Abstract

This study proposes a novel stagnant water layer cooling concept to enhance performance of solar photovoltaic (PV) modules. Three distinct types of water—seawater (Scenario 1), tap water (Scenario 2), and desalinated water (Scenario 3)—were utilized to cool a 10 WP polycrystalline PV module by establishing a stagnant layer of 1.0 cm thickness over it, under the climatic conditions of Visakhapatnam (17.62°N, 83.21°E), India. The average daily temperature variations between the reference and modified PV modules were approximately 7.0 °C, 7.2 °C, and 8.2 °C for Scenarios 1, 2, and 3, respectively. The daily average electrical efficiency & energy output of the modified PV modules under Scenarios 1, 2, and 3 were approximately 16.2 & 14.9, 18.6 & 16.6, and 30.8 & 28.3%, relatively higher than the reference PV module, respectively. Exergy efficiency, sustainability index and specific CO2 emission of desalinated water-cooled PV module were 7.41%, 1.08, and 406 g/kWh, respectively. However, the desalinated water-cooled PV module exhibited 29.1 and 15.1% higher evaporation losses than those of the seawater and tap water-cooled PV modules, respectively, under similar solar energy of 21.4 MJ/m²d. The proposed cooling technique is effective and economic, depends on the type of utilized water.

Similar content being viewed by others

Introduction

The scarcity of fossil fuels, persistent increases in fossil fuel prices, and detrimental gas emissions from fossil fuel combustion have compelled countries to seek clean and renewable energy sources to meet their energy requirements1. The shift to renewable energy sources is essential for meeting energy demands, mitigating climate change, and attaining global sustainable development objectives2. Solar PV systems are integral to this transition towards clean electricity in many countries2 and play an important role in achieving net zero energy use in buildings3. Solar PV systems have significant advantages, including the abundant availability of solar energy resources, a rapid decline in PV module prices, high power density compared to other renewable sources, and zero emissions during operation1. PV modules convert sunlight into electricity; however, their lower conversion efficiency leads to a portion of the absorbed sunlight being transformed into heat energy, which increases their operating temperature significantly. The increased temperature can adversely affect the performance of PV modules by diminishing their conversion efficiency and lifespan4. Annual energy yield of PV modules in sites with hot climatic conditions was lower than the energy yield in sites with moderate climatic conditions due to high PV module operating temperature under harsh conditions5. The conversion efficiency of crystalline silicon PV modules decrease by 0.2 to 0.6% for each one-degree Celsius increase in operating temperature above the reference point of 25 °C6 highlighting the need for modifying PV module design based on site conditions7. Module overheating is one of the factors that limit Building Integrated Photovoltaic (BIPV) systems adoption apart from the lack of unstandardized guidelines for designs & installations8. To address this adverse effect, numerous cooling techniques have been investigated by researchers to lower the operating temperature of PV modules9.

The cooling methods for PV modules can be classified into passive and active techniques10. Active techniques employ external devices such as fans, blowers, and circulation pumps to circulate fluid over the module, facilitating the removal of generated waste heat energy11. Active cooling techniques have reduced PV module operating temperature and improved its efficiency by about 49.2 °C and 47.7%, respectively12. Passive cooling techniques utilize natural fluid motion resulting from density differences induced by temperature variations11. In addition, passive cooling techniques seems more economical than active cooling techniques due to the associated reduced operation costs13. For example, Al-Amri et al.14 observed 6.3 °C temperature drop and 3.0% electrical efficiency improvement by just modifying the PV module racking system to act as heat sink to the PV module to dissipate the heat to the surrounding air. Among all the cooling mediums, water can be used for both cleaning and cooling of PV modules. Cleaning of PV array with water at sunset and sunshine has increased the power output by 1.13 to 3.38%15. Water-based PV cooling systems have garnered considerable interest among different fluids, attributed to water’s high specific heat capacity and efficiency in heat dissipation. Water can dissipate heat energy from PV modules through sensible heat transfer or phase change processes. Water-based cooling systems have significantly reduced PV module operating temperatures and enhanced overall electrical efficiency16. Water-based cooling techniques for PV modules include water veil cooling, water spray cooling, evaporative cooling, immersion cooling, and cooling through water circulation (PV/T collectors)17. Higher improvement in PV electrical efficiency was observed in PV modules incorporated with active water-cooling techniques13.

PV module cooling can be accomplished through the dissipation of waste heat energy from its front and back surfaces. Arefin et al.18 demonstrated that applying a 3 L/min of water over the front surface of a PV module could improve its efficiency by a minimum of 0.8 to 1.0%. Chanphavong et al.19 demonstrated that front surface water veil cooling of mono-crystalline solar PV module can reduce operating temperature by 29.6 °C and enhance maximum power output by 17.35%. Torres et al.20 utilized the front surface of the PV module to dissipate waste heat energy through thin film flow of water, which was also subjected to solar disinfection, in a novel hybrid system termed SolWat. The continuous flow of water over the PV module fulfilled two functions: it disinfected the water and cooled the PV module, thereby improving its electrical efficiency. The prototypes were assessed in Spain, utilizing wastewater from the local treatment facility. The experiments indicated that the prototypes complied with Spanish and European standards for water reuse and enhanced PV module energy generation efficiency by 15–21% relative to a reference PV module lacking water cooling.

Hadipour et al.21 investigated the efficacy of pulsed-spray compared to steady spray water cooling on the front surface of PV module. The steady-spray system enhanced PV module power output by 33.3%, whereas the pulsed-spray system, operating at duty cycles of 1.0 and 0.2, increased PV module power output by 27.7% and 25.9%, respectively. The pulsed-spray system reduced water usage to one-ninth of that of the steady-spray system. Khan et al.22 reported a decrease in PV module operating temperature of 30 °C and an efficiency increase of approximately 0.28% for each one-degree Celsius reduction in PV module temperature when water was sprayed on its front surface. Nizetic et al.23 reported temperature reductions of 26.4, 22.3, and 31.9 °C for PV module surfaces subjected to front surface water spray, back surface water spray, and simultaneous water spray on both sides, respectively. Moreover, self-cleaning effect provided by spraying water has also contributed to boosted power output of PV modules. However, water spraying has utilized power ranging from 2.7 to 4.2 W for spray rates of 144 to 225 L/h. The enhancement in effective power output with water spray on the front surface, back surface, and simultaneous application on both sides of the PV module was approximately 6.0%, 5.4%, and 7.7%, respectively. Additionally, spray angle, pressure, and on/off duration significantly influenced the cooling of PV modules and their subsequent performance improvement24.

The incorporation of wetted wicks and heat exchangers, particularly in PV/T systems, has enhanced thermal management of PV modules by facilitating heat energy dissipation through the rear surface. Cooling PV module’s rear surface with a wetted cotton wick decreased its temperature from 56.4 to 43.8 °C, and improved its electrical efficiency by 53%25. Alktranee and Bencs26 reported a reduction in PV module temperature from 52.0 to 35.7 °C and observed a power output enhancement by 66.6% using wetted cotton wick-fin combination to cool the rear surface of the PV module. The arrangement of a continuously wetted sponge affixed to the rear surface of the PV module resulted in a 4.0 °C reduction in PV module’s operating temperature when compared to the reference module. This cooling method has enhanced maximum power output and efficiency by 6.4 and 2.6%, respectively27. Haidar et al.28 observed a temperature reduction of approximately 20 °C in the PV module and a 14% enhancement in electrical efficiency by employing a continuously wetted cloth to cool the PV module’s rear surface. Mahmood and Aljubury29 reported a PV module temperature reduction of 15 to 20 °C and an efficiency enhancement of 7.4 to 11.2% through the application of a cellulose pad on the PV module’s rear surface, which was continuously wetted by flowing water. The circulation of CuO and Fe2O3 nano-fluids through a heat exchanger affixed to the rear surface of the PV module resulted in reduction of PV module temperature from 52.8 to 42.8 °C and 39.3 °C, respectively thereby, leading to enhancements in electrical efficiency of the corresponding modules by 9.21% and 10.30%, respectively30. A comprehensive examination of different configurations of PV/T collectors is available in references31,32. Capital, operation and maintenance cost of PV/T collectors are about 1.7 times higher than sole PV modules. PV/T collectors perform better in mild climatic conditions and poor in cold climatic conditions33. PV/T collectors can reduce PV module degradation rate and improve its electrical efficiency by 3.0% and 30.0%, respectively34. Thermoelectric cooling system in combination with water circulation has been expected to reduce the PV module operating temperature by 30 to 38 °C35.

