phenomena occur across different media - namely, the boiling liquid, its vapor phase, and the solid heater surface. However, most of the sound-generating events, such as bubble departure, coalescence, and collapse, primarily involve the liquid pool. As a result, the generated acoustic energy propagates mainly through the liquid, with secondary transmission into the solid, and minimal propagation into the surrounding air due to the large acoustic impedance mismatch at liquid–air and solid–air interfaces8,9. Despite this fundamental understanding, several past studies on boiling acoustics appear to overlook the implications of acoustic transmission paths. Consequently, a wide variety of sensors have been employed, including vibration sensors, acoustic emission (AE) sensors, microphones, and hydrophones, to capture vibrations, elastic or stress waves in the heater or chamber wall, airborne sound above the liquid pool, and acoustic waves within the liquid itself10. While each sensor type offers specific capabilities and advantages, it is essential to critically assess which stage of the ebullition cycle each sensor can reliably detect how the sound propagation medium influences the nature and fidelity of the recorded signals. Sensor selection should thus be guided by physics-based insights into the mechanisms of sound generation and transmission in multiphase systems.

Similarly, a fundamental limitation in the field of boiling acoustics lies in the widespread absence of standardized measurement protocols for bubble acoustics. Critical aspects, including sensor calibration, spatial placement, sampling rate selection, synchronization methods, filtering techniques, and data reporting, vary significantly across studies. These inconsistencies in data acquisition and processing hinder reproducibility, complicate cross-study comparisons, and constrain the applicability of datasets in machine learning (ML)-driven boiling acoustics. Effective ML for predictive diagnostics demands high-fidelity ground truth data to support robust preprocessing, meaningful feature extraction, and the design of context-specific ML frameworks. When anchored in experimentally validated protocols, such approaches can enable regime classification, CHF detection, real-time control, and automation at the system level. However, the effectiveness of these ML approaches remains contingent on the resolution, interpretability, and diagnostic integrity of acoustic data, which in turn rely on meticulous experimental design and domain-specific expertise. This is particularly crucial for flow boiling systems, where the dynamic, intricate nature of the process amplifies these data acquisition and interpretability challenges.

This perspective paper critically examines the current state-of-the-art to identify key challenges in the field, followed by practical recommendations to enhance data quality and promote openness within the research community. These include adopting metadata standards, establishing sensor documentation protocols, defining minimal reporting requirements, and implementing standardized experimental methodologies for acquiring bubble acoustics data to ensure reproducibility, transparency, and comparability across studies. We also emphasize the value of comparative studies between vapor and gas bubbles, noting that the gas bubbles, free from phase-change dynamics, offer a simplified yet insightful analog for understanding the vapor bubble acoustics. Such comparisons can aid in isolating dominant sound-generation mechanisms and refining feature selection strategies for machine learning models. Ultimately, we reason that the transformation of boiling acoustics into a generalizable diagnostic and control framework will require tight coupling between physically informed modeling, multimodal and reproducible experimentation, and interpretable machine learning methods. This synergistic development holds promise not only for advancing phase-change heat transfer science but also for enabling real-time thermal system monitoring and intelligent control.

Current state of boiling acoustics: progress and persistent shortcomings

Acoustic sensing in boiling heat transfer has undergone substantial methodological evolution, transitioning from rudimentary sound detection to sophisticated spectral characterization. The foundation for interpreting bubble acoustics was established by Minnaert11, who derived a relation to estimate the resonant frequency of gas bubbles oscillating in a liquid. Although originally developed for gas bubbles, this relation provides a theoretical basis for linking specific frequency components to vapor bubble sizes at various stages of the ebullition cycle. The dynamic interfacial events involved in boiling generate acoustic emissions spanning a broad frequency spectrum - from infrasound (<20 Hz) to audible (20 Hz–20 kHz) and ultrasonic (>20 kHz) ranges, as illustrated in Fig. 1a. Building on this, early investigations into boiling acoustics primarily utilized microphones due to their low cost, ease of deployment, and non-invasive nature for capturing boiling acoustic emissions. Westwater et al.12 were among the first to explore boiling acoustics using externally mounted microphones, focused primarily on the audible frequency range of 20 Hz–20 kHz. They reported a continuous rise in sound pressure level (SPL) with increasing heat flux, both in nucleate and transition boiling regimes. Similarly, Aoki and Welty13 reported elevated SPL in the transition regime, with frequency contents in the range of 125 Hz and 1000 Hz, with major spectral components concentrated in the 250–500 Hz range. Over time, the research focus evolved from broad SPL trends within the audible range to detailed frequency-domain analyses, sometimes even extending into higher-frequency regions. More recent developments, such as those by Geraldo et al.14, employed high-sensitivity high-frequency condenser microphones (up to 70 kHz) to examine the evolving spectral features of boiling noise across different boiling regimes. While less common due to their specialized use and complexity, these microphones offer valuable potential for resolving high-frequency acoustic signatures that deepen the understanding of boiling dynamics.

a Representative frequency ranges of acoustic waves and corresponding sensor detection capabilities: microphones, hydrophones, and acoustic emission (AE) sensors used for monitoring boiling-induced acoustic phenomena. b Acoustic wave propagation at key material interfaces involved in boiling: liquid–solid, liquid–air, and solid–air. Arrows denote wave paths, red for incident (i), green for transmitted (t), and dashed black for reflected (r), with line thickness indicating relative energy transmission and reflection. Schematic illustrations of typical pool boiling setups with various heater configurations and sensor placements: c Type I configuration: plate heater with AE sensor embedded beneath the heating surface, d Type II configuration: rod-type heater (fuel cladding analog) with AE sensor positioned at the remote end, and e Type III configuration: block heater with AE sensor mounted on the chamber wall. In all three configurations (Types I–III), the positions of the hydrophone and microphone remain fixed, with only the AE sensor placement varying.

Advancing beyond standalone acoustic measurements, Negi et al.15 correlated acoustic data with high-speed imaging and compared experimentally observed frequency components with the Minnaert frequency11 for coalescing bubbles. Further analysis revealed that moderate-frequency signals (400–500 Hz) originated from the collapse of large vapor bubbles, while low-frequency components (100–200 Hz) were linked to vapor column collapses. However, their study acknowledged the limited sensitivity of microphones to microscale events such as bubble nucleation and oscillation. Traversing this trajectory, Barathula et al.6 reviewed the evolution of boiling acoustics, emphasizing its role in regime detection and future cooling applications. Subsequently, Barathula et al.16 observed dominant acoustic frequency peaks near 250 Hz and 700 Hz during pool boiling on wire heaters, with high-frequency components intensifying as the system approached CHF. Leveraging this spectral information, they trained three ML models (decision tree, ensemble tree, and naïve Bayes) for boiling regime classification, with the ensemble tree achieving the lowest error rate below 5%. However, the utility of microphones in boiling acoustics is highly dependent on their placement and is significantly restricted by their sensitivity to ambient and structural noise (Fig. 1b). This often necessitates noise-controlled environments, such as semi-anechoic or anechoic chambers15,16, and may also involve spectral denoising using commercial software like “Audacity”15.

