Abstract

In this research, we examined the fine structure of starch in three mealy and three waxy potato varieties to understand their impact on potato texture. This research revealed significant variations in starch granule morphology, particle size, crystalline structure, molecular structure, and pasting properties between the different textures. Mealy potato starch granules appeared as rounded ovoid with inconsistent particle sizes (ranging from 35.9 to 41.8 μm), whereas waxy potato starch granules exhibited sharp polygonal shapes with consistent larger sizes (42.1–49.7 μm). While both types displayed a B-type crystalline morphology, the relative crystallinity of mealy potato starch (31.28%, 38.00% and 29.07%) is higher than that of waxy potato starch (27.38% 26.68% and 26.12%) as determined by X-ray diffraction. Additionally, the mealy potato starches had lower amylopectin content, degree of branching, short-chain amylopectin content, and molecular weight, but higher trough viscosity, final viscosity, and setback value than waxy potato starches. These differences in fine structure contributed significantly to the variations in texture between mealy and waxy potato starches, highlighting potential implications for breeding programs aimed at improving specific textural attributes for targeted application in the food industry.

Similar content being viewed by others

Introduction

Potato (Solanum tuberosum L.) is the world’s third-largest food crop, serving as a staple food for nearly 1 billion people globally1. Notably, China is a significant contributor to global potato production, accounting for approximately a quarter of the total yield. This role in production plays a crucial part in addressing food security challenges and mitigating regional poverty in China.

The sensory attributes of color, flavor, and texture significantly influence consumer acceptance of potatoes. The preferred taste quality serves as a primary determinant for consumers when deciding on a purchase. For instance, mealy potato varieties are favored for baked and mashed potatoes due to their dry and granular texture. These varieties also exhibit better suitability for chip production due to their lower oil absorption. Conversely, waxy potato varieties, known for their moist, gelatinous texture and good consistency, are often chosen for creamy potatoes or potato salad2. The understanding of texture differences in potato varieties, food processing, home cooking, and the selection of new cultivars can greatly benefit from exploring the causes of texture differences in potatoes.

Efforts to comprehend the factors influencing texture differences in potato varieties, starch fine structure, and their impact on sensory responses have been limited. Previous studies have focused on the granular morphology of starch and cellular changes after cooking3. However, the determinants affecting potato texture remain poorly understood. While differences in dry matter content and starch properties have been explored4, the fine structure of starch seems to be the key factor influencing texture. Notably, limited research has focused on comparing the starch fine structure in mealy and waxy potatoes5,6,7,8. Therefore, this study aims to systematically investigate the effect of starch fine structure on potato texture using mealy and waxy potatoes as experimental materials. The results are expected to significantly contribute to potato quality breeding.

Materials and methods

Materials

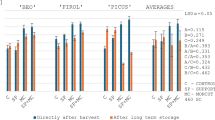

In this study, six pigmented potato resources with diverse genetic backgrounds sourced from the International Potato Center (refer to Table 1) were utilized. These resources were planted in Bainijing Village, Huize County, Yunnan Province in early April 2022, with tuber harvest taking place in late October 2022. The planting and management of the potatoes adhered to standard agronomic practices. Following harvest, the tubers were stored at 4 °C for preservation. The hardness evaluation was conducted by a panel of 9 professional tasters whose ages varied between 20 and 60 years. The hardness was rated on a 9-point scale, where 1 represented very soft and 9 represented very hard. Figure 1 provides a depiction of the texture characteristics of the potato tubers following steaming.

Starch isolation

The protocol followed for the extraction was as mentioned in Slepkov A D et al.9. Potatoes were cut into small pieces and soaked in milli-Q water for 24 h at room temperature for starch extraction. The starch grains get settled at the bottom of the beaker. The top layer of the mixture is discarded and the bottom is subjected to centrifugation at 3,000 rpm at 25℃ for 10 min. The process was repeated until clear pellet is obtained and the supernatant was discarded.

