Abstract

The structural, optical, photocatalytic and dielectric properties of Cd0.40Mn0.60ZnO2 annealed nanocomposites prepared by Hydrothermal and subsequently annealed at temperatures between 200 °C and 600 °C. The particle size, crystallite size, and inter-plane separation were all enlarged with increased Tann at 600 °C and electrical dielectric loss increased. The specific surface area and photocatalytic activity were maximized, obtaining in this case a rate of degradation of 2 × 10-4s-1 at 400 °C. The lowest band gap = 1.55 eV was observed at 400 °C signifying enhanced optical absorption. The optical and dielectric properties exhibited a non-monotonic behavior: absorbance, optical dielectric loss, carrier density, dielectric constant, ac conductivity and Fill-factor, increased to the maximum values at 300 °C followed by a decrease. The dielectric constant (3.22), single and dispersion energies (10.58 eV and 23.33 eV), impedance (3.25–10.70 MΩ) and series resistance (14.3 MΩ) were maximum at 500 °C. From loss, modulus, and impedance curves, relaxation times were calculated by being 82.71 µs, 0.69–10.62 µs, and 15.92–40.94 µs. Two successive semicircles were identified in Cole-Cole plots for the composites after annealing in the range 200–500 °C. Results show composites annealed at 200–400 °C can be utilized for solar cell, supercapacitor, telecommunications, and water purification applications while those annealed at 500–600 °C are more suitable for a high frequency, nonlinear optical, and high-power antenna applications.

Similar content being viewed by others

Introduction

For solar cells, supercapacitors, telecommunications, water purification, and white light-emitting diodes (LEDs), certification is usually required. Generally, nanocomposites are synthesized from multiple independent phases in different dimensions1,2,3,4. For instance, the low-cost hydrothermal production of metal oxide nanocomposite can have a significant impact on the composite’s surface area (SA), oxygen vacancy (OV), and particle size (PZ). For instance, when nanocomposite is heated and annealed during synthesis, it can have a lower PZ, a greater OV, and a bigger SA, making it suitable for such applications6,7. Additionally, certain induced pores are created when inner and outer nanoparticles interact, which can improve the effectiveness of nanomaterials in the purification of water8. Using an adsorption model that accounts for multilayer coverage, SA has been computed using the Brunauer-Emmett-Teller (BET) method9. Similarly, the Barrett-Joyner-Halenda (BJH) model uses the Kelvin model for density functional theory (DFT) to calculate surface area (SA) and pore radius (PR).

ZnO is a wurtzite n-type semiconductor with an energy gap (Eg) of 3.2 eV, while CdO is a cubic n-type semiconductor with an Eg of 2.1 to 2.7 eV10,11. Furthermore, it was discovered that the conduction band (CB) edges of ZnO and CdO are located at -0.20 and − 0.80 eV, respectively12,13. However, when ZnO composited with CdO, the CdZnO2 would be useful for photo- and light-emitting diodes, but when the Eg and some of the optical characteristics were fine-tuned14,15, as well as n-type Mn3O4 of 2.1 eV Eg16,17,18. Moreover, the obtained optical constants can be further used to measure radiation exposure and are calculated from the optical absorbance (A) measured in the Vis-UV range19,20. The majority of optoelectronic devices, including solar cells and filters, require low Eg, while large Eg is additionally required for higher breakdown fields, high power operation, and low electrical disturbances21,22,23,24.

Due to their unique characteristics, nanocomposites have been used to create catalysts more effectively and at cheaper costs, which makes them appropriate for separating and getting rid of dyes in water25,26,27. High stability, a variety of nanostructure morphologies, and a benign nature may be required for photo-catalytic applications28,29. When nanocomposite is stimulated with photon energy, it can produce charge carriers that have increased photocatalytic efficiency (η) and degradation rate, useful for low- and high-field applications30,31. Conversely, ZnO and TiO2 oxides can be photo-induced pairs for wastewater when stimulated by radiation, but they recombine quickly, lowering the η25,26.