Beyond ambient noise, a critical limitation for microphones stems from acoustic impedance mismatches at air–solid and air–liquid boundaries. In Fig. 1b, we illustrate the key acoustic interfaces encountered in boiling systems, emphasizing the stark impedance (\(Z=\rho c\)) contrasts between air [\({\rm{O}}\left({10}^{2}-{10}^{3}\right)\) Rayls], liquid [\({\rm{O}}\left({10}^{6}\right)\) Rayls], and solid [\({\rm{O}}\left({10}^{7}-{10}^{8}\right)\) Rayls]. These vast disparities result in more than 99% reflection (\(r\)) of acoustic energy at both the liquid–air and solid–air interfaces, largely confining the incident (\(i\)) signal to its medium of origin and limiting transmission (\(t\)) to air-coupled sensors8,17. While enclosure techniques and digital filtering can enhance signal clarity, they cannot recover frequency components lost through propagation across multi-phase interfaces.

Beyond airborne acoustic sensing, accelerometers have been used to in boiling acoustics research to monitor boiling-induced structural dynamics18,19,20. It captures lower-frequency resonant responses and structural vibrations (0–10 kHz) of the heater or vessel that arise from bubble dynamics. These structural vibration measurements offer complementary insight to pressure-based sensors (hydrophones and microphones) by focusing on the solid-structure response rather than the fluid-borne sound. For instance, Celata et al.19 demonstrated the utility of accelerometers for early CHF detection by monitoring transitional boiling regimes. More recently, Barathula et al.19 showed that vibrational signals captured by accelerometers can be effectively correlated with heat load fluctuations using machine learning, thereby enhancing boiling monitoring capabilities. However, the utility of accelerometers is subject to significant structural variability. The recorded vibration patterns are highly system-specific, meaning minor changes in chamber geometry, material thickness can drastically alter the signal, making the data non-transferable and difficult to correlate directly with fundamental bubble acoustics. As a result, data acquired from accelerometers do not reliably reflect the fundamental physics of bubble acoustics. Instead, they represent indirect, structure-dependent signatures, which may limit their utility for robust, reproducible measurements in phase-change studies. Despite these, their capacity for non-intrusive diagnosis and monitoring of large-scale mechanical responses makes them valuable components, particularly when integrated into multi-sensor frameworks.

Given the limitations of microphones and accelerometers in capturing only secondary effects of boiling, researchers increasingly switched to hydrophones during the 2000s to measure bubble acoustics directly at their origin within the liquid phase. Hydrophones are immersed directly into the liquid as shown in Fig. 1c–e, and are specifically designed to detect liquid-borne pressure fluctuations and operate across a broad frequency range, typically from 100 Hz to several 100 kHz (Fig. 1a), depending on their design21. Several foundational studies7,22,23,24 laid the groundwork for this transition. For instance, Osborne and Holland22 investigated subcooled boiling and reported high-frequency acoustic emissions in the range of 10–30 kHz, indicating significant sound generation from the rapid collapse of microscopic vapor bubbles occurring before the formation of continuous, visible boiling. Ferri7 detected acoustic signals primarily within the 0–5 kHz band, while Schwartz and Siler23 demonstrated the enhanced capability of hydrophones to capture subsurface boiling activity, which is typically inaccessible to conventional microphones. Similarly, Nishihara and Bessho24 showed that under highly subcooled conditions, boiling sound could extend beyond 50 kHz, emphasizing the need for sensors with broad spectral sensitivity.

Recent studies25,26,27,28,29 have identified regime-dependent spectral features using hydrophones. For instance, Tang et al.10 observed dominant frequencies below 800 Hz across different boiling regimes, accompanied by a 10–20 dB increase in SPL during regime transitions. Sinha et al.25,26,27 reported a shift in peak frequency from 200–250 Hz in NB to 400–500 Hz at the onset of CHF, suggesting the potential of hydrophones in early-stage regime detection. Further, Sinha et al.27 developed a convolutional neural network (CNN) based classification framework for boiling regimes and demonstrated their utility for real-time monitoring and system control. Ueki and Ara28 implemented a multilayer perceptron (MLP) model to classify boiling regimes directly using SPLs with different levels of added noise. Dunlap et al.29 proposed a regression-based ML framework to predict the heat flux during pool boiling using acoustic signals. Recent work has also expanded into enhanced phase-change regimes, such as microbubble emission boiling (MEB)30. Ono and Aoki31 developed a deep learning–based methodology using boiling acoustics to predict the onset of MEB from low-heat-flux conditions. Their study found cepstral features improved prediction accuracy, especially in regression models, and maintained performance under varying subcooling. Further, Mitsuyama et al.32 explored the use of CNNs enhanced with a Convolutional Block Attention Module (CBAM) to predict the heat transfer coefficient (HTC) from spectrograms developed using boiling sound. While slight accuracy decreases occurred in some heat flux ranges, the overall average accuracy improved by 1.12% compared to the baseline CNN, showing the potential of attention-based modeling in capturing key acoustic features under noisy conditions. Despite their capabilities, hydrophones are inherently invasive and may disturb local flow conditions, particularly in confined geometries. As we detail in Table 1, they are also susceptible to fouling, corrosion, and thermal degradation, often requiring specialized high-temperature variants. Moreover, their sensitivity to high-frequency acoustic events such as bubble nucleation is limited due to acoustic impedance mismatch and signal attenuation at the liquid–solid interface.

More recently, the focus has also been shifted to AE sensors, which are surface-mounted devices traditionally used for detecting high-frequency stress/elastic waves caused by cracking or material fatigue33. Since AE sensors are directly coupled to the heated surface or the surrounding vessel, they are well-positioned to detect high-frequency stress waves emitted from rapid phase-change events such as bubble nucleation and early growth. Studies by Wu et al.34, Baek et al.35, and Do Yeong Lim et al.36 have demonstrated AE sensors’ effectiveness in capturing such impulsive signals, with frequency components reaching into the MHz range. As we illustrate in Table 1, AE sensors offer several key advantages: they are non-invasive to the boiling medium, i.e., the liquid, have high sensitivity to transient surface events, and can withstand harsh thermal environments. Accordingly, the obtained data have also been utilized via a transformer-based model demonstrating optimal performance, predicting key boiling parameters such as heat flux, HTC, and boiling regimes36.

However, signal interpretation with AE sensors is inherently complex. These sensors measure structure-borne elastic waves rather than pressure waves arising from bubble dynamics in the liquid. The detected signals are influenced by wave propagation characteristics, material damping, boundary, and coupling conditions at the sensor interface. Their high sensitivity to ambient mechanical noise necessitates proper isolation, and accurate measurements depend strongly on sensor placement and clamping. Unlike hydrophones and microphones, AE sensors require application-specific placement, which varies with heater geometry, such as mounting on chamber walls for block heaters, the far end for rod-type heaters, or beneath the heating surface for flat-plate or thin-film configurations (Fig. 1e–g). Consistent mechanical coupling is critical to ensure effective acoustic transmission and signal fidelity.

The diverse sensor capabilities in Table 1 highlight the multi-physics nature of boiling acoustics, spanning various media and frequencies, with the listed ranges reflecting values typically reported in boiling studies rather than absolute sensor limits. While each sensor offers unique advantages in capturing specific aspects of boiling acoustics, a comprehensive physical understanding of the bubble ebullition cycle and robust modeling and diagnostics necessitate a synergistic approach. No single sensor can fully capture the complete acoustic landscape of the boiling spectrum. A more holistic perspective emerges when these complementary sensing strategies are considered together, allowing for deeper insight into underlying phase-change dynamics. Such an approach is not only required to strengthen the interpretive link between acoustic features and physical events, but also for more unified methodologies in experimentation and modeling.