Al-Amri et al.36 performed experiments in Dammam, Saudi Arabia, to evaluate different cooling techniques for PV modules. Passive cooling utilizing heat sinks decreased PV module temperature by approximately 10 °C. Nonetheless, its efficacy decreased at elevated ambient temperatures. In contrast, module cooling utilizing heat pipes, especially with water as the immersion fluid, demonstrated optimal results, achieving a temperature reduction of approximately 53%. Other heat pipe immersion fluids, including ethylene glycol and engine oil, resulted in PV module temperature reductions of 48% and 25%, respectively; however, their effectiveness was inferior to that of water. Chowdury et al.37 identified wind convection as the cause of cooling in floating PV modules and posited that the resulting efficiency enhancement ranges from 0.5 to 3.0%. Ebrahimi et al.38 experimentally demonstrated that natural vapor from water bodies such as ponds and lakes can reduce the temperature of PV modules installed above them by 7.0 to 16.0 °C. Elminshawy et al.39 reported a 22.77% increase in power output and a 33.31% decrease in PV module operating temperature by employing perforated heat sinks that were partially submerged in water and affixed to the rear surface of floating PV modules. The floating PV module in direct water contact, demonstrated an energy yield increase of 5.0 to 7.0% compared to the air-cooled PV module40.

Immersing 10% of a PV module’s body in water has resulted in a reduction of its operating temperature from 42.5 °C to 37.5 °C and an enhancement of its power output by 18.2%, respectively, when compared to the ground-mounted PV module41. However, partial immersion of PV module can result in non-uniform cooling thereby leading to thermal stress and early failure/breakage. Hence, full immersion cooling technique seems beneficial than the partial immersion cooling technique. Moreover, the full immersion cooling technique has been suggested as a suitable option to eliminate hot spots in PV modules42. Numerous innovative concepts have been explored, particularly regarding full immersion cooling of PV modules. Experiments involved fully immersing PV modules in water at two distinct depths: 4 cm and 40 cm have been studied. The submerged crystalline PV module exhibited a surface temperature of 30 °C, in contrast to the reference PV module, which maintained a temperature range of 70 to 80 °C. At a depth of 4 cm, the submerged PV module exhibited an average electrical efficiency increase of 11%; conversely, at a depth of 40 cm, its electrical efficiency decreased by 23%43. Fadliondi et al.44 initially encapsulated the PV module with a transparent plastic cover and subsequently immersed the entire assembly in water, leading to a reduction in the PV module’s operating temperature by 23 °C. Nevertheless, the specifics concerning the depth of submersion were not disclosed. Mehrotra et al.45 conducted experiments on crystalline PV modules submerged in water at depths ranging from 1 to 6 cm. The optimal depth for enhanced electrical efficiency was determined to be 1.0 cm, resulting in an efficiency increase of 17.8% and a temperature reduction of 24.6 °C, in comparison to the reference emerged PV module. An amorphous PV module submerged in water at a depth of 4 cm exhibited a 21.6% increase in electrical efficiency and maintained an operating temperature 20 °C lower than that of the reference PV module46. Tap water, rainwater, and distilled water have been employed for the immersion cooling of PV modules47. Venkatesan et al.48 performed experiments on PV modules utilizing a 2 mm thick layer of deionized water and a standard water layer above it. The maximum temperatures observed were approximately 79.0 °C for the reference PV module, 47.0 °C for the deionized water PV module, and 48.0 °C for the standard water immersed PV module. Presence of water layer over the PV module could actually reduce the solar irradiation reaching the module due to associated reflections and transmission losses. However, the observed power output reduction for a 60 W PV module with water layer over it was only 0.3 W when exposed to a solar irradiation of 420 W/m2. This observation clearly indicated the negligible effect of thin water layer over the PV module in reducing its power output49.

Alternative liquids to water have also been examined for their potential use in PV module immersion cooling. Abrahamyan et al.50 conducted research by submerging the PV module in a glycerine solution with a depth of 5 to 6 mm. The efficiency of the submerged PV module improved by 40–60% relative to the reference PV module. Wang et al.51 conducted experiments testing three immersion liquids—tap water, silicon oil, and ethanol—for PV module submersion cooling at depths of 3, 6, and 9 mm. The findings indicated that silicon oil is the most effective liquid for immersion cooling and power enhancement in PV modules. The PV module was submerged in several liquids, specifically isopropyl alcohol (IPA), ethyl acetate, deionized (DI) water, and dimethyl silicone oil, and tested over a duration of 180 days at depths of 1.5 and 9.0 mm. At an optimal depth of 1.5 mm, the efficiency enhancement of the immersion-cooled PV module varied between 8.5 and 12.2%52.

The reviewed literature indicates that water cooling, specifically immersion cooling, is more effective in reducing PV module’s operating temperatures. Furthermore, in all the studies referenced regarding PV module immersion cooling, the PV module is entirely submerged in the fluid, necessitating the protection of the PV module junction box and frames43,44,45,46,47,48. Moreover, complete PV module immersion may influence fluid quality as a result of possible corrosion and erosion of the PV module’s metal frames. This work proposes a simple, low cost and novel methodology for the immersion cooling of PV modules, ensuring that the junction box and aluminum frames remain free from fluid contact. Furthermore, the use of chemicals as cooling mediums presents potential environmental and safety risks; therefore, various forms of water namely seawater, tap water and desalinated water have been employed as cooling mediums in this study and their impacts were compared. Moreover, on contrast to other studies with low depth water immersion cooling48,51,52, in this study the continuous evaporation of the stagnant thin water layer over the PV module to the ambient was allowed thereby, the water depth will be varying throughout the experimental day. Moreover, the water-energy-economics-environment nexus related to a water-immersion cooled 1.0 kWP capacity solar PV array has been estimated and presented in a straightforward manner.

The primary objectives of this research are listed below:

-

a.

To assess the capacity of a stagnant water layer in modulating the operating temperature of PV modules.

-

b.

To evaluate the influence of cooling medium type on the thermal and electrical characteristics of PV modules.

-

c.

To compare the performance of the reference (uncooled) PV module with that of the water-immersion cooled PV module in terms of energy output, electrical efficiency, exergy efficiency and sustainability index.

-

d.

To assess the water consumption, net CO2 emission mitigation potential, specific CO2 emission and cost per kWh of electric energy generated by water immersion-cooled and reference PV modules.

This paper is structured into six sections. Section Introduction provides an introduction that outlines the necessity of cooling for PV modules, reviews available water-based cooling techniques, and states the objectives of this study. Section Test PV Modules – System Description provides a description of the experimental setup and outlines the development procedure. The experimental procedure and instrument details are discussed in Sect. Experimental Methodology. Section Results and Discussion presents a discussion on site climatic conditions, water quality results, test PV module performance, water evaporation loss, sustainability index and aspects of the water-energy-economic-environment nexus. The conclusion of this research is presented in Sect.Conclusion. Section Limitations of the Present Work and Scope for Future Works presents the limitations of the current research. This research presents findings that are both interesting and promising as indicated in Fig. 1, thereby contributing to the development of efficient, low-cost PV module cooling techniques utilizing affordable resources for adoption in built environment.

Test PV Modules – System description

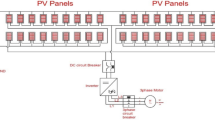

Figure 2(a-c) illustrates the schematic of the conventional and modified PV modules examined in this study. One PV module served as the reference, while the other was modified to retain a stagnant layer of water on its upper surface. No cracks or gaps were observed in PV modules during manual inspection. Four transparent glass strips, each 3.0 mm thick and 30.0 mm high, were affixed along the perimeter of the front surface of the PV module using silicone adhesive, thereby creating an open water container with the PV module serving as its base. The silicone adhesive was applied on both the inner and outer perimeters of the formed open water container thereby, the seepage of water through the gap (if any) between PV module glass cover and aluminum frame were prevented thereby potential corrosions and short circuit were avoided. Figure 2b illustrates the specific dimensions of this arrangement. The open container was used to hold a 1.0 cm thick layer of seawater, tap water, or desalinated water, which were examined as cooling mediums in this study. Five black tape strips were adhered to the rear surface of both PV modules, as illustrated in Fig. 2c, to enable temperature measurement through a non-contact method using an Infrared Thermal Gun. The test PV modules were positioned horizontally (zero tilt angle) on a mild steel stand, as illustrated in Fig. 3. Table 1 presents the technical specifications of the PV modules utilized in the experiments.

The analog ammeter, analog voltmeter, and rheostat were connected to the PV module in series, parallel, and series configurations, respectively. The circuit was supplied with a resistive load by the linked rheostat. A comparable configuration has been employed to evaluate the experimental performance of PV modules in references53,54. When solar radiation strikes the PV module, a fraction is reflected, while the majority is absorbed and transformed into electrical and thermal energy. The generated thermal energy is dispersed to the environment by convection and radiation heat loss in the reference PV module. In the event of a modified PV module with a water layer, the generated thermal energy is dispersed to the environment by convection, radiation, and evaporative heat loss from its front surface, potentially leading to an operating temperature that differs from that of the reference PV module. Furthermore, the existence of a water layer on the PV module may influence its electrical characteristics. The electrical characteristics were evaluated by estimating the test PV modules power output and electrical efficiency.