The complex dielectric parameters (ε\ and ε\\) in nanocomposites can be used to characterize the dielectric mechanism over a broad frequency range (f) up to 10 GHz. These parameters are mostly influenced by internal or induced defects32,33,34,35. Low ε\ materials are more suitable for high-frequency and nonlinear optical devices, whereas high ε\ materials can be employed in microwave integrated circuits and mobile phones36,37,38,39,40,41. Koop’s theory states that current flows via parallel grain alignments composed of conducting grains that are separated by barriers of weak conductivity at low f and prominent at high f42,43,44,45,46. Furthermore, ZnO/Fe2O3, ZnO/V2O5, ZnO/Fe2O3/V2O5, Al/ZnO, and (Al + Mn)/ZnO nanocomposites exhibit f-dependent ac conductivity that is in line with Jonscher’s power law, indicating a hopping mechanism and non-Debye relaxation, which is advantageous for solar cell performance47,48.

The application of CdO, MnO, and ZnO oxides may be limited since they suffer from poor selective absorption and high recombination rates, but the composites between them can be adopted. Unfortunately, the subject still raises questions when they are annealed at various temperatures (Tann), which is reliant on numerous criteria for advanced devices49. Annealing is a necessary step as it results in alteration of the morphology, i.e., shape and particle size, of the nanoparticles, which may affect the crystallinity of the as-synthesized composite by modifying their properties so that it can be used for technological purposes. Recently, G. Abady and A. Sedky et al. have been approved that an increase in annealing temperature (Tann) has correlated with a significant change in the PZ and Eg of Cd1-xMnxZnO2 nanocomposites along with a strong ferromagnetic signature50. Further, the effects of Tann on the characteristics of Cd00.40M0.60ZnO2 nanocomposites (M = Mn or Ni) have also been studied by Sedky et al.51. It has been found that mechanical and ferromagnetic behaviors significantly alter in response to an increase in Tann between (200–600 oC). Furthermore, Sedky et al.52 reported the impact of a similar Tann range on the optical and dielectric characteristics of Cd0.40Ni0.60ZnO2 nanocomposites. It is seen that previous data based on annealed Cd1-xMnxZnO2 nanocomposites using the SA, optical, photocatalytic, and dielectric measurements are very poor, although they are required for applications. All of the above indicated that annealing of as as-synthesized composites is most often a necessary step for unexpected behaviors required for most advanced applications. In light of this, the optical, photocatalytic, and dielectric characteristics of Cd0.40Mn0.60ZnO2 nanocomposites are well advanced and were likely never published at all, which emphasizes the current study.

This research aims to explore metal oxides, especially Cd0.40Mn0.60ZnO2 nanocomposites, for advanced technological applications through their synthesis, characterization, their properties, and doping effects. This also involves investigating the influence of annealing temperature (Tann) on structural, morphology, and optical characteristics such as particle size (PZ), surface area (SA), oxygen vacancy (OV), and energy gap (Eg). The nanocomposites synthesis via simple co-precipitation technique is followed by investigations of their optical and photocatalytic properties to assess parameters such as their energy gap tuning, optical constants, and efficiency to generate photon-generated charges for applications in water treatment/ purification and optoelectronic devices. Further, the dielectric and electrical characteristics: complex dielectric parameters (ε’ and ε’’) and ac conductivity will also be examined over an extensive frequency range to explore their potential for high-frequency devices and solar cells.

Experimental details

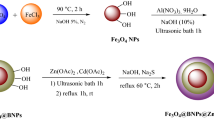

High-purity starting materials (CdCl₂·H₂O: 99.99%, ZnCl₂: 99.99%, MnCl₂·4 H₂O: 99.99% and NaOH: 99.99%) were used to synthesize the Cd0.40Mn0.60ZnO2 nanocomposites by a hydrothermal method. Standardized protocol was followed; 5520 mL of double-distilled H₂O were used to dissolve CdCl₂·H₂O, ZnCl₂ and MnCl₂·4 H₂O and stirred for 30 min. The complete balanced chemical reaction is as follows:

\(0.40CdC{l_2}+0.60MnC{l_2}+ZnC{l_2}+4NaOH \to C{d_{0.{\text{ }}40}}M{n_{0.{\text{ }}60}}Zn{O_2}+4NaCl\,+\,2{H_2}Oa\)