Amylose content

The method for the determination of the content of amylose starch was referred to Kowsik and Mazumder10. Starch (100 mg) was weighed and mixed with 0.36 g (0.0089 mol) of NaOH in 9 mL of distilled water and 1 mL absolute ethanol. A control sample, without starch was prepared and both the flasks were heated for 10 min. After cooling, 1 mL acetic acid and 2 mL iodine solution was added. The volumes were made up to 100 mL and left for an hour at room temperature. OD was then recorded at 550 nm. The amylose content was calculated using the formula:

Morphology observation of starch

The surface structures of starch were obtained using a scanning electron microscope (TM4000 Plus II, Hitachi Instruments Ltd., Tokyo, Japan) according to the method described by Chao et al.11.

Granule size analysis of starch

The distribution of granule size was determined using a Malvern Mastersizer 2000, with the measurement method referencing Cai et al.12.

Degree of branching

The degree of branching of starch was measured using the AVANCE III 400 MHz NMR Spectrometer(Bruker, karlsruhe, Switzerland) according to the method of Yang et al.13.

Molecular weight distribution of starch

Mw was analyzed using the Agilent PL-GPC 220 high-temperature chromatograph and multiangle laser-light scatteringwith differential refractive index detector14,15.

Chain length distribution of amylopectin

Amylopectin branch chain length distribution of starch was measured using high-performance anion exchange chromatography16. Flow rate was set as 0.5 mL/min. The elution gradient was made with 500 mM sodium acetate in 150 mM NaOH against 150 mM NaOH as follows: 0–20% for 0–5 min, 20–45% for 5–15 min, 45–60% for 15–40 min, 60–70% for 40–65 min, and 70–100% for 75–80 min.

Crystalline structure

According to the method described byGao17, the crystalline structure of starch was analyzed with X-ray diffraction (XRD) (D8, Bruker, karlsruhe, Germany).

Pasting property analysis of starch

Potato starch pasting properties were determined using a Rapid Visco Analyser (RVA, Newport Scientific, Pty Ltd., Australia). Starch (1.5 g, 12% d.b.) was mixed with 25 g of double-deionised water in the RVA sample can. The heating and cooling cycle was set as follows: (1) holding at 50℃ for 1 min, (2) heated to 95℃ in 3.8 min, (3) holding at 95 ℃ for 2.5 min, (4) cooling to 50 ℃ in 3.8 min, (5) holding at 50℃ in 1.4 min. The RVA paddle speed was at 960 rpm for the first 10 s of the test, after which the speed was at 160 rpm.

Statistical analysis

All determinations were replicated three times and the data were subjected to one-way analysis of variance and Tukey’s multiple-comparison analysis using origin2021b.

Results and discussion

Amylose content of potato starches with different texture

The amylose and amylopectin contents of various potato starch textures were analyzed and the findings are detailed in Table 2. The amylose content of the three mealy potato starch samples was determined to be 29.49%, 33.02% and 31.49% respectively, while the waxy potato starches exhibited amylose contents of 24.73%, 26.46% and 27.50% respectively. The amylose to amylopectin ratio for mealy potato starches ranged from 0.50 to 0.63, whereas the ratio for waxy potato starches ranged from 0.45 to 0.46. These results clearly demonstrate that mealy potato starches possess a higher amylose content compared to waxy potato starches.

Particle morphology and size distribution of potato starches with different texture

The morphology of starch granules differs based on the potato texture. Mealy potato starch granules exhibit an ovoid shape with smoth edges. In contrast waxy potato starch granules display a polygonal shape with sharp edges, consistent sizes. This suggests a correlation between starch particle morphology and potato texture. Results from particle size distribution analysis revealed that mealy potato starches had a range of 35.9–41.8 μm, whereas waxy potato starches exhibited a range of 42.1–49.7 μm, confirming the disparities in granule distribution. These variations stem from differing proportions and contents of amylose and amylopectin during starch biosynthesis, as well as variances in the spatial folding and circling of different chain lengths and branches within the granules. Briant correlated lower mealiness with a high percentage of small starch granules18, while Barrios found larger granules in mealy Russet Burbank than in LaSoda19. However, starch granule size has not been found to be related to mealiness by other researchers20.

Degree of branching, molecular weight and amylopectin chain length distribution of potato starches with different texture.