Experimental methodology

Experiments were performed using the established experimental setup on the terrace of the Tech Horizon Building at the Indian Institute of Petroleum and Energy (IIPE) in Visakhapatnam (17.68°N, 83.21°E) from 9:30 A.M. to 4:30 P.M. during May and June 2024. Seawater, one of the cooling mediums, was collected from the Rama Krishna beach, located approximately 1.5 km from the experimental site. Tap water, another cooling medium, was sourced from the borewell water supply to the IIPE. Desalinated water, which has been examined as a cooling medium in this study, was acquired through the solar desalination of seawater utilizing a basic basin solar still55. A total of 920 mL of cooling medium, corresponding to a depth of 1.0 cm, was manually loaded into the modified PV module on each experimental day immediately prior to the commencement of experiments. The experimental plan utilized in this research is presented in Table 2.

The global horizontal solar irradiation (GHI) was quantified utilizing a digital lux meter. Ambient temperature, wind speed, and relative humidity were quantified utilizing a hand-held digital anemometer. The PV module temperature was assessed using an Infra-Red thermometer, with emissivity tuned to 0.95. The PV module temperature measurement was conducted by directing the Infra-Red thermometer towards the black tape strips affixed at multiple locations on the rear surface of the PV modules, as illustrated in Fig. 2c. Due to horizontal orientation, the rear surface of PV module is never exposed to solar irradiation thereby the presence of black tape strips does not affect PV module temperature. The mean of the five recorded temperature readings was reported as PV module temperature. All readings were taken at 15-minute intervals throughout the experimental period. At the conclusion of each experimental day, the volume of unevaporated cooling medium (seawater, tap water, or desalinated water) over the modified PV module was collected and measured manually with a 60 mL medical syringe. The daily water evaporation loss was calculated by subtracting the remaining volume of the cooling medium (seawater, tap water, or desalinated water) at the end of the experiment from the initial volume loaded at the start of the experiment. The water quality parameters, including pH, electrical conductivity, total dissolved solids, salinity, and turbidity, were measured three times, and the average values are reported.

Power output of the test PV module was estimated by56,

The ratio of PV module power output to the incident solar energy over the PV module is termed as electrical efficiency29 and was estimated by,

The uncertainty in measurements obtained using analog instruments was estimated by53,

The uncertainty in measurements obtained using digital instruments was estimated by53,

Table 3 presents the instruments utilized for experimentation, along with their associated uncertainties.

The standard uncertainty related to power measurement was estimated by57,

The standard power measurement uncertainty in this study, as estimated from the aforementioned formula, was approximately ± 0.13 W.

The standard uncertainty related to the PV module electrical efficiency was estimated by21,25,

The estimated standard uncertainty in PV module electrical efficiency was about ± 0.54%.

Results and discussion

Weather condition on experimental days

The weather conditions recorded on experimental days include ambient temperature, wind speed, relative humidity, and global horizontal solar irradiation. Figure 4 presents the plot of measured wind speed on experimental days across the examined scenarios. Wind speed exhibited fluctuations during the experimental periods. The instantaneous wind speed on experimental days for Scenario 1 and Scenario 3 ranged from 0.0 to 3.0 m/s, whereas Scenario 2 exhibited a broader distribution with the highest daily average value between 3.0 and 3.6 m/s. The daily average wind speeds for Scenario 1 and Scenario 3 ranged from 1.0 to 2.4 m/s and 1.2 to 2.8 m/s, respectively. The standard deviation of the measured hourly average wind speed for Scenarios 1, 2, and 3 ranged from 0.5 to 2.6 m/s, 0.4 to 1.5 m/s, and 0.4 to 2.3 m/s, respectively. This observation demonstrated considerable variation in instantaneous wind speed across the experimental days within each scenario.

Relative humidity plays a crucial role in enabling evaporative cooling, which has been employed in this study to enhance the performance of PV modules. It is defined as the ratio of the actual water vapor content in the air to the maximum water vapor capacity at a specific temperature. The instantaneous variation of ambient relative humidity measured on experimental days under Scenarios 1, 2, and 3 is presented in Fig. 5. The daily average ambient relative humidity varied from 61.0 to 70.0%, 63.0–65.0%, and 57.0–64.0% in Scenarios 1, 2, and 3, respectively, indicating relatively humid ambient conditions. The standard deviation of the measured hourly average ambient relative humidity for Scenarios 1, 2, and 3 ranged from 2.5 to 9.9%, 1.4–6.8%, and 1.0–9.6%, respectively, indicating notable variation in ambient relative humidity across the experimental days for each scenario.

The ambient temperature recorded during the experimental days was illustrated in Figs. 6, 7 and 8. The measured ambient temperatures were elevated during the forenoon but exhibited a decreasing trend in the afternoon. The daily average ambient temperatures under Scenario 1 were approximately 35.2 °C, 35.1 °C, 33.6 °C, and 33.9 °C on May 31, June 1, June 3, and June 6, 2024, respectively. In Scenario 2, the daily average ambient temperature remained consistent at 33.5 °C from June 7 to June 10, 2024. In Scenario 3, the recorded daily average ambient temperatures were 34.1 °C, 35.6 °C, 35.8 °C, and 35.7 °C on June 11, 14, 15, and 16, 2024, respectively. The standard deviation of the measured hourly average ambient temperature values on experimental days for Scenario 1, Scenario 2, and Scenario 3 ranged from 0.4 to 1.9 °C, 0.5 to 1.6 °C, and 0.3 to 2.4 °C, respectively, indicating comparable ambient temperatures across each scenario.

The hourly variation of GHI at the experimental site on designated experimental days was measured and illustrated in Figs. 10, 11 and 12. All experimental days, with the exception of June 8 and June 11, 2024, were predominantly clear, exhibiting minimal cloud cover. Table 4 presents the daily maximum, minimum, and average GHI values recorded on experimental days across all considered scenarios. The GHI varied from 729.0 to 1261.0 W/m² across the experimental days. The GHI can attain approximately 1300.0 W/m² in the absence of cloud cover58. The maximum GHI recorded in Egypt was approximately 1200.0 W/m²59. The daily average GHI recorded during the experimental days in this study varied from 530.0 to 1007.0 W/m². The daily average cumulative GHI potential for Scenarios 1, 2, and 3 were 21.4, 21.4, and 18.8 MJ/m²d, respectively. The estimated standard deviation values presented in Table 4 indicate a significant difference in GHI values across the experimental days for each Scenario.

Quality aspects of cooling medium

The quality parameters, including pH, electrical conductivity, total dissolved solids, salinity, and turbidity of the potential PV cooling mediums examined in this study, are presented in Table 5. Seawater exhibited greater electrical conductivity compared to tap and desalinated water, attributable to its higher concentration of inorganic dissolved solids, as supported by the total dissolved solids values presented in Table 5. The pH value indicated that seawater is caustic, whereas tap water and desalinated water are weakly acidic60,61. The pH value of desalinated water ranged from 6.21 to 6.87 during the seawater desalination process utilizing Reverse Osmosis technology61. Salinity, defined as the salt concentration of seawater, was approximately 58 and 1975 times higher than that of tap and desalinated water, respectively, indicating potential salt deposition on the PV modules during prolonged operation. Furthermore, the elevated electrical conductivity and minimal mineral content, coupled with a relatively low pH, render both seawater and desalinated water corrosive, respectively61,62. Turbidity, defined as the clarity of a fluid in terms of light transmission, is a crucial parameter in this study, given that the water layer is maintained above the module. The turbidity value is influenced by the presence of particles that scatter light63. The turbidity of seawater was found to be greater than that of tap water and desalinated water. However, their magnitudes are below 1.0 NTU, indicating that all three cooling mediums are relatively clear. Water with a turbidity value exceeding 0.1 NTU is generally prone to fouling64. Therefore, this study recommends the daily replacement of unevaporated water to mitigate potential negative effects in the long term.

Temperature aspects of test PV modules

The hourly variation of ambient temperature, investigated module temperatures along with the difference between the module and ambient temperature in Scenario 1, 2 and 3 are presented in Figs. 6, 7 and 8, respectively. The reference PV module showed higher operating temperature throughout the experiments due to lack of evaporative cooling. The operating temperatures of seawater PV module (SWM), tap water PV module (TWM) and desalinated water PV module (DWM) were always lower than the reference PV module and seem closer to ambient temperature even during sunny hours. The difference between the investigated PV module operating temperature and ambient temperature were very much lower in early morning and late evening hours of the experimental days. In case of evaporatively cooled PV modules, the operating temperature had fell even below the ambient temperature especially, during late evening hours. In order to understand the impact of solar irradiation on PV module operating temperature, the operating temperatures of the reference PV module, SWM, TWM and DWM under varying GHI on experimental days have been compiled, compared, and presented in Fig. 9(a-c). The PV module operating temperature exhibited a linear increase corresponding to the rise in the magnitude of GHI. This observation may be associated with the PV module’s inefficiency in converting the entire spectrum of solar irradiation into electricity.