Critical knowledge gaps and underexplored domains

Despite significant advances in boiling acoustics, several foundational challenges remain unresolved. These include ambiguities in signal origin, inconsistent experimental practices for capturing boiling acoustics, and reliance on opaque (black box) ML models. This section delineates the key limitations and pervasive research gaps that require targeted investigation to advance the field.

Origin, nature, and propagation of bubble acoustics

A major challenge in establishing boiling acoustics as a reliable quantitative diagnostic tool lies in the limited mechanistic understanding of sound generation across the various stages of the ebullition cycle and its propagation through multiphase media. While boiling progresses through well-known stages— nucleation, growth, necking, detachment, collapse, and coalescence—each capable of generating distinct acoustic events, the physical origins and corresponding frequency content of these emissions remain poorly characterized. These phenomena span a wide range of spatial and temporal scales, producing both solid-borne elastic waves and liquid-borne pressure waves. For instance, nucleation (Fig. 2a), which involves rapid vapor formation at the heated surface, seems to generate a sharp mechanical impulse that excites high-frequency elastic waves in the solid. These signals are best captured using AE sensors37. However, as these high-frequency waves enter the liquid, much of their energy is attenuated due to acoustic impedance mismatch and viscous damping, making them difficult to detect with hydrophones. In contrast, subsequent stages, such as bubble growth, necking, and departure (Fig. 2b–d), primarily produce pressure waves in the liquid, which are more effectively recorded by hydrophones. AE sensors, on the other hand, are less sensitive to these liquid-borne signals. While certain individual ebullition events have been reasonably well-characterized in the literature24, particularly in the isolated bubble regime, multi-bubble interactions introduce significant complexity that remains largely unresolved.

a Nucleation, b growth, c necking, d departure, e coalescence, f collapse, g mutual interference, and h multi-bubble interactions. Arrows represent wave paths-red for primary generation, orange for secondary generation, green for transmitted, and dashed black for reflected components. Line thickness qualitatively indicates relative energy content in each path. Configurations depict liquid in contact with a heated solid surface, with acoustic signals propagating into surrounding media and toward sensors.

The interpretation becomes even more challenging in the presence of complex collective phenomena38, such as bubble coalescence (Fig. 2e) and collapse (Fig. 2f), mutual interference (Fig. 2g), and multi-bubble interactions (Fig. 2h), which give rise to overlapping acoustic signatures that are difficult to disentangle. Although we discuss the feasibility of linking acoustic emissions to individual stages of boiling, this mapping has not yet been conclusively established through synchronized, multiphase diagnostics. For instance, the specific acoustic signature of coalescence remains poorly understood, particularly under saturated and near-CHF conditions. A critical limitation remains the lack of controlled single-vapor bubble studies, which are essential for developing the mechanistic understanding. While early investigations22,23,24 provided preliminary insights into growth and collapse dynamics, variations in heater geometry and fluid properties have led to inconsistencies in the reported frequency ranges. Moreover, direct identification of acoustic emissions associated with departure or coalescence is largely absent. These gaps in experimental data also hinder the development of high-fidelity computational models capable of isolating the acoustic signatures of individual ebullition events. Notably, current CFD-based efforts attempted primarily to model sound propagation in the liquid phase, with virtually no attempts made to simulate elastic wave generation in solids, despite its relevance for interpreting AE signals originating from boiling.

Fragmented acoustic sensing protocols

The rapid growth in passive boiling acoustics research has not been accompanied by convergence in findings, largely due to the lack of standardized experimental protocols for acquiring boiling acoustics. Studies often differ widely in sensor types (microphones, hydrophones, AE sensors, accelerometers), sensitivities, calibrations, acquisition bandwidth, placements, and preamplifier settings, as well as in heater geometries, boiling chambers, acquisition rates, synchronization methods, and laboratory conditions. Among these factors, sensor positioning and mounting strategy represent a particularly underemphasized source of variation. For instance, AE sensors attached to block, rod-type, or thin film heaters can produce markedly different signal amplitudes and frequency characteristics. Similarly, hydrophones placed either too close or too far from the boiling surface—especially in constrained geometries—can distort pressure waveforms or fail to detect critical transient events. Despite their influence, such spatial configurations are rarely described in sufficient detail. Additionally, signal acquisition settings such as sampling rate, bandwidth, and filtering thresholds strongly affect the detectability of short-lived transients such as nucleation spikes and collapse events. The absence of standardized criteria for these parameters impedes data fusion and limits the development of generalizable acoustic feature sets. Compounding this issue, acoustic signals are often presented in isolation, without contextual support from synchronized high-speed imaging or other diagnostics. This lack of multimodal integration restricts the physical interpretability of acoustic events and complicates signal labeling, especially during transitional boiling regimes such as the ONB or the CHF.

Signal processing pathways and pitfalls

Even when high-quality signals are obtained, extracting meaningful features from boiling acoustics remains a nontrivial challenge. Broadly, two principal analytical approaches have emerged: intensity-based and frequency-based methods. Intensity-based approaches, which focus on overall signal amplitude and energy levels, have long served as foundational tools in the field. Within this category, hit-based analysis is a traditional technique that identifies discrete transient events whenever acoustic signals exceed a predetermined threshold, enabling the extraction of features such as amplitude, duration, and energy39. Recent frameworks, such as Hit2Flux40, leverage hit-level features in combination with machine learning models to predict heat flux and classify boiling regimes. While effective in isolating rapid nucleation and collapse events, these methods depend strongly on experimental calibration and system-specific factors, including heater and chamber size, bubble population, and sensor setup. Variations in heater size and boiling chamber geometry can significantly alter signal intensity, rendering thresholds non-transferable and limiting cross-study scalability - a challenge common to many fields reliant on intensity or SPL metrics. Moreover, subtle changes in surface properties, such as wettability, may trigger early CHF at lower amplitudes, potentially eluding conventional hit-based detection. Nonetheless, intensity-based analyses remain effective for identifying sharp regime transitions such as ONB and CHF, where abrupt acoustic shifts offer strong diagnostic cues.

Frequency-domain and time–frequency approaches have been increasingly adopted to address these challenges. Methods such as Fast Fourier Transform (FFT), Power Spectral Density (PSD), wavelet transforms, and spectrograms reveal spectral components linked to bubble oscillation, growth, and collapse dynamics. These descriptors provide more fundamental and generalizable signatures of boiling mechanisms. Importantly, time–frequency representations capture the inherently transient and non-stationary nature of boiling, making them particularly suited for regime identification near ONB41 and CHF27,42. Beyond individual methods, multimodal feature fusion, combining signals from multiple sensors, has shown promise in enhancing diagnosis43. Despite the diversity of processing techniques, the lack of standardized protocols and variability across laboratories significantly hinders the development of consistent, generalizable models. This variability in experimental practices and data processing not only complicates cross-comparison but also limits the robustness and interpretability of machine learning approaches, which rely heavily on high-quality, reproducible input data for reliable predictions.

Machine learning advances and limitations

Despite the promising advancements of ML in boiling acoustics, several key challenges continue to impede the development of robust, generalizable, and physically interpretable models44,45. A primary concern lies with the heavy reliance on supervised learning, which necessitates extensive, accurately labeled datasets for effective training and validation. In boiling systems, labeling is particularly challenging near regime transition boundaries, such as the ONB, the departure from nucleate boiling—DNB, or the approach to CHF. Though widely adopted, these methods are inherently subjective, application-specific, and susceptible to human bias. Moreover, ground truth estimates for quantities such as local heat flux, wall superheat, or boiling regime classification are typically obtained from thermocouples or high-speed cameras. However, thermocouples suffer from high latency and low spatial resolution, while high-speed visualization captures only 2D peripheral behavior, limiting its ability to resolve the full 3D dynamics of boiling in the fluid bulk. These labeling uncertainties compromise training fidelity, limit model generalizability, and predictive reliability across diverse operating conditions and experimental configurations. Moreover, the prevailing focus on performance metrics such as accuracy, precision, or mean absolute error often limits insight into the model’s decision-making process.