The data in Table 2 presents the degree of branching, weight-average molecular mass (Mw), and number average molecular mass (Mn) of potato starches with varying textures. It was observed that waxy potato starches (9.44%, 6.83% and 8.10%) exhibited a higher degree of branching compared to mealy potato starches (5.16%, 4.78% and 5.99%). Notably, amylose was linked by α−1,4-glycosidic bond, while amylopectin was primarily linked by α−1,6-glycosidic bond, with a minor linkage by α−1,4-glycosidic bond. Consequently, the degree of branching displayed a negative correlation with the amylose content. Starches with higher molecular weight predominantly consisted of amylopectin. The results indicated that both Mw (5955.06 kDa) and Mn (4019.37 kDa) were lower in mealy potato starches compared to waxy potato starches (6640.73 and 4688.50 kDa, respectively). Previous studies have reported that the Mw of amylopectin surpasses that of amylose21. Given the higher amylopectin content in waxy potato starches, they exhibited higher Mw and Mn. Additionally, studies by Yang have shown that waxy proso and foxtail millets also display higher Mw13. Similarly, research by Li has indicated that rice starch with high amylose content tends to have smaller amylopectin and amylose molecular sizes22, aligning with the findings in potatoes.

The distribution of amylopectin chain lengths significantly influences the functional properties of starch, including retrogradation, pasting, gelation, and digestion23. A longer average chain length of amylopectin renders the starch structure more resistant to hydrolysis by amylase24,25. The chain length distribution of amylopectin, as presented in Table 3; Fig. 3B, displays a bimodal distribution peaking at DP12. According to the clustering model described by Hizukuri{Hizukuri, 1986 #49}, amylopectin was categorized into A chain, B1 chain (DP13-24), B2 chain (DP25-36), and B3 chain (DP > 36), with A chain and B1 chain representing short chains, and B2 chain and B3 chain representing long chains. The average chain length of amylopectin in mealy potato starches (21.64%, 21.97% and 21.80%) was higher than that of waxy potato starches (21.15%, 21.06% and 21.24%). In comparison with mealy potato starches, waxy potato starches exhibited higher proportions of A chain and DP13-24, but lower amounts of DP25-37 and DP ≥ 37. Furthermore, waxy potato starches displayed a higher proportion of A chain, while mealy potato starches had higher proportions of DP25-37 and DP ≥ 37. These results indicate that waxy potato starches have a higher proportion of short chains and a lower proportion of long chains, consistent with studies in rice, maize, proso, and foxtail millets13,26.

Fourier transform infrared spectroscopyof potato starches with different texture

To examine the short-range molecular order of mealy and waxy potato starches, we acquired deconvoluted spectra within the 1200 –900 cm−1 range (Fig. 3A). The FTIR bands at 1047 and 1022 cm−1 are responsive to alterations in the crystalline and amorphous regions, respectively. The 1047/1022 cm−1absorbance ratio serves as a commonly utilized indicator of short-range ordered structure in starch27. The absorbance ratios at 1047/1022 cm−1 for potato starches are outlined in Table 3. Notably, the waxy potato starches exhibited elevated absorbance ratios at 1047/1022 cm−1(0.92, 0.91 and 0.91). This outcome suggests that waxy potato starches possess a greater amount of short-range ordered structure compared to mealy potato starches. This finding aligns with the results pertaining to the proportion of intermediate chains and DP 13–24 (Table 3), which primarily contribute to the formation of double helices.

Crystalline structure of potato starches with different texture

The X-ray diffraction patterns of various potato starches are depicted in Fig. 3C. These starches exhibited both sharp and diffuse diffraction characteristics, with distinct sharp diffraction peaks observed at 2θ of 5.6°, 15°, 17.2°, 22.2° and 24°, indicative of the typical “B” type crystal structure. The relative crystallinity of mealy potato starches, as determined from X-ray diffraction patterns, ranged from 29.07 to 38.00%, while that of waxy potato starches ranged from 26.12 to 27.38% (see Table 3). The discrepancy between the order of relative crystallinity and the short-range ordered structure determined by FTIR is notable. Amylopectin is attributed to the formation of crystallites in starch, with waxy starch exhibiting higher amylopectin content and thus higher crystallinity compared to mealy starch. Furthermore, waxy potato starches displayed a greater amount of short-range molecular order of double helices but slightly lower crystallinity compared to mealy potato starches, suggesting a lower amount of double helices in mealy starches are arranged into crystallites.