The unutilized spectrum absorbed by the PV module significantly increased its operating temperature. The temperature of the reference PV module varied from 30.0 to 60.0 °C, consistently exceeding that of the modified PV modules. The average operating temperatures for the SWM, TWM and DWM were approximately 7.4 °C, 7.2 °C, and 8.2 °C lower than that of the reference PV module, respectively. The reduced operating temperature of the modified PV modules, relative to the reference PV module, can be attributed primarily to the heat loss from evaporation occurring within them. The average operating temperatures of SWM, TWM, and DWM were 1.4 °C, 1.3 °C, and 0.8 °C above ambient temperature, respectively. The evaporative cooling across the entire modified PV module area led to uniform cooling, resulting in the PV module’s operating temperature approaching the ambient temperature. Additionally, the instantaneous operating temperature of evaporative cooled PV modules was observed to be several degrees lower than the ambient temperature during late afternoon hours in this study. The reference PV module, in contrast, functioned at average temperatures of approximately 8.8, 8.5, and 9.1 °C, exceeding the ambient temperature observed in Scenarios 1, 2, and 3, respectively. Evaporative cooling is contingent upon relative humidity65. Therefore, a significant reduction in PV module operating temperature is anticipated through the implementation of this proposed cooling technique in hot and dry arid regions. The temperature data for the test PV modules during the experimental days were compiled and presented in Table 6.

Electrical aspects of test PV modules

The hourly variation in solar irradiation along with the power output and electrical efficiency of the test PV modules in Scenario 1, 2 and 3 is shown in Figs. 10, 11, and 12. It could be seen clearly that the power output of the test PV modules is directly proportional to solar irradiation and followed the hourly solar irradiation profile. In addition, it could be interesting to notice that the PV module instantaneous electrical efficiency falls during noon hours highlighting reduced conversion of the incident high intensity solar irradiation due to PV module temperature rise effects. However, the power output and electrical efficiency of the SWM, TWM and DWM were higher than the reference PV module indicating better cooling effect caused by the water layer over the PV modules. Figure 13(a-c) illustrates the relationship between power output and electrical efficiency of the test PV modules with respect to GHI. The power output of all test PV modules increased with rising incident GHI. The average power output of SWM, TWM, and DWM was approximately 15.0%, 16.2%, and 28.2% greater than that of the reference PV module, respectively. The daily average power outputs for the reference PV module, SWM, TWM, and DWM were approximately 4.04 W (in Scenario 3), 5.33 W, 5.38 W, and 5.18 W, respectively. The instantaneous electrical efficiency of SWM, TWM, and DWM exceeded that of the reference PV module. Lower electrical efficiency was noted at both very low and very high GHI across all test PV modules. The reduced efficiency at low GHI is attributed to the decreased availability of photons for conversion. The reduced electrical efficiency observed at elevated GHI levels can be attributed to the considerable influence of high PV module operating temperatures. The daily average electrical efficiencies of SWM, TWM, and DWM were approximately 16.2%, 18.5%, and 30.6% greater than that of the reference PV module, respectively. The daily average electrical efficiencies of the reference PV module, SWM, TWM, and DWM ranged from approximately 5.0% (Scenario 3) to 5.26% (Scenario 1), 6.11%, 6.18%, and 6.54%, respectively. The average solar energy potential during Scenario 3 was 18.8 MJ/m2d, which was approximately 2.6 MJ/m2d, lower than the average values recorded in Scenarios 1 and 2.

Figure 14(a-c) presents the current and voltage outputs of reference PV module, SWM, TWM, and DWM under different GHI. The output current and voltage of all test PV modules increased with rising incident GHI. Nevertheless, minimal improvement was noted beyond 800 W/m2. The average current and voltage outputs of the SWM, TWM, and DWM were approximately 7.2% and 8.0%, 7.6% and 8.5%, and 15.6% and 12.2%, respectively, exceeding those of the reference PV module. The percentage increase in the current output of the DWM, when compared to the reference PV module, exceeded that of the TWM, which was followed by the SWM. The observed percentage increase in the PV module’s current output confirms the influence of water quality, specifically salinity, on PV module performance. Salts and dissolved solids in water influence the transmission of light rays. Consequently, seawater with elevated salt concentration and dissolved solids exhibits inferior transmission compared to tap water and desalinated water66. Desalinated water with minimal salt concentration exhibits a higher current and voltage output in PV module compared to other PV modules. The increased voltage output of SWM, TWM and DWM, relative to the reference PV module, can be attributed to the cooling effect resulting from water evaporation. These observations confirmed a reduction in reflection and an enhancement in refraction of incident solar rays attributed to the 1.0 cm thick water layer over the modified modules43,67. The correlation between the daily energy output of test PV modules and the daily solar energy incident on the PV modules is illustrated in Fig. 15(a-b). The observed linear relationship indicates that the DWM exhibits a higher daily energy output compared to the SWM and TWM when subjected to the same solar energy. The electrical characteristics of the test PV modules during experimental days were compiled and presented in Table 7.

Relative temperature drop and electrical efficiency improvement in PV modules employing various water-based cooling techniques is tabulated in Table 8. Highest temperature drop was observed for the PV module fully immersed in water at a depth of 4 cm43 which was then followed by front surface water spray21, both surfaces water spray23 and front surface water veil19 cooled PV module. Highest electrical efficiency improvement was observed in PV module employing front surface water spray21. Stagnant desalinated water layer-cooled PV module proposed in the present study had an electrical efficiency improvement closer to that of PV module cooled by partial submersion in water41. Least temperature reduction and electrical efficiency improvement were observed in PV module cooled by fins in combination with wetted cotton wick69. The low temperature drop observed in the proposed study compared to full submersion cases43,45 may due to the presence of thin water layer whose depth continuously drops with time due to evaporation. However, it has shown comparable electrical efficiency improvement observed with full submersion cooling cases43,45, wick cooled cases68,69, water veil cooling case19 and water spray cooling23. This can be attributed to the presence of thin water layer over the PV module in this study which allows good light transmission, and better conversion apart from reasonable cooling. The electrical efficiency improvement observed in desalinated water-cooled PV module was higher than the tap water and seawater cooled PV module due to increased salinity effects in tap and seawater caused by continuous evaporation.

Evaporation water loss in test PV modules

The average relative humidity, ambient temperature, and wind speed recorded during Scenarios 1, 2, and 3 were 34.5 °C, 64.4%, and 1.9 m/s; 33.5 °C, 64.1%, and 3.3 m/s; and 35.3 °C, 59.8%, and 1.9 m/s, respectively. The average solar energy measured during these scenarios was 21.4, 21.4, and 18.8 MJ/m²d, respectively. The mean operating temperatures for SWM, TWM and DWM on experimental days were 35.8 °C, 34.8 °C, and 36.1 °C, respectively. The daily water evaporation rate from the PV module during Scenarios 1, 2, and 3 was plotted against cumulative incident solar energy, as shown in Fig. 16. The estimated average daily water loss due to evaporation in Scenarios 1, 2, and 3 was 489.0 mL (53.2%), 560.0 mL (60.9%), and 555.0 mL (60.3%), respectively, from the total initial volume of 920 mL (100%). The average ambient conditions were comparable on the operational days of the SWM (Scenario 1) and the TWM (Scenario 2). The observed low evaporation water loss in the SWM compared to the TWM can be attributed to its high salinity (Table 4). Despite reduced incident solar energy on the DWM (Scenario 3), its evaporation water loss was markedly greater than that of the SWM. This discrepancy can be attributed to the combined effects of the low salinity of desalinated water and the relatively low relative humidity during its operational day. Furthermore, the straightforward extrapolation of the correlations presented in Fig. 16 indicates potential increases in water evaporation loss of at least 29.1% and 15.1% for the DWM compared to the SWM and TWM, respectively, under equivalent incident solar energy of 21.4 MJ/m²d. This observation indicates that cooling PV modules with desalinated water results in a relatively high-water loss compared to using seawater and tap water as cooling mediums. Additionally, it is important to note that substantial costs are associated with the production of desalinated water70. Conversely, the costs of seawater and tap water are negligible and low, respectively. In arid, coastal, and under-developed regions, the consistent availability of tap water remains uncertain.

Exergy efficiency and sustainability aspects of test PV modules

Exergy represents the quality of the energy and is not conserved71. The electrical power output of PV module is high quality and is called the electrical exergy. Exergy efficiency of PV module is the ratio of electrical exergy output to the incident solar irradiation exergy72. In some studies, thermal exergy rate from the electrical power output was subtracted to evaluate electrical exergy73. However, this approach has been considered as inappropriate as electrical energy itself is a high-grade energy and it is the only useful exergy output from PV modules without any heat recovery devices71,72,74,75. Hence, exergy output of PV module is equal to its power output71,72,74,75.

The daily exergy efficiency of PV module is the ratio of daily actual exergy output of PV module to the daily incident solar irradiation exergy72,74,75 and is mathematically expressed as,

The temperature of the sun is 5777 K73.