The black-box nature of many ML models46, particularly deep neural networks, poses a challenge to physical interpretability and reduces confidence in their applicability to complex multiphase systems. Without explainability tools such as saliency maps, Grad-CAM, or attention-weight visualization, the connection between learned features and underlying physical mechanisms remains elusive. While some studies27,29 have demonstrated model robustness across varied operating conditions within a single experimental setup, there is a lack of systematic evaluation on datasets collected from independent laboratories or distinct experimental platforms. This is partly due to the limited availability of publicly shared datasets, which hampers efforts to assess cross-laboratory generalization. As a result, the true generalizability of these models across diverse sensor configurations, boundary conditions, and experimental protocols remains largely unquantified. The field also lacks publicly available, standardized datasets accompanied by detailed metadata, which impedes benchmarking, reproducibility, and collaborative advancement.

The flow boiling blindspot

While acoustic sensing in pool boiling has advanced considerably, its application to flow boiling systems remains relatively underexplored—despite their critical importance in practical thermal technologies such as microchannel heat exchangers, reactor cores, and high-flux electronics cooling. Flow boiling adds complexity through convective interactions, spatial velocity gradients, and the interplay between bubble dynamics and imposed flow conditions. These factors affect both the generation and propagation of acoustic signals but are often overlooked in current models and experiments.

Sensor selection for flow boiling is also nontrivial. Unlike pool boiling, where the liquid environment supports the use of hydrophones, flow boiling often involves complex geometries, two-phase flow regimes, or partially wetted surfaces where direct liquid contact is not guaranteed. As a result, hydrophones may be impractical or unreliable. In such scenarios, alternative sensors such as acoustic AE sensors or surface-mounted microphones or accelerometers may be more appropriate, but require careful consideration of coupling conditions, flow-induced noise, and signal fidelity. Consequently, insights from pool boiling may not directly translate to flow boiling systems, underscoring the need for dedicated modeling, experimentation, and sensor strategy tailored to the complexities of flow-driven phase-change.

Strategic roadmap for decoding boiling acoustics

We propose that boiling acoustics, when grounded in multi-modal sensor fusion and interpretable ML, can evolve into a non-invasive, real-time thermal diagnostic platform for industrial systems. Realizing this vision demands coordinated progress across physical modeling, experimental fidelity, and data-driven analytics. This section presents a roadmap that begins with standardized multi-sensor experimental protocols for boiling acoustics, advances toward deeper physical understanding of bubble-driven acoustic signatures, and culminates in the development of interpretable, physics-informed machine learning frameworks. Together, these elements aim to bridge laboratory research with scalable industrial deployment.

Standardizing multi-sensor experimental framework

A critical step toward reliable and reproducible boiling acoustic diagnostics is the establishment of a standardized experimental framework that captures the full spectrum of physical phenomena occurring across the heater surface. We envision a multi-sensor architecture that synergistically combines hydrophones, AE sensors, microphones, and accelerometers to capture distinct stages of bubble dynamics. This approach is illustrated in Fig. 3, which depicts how each sensor leverages its unique detection capability within a unified experimental framework. Instead of relying on a single modality, this framework aims to resolve the full ebullition cycle from bubble nucleation, growth, and departure to collapse by synergizing stress-wave, pressure-wave in liquid and air, and vibration data, each associated with distinct physical mechanisms and frequency bands. As shown in Fig. 3, AE sensors, mounted on the surface of the container or directly on the heater, are suitably positioned for detecting high-frequency nucleation-induced stress waves (10 kHz–1 MHz). Hydrophones allow detection of the liquid-borne transient pressure signals spanning 1–10 kHz, while accelerometers help measure low-frequency structural resonances typically below 20 kHz. Microphones serve a complementary role by monitoring ambient acoustic conditions and subtly capture the sharp sounds generated when bubbles rupture at the liquid–air interface, signals that are often inaccessible to submerged hydrophones. This integrated approach ensures a comprehensive picture of the pressure waves generated by the entire boiling process.

a A generalized configuration for the experimental setup integrating Type I heater, a hydrophone, and an AE sensor for multiscale acoustic measurements, along with a microphone and an accelerometer for broadband signal capture. A high-speed camera, synchronized via a master trigger, enables simultaneous optical diagnostics. Data is collected through a standardized acquisition chain comprising preamplification, DAQ, and computer logging. Five interchangeable configurations replacing Type I heater with: b gas injection, c vapor injection, d single cavity, e multiple cavities, and f flow boiling. The figure also illustrates specific AE sensor placements for other heater types detailed in Fig. 1: g Type II configuration (rod-type heater) and h Type III configuration (block heater).

Sensor placement is central to the fidelity of this framework and must be adapted to heater geometry and chamber design. For AE sensors, optimal signal transmission comes from direct mounting on the thin-film or rod heaters to ensure efficient solid-to-solid transmission of high-frequency waves or on the chamber wall for block heaters. In chamber designs where the heater block is exposed outside the chamber, the AE sensor can be mounted directly on the exposed block. While external mounting is possible for thin-film and rod heaters, it often compromises signal quality and is generally avoided. Hydrophones must be positioned directly within the liquid pool but carefully placed to avoid vibrations induced by fluid or bubble flow, which can introduce noise and degrade signal fidelity. Importantly, hydrophones should not be in direct contact with vapor, as this can distort measurements and expose the sensor to potential thermal damage. Microphones are placed near the air–liquid interface of the pool, with care taken to avoid exposure to hot vapor streams that could damage the device. Accelerometers are typically mounted on the boiling chamber structure, but their placement must be carefully selected to ensure acquisition of a clean, high-quality structural signal, with effective noise isolation from external vibration sources such as equipment fans and motors. Overall, sensor placement must be tailored to the specific heater configuration and boiling chamber design.

A crucial component of this framework is the integration of synchronized high-speed visualization, which allows for the direct correlation of acoustic signatures with observable boiling phenomena and ensures precise spatiotemporal alignment of data. Equally important is the use of auxiliary side (rod) heaters to maintain the liquid pool at saturation, or desired subcooled conditions, before measurements. To prevent their own bubble activity from contaminating acoustic signals, the auxiliary heaters should be switched off just before data acquisition. However, for longer or continuous transient experiments, stick or wrap heaters placed around the chamber walls can maintain the desired temperature without compromising the acoustic signal fidelity. A unified data acquisition system must also facilitate precise time-alignment, consistent amplitude scaling, and reproducible sampling for all sensor channels. Standardization of sensor mounting locations, acquisition parameters, and metadata reporting is essential to enable advanced ML-driven modeling, facilitate benchmarking across laboratories, and validate CFD simulations against real-world measurements. Beyond instrumentation, effective acoustic diagnostics mandates a controlled experimental environment to minimize artifactual signals and electrical interference. Therefore, experimental setups should be engineered with vibration-damped and acoustic shielding in case one suspects external noise.