Pasting properties of potato starches with different texture

When an aqueous starch solution was heated, starch granules undergo water absorption and swelling. Upon reaching maximum swelling capacity, the granules rupture, releasing their amylose and amylopectin content. The critical aspect of pasting involves disrupting crystalline and double helical structures28. Peak viscosity, trough viscosity, breakdown, final viscosity, and setback of mealy potato starches ranged from 2038 to 2535 cP, 1706–1796 cP, 242–777 cP, 2022–2180 cP and 297–385 cP, respectively. Waxy potato starches exhibited values of 2850–3226 cP, 1273–1453 cP, 1576–1813 cP, 1478–1713 cP and 204–260 cP, respectively. Notably, peak viscosity and breakdown were higher for waxy potato starches compared to mealy potato starches, while trough viscosity, final viscosity, and setback were higher for mealy potato starches compared to waxy potato starches. A study on proso millet revealed a strong negative correlation between amylose content and peak viscosity, trough viscosity, and breakdown. Additionally, the study reported a strong positive correlation between amylose content, setback, and pasting temperature13, consistent with our findings.

Correlation analysis of starch fine structure with texture

Correlation analyses were conducted (refer to Fig. 4) to further elucidate the relationship between starch fine structure and potato texture. The hardness of mealy potatoes was observed to be lower than that of waxy potatoes, with potato tuber hardness exhibiting significant positive correlations with PV, BD, DB, DP6-12, and 1047/1022 cm−1, and significant negative correlations with TV, FV, SB, PT, PTM, AM and ACL. Amylose content emerged as the primary factor influencing the physicochemical properties of starch29. Zhou et al. reported significant correlations between amylose content and various pasting parameters30. Amylose content demonstrated positive correlations with Trough Viscosity, Final Viscosity, Setback, Peak Time, and Pasting Temperature, while exhibiting negative correlations with peak viscosity and breakdown30. A study on rice showed that cooked rice from rice cultivars with high amylose content tends to be dry, fluffy, separate, and hard, while cooked rice with low amylose content tends to be glossy, soft, and sticky31,32.

Correlation coefficients between structural and physicochemical properties of the starches. PV: Peak Viscosity; TV: Trough Viscosity; BD: Breakdown; FV: Final Viscosity; SB: Setback; PT: PeakTime; PTM: Pasting temperature; AM: Amylose Content; DB: Degree of Branching; Mw: Molecular Weight; RC: Relative Crystallinity; ACL: Average Chain Length. of Amylopectin; HD: Hardness.

Conclusions

The present investigation sought to elucidate the relationship between potato texture and starch fine structure through a comprehensive analysis of potato starch granules. Employing advanced physical techniques, this study meticulously examined the morphology, particle size distribution, crystalline architecture, molecular configuration, and granule heterogeneity of various potato starches. The findings underscored significant differences in starch granules associated with distinct textural attributes: mealy potatoes displayed smaller particle sizes relative to waxiness counterparts. Despite both categories manifesting the B-type crystalline pattern, variations in relative crystallinity were evident, with mealy potato starches demonstrating elevated levels. Moreover, mealy potato starches featured reduced amylopectin content, degree of branching, short-chain amylopectin fraction, and molecular weight compared to their waxiness counterparts. These alterations in starch molecular architecture were identified as pivotal factors governing the assembly of crystalline structures and shaping granule morphology, thereby influencing texture development. Collectively, these insights contribute to a deeper understanding of how subtle changes in starch fine structure can profoundly influence the textural characteristics and practical applications of potatoes, offering valuable guidance for breeders, food scientists, and industry stakeholders aiming to optimize potato quality and utility based on specific end-use requirements.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Mullins, E., Milbourne, D., Petti, C., Doyle-Prestwich, B. M. & Meade, C. Potato in the age of biotechnology. Trends Plant. Sci. 11, 254–260. https://doi.org/10.1016/j.tplants.2006.03.002 (2006).

Charley, H. Food Science (Wiley, 1982).

McComber, D. R., Horner, H. T., Chamberlin, M. A. & Cox, D. F. Potato cultivar differences associated with mealiness. J. Agric. Food Chem. 42, 2433–2439. https://doi.org/10.1021/jf00047a013 (2002).