The sustainability aspects of PV module can be evaluated through sustainability index which is related to the exergy efficiency76 and is evaluated by77,

The hourly exergy efficiency variation in the investigated test PV modules in Scenario 1, 2 and 3 are displayed in Figs. 17, 18 and 19. The exergy efficiency of SWM, TWM and DWM was higher than the reference PV module except during early morning and late evening hours. The daily exergy efficiency and sustainability index of the test PV modules is displayed in Fig. 20. The daily exergy efficiency of reference module, SWM, TWM and DWM ranged between 5.30 and 6.16%, 6.54 to 6.89%, 6.42 to 7.19% and 7.12 to 7.69%, respectively. The system which is sustainable will be having a sustainable index higher than 176,77. The sustainability index of reference module, SWM, TWM and DWM was about 1.062, 1.072, 1.073 and 1.080, respectively. These magnitudes indicate cooled PV modules to be more sustainable than the reference module among which the DWM ranked the highest. Sustainability index of solar thermal collector, solar PVT air collector, and PV-DESAL modules are about 1.0073, 1.148, and 1.22, respectively77,78,79. Sustainability index of PVT collectors and PV-DESAL modules are higher due to recovery of waste heat for useful purposes in addition to electricity generation.

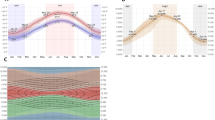

Water-Energy-Economics-Environment nexus aspects of test PV modules

The monthly average ambient temperature, relative humidity, and global horizontal solar energy potential for the test site, Visakhapatnam, India, are presented in Fig. 21. The weather data suggest that Visakhapatnam is characterized by a warm, humid climate and possesses considerable solar radiation energy potential. The annual average solar energy potential, ambient temperature, and relative humidity at the site were approximately 18.6 MJ/m²/day, 27.7 °C, and 71.8%, respectively. The peak sun hours per day varied from 3.6 h in July to 7.0 h in April. The period from October to May is anticipated to exhibit peak sun hours ranging from approximately 5.0 to 7.0 h. This climatic data indicates the potential for elevated PV modules operating temperatures in Visakhapatnam’s climatic conditions.

The cooling technique presented in this study enabled the PV module to operate nearer to ambient temperature, resulting in a notable enhancement in power output and electrical efficiency, albeit with the drawback of water loss due to evaporation. Therefore, it is essential to assess the relationship between water evaporation loss and the increase in power output for further evaluations of this proposed technique. The polycrystalline PV module utilized in the experiment exhibits a maximum power output of 10 WP and covers an area of 0.105 m². The correlations presented in Figs. 15 and 16 were utilized to estimate daily water evaporation loss from the modified PV module and the daily energy output of the modified PV module operating under comparable water quality and depth (1.0 cm), respectively.

Conceptual representation of stagnant water-cooled PV array adopted building is shown in Fig. 22. To commission a 1.0 kWP solar array, it is necessary to utilize 100 modules, each rated at 10 WP. The daily water evaporation loss from the tap water, seawater and desalinated water-cooled solar PV array per kWh of excess energy generated per day was estimated by,

The cost incurred in generation of excess electricity by tap water, seawater and desalinated water-cooled solar PV array was estimated by,

Cost of electricity generated was estimated by the ratio of the overall cost associated with the considered solar array to the electrical energy generated by the considered solar PV array over its life time and is mathematically expressed in Eq. (12)

The capital cost of the 1.0 kWp solar PV array was about 1177 USD which was estimated based on the market cost of experimented 10 Wp single module (11.77 USD). The maintenance and operation cost per year was about 6.0% of the capital cost82. The costs of desalinated water, tap water, and seawater in Visakhapatnam were about 1.18 USD/m3 (100 INR/m3)83, 0.06 USD/m384, and 0.0 USD/m3, respectively. The life time of the solar PV array in general was expected to be 25 to 35 years85. However, in this work, life time of 10 to 30 years has been considered for economics and environmental benefit analyses.

The energy spent to fabricate solar PV array starting from ore extraction to final product is termed as embodied energy. The energy consumed for these processes will be through conventional fossil fuel power plants. The embodied energy of solar PV module was about 976 kWh/m285. Hence, the embodied energy of solar PV array (10.5 m2) considered in this study was estimated to be about 10,248 kWh. The CO2 emission intensity in the Indian coal power plants is about 0.98 kg/kWh of electricity generated85. However, during the operation of solar PV array, CO2 emission will be mitigated due to the prevention of fossil fuel usage in the Indian power plants to generate the similar amount of electricity. The water used for PV array cooling are extracted or produced through some process. Hence, it becomes necessary consider the CO2 emission associated with those processes. The CO2 emission intensity associated with sea water extraction, ground water extraction and desalinated water production are about 0.031, 0.04 and 2.46 kg/m3 of water extracted/produced, respectively86. The net CO2 emission mitigated by the solar PV array over its life time was evaluated by,

Solar PV array’s embodied energy and the energy associated with water extraction/desalination process has also contributed to CO2 emission. Hence, it is necessary to estimate the specific CO2 emission of the solar PV array per kWh of electricity generated by it. The specific CO2 emission per kWh of electricity generated was evaluated by,

The daily average water evaporation loss and energy generation per kWP installation of the water-cooled solar PV array for different months in Visakhapatnam were estimated and presented in Table 9. The daily energy output of reference, SWM, TWM, and DWM-based solar PV array ranged from 2.05 to 3.96 kWh/d, 2.36 to 4.56 kWh/d, 2.36 to 4.57 kWh/d, and 2.62 to 5.05 kWh/d, respectively. The annual average daily energy output was approximately 2.92, 3.36, 3.37, and 3.73 kWh/d for SWM, TWM, and DWM-based solar PV array, respectively. The daily energy outputs of SWM, TWM, and DWM-based solar PV array were approximately 15.1%, 15.5%, and 27.7% higher than that of the reference PV array, respectively. Water evaporation loss varied from 30.0 to 58.0 L/d, 33.5 to 65.0 L/d, and 39.0 to 75.0 L/d for 1.0 kWp capacity SWM, TWM, and DWM-based solar PV arrays, respectively. The daily evaporation water loss in TWM and DWM-based PV array was approximately 12.1% and 29.1% greater than that in SWM-based PV array, respectively. Furthermore, daily water evaporation losses of approximately 97 mL, 106 mL, and 68 mL were observed for each Watt-hour of excess energy produced by SWM, TWM, and DWM-based solar PV array, respectively, when compared to the reference PV array.

The cost of electricity generated by the 1.0 kWp capacity solar PV array under different scenarios for various life time is tabulated in Table 10. The electricity generation cost of SWM, TWM and TWM-based PV array was lower than the reference module-based PV array. The electricity generation cost decreased by 37.5% with increase in life time from 10 to 25 year for reference PV array, SWM and TWM-based PV array while the cost reduction of 33.3% was observed for DWM-based PV array. For a life time of 25 year, the cost of electricity generated by SWM, TWM and DWM-based PV array were about 13.1%, 12.6% and 5.9% lower than the reference PV array. SWM based PV array seemed to produce cheap electricity among all the investigated PV arrays due to its no water cost. In spite of high energy production, the DWM-based PV array produced electricity at a cost which was about 8.3% and 7.7% higher than SWM and TWM-based PV array due to the high cost associated with desalinated water. The cost of electricity generated by the reference PV array, SWM, TWM and DWM-based PV array with a life time of 25 year was about 0.110, 0.096, 0.097 and 0.104 USD/kWh, respectively. These observations justify the benefit offered by the stagnant water cooling in economical electricity generation. The electricity tariff for domestic and commercial use in Visakhapatnam ranges from 1.90 to 9.75 INR/kWh (0.022 to 0.115 USD/kWh) and 5.40 to 12.25 INR/kWh (0.064 to 0.144 USD/kWh), respectively87.

It should be remembered that in this study, cost of PV array was estimated based on the cost of 10 Wp module that was used for experiments which is expensive compared to that of commercial PV modules of higher capacity typically used for solar PV array building. This was the major reason for slightly higher electricity generation cost with investigated PV array compared to local commercial grid electricity tariffs. Hence, it becomes necessary to evaluate the cost associated with excess electricity generated in investigated water cooled PV array. The cost associated with increasing the daily energy output of DWM, TWM, and SWM based PV array by 1.0 kWh was estimated to be approximately 0.081 USD/kWh (6.89 INR/kWh), 0.0063 USD/kWh (0.54 INR/kWh), and 0.0 USD/kWh (0.0 INR/kWh), respectively. The expenses associated with the production of surplus electricity from the TWM and SWM based PV array were significantly lower than the minimum domestic electricity tariff in Visakhapatnam. Conversely, the cost associated with the generation of excess electricity from a DWM based PV array was approximately 3.6 times greater than the minimum domestic electricity tariff and 0.71 times less than the maximum domestic electricity tariff in Visakhapatnam. Hence, it can be concluded that TWM and SWM based PV arrays are applicable across various energy consumption sectors, whereas DWM based PV arrays are more suitable for commercial sectors.