A key practical limitation in scaling boiling acoustics involves the current reliance on polymer-based sensors such as hydrophones, which lack the thermal durability needed for high-temperature or industrial applications. This limits their use in full-scale or industrial systems. In contrast, AE sensors, which are non-invasive and robust under harsh conditions, offer greater promise for industrial deployment37. Unlocking the full potential of boiling acoustics hinges on developing high-temperature-compatible sensors and scalable, non-invasive diagnostics tailored for real-world thermal systems. Furthermore, a pivotal area for future investigation involves deciphering the intricate role of flow in shaping boiling acoustics, especially given the prevalence of flow boiling in most real-world applications. We recommend targeted comparative experiments between pool and forced convective boiling setups, aiming to understand how flow influences acoustic signatures while maintaining similar bubble characteristics. This approach can help decouple the influence of hydrodynamics on acoustic signatures and reveal how liquid motion affects bubble interactions, coalescence, and collapse events. This is a vital step, as most industrial boiling processes occur in flowing systems (e.g., in cooling loops, reactors, and thermal exchangers). Gaining such insight is crucial for bridging the gap between laboratory-scale diagnostics and field-deployable monitoring strategies in industrial systems such as heat exchangers or reactor cooling loops. Ultimately, standardizing experimental strategies is not just a methodological necessity; it is the foundation upon which boiling acoustics can transition from academic curiosity to a cornerstone of industrial thermal management.

Deepening physical understanding

Advancing the field of passive boiling acoustics in multi-bubble systems requires a clear understanding of the acoustic emissions associated with each stage of the ebullition cycle10,24,37. This can be achieved through a progression of controlled experiments, beginning with simplified systems and gradually moving toward complex, application-relevant configurations. The generalized experimental setup in Fig. 3(a) integrates a Type I heater with synchronized acoustic–optical diagnostics, serving as the baseline for all subsequent configurations. It may begin with controlled gas bubble experiments [configuration (b) in Fig. 3] as the initial comparative baseline, allowing isolation of inertial and oscillatory contributions in the absence of phase-change. Gas bubble studies help determine fundamental frequencies, multi-bubble interference, resonance effects, and interactions with acoustic fields under simplified thermal and interfacial conditions47,48,49. This may then be followed by well-controlled vapor or steam injection experiments [configuration (c) in Fig. 3] that primarily capture evaporation–condensation (phase-change) dynamics and the associated acoustic signatures, excluding the fundamental nucleation and growth processes. This approach, previously used by Tang et al.50, bypasses the nucleation stage entirely and allows targeted study of interfacial evaporation–condensation and its acoustic footprint. Unlike gas bubbles, vapor bubbles inherently involve phase-change, producing distinct acoustic signatures linked to rapid evaporation and condensation. Together, gas and vapor bubble experiments provide complementary insights: the former isolates bubble dynamics, while the latter highlights the additional contributions from phase-change.

The next stage of investigation may be single-cavity boiling experiments [configuration (d) of Fig. 3]. Here, a single vapor bubble nucleates from a well-defined cavity and can be monitored using multi-sensor setups (hydrophones, AE sensors, microphones). These experiments should reveal characteristic signatures of nucleation, growth, departure, and rewetting. Under subcooled conditions, bubble collapse can also be captured50. Building on this, multiple-cavity experiments with a known number of nucleation sites [configuration (e) of Fig. 3] would enable a systematic study of bubble–bubble interactions. Synchronized audio-video recordings in such controlled setups can elucidate acoustic features arising from lateral bubble coalescence and mutual interference. As a baseline, analogous insights into controlled coalescence can also be obtained from gas bubble experiments with multi-nozzle injection, which provide a non-phase-change reference for studying multiple bubble interactions. These detailed investigations are essential for both mechanistic understanding and practical applications, especially in systems where external acoustic fields are used to enhance boiling performance metrics such as CHF and HTC51,52. When combined, single and multiple-cavity experiments provide a pathway to gradually scale from isolated bubble events to collective dynamics, while retaining interpretability. One can choose any type of heater configurations, such as Type I (thin plate heater), Type II (rod heater), and Type III (block heater), to perform single or multiple-cavity experiments, to pave the way for systematic exploration of more intricate scenarios, such as flow boiling, as illustrated in configuration (f), where the methodology can be extended to realistic, application-relevant scenarios. This structured progression from gas bubbles to vapor bubbles, to controlled single and multiple cavities boiling, and ultimately to flow boiling provides a comprehensive and logically layered roadmap. Each step builds upon the last without conflating results prematurely, ensuring that mechanistic understanding advances systematically toward real-world boiling scenarios.

These simplified configurations, when paired with multi-sensor data acquisition, facilitate precise identification of acoustic signatures tied to discrete bubble events. To deepen the physical understanding of these signatures, we advocate drawing analogies with classical models such as the spring–mass–damper system or damped harmonic oscillator11,53,54. In this model, the vapor bubble acts as a spring, the surrounding liquid shell serves as the mass, and damping arises from viscous, thermal, phase-change, and acoustic effects. The nature of the forcing function is critical: bubble departure may resemble an impulsive force (e.g., Maxwell–Boltzmann type53), while growth and collapse might exhibit more sustained, sinusoidal-like excitation55,56. CFD simulations can aid in identifying the dominant forcing mechanism by resolving local flow and thermal fields near the bubble interface53. Irrespective of the forcing nature or spectral content, the bubble tends to oscillate predominantly at its natural frequency. Hence, the frequencies recorded in acoustic signals during various boiling events can be directly linked to the bubble’s natural frequency. Although simplified models such as those of Minnaert11 or Prosperetti57 estimate natural frequencies based on static bubble sizes, real-world scenarios involve transient and evolving bubble geometries. This complexity necessitates the development of a more robust analytical framework that can predict the range of natural frequencies and damping constants for vapor bubbles in dynamic boiling environments. The spring–mass–damper analogy offers a potent yet intuitive approach to relate these acoustic features to underlying physical processes across different stages of boiling.

Finally, the integration of simplified experimental configurations, multi-sensor data acquisition, and numerical and analytical modeling presents a promising approach for decoding passive bubble acoustics in complex, real-world scenarios such as flow boiling [configuration (e) in Fig. 3]. While AE sensors offer advantages in confined flow systems, whether for boiling58 or condensation59, they should be complemented by hydrophones placed strategically to capture the full range of acoustic emissions. Collectively, these insights enable robust regime identification and CHF prediction, both of which are critical for ensuring the safety and performance of boiling-based thermal systems. Importantly, such a physically grounded understanding lays the foundation for machine learning frameworks that are not only predictive but also physically interpretable.

Signal processing and feature extraction

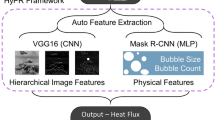

Following the acquisition of boiling acoustic signals, a robust signal processing pipeline is essential for converting raw, noisy acoustic data into a format suitable for advanced diagnostics. The workflow, as outlined in Fig. 4, begins with preprocessing techniques such as filtering (e.g., bandpass, wavelet transforms) that suppress noise and isolate specific frequency bands, while segmentation divides the continuous signal into manageable, often event-triggered windows. Normalization ensures data consistency across different sensors and experimental conditions60. After preprocessing, signals are transformed into various informative representations for feature extraction. Time-domain signals are ideal for detecting anomalies and rapid regime transitions, while frequency-domain spectra reveal dominant oscillatory components that can be linked to events within the ebullition cycle. For analyzing non-stationary phenomena, time–frequency transforms (e.g., Short-Time Fourier Transform, STFT, wavelets) are particularly valuable, as they capture how signal frequencies evolve temporally. Additionally, emerging techniques such as cepstrum analysis31 have shown promise for identifying periodic patterns in boiling dynamics.