To that mixture, NaOH was dropwise added and stirred for 1 h, autoclaved at 160 °C for 12 h, centrifuged for 30 min, dried at 80 °C for 10 h, and annealed at 200–600 °C for 3 h. X-ray diffraction (XRD) patterns were recorded in a regime of 20 − 80° at a scan rate of 0.02°/s on a Philips PW 1710 X-ray diffractometer (Cu-Kα radiation, λ = 0.15405 nm) at an error of ± 0.01°.A JEM-2100 h-TEM (200 kV, ± 0.1 nm resolution) was used as a confirmation of particle morphology and size. Surface area was calculated from N₂ adsorption isotherms at 77 K on a NOVA 2200 BET analyzer (error ± 0.5 m²/g) and optical properties were measured on a Jasco V-570 UV-visible-NIR spectrophotometer (200–900 nm, accuracy ± 0.3 nm). Photocatalytic activity was tested through the degradation of methylene blue (MB) under a 450 W/m² solar simulator (Oriel SO12A), and degradation rates were monitored using a Lambda 750 UV-visible spectrophotometer (± 5% error). The dielectric properties were characterized at room temperature by using a Novo Control GmbH Alpha analyzer (0.10 Hz–20 MHz, parallel plate configuration, ± 0.1 error in dielectric constant).

Results and discussion

XRD and SA analysis

The XRD pattern of the as-synthesized and annealed Cd0.40Mn0.60ZnO2 composite is composed of hexagonal and monoclinic ZnO and Cd2Mn3O8 phases, as shown in Fig. 1. It is seen that some of extra lines of lower intensity, at 2ϴ = 18.46o, 39.22o, 56.71o and 61.28o, could be obtained in the XRD pattern of as synthesized sample. However, such lines were nearly disappeared by annealing except the line at 18.46o which was seen at 600 oC. It was further verified that the measured, calculated, and standard XRD values fit each other well. The pw% of the ZnO phase of as synthesized decreased by annealing while the pw% of the Cd2Mn3O8 phase rose. Table 1 shows the unit cell volume (Vavg) of synthesized and annealed composites, which rose gradually against Tann53,54.

Using K = 0.89 and β (FWHM), the size of crystallite (D) given by;\(\frac{{K\lambda }}{{\beta \cos \theta }}\). The value of D of the as-synthesized composite is 22.23 nm, but it was reduced till it was 19.77 nm at 600 °C. After annealing to 300 oC, the interspacing (d) given in Table 1 decreased from 1.553 nm for the as-synthesized composite to 1.187 nm at 300 oC, followed by a gradual, significant increase till it reached 4.748 nm at 600 oC. The PZ, which ranges from 3.08 to 11.72 nm, increases linearly with increasing Tann, according to the TEM micrographs displayed in Fig. 2. Particles are collected into clusters that create a small polygon-like sheet and a comparatively big rod-like sheet. Particles are collected into clusters that create a small polygon-like sheet and a comparatively big rod-like sheet. The rods’ average diameter and length fell from 95 ± 42 to 98 ± 19 nm and from 435 ± 195 to 225 ± 74 nm, respectively. On the other hand, the polygon grows in size from 54 ± 12 nm to 79 ± 45 nm. Although annealing to 600 oC has a little bit of effect on D, it has a significant effect on the V, PZ, and d.

Figure 3a shows the amounts of N2 gas adsorbed (V) against relative pressure (P/Po). It is evident that V increased more quickly as (P/Po) got closer to unity but more slowly as (P/Po) increased. The isotherm of adsorption and desorption exhibits type IV hysteresis with an H3-type loop in mesopore size (2–50 nm)55,56. The plots of [1/W (P/Po) − 1] against (P/P0) shown in Fig. 3b were used to determine SA in (m2/g)57, where W is the gas volume adsorbed at STP. Table 1 approved that composites annealed between 200 and 400 oC have the highest values of SA, PR, and PV, but they drastically drop more than 400 oC. The rise in pore reactive sites would allow contaminations in wastewater to be adsorbed and raise photo/Fenton activity58. When Tann is below 400 oC, the behavior of SA with Tann is similar to D and pw% of phases; nevertheless, an inverse trend was seen when Tann increased to 500 oC. An inverse trend could be obtained between SA with both PZ and d, that is, SA α (1/PZ) and (1/d). The current composites, when annealed between 200 and 400 °C, can be employed for splitting and water filtration.