The net CO2 emission mitigation potential and specific CO2 emission per kWh of electricity generated by the investigated 1.0 kWp solar PV array in Visakhapatnam under different scenarios and life time is tabulated in Table 11. Solar PV module cooling techniques not only improve the power output but also plays a significant role in CO2 emission reduction88. DWM-based PV array showed the highest net CO2 emission mitigation potential. The investigated PV arrays could mitigate about 16.06 to 28.46 tons of CO2 emission during their life time of 30 years. Net CO2 emission mitigation potential of SWM, TWM and DWM based PV array for 20-year life time was about 28.9, 29.6 and 44.2% higher than the reference PV array, respectively. Moreover, it could be noticed that the CO2 emission associated with 1.0 kWh of electricity generated by the solar PV array is lower than the emission associated with conventional coal power plants in India (980 kg/kWh). DWM based PV array has the lowest specific CO2 emission per kWh of electricity generated up to a life time of 20 years than the SWM and TWM-based PV array. However, beyond 20 years, slight increase of about 1.1 to 3.3% in specific CO2 emission was observed due to high desalinated water consumption and its associated emissions. The economics and environmental analysis indicated that the SWM and TWM based PV array has similar economics and environmental benefits while DWM based PV array has the highest environmental benefits with slightly higher electricity generation cost.

Conclusion

In this experimental work, a new configuration of solar PV module immersion cooling technique has been proposed and the same has been compared with reference standard PV module to assess the performance and water-energy-economic-environmental nexus aspects under the climatic conditions of Visakhapatnam, India. The cooling medium utilized were 1.0 cm thick (initial depth) stagnant seawater, tap water and desalinated water layer over the PV module and such modules were termed seawater module (SWM), tap water module (TWM) and desalinated water module (DWM), respectively. The important findings of this work are listed below:

-

a.

Daily average operating temperature of water-cooled PV module was closer to ambient temperature and lower than the operating temperature of reference standard PV module by 7.2 to 8.2 °C.

-

b.

Water quality aspects have significant impact in deciding performance aspects of the PV module. Desalinated water with low salinity and turbidity values helped PV module to generate about 28.3% higher daily energy output than the reference PV module. The increment in daily energy output was about 16.6 and 14.9% higher for TWM and DWM based PV module in comparison to the reference PV module.

-

c.

For every one Watt-Hour of excess energy generated around 97 mL, 106 mL and 68 mL of seawater, tap water and desalinated water, respectively were consumed while cooling the PV module with the respective fluids.

-

d.

Evaporation loss was higher for DWM and lower for SWM. Interestingly, no salt deposition was observed even for SWM during experimental hours in the considered experimental site possibly, due to daily change of loaded water.

-

e.

All the water types improved the performance of the PV module. However, DWM generated the best results in terms of performance.

-

f.

On the economic front, SWM based PV array has the lowest electricity generation cost and outperformed both TWM and DWM based PV array with increase in PV module life time due to vast availability and almost negligible price of seawater.

-

g.

On the environmental benefit aspect, DWM based PV array outperformed other investigated PV arrays. For a life time of 20 years, net CO2 emission mitigation potential of DWM based PV array was observed to be 44.2% higher than the reference PV array.

The electricity generated in stagnant water-cooled PV module reduces grid electricity consumption and prevents CO2 emission thereby facilities rapid movement of the built environment towards net-zero emission89.

Limitations of the present work and scope for future works

This study examined the effects of various water types on the thermal management and performance characteristics of stagnant water-cooled PV modules. The findings of this study were significant and have yielded several implications for future research. However, the reported work has few limitations:

-

a.

Investigations have focused on modified PV modules of small, fixed size and capacity; however, further research on modified commercial PV modules of varying sizes is necessary.

-

b.

The proposed PV module cooling technique has been evaluated solely in a horizontal orientation; however, in practical applications, PV modules are positioned at a tilt angle that aligns with the local latitude. This aspect requires further investigation for the modified PV module.

-

c.

The investigation has focused solely on a water depth of one centimeter; however, exploring varying water depths is crucial for determining the optimal depth under different climatic conditions.

-

d.

Daily change of loaded water has prevented the investigation of issues related to salt, silt deposition, microbial growth or algae formation and dust accumulation in this study.

-

e.

Impact of water layer without daily water replenishment on PV module optical clarity and performance has to be investigated.

Data availability

Data can be obtained from the corresponding author through mail on request.

Abbreviations

- \({A_{PV}}\) :

-

PV module area (m2)

- \({C_{EE}}\) :

-

Cost incurred in excess electrical energy generated from water cooled PV array (USD/kWh)

- \({C_{{\text{SW(or)TW(or)DW}}}}\) :

-

Cost of seawater or tap water or desalinated water (USD/m3)

- \(CE{I_{CPP}}\) :

-

Carbon emission intensity in coal power plants (kg/kWh)

- \(CE{I_{SW(or)TW(or)DW}}\) :

-

Carbon emission intensity in seawater or tap water (ground water) extraction or desalinated water production (kg/kWh)

- \(E{E_{{\text{Ref(or)SWM(or)TWM(or)DWM}}}}\) :

-

Embodied energy of reference or seawater or tap water or desalinated water solar PV array (kWh)

- \({E_{DWM}}\) :

-

Daily energy generated by desalinated water module or array (Wh/d or kWh/d)

- \({E_{SWM}}\) :

-

Daily energy generated by seawater module or array (Wh/d or kWh/d)

- \({E_{TWM}}\) :

-

Daily energy generated by tap water module or array (Wh/d or kWh/d)

- \({E_{{\text{Ref}}}}\) :

-

Daily energy generated by reference module or array (Wh/d or kWh/d)

- \(E{x_{PV}}\) :

-

PV module electrical exergy (W)

- \({f_{O\& M}}\) :

-

Annual operation and maintenance factor

- \({G_H}\) :

-

Daily cumulative solar energy incident over the PV module (MJ/d)

- \(I\) :

-

PV module current output (Ampere)

- \({I_h}\) :

-

Global horizontal solar irradiation (W/m2)

- \({M_d}\) :

-

Daily water evaporation from cooled PV module or array (L/d or m3/d)

- \({P_{PV}}\) :

-

PV module power output (W)

- \({T_a}\) :

-

Ambient temperature (°C)

- \({T_s}\) :

-

Temperature of the sun (K)

- \({U_{ana\log }}\) :

-

Standard uncertainty of analog instruments

- \({U_{ammeter}}\) :

-

Standard uncertainty of Ammeter (Ampere)

- \({U_{digital}}\) :

-

Standard uncertainty of digital instruments

- \({U_{el}}\) :

-

Standard uncertainty of PV module electrical efficiency (%)

- \({U_{luxmeter}}\) :

-

Standard uncertainty of luxmeter (Lux)

- \({U_{power}}\) :

-

Standard uncertainty of PV module power output (W)

- \({U_{{\text{PV area}}}}\) :

-

Standard uncertainty of PV area (m2)

- \({U_{voltmeter}}\) :

-

Standard uncertainty of voltmeter (Volt)

- \(V\) :

-

PV module voltage output (Volt)

- \(W{E_{Loss}}\) :

-

Daily water evaporation loss from water cooled PV array for every 1 kWh of excess electricity generated (m3/kWh)

- \(YW{C_{{\text{SWM(or)TWM(or)DWM}}}}\) :

-

Yearly water consumption in seawater or tap water or desalinated water based solar PV array (m3)

- \({\eta _{el}}\) :

-

Electrical efficiency of PV module (%)

- \({\eta _{ex}}\) :

-

Exergy efficiency of PV module (%)

- CC:

-

Capital cost of PV array (USD)

- CEG:

-

Cost of electrical energy generated by the PV array (USD/kWh)

- DWM:

-

Desalinated water module

- GHI:

-

Global horizontal irradiation

- LT:

-

Life time of the PV array (Year)

- NCEM:

-

Net CO2 emission mitigation potential of PV array (kg)

- PV :

-

Photovoltaic

- SCE:

-

Specific CO2 emission (kg of CO2 per kWh of electricity generated)

- SI:

-

Sustainability index

- SWM:

-

Seawater module

- TWM:

-

Tap water module

References

Jordehi, A. R. Parameter Estimation of solar photovoltaic (PV) cells: A review. Renew. Sustain. Energy Rev. 61, 354–371 (2016).

Comello, S., Reichelstein, S. & Sahoo, A. The road ahead for solar PV power. Renew. Sustain. Energy Rev. 92, 744–756 (2018).

Shirinbaksh, M. & Harvey, L. D. D. Feasibility of achieving net-zero energy performance in high-rise buildings using solar energy. Energy Built Environ. 5, 946–956 (2024).

Harmailil, I. O. et al. A review on recent photovoltaic module cooling techniques: types and assessment methods. Results Eng. 22, 102225 (2024).

Khanam, S. et al. Md. Meraj, Md. Comparative performance analysis of photovoltaic modules of different materials for four different climatic zone of India, Urban Climate 39 100957. (2021).