McComber, D. R., Osman, E. M. & Lohnes, R. A. Factors related to potato mealiness. J. Food Sci. 53, 1423–1425. https://doi.org/10.1111/j.1365-2621.1988.tb09291.x (2006).

Li, H., Fitzgerald, M. A., Prakash, S., Nicholson, T. M. & Gilbert, R. G. The molecular structural features controlling stickiness in cooked rice, a major palatability determinant. Sci. Rep. 7, 43713. https://doi.org/10.1038/srep43713 (2017).

Ratnayake, W. S. & Jackson, D. S. A new insight into the gelatinization process of native starches. Carbohydr. Polym. 67, 511–529. https://doi.org/10.1016/j.carbpol.2006.06.025 (2007).

Lin, L. et al. Relationships between amylopectin molecular structures and functional properties of different-sized fractions of normal and high-amylose maize starches. Food Hydrocoll. 52, 359–368. https://doi.org/10.1016/j.foodhyd.2015.07.019 (2016).

Aboubacar, A., Moldenhauer, K. A. K., McClung, A. M., Beighley, D. H. & Hamaker, B. R. Effect of growth location in the united States on amylose content, amylopectin fine structure, and thermal properties of starches of long grain rice cultivars. Cereal Chem. 83, 93–98. https://doi.org/10.1094/cc-83-0093 (2006).

Slepkov, A. D., Ridsdale, A., Pegoraro, A. F., Moffatt, D. J. & Stolow, A. Multimodal CARS microscopy of structured carbohydrate biopolymers. Biomed. Opt. Express. 1, 1347–1357. https://doi.org/10.1364/BOE.1.001347 (2010).

Kowsik, P. V. & Mazumder, N. Structural and chemical characterization of rice and potato starch granules using microscopy and spectroscopy. Microsc Res. Tech. 81, 1533–1540. https://doi.org/10.1002/jemt.23160 (2018).

Chao, G. et al. Starch physicochemical properties of waxy proso millet (Panicum miliaceum L). Starch - Stärke 66, 1005–1012. https://doi.org/10.1002/star.201400018 (2014).

Cai, C. et al. Different structural properties of high-amylose maize starch fractions varying in granule size. J. Agric. Food Chem. 62, 11711–11721. https://doi.org/10.1021/jf503865e (2014).

Yang, Q., Zhang, W., Li, J., Gong, X. & Feng, B. Physicochemical properties of starches in proso (Non-Waxy and Waxy) and Foxtail millets (Non-Waxy and Waxy). Molecules. https://doi.org/10.3390/molecules24091743 (2019).

Zeng, F., Gao, Q. Y., Han, Z., Zeng, X. A. & Yu, S. J. Structural properties and digestibility of pulsed electric field treated waxy rice starch. Food Chem. 194, 1313–1319. https://doi.org/10.1016/j.foodchem.2015.08.104 (2016).

Guo, K., Lin, L., Fan, X., Zhang, L. & Wei, C. Comparison of structural and functional properties of starches from five fruit kernels. Food Chem. 257, 75–82. https://doi.org/10.1016/j.foodchem.2018.03.004 (2018).

Kim, Y. Y., Woo, K. S. & Chung, H. J. Starch characteristics of Cowpea and Mungbean cultivars grown in Korea. Food Chem. 263, 104–111. https://doi.org/10.1016/j.foodchem.2018.04.114 (2018).

Gao, J. et al. Tartary buckwheat (Fagopyrum Tataricum Gaertn.) starch, a side product in functional food production, as a potential source of retrograded starch. Food Chem. 190, 552–558. https://doi.org/10.1016/j.foodchem.2015.05.122 (2016).

Briant, A. M. & Gassel, E. G. Physical properties of starch from potatoes of different culinary quality. J. Food Sci. 10, 437–444. https://doi.org/10.1111/j.1365-2621.1945.tb16189.x (1945).

Unrau, A. M. & Nylund, R. E. The relation of physical properties and chemical composition to mealiness in the potato. I. Physical properties. Am. Potato J. 34, 245–253. https://doi.org/10.1007/bf02855191 (1957).