Optical analysis

The absorbance (A) versus wave length (λ) is plotted in Fig. 4a, where A grew as Tann increased from 200 to 300 oC before declining. The A rises slightly below 400 nm, signifying a shift in the band structure’s carrier concentration states. However, greater values of A in composites annealed ≤ 300 oC can be employed in optoelectronic devices such as solar cells. The increase in optical absorbance until 300 °C is also connected with the decrease in many defects (e.g., oxygen vacancies and interstitial defects) that facilitate the improvement in the light absorbency of material. At a higher temperature of 300 °C, the material becomes more structurally ordered, which reduces both scattering losses and enhances the light absorption efficiency. An optimal balance between defect minimization and structural stability provides the highest absorption at 300 °C. However, at elevated temperatures, this equilibrium is disrupted, resulting in a decline of optical performance. The difference in the intensity of the absorbance peaks is primarily due to variations in the material’s intrinsic optical properties and the concentration of the composite absorbing species. Factors such as PZ, D, and surface defects can influence the absorbance. These properties vary depending on the synthesis conditions and post-treatment processes applied to the samples.

The Eg determined using Tauc’s Eqs59,60;

where d = 0.85 cm and α is the absorption coefficient given by; 2.303 (A/d). The linear plot between (αhυ)2 and hυ shown in Fig. 4b was used to obtain the Eg listed in Table 2. The lowest Eg values (1.80, 1.75, and 1.55 eV) are found between 200 and 400 oC; however, at Tann ≥ 500 oC, the Eg rise to 1.95 and 2.05 eV.

However, CdO exhibits a narrow Eg (2.2–2.5 eV), whereas ZnO is a wide Eg (3.3–3.4 eV). This makes ZnO suitable for applications requiring strong UV absorption and transparency in the visible spectrum. At present, the Cd0.40Mn0.60ZnO2 composite shows Eg that lies between the Eg of CdO and ZnO. The alteration in the Eg by annealing can be explained as follows: At lower Tann, the thermal energy may promote the reduction of defect density especially the Ov and interstitial defects, which generate localized energy levels near the CB and VB14,20,59,60. As the tail states are eliminated and the energy levels of the material stabilize, their reduction results in an Eg shrinkage. This might lower the Eg a little bit since the better orbital overlap might only happen at a few bonding sites due to the disordered structure in non-annealed material, while the annealing might improve the crystallinity leading to less degree of disorder. At high Tann, however, oxidation or surface modifications can widen Eg. At elevated Tann, there could also be a redistribution of atoms within the lattice. This can change the lengths and angles of the bonds, and hence the band structure of the electrons. In particular, the hybridization of orbitals or the local environment around Cd, Mn, and Zn atoms can change and, thus, cause the CB and VB to shift. Moreover, the collapse resulted in a decrease of both surface area and active sites at high temperature also may lead to high band gap. On the other hand, As a highly photocatalytic material, the Cd0.40Mn0.60ZnO2 nanocomposite was therefore could be an efficient material for water purification by destroying organic pollutants, bacteria, and toxic chemicals with light irradiation. The small bandgap (1.55 eV @ 400 °C) enables strong absorption of visible light making it a suitable candidate for use in solar-driven purification systems and high surface area and optimized defect density improve adsorption and degradation efficiencies. The ideal bandgap at 400 °C highlights the suitability of the material for photocatalytic purification of water stimulated by visible light. The carrier concentration, the induced OV during synthesis, and the shift in insulating states in the forbidden gap all influence the Eg58,59,60,61. In any case, solar cells and light-emitting diodes (LEDs) benefit from dropping the Eg below 3 eV61,62.