Dubey, S., Sarvaiya, J. N. & Seshadri, B. Temperature dependent photovoltaic (PV) efficiency and its effect on PV production in the world A review. Energy Procedia. 33, 311–321 (2013).

Bamisile, O., Acen, C., Cai, D., Huang, Q. & Staffell, I. The environmental factors affecting solar photovoltaic output. Renew. Sustain. Energy Rev. 208, 115073 (2025).

Agathokleous, R. A. & Kalogirou, S. A. Status, barriers and perspectives of Building integrated photovoltaic systems. Energy 191, 116471 (2020).

Salameh, T. et al. Review of solar photovoltaic cooling systems technologies with environmental and economical assessment. J. Clean. Prod. 326, 129421 (2021).

Hasanuzzaman, M., Malek, A. B. M. A., Islam, M. M., Pandey, A. K. & Rahim, N. A. Global advancement of cooling technologies for PV systems: A review. Sol. Energy. 137, 25–45 (2016).

Bhakre, S. S., Sawarkar, P. D. & Kalamkar, V. R. Performance evaluation of PV panel surfaces exposed to hydraulic cooling – A review. Sol. Energy. 224, 1193–1209 (2021).

Bilen, K. & Erdogan, I. Effects of cooling on performance of photovoltaic/thermal (PV/T) solar panels: A comprehensive review. Sol. Energy. 262, 111829 (2023).

Ghadikolaei, S. S. C. Solar photovoltaic cells performance improvement by cooling technology: an overall review. Int. J. Hydrog. Energy. 46, 10939–10972 (2021).

Al-Amri, F., Saeed, F. & Mujeebu, M. A. Novel dual-function racking structure for passive cooling of solar PV panels–thermal performance analysis. Renew. Energy. 198, 100–113 (2022).

Baskesen, M. C. & Taskin, O. Rainwater harvesting and wastewater recycling for an alternative solar panel cleaning. Renew. Energy. 256, 123917 (2026).

Dwivedi, P., Sudhakar, K., Soni, A., Solomin, E. & Kirpichnikova, I. Advanced cooling techniques of P.V. Modules: A state of Art. Case Stud. Therm. Eng. 21, 100674 (2020).

Akrouch, M. A. et al. Advancements in cooling techniques for enhanced efficiency of solar photovoltaic panels: A detailed comprehensive review and innovative classification. Energy Built Environ. 6, 248–276 (2025).

Arefin, M. A., Islam, M. T., Zunaed, M. & Mostakim, K. Performance analysis of a novel integrated photovoltaic–thermal system by top-surface forced circulation of water. Clean. Energy. 4 (4), 316–327 (2020).

Chanphavong, L., Chanthaboune, V., Phommachanh, S., Vilaida, X. & Bounyanite, P. Enhancement of performance and exergy analysis of a water-cooling solar photovoltaic panel. Total Environ. Res. Themes. 3-4, 100018 (2022).

Torres, J., Vivar, M., Fuentes, M. & Palacios, A. M. SolWat technology for simultaneous wastewater disinfection and higher energy generation utilizing PV module front surface. J. Water Process. Eng. 57, 104698 (2024).

Hadipour, A., Rajabi Zargarabadi, M. & Rashidi, S. An efficient pulsed- spray water cooling system for photovoltaic panels: experimental study and cost analysis. Renew. Energy. 164, 867–875 (2021).

Khan, Y. et al. Thermodynamic analysis and experimental investigation of the water spray cooling of photovoltaic solar panels. J. Therm. Anal. Calorim. 148, 5591–5602 (2023).

Nizetic, S., Coko, D., Yadav, A. & Grubisic-Cabo, F. Water spray cooling technique applied on a photovoltaic panel: the performance response. Energy. Conv. Manag. 108, 287–296 (2016).

Benato, A., Stoppato, A., De Vanna, F. & Schiro, F. Spraying cooling system for PV modules: experimental measurements for temperature trends assessment and system design feasibility. Designs 5, 25 (2021).

Alktranee, M. (ed Bencs) Effect of evaporative cooling on photovoltaic module performance. Process. Integr. Optim. Sustain. 6 921–930 (2022).

Alktranee, M. & Bencs, P. Experimental comparative study on using different cooling techniques with photovoltaic modules. J. Therm. Anal. Calorim. 148, 3805–3817 (2023).

Musthafa, M. M. Enhancing photoelectric conversion efficiency of solar panel by water cooling. Int. J. Appl. Power Eng. 3 (3), 199–204 (2014).

Haidar, Z. A., Orfi, J. & Kaneesamkandi, Z. Experimental investigation of evaporative cooling for enhancing photovoltaic panels efficiency. Results Phys. 11, 690–697 (2018).

Mahmood, D. M. N. & Aljubury, I. M. A. Experimental investigation of a hybrid photovoltaic evaporative cooling (PV/EC) system performance under arid conditions. Results Eng. 15, 100618 (2022).

Alkantree, M. et al. Experimental and numerical study of a photovoltaic/thermal system cooled by metal oxide nanofluids. Alexandria Eng. J. 94, 55–67 (2024).

Charalambous, P. G., Maidment, G. G., Kalogirou, S. A. & Yiakpumetti, K. Photovoltaic thermal (PV/T) collectors: A review. Appl. Therm. Eng. 27, 275–286 (2007).

Reddy, S. R., Ebadian, M. A., Cheng-Xian & Lin A review of PV–T systems: thermal management and efficiency with single phase cooling. Int. J. Heat Mass Transf. 91, 861–871 (2015).

Zhang, T., Zhai, J., Shi, Z., Li, Q. & Cai, J. Comparison of PV and PV/T systems in different regions of china: energy gain, energy cost, energy payback and energy return. Energy Built Environ., https://doi.org/10.1016/j.enbenv.2024.12.001

Piotrowski, L. J., Simoes, M. G. & Farret, F. A. Feasibility of water-cooled photovoltaic panels under the efficiency and durability aspects. Sol. Energy. 207, 103–109 (2020).

Chandel, R., Chandel, S. S. & Khosla, A. Modelling and experimental investigation of cooling of field-operating PV panels using thermoelectric devices for enhanced power generation by industrial solar plants. Next Energy. 5, 100162 (2024).

Al-Amri, F. et al. Innovative technique for achieving uniform temperatures across solar panels using heat pipes and liquid immersion cooling in the harsh climate in the Kingdom of Saudi Arabia. Alexandria Eng. J. 61 (2), 1413–1424 (2022).

Chowdhury, G., Haggag, M. & Poortmans, J. How cool is floating PV? A state-of-the-art review of floating pv’s potential gain and computational fluid dynamics modeling to find its root cause. EPJ Photovoltaics. 14, 24 (2023).

Ebrahimi, M., Rahimi, M. & Rahimi, A. An experimental study on using natural vaporization for cooling of a photovoltaic solar cell. Int. Commun. Heat Mass Transfer. 65, 22–30 (2015).

Elminshawy, N. A. S., Elminshawy, A. & Osama, A. An innovative cooling technique for floating photovoltaic module: adoption of partially submerged angle fins. Energy Convers. Management: X. 20, 100408 (2023).

Kjeldstad, T., Limdholm, D., Marstein, E. & Selj, J. Cooling of floating photovoltaics and the importance of water temperature. Sol. Energy. 218, 544–551 (2021).

Elminshawy, N. A. S., Osama, A., Saif, A. M. & Tina, G. M. Thermo-electrical performance assessment of a partially submerged floating photovoltaic system. Energy 246, 123444 (2022).

Bukar, A. M., Almerbati, A., Shuja, S. Z. & Zubair, S. M. Enhancing solar PV panel performance through active and passive cooling techniques: A comprehensive review. Renew. Sustain. Energy Rev. 216, 115611 (2025).

Rosa-Clot, M., Rosa-Clot, P., Tina, G. M. & Scandura, P. F. Submerged photovoltaic solar panel: SP2. Renew. Energy. 35 (8), 1862–1865 (2010).

Fadliondi, F., Budiyanto, B. & Chamdareno, P. G. The improvement of solar panel performance using cooling method. Trends Sci. 20 (11), 6710 (2023).

Mehrotra, S., Rawat, P., Debbarma, M. & Sudhakar, K. Performance of a solar panel with water immersion cooling technique. Int. J. Sci. Environ. Technol. 3, 1161–1172 (2014).

Sheeba, K. N., Madhusudhana Rao, R., Jaisankar, S. & Recovery, A. A Study on the Underwater Performance of a Solar Photovoltaic Panel, Energy Sources, Part Utilization Environ. Eff. 37(14) 1505–1512. (2015).

Moh, T. S. Y. & Ting, E. M. S. Efficiency improvement based on cooling effect via immersion technique in a PV solar panel: tropical and cloudy weather setting. Int. J. Innovative Res. Electr. Electron. Instrum. Control Eng. 4 (10), 1–6 (2016).

Venkatesan, M., Satish Gandhi, V. C., Kumaravelan, R. & Ramesh, S. Experimental-study-of-cooling-effect-of-photovoltaics-cells, (2016). (Last Accessed via Researchgate.com on 19th March 2025).