A pivotal step in this pipeline is feature extraction. This can be achieved by deriving handcrafted features from the various signal representations or by using advanced methods such as self-supervised and unsupervised learning to learn them automatically. As discussed earlier, traditional methods such as hit-based analysis complement these approaches by providing transient event features sensitive to nucleation or the boiling crisis. The robustness of feature extraction is significantly enhanced by acoustic data fusion, which combines signals from diverse sensor types (e.g., hydrophones, AE sensors) to capture complementary physical features across a broad spectrum of frequencies. Multimodal integration with optical data further strengthens the diagnostic capabilities by correlating acoustic signatures with observable boiling phenomena. Additionally, signal separation methods such as Principal Component Analysis (PCA), auto-encoders, and clustering (e.g., K-Means, t-SNE) can be deployed to disentangle overlapping signals, which is invaluable in complex, multi-bubble regimes where acoustic signatures are difficult to distinguish. This comprehensive pre-processing and feature engineering pipeline forms a robust foundation for building interpretable and predictive machine learning models for boiling diagnostics.

Data-driven methods

The future of boiling diagnostics lies at the intersection of high-fidelity sensor data and interpretable machine learning—a synergy that transforms raw acoustic signals into real-time insights. While physical modeling and multi-sensor experimentation provide the foundation, scalable deployment demands data-driven frameworks that bridge empirical observations with mechanistic understanding44. In this context, machine learning becomes more than just a pattern-recognition tool; it evolves into a quantitative framework for classification, anomaly detection, and predictive modeling, capable of adapting to complex, transient thermal environments.

Once preprocessed, the signals can follow multiple modeling paths. They may be directly fed into deep learning models such as 1D CNNs61 or RNNs, which excel at learning hierarchical patterns from raw inputs62. Alternatively, handcrafted features extracted across time, frequency, and time-frequency domains provide interpretable signal descriptors, as illustrated in Fig. 4. Time-domain features (e.g., RMS, skewness, kurtosis) enable quick anomaly detection and can serve as inputs for simple thresholding algorithms63. Frequency-domain descriptors, such as PSD and FFT peak, expose boiling-specific patterns, and they are often leveraged in models such as SVMs and Random Forests64,65. Time-frequency representations such as STFT and wavelets yield spectrograms and scalograms, ideal for detecting transients and feeding deep models such as CNNs or Transformers. Finally, the integration of features from multiple sensor types (hydrophones, AE sensors, microphones, and accelerometers) can enhance diagnostic robustness by providing complementary information, enabling richer and more accurate insights across boiling regimes.

Leveraging the extracted acoustic features as structured in Fig. 4, ML models are employed to address key tasks such as boiling regime classification27,42, CHF detection27, estimation of localized HTC or surface heat flux29, anomaly detection66, and early warning27. However, in the context of safety-critical and physics-rich boiling systems, accuracy alone is fundamentally insufficient. Models must achieve high prediction performance to align with known thermal-fluid phenomena, and this alignment is non-negotiable to ensure reliability and trustworthiness under real-world operating conditions. Observations from previous research27 have highlighted that models, while accurate in ideal conditions, can sometimes rely on subtle or unintended cues, such as spectral silence, rather than directly on the physically salient frequency components of boiling. This can lead to performance degradation in the presence of noise42, emphasizing the critical need for models inherently grounded in the underlying physics of the system. To address this, incorporating Explainable AI (XAI) techniques67 such as saliency maps, Grad-CAM, and integrated gradients featured in Fig. 4, is essential. These methods allow researchers to identify which input portions contribute most to the model’s output. By explicitly linking learned features back to specific boiling mechanisms, XAI facilitates the development of robust, interpretable models better suited for real-time deployment, anomaly detection, and design validation in complex, safety-critical boiling systems.

Equally important to interpretability is generalizability, especially for models deployed across varying system conditions, fluids, or heater geometries. One promising strategy to enhance generalizability and reduce dependence on large, condition-specific datasets is transfer learning68. By leveraging pretrained neural networks developed for related tasks, such as audio event classification, transfer learning allows models to reuse low-level representations such as spectral patterns, improving both robustness and data efficiency. For instance, our recent work42 has demonstrated that fine-tuning pre-trained models, such as YAMNet69 achieves high accuracy while exhibiting greater resilience to noise and better generalization across diverse boiling conditions and fluids. This exemplifies the pragmatic potential of transfer learning for building predictive and robust boiling diagnostics with minimal labeled data and enhanced real-world reliability. Despite these strides, a persistent challenge is the limited availability of labeled datasets, particularly in boundary regions such as the near-CHF transition or under seldom-observed conditions. This bottleneck motivates the use of semi-supervised70 and unsupervised learning techniques71, which can exploit large volumes of unlabeled data to discover latent patterns without explicit supervision. Approaches such as clustering72, self-supervised learning73, and contrastive learning74 are particularly effective in boiling acoustics, where rich time-series signals contain significant internal correlations and recurring motifs. Crucially, these techniques address a fundamental challenge of manual labelling, which is time-consuming, subjective, and difficult to scale, especially when relying on visual or thermal cues. Within this framework, anomaly detection plays a crucial role by enabling the early identification of critical boiling phenomena. Beyond CHF, these methods can capture events such as the ONB and other regime transitions, thereby offering comprehensive early warning signals. Such proactive detection strengthens system safety and reliability by facilitating timely responses to evolving thermal conditions. Overall, embracing these data-centric learning paradigms is the definitive step towards generalizable, scalable, and highly insightful models for real-world boiling diagnostics.

Outlook

Overall, boiling acoustics holds immense promise as a diagnostic tool for understanding and predicting the complex dynamics of phase-change heat transfer. While significant progress has been made, the full potential of the field remains largely untapped due to a lack of standardized acquisition protocols for boiling acoustics, incomplete physical understanding, and challenges in developing robust, interpretable data-driven models. To overcome these limitations, a unified, synergistic approach is essential. This involves implementing consistent sensor calibration, placement, data acquisition, and reporting across studies, which is crucial for reproducibility and reliable cross-study comparisons. A multi-sensor approach combining hydrophones, AE sensors, microphones, and accelerometers, synchronized with high-speed optical visualization, offers a comprehensive view of bubble dynamics. Furthermore, a more complete mechanistic understanding of the acoustic signatures generated at each stage of the ebullition cycle - from nucleation to collapse and complex multi-bubble interactions - is needed, and controlled single-bubble studies along with advanced computational models can help disentangle these complex signals. Importantly, future progress must address flow boiling, which is common in practical applications such as reactor cooling, microchannel devices, and industrial heat exchangers. Flow introduces additional complexity through convective transport, velocity gradients, and evolving two-phase interactions, all of which influence both acoustic signal generation and propagation. Bridging the gap between pool and flow boiling through comparative experiments and context-specific sensor deployment is crucial. Finally, the development of interpretable, physics-informed machine learning models, trained on high-fidelity, standardized datasets, is vital. Addressing issues of subjective labeling, ensuring model generalizability across different experimental setups, and promoting open data practices will accelerate progress. By aligning on these priorities and fostering collaboration between fundamental research and applied diagnostics, boiling acoustics can evolve from a promising technique into a powerful, predictive, and application-ready tool for real-time thermal management and adaptive control in energy-intensive systems.

Data availability

No datasets were generated or analysed during the current study.