The reflective index (n) against λ is given by63,64:

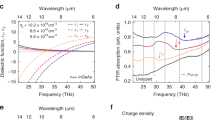

where m* and N are the electron effective mass and free carrier concentration, and εL is the lattice dielectric constant. The linear fit of (n2-k2) to λ2 in Fig. 5 yielded the values of εL and (N/m*) listed in Table 2. It is found that annealing to 300 oC increased the (N/m*) from 7.83 X1054 to 8.61 X1054 (g.cm3)−1; however, at 600 oC causes it to decrease. Annealing often results in a drop in εL, which reaches its maximum value of 3.22 at 500 oC. With an increasing annealing temperature (Tann), the generation of a defects like oxygen vacancies and interstitials decreases and hence carrier density increases. This improvement increases carrier generation and mobility. Middle-range temperatures, near 300 °C, leads to the maximum carrier density, detailed the study, which is enabled by increased crystallinity and decreased recombination losses. At elevated Tann, for example at 500 °C, this would be offset by excessive grain growth and structural modifications resulting in a minor decrease in the carrier content.

On the other hand, The dissipation factor (tan δ) was calculated65:

Where ɛr and ɛi represent the imaginary part of the dielectric constant, εi = 2nk, and the real part, εr = n2-k2. Tan (δ) declined as hυ increased, as Fig. 6a illustrates, although it grew against Tann from 200 to 300 oC before decreasing, suggesting that composites annealed over 400 oC might be used in high-quality supercapacitor fabrications66. Frequency-dependent dielectric constants are used in the Wemple-DiDomenico (WDD) single oscillator model to calculate the dispersion and single oscillator energies (Ed and Eo) as67,68.

-The Eo and Ed values mentioned in Table 2 are obtained from the linear plot between (n2–1)–1 and (hυ)2 depicted in Fig. 6b. The variation of Eo and Ed (3.17–10.58 eV), and (6.53–23.33 eV), against Tann clearly show comparable tendencies. Specifically, E₀ = 4.57 eV at 200 °C. The E₀ at 300 °C was reduced to 3.17 eV owing to crystallinity improvement and defect density decrease. On the other hand, at a high temperature of 400 °C, E₀ shows a significant rise to 10.15 eV, indicating improved electronic stability and higher polarization impact. At 500 °C, the value of E₀ peaks to 10.58 eV, indicating more optimization for the electronic structure of the material. E₀ reduces to 6.93 eV at 600 °C, probably due to structural alterations or oxidization processes taking place at high temperatures. In contrast, Ed takes the value of 12.43 eV at 200 °C, which decreases to 6.68 eV at 300 °C, indicating a decreasing energy dispersion because of better structural order of materials. At 400 °C, Ed increases to 15.40 eV with a notable increase in the non-bonding electronic interactions and polarization. The optimal electronic and structural conditions are found at Ed = 23.33 eV and T = 500 °C. At 600 °C, however, Ed decreases to 6.53 eV, possibly due to grain coarsening or structural damage at elevated temperatures.

Figure 5 The linear plot between (n2-k2) and (λ)2 for Cd0.40Mn0.60ZnO2 annealed nanocomposites.

Photocatalytic analysis

The plots of A against λ of MB at different irradiation times (t) shown in Fig. 7a-e have been used to determine the photo-degradation efficiency (η) and degradation rate (k) of the catalysts at 665 nm. The η is supplied by69,70,71;

Co and Cr are the concentrations of MB before and after irradiation determined from Ao and Ar (Co = 1.19\(\:\times\:\)10−5 Ao and Cr = 1.19\(\:\times\:\)10−5 Ar). The behavior of η against t is depicted in Fig. 8a, where an increase in η with increasing t was obtained due to increasing free carriers produced during the irradiation. The highest values of η obtained at t = 150 min were 74.28, 71.40, and 81.15% for Tann < 400 oC at t = 150 min, while they dropped to 62.08 and 60.53% at Tann > 400 oC. Structural and optical properties of the material affect the correlation between photocatalytic efficiency and annealing temperature (Tann). The higher surface area and abundant defects in the material at lower Tann could favour photocatalytic activity by offering more active sites for the reaction. However, with increasing Tann, the material crystallizes, and grain growth occurs, leading to the reduction of the surface area and the number of defects, which may give rise to lower photocatalytic activity. The maximum photocatalytic efficiency of 81.15% was observed at 400 °C in this study, where the material could be well-balanced for the crystallinity, surface area, and defect density. In addition, excessive grain growing and a lower specific surface area at higher Tann (e.g., 500 °C) can lead to the decrease of photocatalytic performance. As such, Tann acts as an invaluable lever to optimize the structural and optical characteristics responsible for photocatalytic performance. According to the degradation kinetics, the degradation process then proceeds slowly. The MB dye degradation rate was used to quantitatively evaluate the photoreactivity pseudo-first-order response’s disintegration rate which followed the Langmuir-Hinshelwood kinetic equation72;