Firoozzadeh, M., Lotfi, M., Shiravi, A. H. & Dezfuli, M. R. An experimental study on using water streaks and water film over PV module to enhance the electrical efficiency. Environ. Sci. Pollut. Res. 31, 18226–18238 (2024).

Abrahamyan, Y. A. et al. The efficiency of solar cells immersed in liquid dielectrics. Sol. Energy Mater. Sol. Cells. 73 (4), 367–375 (2002).

Wang, Y. et al. The performance of silicon solar cells operated in liquids. Appl. Energy. 86, 1037–1042 (2009).

Han, X., Wang, Y. & Zhu, L. The performance and long-term stability of silicon concentrator solar cells immersed in dielectric liquids. Energy. Conv. Manag. 66, 189–198 (2013).

Elavarasan, R. M., Nadarajah, M., Pugazhendhi, R. & Gangatharan, S. An experimental investigation on coalescing the potentiality of PCM, fins and water to achieve sturdy cooling effect on PV panels. Appl. Energy. 356, 122371 (2024).

Srithar, K., Akash, K., Nambi, R., Vivar, M. & Saravanan, R. Enhancing photovoltaic efficiency through evaporative cooling and a solar still. Sol. Energy. 265, 112134 (2023).

Sharon, H., Prasad, M., Gowtham, L., Gopal, P. V. & Aswin, S. Techno–Enviro–Economic feasibility assessment of Family-Scale solar still (F-SSS) desalination plant in central American and Caribbean sites for sustainable clean water supply. Energies 18 (6), 1431 (2025).

Sudhakar, K. & Srivastava, T. Energy and exergy analysis of 36 W solar photovoltaic module. Int. J. Ambient Energy. 35 (1), 51–57 (2014).

Farrance, I. & Frenkel, R. Uncertainty of measurement: A review of the rules for calculating uncertainty components through functional relationships. Clin. Biochem. Rev. 33, 49–75 (2012).

Hiasa, S., Birgul, R. & Catbas, F. N. Investigation of effective utilization of infrared thermography (IRT) through advanced finite element modeling. Constr. Build. Mater. 150, 295–309 (2017).

Elmetwalli, A. H., Darwesh, M. R., Amer, M. M. & Ghoname, M. S. Influence of solar radiation and surrounding temperature on heating water inside solar collector tank. J. Energy Storage. 47, 103648 (2022).

Flendrig, L. M., Shah, B., Subrahmaniam, N. & Ramakrishnan, V. Low cost thermoformed solar still water purifier for D&E countries. Phys. Chem. Earth. 34, 50–54 (2009).

Cai, M. et al. Impact of pipeline materials on water quality stability of desalinated seawater in the pipeline network. Desalination 556, 116558 (2023).

Shokri, A. & Fard, M. S. Corrosion in seawater desalination industry: A critical analysis of impacts and mitigation strategies. Chemosphere 307, 135640 (2022).

USGS. https://www.usgs.gov/special-topics/water-science-school/science/turbidity-and-water (2025). (Last accessed on 25th March 2025).

Nada, A., Ibrahim, M. G., Elshemy, M., Fujii, M. & Sharaan, M. Integrated water quality and performance assessment of seawater desalination plants along two Coasts in Egypt. Desalination 586, 117844 (2024).

Dida, M., Boughali, S., Bechki, D. & Bouguettaia, H. Experimental investigation of a passive cooling system for photovoltaic modules efficiency improvement in hot and arid regions. Energy. Conv. Manag. 243, 114328 (2021).

Kanayama, K. & Baba, H. Transmittance of distilled water and sodium chloride water solutions. J. Sol. Energy Eng. 110, 113–119 (1988).

Tina, G. M., Rosa-Clot, M., Rosa-Clot, P. & Scandura, P. F. Optical and thermal behavior of submerged photovoltaic solar panel: SP2. Energy 39, 17–26 (2012).

Chandrasekar, M., Suresh, S., Senthilkumar, T. & Karthikeyan, M. G. Passive cooling of standalone flat PV module with cotton Wick structures. Energy. Conv. Manag. 71, 43–50 (2013).

Chandrasekar, M. & Senthilkumar, T. Experimental demonstration of enhanced solar energy utilization in flat PV (photovoltaic) modules cooled by heat spreaders in conjunction with cotton Wick structures. Energy 90, 1401–1410 (2015).

Karagiannis, I. C. & Soldatos, P. G. Water desalination cost literature: review and assessment. Desalination 223, 448–456 (2008).

Rosen, M. A. & Bulucea, C. A. Using exergy to understand and improve the efficiency of electrical power technologies. Entropy 11, 820–835 (2009).

Rawat, R., Lamba, R. & Kaushik, S. C. Thermodynamic study of solar photovoltaic energy conversion: an overview. Renew. Sustain. Energy Rev. 71, 630–638 (2017).

Prakash, K. B. et al. Energy and exergy enhancement study on PV systems with phase change material. Sustainability 15, 3627 (2023).

Alshibil, A. M. A. et al. Optimization of dual-cooling technique in perforated solar PV modules: experimental insights towards carbon neutrality and sustainability. Energy Convers. Management: X. 27, 101094 (2025).

Rawat, R., Kaushik, S. C., Sastry, O. S., Singh, Y. K. & Bora, B. Energetic and exergetic performance analysis of cds/cdte based photovoltaic technology in real operating conditions of composite climate. Energy. Conv. Manag. 110, 42–50 (2016).

Rosen, M. A., Dincer, I. & Kanoglu, M. Role of exergy in increasing efficiency and sustainability and reducing environmental impact. Energy Policy. 36, 128–137 (2008).

Caliskan, H. Energy, exergy, environmental, enviroeconomic, exergoenvironmental (EXEN) and exergoenviroeconomic (EXENEC) analyses of solar collectors. Renew. Sustain. Energy Rev. 69, 488–492 (2017).

Fudholi, A. et al. Exergy and sustainability index of photovoltaic thermal (PVT) air collector: A theoretical and experimental study. Renew. Sustain. Energy Rev. 100, 44–51 (2019).

Sharon, H. & Vivar, M. Solar photovoltaic module-based Co-generation system – Performance and enviro-economic aspects in arid desert sites. Solar Energy Mater. Solar Cells. 282, 113370 (2025).

PVGIS. https:// (2025). joint-research-centre.ec.europa.eu/photovoltaic-geographical-information-system-pvgis_en (Last accessed on 25th March 2025).

WAC. https://weather-and-climate.com/average-monthly-Humidity-perc,visakhapatnam-andhra-pradesh-in,India (2025). (Last accessed on 25th March 2025).

Yaghoubirad, M., Azizi, N., Ahmadi, A., Zarei, Z. & Moosavian, S. F. Performance assessment of a solar PV module for different climate classifications based on energy, exergy, economic and environmental parameters. Energy Rep. 8, 15712–15728 (2022).

Indian Infrastructure https://indianinfrastructure.com/2022/11/20/working-with-seawater-desalination-for-industrial-use/ (2025). (Last accessed on 25th March 2025).

Tariffs (2025). https://tariffs.ib-net.org/sites/IBNET/ViewTariff?tariffId=7340&countryId=0 (Last accessed on 25th March 2025).

Nawaz, I. & Tiwari, G. N. Embodied energy analysis of photovoltaic (PV) system based on macro- and micro-level. Energy Policy. 34, 3144–3152 (2006).

Biswas, W. K. & Yek, P. Improving the carbon footprint of water treatment with renewable energy: a Western Australian case study. Renewables 3, 14 (2016).

APSPDCL. (2025). https://www.apspdcl.in/regulatory/Tariff%20Schedule%20for%20FY%202024-25.pdf (Last accessed on 25th March 2025).

Ghadikolaei, S. S. C. An enviroeconomic review of the solar PV cells cooling technology effect on the CO2 emission reduction. Sol. Energy. 216, 468–492 (2021).

Edmund, J. W., Thoy, Y. I. & Go Enhancement and validation of Building integrated PV system: 3D modelling, techno-economics and environmental assessment. Energy Built Environ. 3, 444–466 (2022).

Acknowledgements

The authors acknowledge the necessary infrastructure support provided by the concerned authorities namely Prof. Shalivahan (Director), Prof. Vijaya Kumar Kopparapu (Dean R&D) and Prof. P. Sivasankar (Associate Dean Planning & Resources) to carry out and complete the work in the stipulated time frame. Pavan Darbha acknowledges the summer internship fellowship offered through the Scientific Social Responsibility (SSR) of the SERB project (SRG/2023/000017).The authors acknowledge the 100% APC waiver support from the Springer Nature and Scientific Reports which enabled publication of this reasearch work.

Funding

The authors acknowledge the “Start-Up Research Grant” funding from the Science and Engineering Research Board (SERB), Department of Science and Technology (DST), Government of India (Grant No: SRG/2023/000017).

Author information

Authors and Affiliations

Contributions