References

Carey, P. Van. Liquid-Vapor Phase-Change Phenomena: An Introduction to the Thermophysics of Vaporization and Condensation Processes in Heat Transfer Equipment (CRC Press, 2020).

Frank, P. Incropera, D. P. D. Fundamentals of Heat and Mass Transfer (Wiley, New York, 1996).

Faghri, A. & Zhang, Y. Fundamentals of Multiphase Heat Transfer and Flow (Springer, 2020).

Nguyen, T. B. et al. Critical heat flux enhancement in pool boiling through increased rewetting on nanopillar array surfaces. Sci. Rep. 8, 4815 (2018).

Macleod, I. D., Catling, E. & Taylor, C. G. Acoustic detection of boiling in LMFBRs: An estimate of sensitivity derived from experiments during the commissioning of PFR. Prog. Nucl. Energy 1, 469–485 (1977).

Barathula, S. & Srinivasan, K. Review on research progress in boiling acoustics. Int. Commun. Heat Mass Transfer 139, 106465 (2022).

Ferri, A. & Stephen, M. Acoustical boiling detection. PhD Thesis, The University of Arizona (1977).

Xiang, N. & Blauert, J. Acoustics for Engineers (Springer, Heidelberg, 2021).

Pierce, A. D. Acoustics: An Introduction to Its Physical Principles and Applications. Physics Today - PHYS TODAY (Springer, 2019).

Tang, J. et al. Experimental study of sound emission in subcooled pool boiling on a small heating surface. Chem. Eng. Sci. 188, 179–191 (2018).

Minnaert, M. On musical air-bubbles and the sounds of running water. Phil. Mag. 16, 235–248 (1933).

Westwater, J. W., Lowery, A. J. & Pramuk, F. S. Sound of boiling. Science 122, 332–333 (1955).

Aoki, T. & Welty, J. R. Frequency distribution of boiling-generated sound. J. Heat Transfer 92, 542–544 (1970).

Geraldo, I. C. et al. Acoustic monitoring of sodium boiling in a liquid metal fast breeder reactor from autoregressive models. Nucl. Eng. Des. 278, 573–585 (2014).

Negi, A., Rishi, A. M. & Kandlikar, S. G. Effect of heat flux on bubble coalescence phenomena and sound signatures during pool boiling. J. Heat Transfer 143, 051601 (2021).

Barathula, S., Chaitanya, S. K. & Srinivasan, K. Evaluation of machine learning models in the classification of pool boiling regimes up to critical heat flux based on boiling acoustics. Int. J. Heat. Mass Transf. 201, 123623 (2023).

Chiffoleau, G. J. A., Steinberg, T. A. & Veidt, M. Reflection of structural waves at a solid/liquid interface. Ultrasonics 41, 347–356 (2003).

Celata, G. P., Dell’Orco, G. & Gaspari, G. P. Detection of subcooled boiling heat transfer regimes up to critical heat flux by accelerometric equipment. Fusion Eng. Des. 28, 44–52 (1995).

Barathula, S., Karthik, R., Alapati, J. K. K., Srinivasan, K. & Wong, T. N. A multi-modal approach to pool boiling dynamics: acoustic and vibration data for regime classification and heat flux prediction. Therm. Sci. Eng. Prog. 64, 103760 (2025).

Arranz, F., Olmos, P. & Brañas, B. Accelerometers data processing for boiling onset detection on the LIPAc beam stopper. Fusion Eng. Des. 121, 152–158 (2017).

Saheban, H. & Kordrostami, Z. Hydrophones, fundamental features, design considerations, and various structures: a review. Sens Actuators A Phys. 329, 112790 (2021).

Osborne, M. F. M. & Holland, F. H. The acoustical concomitants of cavitation and boiling, produced by a hot wire. I. J. Acoust. Soc. Am. 19, 13–20 (1947).

Schwartz, F. L. & Siler, L. G. Correlation of sound generation and heat transfer in boiling. J. Heat Transfer 87, 436–438 (1965).

Nishihara, H. & Bessho, Y. Acoustic emission in subcooled nucleate pool boiling. J. Nucl. Sci. Technol. 14, 407–415 (1977).

Nishant Ranjan Sinha, K., Ranjan, D., Kumar, N., Qaisar Raza, M. & Raj, R. Simultaneous audio-visual-thermal characterization of transition boiling regime. Exp. Therm Fluid Sci. 118, 110162 (2020).

Nishant Ranjan Sinha, K. et al. In-situ acoustic detection of critical heat flux for controlling thermal runaway in boiling systems. Int. J. Heat. Mass Transf. 138, 135–143 (2019).

Sinha, K. N. R., Kumar, V., Kumar, N., Thakur, A. & Raj, R. Deep learning the sound of boiling for advance prediction of boiling crisis. Cell Rep. Phys. Sci. 2, 100382 (2021).

Ueki, Y. & Ara, K. Proof of concept of acoustic detection of boiling inception and state transition using deep neural network. Int. Commun. Heat. Mass Transf. 129, 105675 (2021).

Dunlap, C., Pandey, H., Weems, E. & Hu, H. Nonintrusive heat flux quantification using acoustic emissions during pool boiling. Appl Therm. Eng. 228, 120558 (2023).

Tang, J., Sun, L., Liu, H., Liu, H. & Mo, Z. Review on direct contact condensation of vapor bubbles in a subcooled liquid. Exp. Comput. Multiph. Flow 4, 91–112 (2022).

Ono, J. et al. Acoustic state detection of microbubble emission boiling using a deep neural network based on cepstrum analysis. Int. J. Multiph. Flow. 166, 104512 (2023).

Mitsuyama, F., Umeno, R., Yabuki, T. & Kamiya, T. Deep learning based prediction of heat transfer coefficient using spectrogram images from boiling sound. In Proc. 2024 International Conference on Artificial Life and Robotics 914–917 (A Life Robotics Corporation Ltd., 2024).

Huang, M. et al. Using acoustic emission in fatigue and fracture materials research. JOM 50, 1–14 (1998).

Wu, K., Baek, S.-H., Shim, H.-S., Haeng, H. D. & Hyun, L. D. Understanding of sub-cooled nucleate boiling on the nuclear fuel cladding surface using acoustic emission energy parameter. In Proc. 11th International Conference on Non Destructive Evaluation in Relation to Structural Integrity for Nuclear and Pressurized Components 19–21 (2015).

Baek, S. H. et al. Acoustic emission monitoring of water boiling on fuel cladding surface at 1 bar and 130 bar. Measurement 109, 18–26 (2017).

Yeong et al. Convolutional neural network-based boiling regime determination using acoustic emission signal image. In Proc. 19th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-19) (Brussels, 2022).

Lim, D. Y. & Bang, I. C. A novel non-destructive acoustic approach for investigating pool boiling phenomena. Int. J. Heat. Mass Transf. 222, 125166 (2024).

Kothare, N., Chirammel, S. S., Murallidharan, J. S. & Sharma, A. Coalescence regimes during single bubble nucleate boiling under periodic exponential heating. ASME J. Heat Mass Transfer 147, 101601 (2025).

Droste, D. W. & Ringelstein, E. B. Detection of high intensity transient signals (HITS): How and why?. Eur. J. Ultrasound 7, 23–29 (1998).

Dunlap, C., Li, C., Pandey, H. & Hu, H. Hit2flux: a machine learning framework for boiling heat flux prediction using hit-based acoustic emission sensing. AI Therm. Fluids 1, 100002 (2025).