The values of k given in Table 2 were determined by utilizing the linear fitting between ln(Ct/C0) and t, as seen in Fig. 8b. Since k behaves almost like η, water filtering can be achieved by annealing such a composite between 200 and 400 oC. At a Tann of 400 °C, the Cd₀.₄₀Mn₀.₆₀ZnO₂ nanocomposite exhibits the most significant degradation (k = 2 × 10⁻⁴ s⁻¹) ratio. The highest photocatalytic efficiency at 400 °C is mainly due to the largest surface area (22.84 m²/g), crack-free crystallinity, and reduced bandgap (1.55 eV), leading to improved light absorption, efficient charge carrier separation, and enhanced active site availability. At lower Tann, a higher relative number of underlying surface defects leads to poor performance whereas at higher Tann, grain growth and reduced surface area reduce efficiency. So that 400 °C is the suitable temperature for achieving optimal photocatalytic activity.

Dielectric analysis

The real and imaginary parts ε′ and ε’’ of dielectric constant (ε), loss factor (tan δ) and q-factor are given by73,74;

C and C0 are the capacitances of the sample and empty cell (C0 = ε0A/d). Figure 9a plots the relationship between ε′ and frequency (f) and shows that ε\ steadily.

The connection between ε′ and f is plotted in Fig. 9a, which demonstrates that ε\ decreased continuously as f climbed up to 100 kHz; after that, it saturated. The presence of interfacial polarization resulting from space charge polarization is evidently indicated by the greater values of ε′ at lower f. A dipolar polarization, in which the carriers are unable to track the field reversal, may occur when f is elevated over 100 kHz75. The ε′ was raised by annealing from 200 to 300 °C. It reached its maximum at 300 °C and then began to decline with more annealing temperature to less than 200 °C. The increase of ε\ by annealing between 200 and 400 oC is due to defects spreading throughout the composites and causing a leakage current, which is compatible with the space charge polarization hypothesis offered by Maxwell-Wagner76.

For nonlinear optics and high-frequency antennas, annealed nanocomposites between 500 and 600 oC are required; however, for integrated microwave circuits and telecommunications, those between 200 and 400 oC are more useful77. Figure 9b shows the variation of tanδ against f. As f increased, tanδ steadily decreased until it approached zero at 20 MHz, which qualified for a supercapacitor, but at high f. None of the annealed composites displayed any relaxation peaks (RPs), with the exception of the composite that was annealed at 300 °C, which displays modest RPs at 75.90 kHz, suggesting a non-Debye-type78.

The total electrical conductivity (σt) can be obtained by79;

where s is the frequency exponent, σdc is the DC conductivity, B is a constant, and σac is the AC conductivity. The plot of σac against f in Fig. 10a illustrates how σac progressively rises up to 20 MHz. At a critical f, however, σac follows the equation (σac ∼ ωs), where s < 0.50 for hole conduction and s > 0.50 for electronic conduction. The values of s that are displayed in Table 3 are obtained from the linear plot of ln σac against ln ω, Fig. 10b. As may be observed, s < 0.50 which denotes hole conduction. The reduction of defects with increasing annealing temperature (Tann) leads to an increase in charge carrier density. The AC conductivity of Cd₀. ₄₀Mn₀. ₆₀ZnO₂ rises with temperature, until 300 °C, its increase being attributed to a decrease in defects and an increase in crystallinity, because these factors promote mobility of charge carriers. The material at 300 °C gives the optimal balance of crystallinity and minimized defects and therefore reaches its peak conductivity. At temperatures above 300 °C, however, conductivity begins to drop. The reason is that too much grain growth, oxidation and structural defects restrict charge carrier mobility and lower the specific surface area of the material during charging and discharging of batteries. Thus, 300 °C is found to be the optimum annealing temperature to reach the highest conductivity and higher temperatures lead to reduced performance.