Barrios, E. P., Newsom, D. W. & Miller, J. C. Some factors influencing the culinary quality of Irish potatoes II. Physical characters. Am. Potato J. 40, 200–208. https://doi.org/10.1007/bf02849340 (1963).

Shin, S. I. et al. Structural characteristics of low-glycemic response rice starch produced by citric acid treatment. Carbohydr. Polym. 78, 588–595. https://doi.org/10.1016/j.carbpol.2009.05.017 (2009).

Li, X. et al. Partial branching enzyme treatment increases the low glycaemic property and alpha-1,6 branching ratio of maize starch. Food Chem. 164, 502–509. https://doi.org/10.1016/j.foodchem.2014.05.074 (2014).

Gayin, J., Abdel-Aal, E. M., Manful, J. & Bertoft, E. Unit and internal chain profile of African rice (Oryza glaberrima) amylopectin. Carbohydr. Polym. 137, 466–472. https://doi.org/10.1016/j.carbpol.2015.11.008 (2016).

Srichuwong, S., Sunarti, T. C., Mishima, T., Isono, N. & Hisamatsu, M. Starches from different botanical sources II: contribution of starch structure to swelling and pasting properties. Carbohydr. Polym. 62, 25–34. https://doi.org/10.1016/j.carbpol.2005.07.003 (2005).

Hizukuri, S. Polymodal distribution of the chain lengths of amylopectins, and its significance. Carbohydr. Res. 147, 342–347. https://doi.org/10.1016/S0008-6215(00)90643-8 (1986).

Huang, J. et al. Comparison of molecular structures and functional properties of high-amylose starches from rice Transgenic line and commercial maize. Food Hydrocoll. 46, 172–179. https://doi.org/10.1016/j.foodhyd.2014.12.019 (2015).

van Soest, J. J. G., Tournois, H., de Wit, D. & Vliegenthart, J. F. G. Short-range structure in (partially) crystalline potato starch determined with attenuated total reflectance Fourier-transform IR spectroscopy. Carbohydr. Res. 279, 201–214. https://doi.org/10.1016/0008-6215(95)00270-7 (1995).

BeMiller, J. N. Pasting, paste, and gel properties of starch–hydrocolloid combinations. Carbohydr. Polym. 86, 386–423. https://doi.org/10.1016/j.carbpol.2011.05.064 (2011).

Zhang, C., Xue, W., Li, T. & Wang, L. Understanding the relationship between the molecular structure and physicochemical properties of soft rice starch. Foods. https://doi.org/10.3390/foods12193611 (2023).

Zhou, H. et al. Characterization of amylopectin fine structure and its role on pasting properties of starches in rice (Oryza sativa L). Food Sci. Technol. Res. 24, 347–354. https://doi.org/10.3136/fstr.24.347 (2018).

Bergman, C. in Rice 273–337 (2019).

Cameron, D. K. & Wang, Y. J. A better Understanding of factors that affect the hardness and stickiness of Long-Grain rice. Cereal Chem. 82, 113–119. https://doi.org/10.1094/cc-82-0113 (2005).

Acknowledgements

This research was supported by the Yunnan Academy of Agricultural Sciences Scientific Research Pre-research Project (2023KYZX-05),Yunnan Joint Agricultural Program (202301BD070001-217), the Agriculture Research System of China (CARS-09-P03), National Natural Science Foundation of China (32260505), Yunnan Talent Project (202305AC160032), Yunnan Agricultural Joint Foundation (202101BD070001-022) and Yunnan Provincial Joint Laboratory for Seeds and Seed Industry (202205AR070001).

Author information

Authors and Affiliations

Contributions

Conceptualization, Ying Wang; Methodology, Wenjing Huang, Fengkui Zeng, Jitian He and Zhechao Pan; Writing-Original Draft, Ying Wang; Supervision, and Darft Editing, Xianping Li, Zulfiqar Ali Sahito and Wanlin Yang. All authors have reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval and consent to participate

Not applicable for that section.

Consent for publication

All authors agreed to publish this manuscript.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Huang, W., Zeng, F. et al. A study focusing on the distinct fine structure of starch in mealy and waxy potatoes. Sci Rep 15, 13895 (2025). https://doi.org/10.1038/s41598-025-95977-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-95977-w