Cabarcos, A., Paz, C., Concheiro, M., Conde-Fontenla, M. & Suárez, E. Comparative analysis of machine learning approaches for boiling ONB prediction. In Proc. 4th International Conference on Fluid Flow and Thermal Science (ICFFTS 2023) https://doi.org/10.11159/icffts23.158 (Avestia Publishing, 2023).

Suriyaprasaad, B., Upadhyay, A., Thakur, A. & Raj, R. Explainable boiling acoustics analysis using Grad-CAM and YAMNet for robust pool boiling regime classification. Appl. Therm. Eng. 278, 127220 (2025).

Pandey, H., Li, C. & Hu, H. Multimodal boiling dataset with synchronized acoustic, optical, and thermal measurements under steady-state and transient heat loads. Data Brief. 55, 110582 (2024).

Upadhyay, A., Hazra, S. K., Assam, A. & Raj, R. Review of the current status and the potential of machine learning tools in boiling heat transfer. Numer. Heat. Transf. Fundament. 85, 1489–1532 (2024).

Suh, Y., Chandramowlishwaran, A. & Won, Y. Recent progress of artificial intelligence for liquid-vapor phase change heat transfer. npj Comput Mater 10, 65 (2024).

Rudin, C. Stop explaining black box machine learning models for high stakes decisions and use interpretable models instead. Nat. Mach. Intell. 1, 206–215 (2019).

Prosperetti, A. Bubble phenomena in sound fields: Part One. Ultrasonics 22, 69–77 (1984).

Khabeev, N. S. Resonance properties of vapor bubbles. J. Appl. Math. Mech. 45, 512–517 (1981).

Prosperetti, A. The speed of sound in a gas–vapour bubbly liquid. Interface Focus 5, 20150024 (2015).

Tang, J., Yan, C. & Sun, L. Feature of acoustic sound signals involved in vapor bubble condensation and its application in identification of condensation regimes. Chem. Eng. Sci. 137, 384–397 (2015).

Hughes, M. T. & Garimella, S. A review of active enhancement methods for boiling and condensation. Int J. Heat. Mass Transf. 218, 124752 (2024).

Legay, M., Gondrexon, N., Le Person, S., Boldo, P. & Bontemps, A. Enhancement of heat transfer by ultrasound: review and recent advances. Int. J. Chem. Eng 1, 670108, https://doi.org/10.1155/2011/670108 (2011).

Alam, M. Q., Upadhyay, A., Assam, A. & Raj, R. On the origin and nature of acoustic emissions from bubbles departing an underwater nozzle. Phys. Fluids 37, 4 (2025).

Zhang, Y., Gao, Y., Guo, Z. & Du, X. Effects of mass transfer on damping mechanisms of vapor bubbles oscillating in liquids. Ultrason Sonochem. 40, 120–127 (2018).

Dorofeev, B. M. The variation of the radius of a vapor bubble under conditions of boiling in a volume of subcooled liquid and the sound pulses generated by bubbles. High. Temp. 40, 437–442 (2002).

Dorofeev, B. M. & Volkova, V. I. The effect of evaporation and condensation in vapor bubbles on the hydrodynamic sound generation in a subcooled boiling liquid. Acoust. Phys. 52, 173–179 (2006).

Prosperetti, A. Vapor bubbles. Ann. Rev. Fluid Mech. 49, 221–248 (2017).

Lim, D., Liu, Y. & Bang, I. C. Predicting boiling heat flux, heat transfer coefficient, and regimes non-intrusively using external acoustics and deep learning. Sci. Rep. 15, 22690 (2025).

Wallen, D. et al. Unsupervised machine learning framework for non-destructive acoustic emission sensing of flow condensation. AI Therm. Fluids 2–3, 100010 (2025).

Smith, S. W. Digital Signal Processors (California Technical Publishing, 1997).

Tang, W. et al. Omni-Scale CNNs: a simple and effective kernel size configuration for time series classification. In The Tenth International Conference on Learning Representations (ICLR'22) (2022).

Goodfellow, I., Bengio, Y. & Courville, A. Deep Learning (MIT Press, 2016).

Constantinescu, C. & Brad, R. An overview on sound features in time and frequency domains. Int. J. Adv. Stat. ITC Econ. Life Sci. 13, 45–58 (2023).

Bartusaik, E. R. & Delp, E. J. Frequency Domain-Based Detection of Generated Audio. In Proc. IS&T Int’l. Symp. on Electronic Imaging: Media Watermarking, Security, and Forensics, 2021, 273-1–273-7, https://doi.org/10.2352/ISSN.2470-1173.2021.4.MWSF-273 (2022).

Xu, K. et al. Learning in the frequency domain. In Proc. IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR) 1740–1749 (IEEE, 2020).

Reddy, C. P., Singh, O. P., Vyjayanthi, R. K. & Prabhakar, R. A new approach in signal processing for sodium boiling noise detection by probability density function estimates. Nucl. Technol. 80, 371–379 (1988).

Tang, J., Kan, M.-Y., Zhao, D., Li, S. & Zan, H. Natural language processing and Chinese computing. Proc. West Mark Ed. Assoc. Conf. http://www.springer.com/series/1244 (2005).

Weiss, K., Khoshgoftaar, T. M. & Wang, D. D. A survey of transfer learning. J. Big Data 3, 9 (2016).

Howard, A. G. et al. MobileNets: efficient convolutional neural networks for mobile vision applications. http://arxiv.org/abs/1704.04861 (2017).

Van Engelen, J. E. & Hoos, H. H. A survey on semi-supervised learning. Mach. Learn 109, 373–440 (2020).

Azlinah, M. W. B., Bee, M. & Yap, W. Supervised and Unsupervised Learning for Data Science Unsupervised and Semi-Supervised Learning Series. Springer (Springer, 2020).

Saxena, A. et al. A review of clustering techniques and developments. Neurocomputing 267, 664–681 (2017).

Liu, X. et al. Self-supervised learning: generative or contrastive. IEEE Trans. Knowl. Data Eng. 35, 857–876 (2023).

Chen, T., Kornblith, S., Norouzi, M. & Hinton, G. A simple framework for contrastive learning of visual representations. In Proc. 37th International Conference on Machine Learning (eds. III, H. D. & Singh, A.) vol. 119 1597–1607 (PMLR, 2020).

Barathula, S., Alapati, J. K. K. & Srinivasan, K. Investigation of acoustic spectral variations in the pool boiling regimes of water on wire heater. Appl. Therm. Eng. 226, 120281 (2023).

Acknowledgements

The authors wish to acknowledge the funding support received from the Swarnajayanti Fellowship scheme of the Anusandhan National Research Foundation (ANRF), previously Science and Energy Research Board (SERB), Government of India, through Project No. SB/SJF/2021-22/15. The authors acknowledge the use of AI-assisted tools, specifically ChatGPT, for creating some illustrative icons in the figures and for language refinement to improve grammatical clarity.

Author information

Authors and Affiliations

Contributions

B.S. led the conceptualization, methodology development, validation, and original drafting of the manuscript. A.U. contributed to conceptualization, methodology, validation, and manuscript review and editing. A.T. provided conceptual input, supervision, and participated in manuscript review and editing. R.R. was responsible for conceptualization, funding acquisition, project administration, resource provision, supervision, and manuscript review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Suriyaprasaad, B., Upadhyay, A., Thakur, A. et al. A roadmap for decoding the sound of boiling. npj Therm. Sci. Eng. 1, 2 (2026). https://doi.org/10.1038/s44435-025-00004-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44435-025-00004-z