The binding energy Wm, is given by correlated barrier hopping (CBH) model80;

Table 3 shows that annealing frequently caused a decrease in Wm, which is consistent with the phenomenological theory proposed by Koops81. A higher value of the Full (F) factor for the figure of merit given provides strong support for solar cell design82. The Tann is the most pertinent factor determining the composite’s full factor (F-factor) through changes in the structural and electronic properties of the composite. The material achieves a balanced state at 300 °C, whereby the increase in crystallinity with a subsequently decreased defect density increases carrier mobility and lowers recombination losses. This results in the high F-factor which makes the composite truly applicable in solar cell applications. With incomplete crystallization and high defect concentrations, the recombination rate will increase, which can lead to lower F-factor at lower Tann. Conversely, at higher Tann, rapid grain growth and structural changes e.g. oxidation or atomic rearrangement tends to degrade electronic properties and hence reduces further the F-factor. The dependence of the F-factor (shown in Fig. 11) is therefore weak on Tann at low frequencies (10 kHz). Among these results, the composite that is annealed at 300 °C exhibits the best photogenerated electron to hole transport ratio (as indicated by the F-factor), demonstrating its promising application as a potential solar cell.

.

The electric modulus (M\\) and electric impedance (Z\\) for the annealed nanocomposites are plotted against f in Fig. 12a, b. It is evident from both graphs that distinct RPs appear in relation to Tann. The RPs derived from M\\ curves indicated in Table 3 are 15 kHz at 200 oC, 232 kHz at 300 oC, and then steadily dropped to 15, 15, and 24.90 kHz with an additional increase of Tann to 600 oC. The high peak of M// for Tann = 300 °C may be occurs when the resistance of grains is much higher than that of their boundaries, and so, electrons have the most energy loss. Thus, the M\\ plots are able to pick out those of the smallest capacitances. Annealing at at 300 oC may have a lot of Ov, which lead to the formation of barrier layers at the grain-grain boundary interface, thus affecting their impedance83,84. The relaxation periods associated with the relaxation peaks (RPs) for the Cd₀.₄₀Mn₀.₆₀ZnO₂ nanocomposites can be determined using the formula:

The following conclusions are drawn from the plot of M″ against frequency: the RP at 200 °C is at 15 kHz with corresponding relaxation time of 10.62 µs; the RP at 300 °C shifts to 232 kHz with relaxation time of 0.69 µs; the RP at 400 °C, 500 °C, and 600 °C are at 15 kHz, 15 kHz, and 24.90 kHz with relaxation time of 10.62 µs, 10.62 µs, and 6.39 µs; the RPs at Impedance (Z″) curves are at: 3.89 kHz, 5.64 kHz, 3.89 kHz, 4.76 kHz, and 10 kHz with relaxation times of 40.94 µs, 28.25 µs, 40.94 µs, 33.45 µs, and 15.92 µs respectively. These findings show that the relaxation periods depend on both the annealing temperature and the kind of measurement used. The extracted relaxation times reveal significant information about the dielectric and electrical characteristics of the material, which are crucial in enhancing its performance in diverse technological applications85,86,87.

Figure 13 of Cole-Cole plots illustrates how a similar circuit composed of parallel R and C might reflect the grain at high f and the grain boundary at low f. Plots all display dispersion as opposed to the central semicircle on the real axis required for non-Debye relaxation, indicating that the speeds at which the dipole moments relax vary88. Two successive semicircles were formed between 200 and 500 °C, indicating that the f-range in use is trying to separate the conductivity of grains from their borders. In contrast, two successive semicircles can be represented by a series combination of two parallel RC circuits. As Tann rose to 600 oC, the semicircle was stretched by straight lines with a positive slope, indicating more conductivity, which could aid in grain boundary transport for grain growth. However, as Table 4 illustrates, the impedances Z\(g) and Z\(gb) were determined using the radius of the semicircle. They were reduced by raising Tann to 300 oC, then increasing it up to 500 oC, and finally reducing it to 600 oC.

The variations of Z\ and Z\\ against f are given in terms of the effective capacitance (Ceff) and series resistance (RB)89;

The values of RB and Ceff were obtained from the linear plot between [1/Z\(ω)] and (ω2) (see Table 4). While Z\ of grains and grain boundaries behaves similarly to RB, Ceff behaves differently, indicating that [(Z\ α 1/Ceff and Z\ α (1/RB)]90. The annealing temperature (Tann) has a considerable influence on the effective capacitance (Ceff) and residual dielectric constant (εL) of the studied nanocomposites. Ceff is highly dependent on grain structure, defect density, and interfacial properties. At 300 °C, a large number of oxygen vacancies (Ov) are generated in the materials, forming barrier layers at the grain boundary, increasing resistance, and affecting capacitance. This phenomenon is corroborated in the relaxation peaks (RPs) in the M″ and impedance Z″ plots. The peak occurs at Tann = 300 °C for 232 kHz as seen in M″ plot, suggesting considerable energy loss and capacitor picture. At temperatures beyond 300 °C, grain growth and structural changes result in reduced avalanches of defects that also change the interfacial properties, which leads to lowered RPs and effective capacitance. PZ and SA values essentially control micro-capacitor deformation, which is responsible for the annealing-induced increase in Ceff. It’s interesting to notice that Li-ion batteries that perform well in oxidation and reduction reactions have lower RB and Ceff values91. Conversely, a supercapacitor should have a higher Ceff and a smaller RB in order to limit the energy lost in the RB92. These findings strongly imply that an annealed composite between 200 and 400 °C is convenient for a supercapacitor.

The dielectric constant at high f utilizing the Clausius-Mossotti relation (C-M) could be utilized to derive the electronic polarizability αe as follows93:

By raising Tann to 300 oC, the values of αe given in Table 4 are first reduced and subsequently increased.

Compared to greater levels of A and SA, the properties of such composites increase between 200 and 400 °C were associated with lower values of d and Eg. The question now is why such properties are slightly diminished by annealing at 500–600 °C. This means that annealing above 400 °C may affect the OV and reduce its user efficiency. Therefore, Cd0.40Mn0.60ZnO2 composite can be used in solar cells, supercapacitors, integrated microwave circuits, water purification, and white light-emitting diodes (LEDs) when it is annealed between 200 and 400 oC. In contrast, high-frequency, nonlinear, photonic, high-power applications require composites that are annealed above 500 °C.

The D, PZ, and Eg of the Cd0.40Ni0.60ZnO2 composite that was annealed at 400 oC are roughly 24.89 nm, 20.70 nm, and 2.25 eV52. While the current values for Cd0.40Mn0.60ZnO2 composite are 21.98 nm, 8.47 nm, and 1.55 eV. This is logically due to the different structural compositions between them since the Cd2Mn3O8 phase has replaced the CdO phase. For more clarification, Fig. 14a–i compares the current composite with those published for the Cd0.40Ni0.60ZnO251,52. The values of η%, Z/, RB, Wm, and saturated magnetization (Ms) are found to be higher than those of Mn-series; however, this is not the case for SA, Eg, (N/m*), εL, Ceff, and f (RPs). It can be inferred that the parent parameter behaviors and the D, PZ, and d outcomes (see Fig. 14a) have inverse relationships, whereas for the latter, the opposite is true. As also reported for a comparable composite, these results demonstrated that the parameters that are achieved are essentially controlled by the internal structure of the composite94.

Conclusion

The structural, optical, photocatalytic, and dielectric properties of Cd0.40Ni0.60ZnO2 nanocomposites have been extensively studied as a function of the annealing temperature (Tann). Optimised performance (SA: 22.84 m²/g, η: 81.15%, k: 2 × 10⁻⁴ s⁻¹) was obtained when the material was annealed at 400 °C. Furthermore, it had a reduced bandgap (Eg) of 1.55 eV, making it highly effective for use in solar energy harvesting and water purification applications. The composite showed greatest values of absorbance (A), dielectric loss (tan δ), carrier density (N/m), dielectric constant (ε′), AC conductivity (σac), fill factor (F-factor) and effective capacitance (Ceff) at 300 °C, indicating its application in supercapacitors and telecommunication devices. In addition, the dielectric properties manifested by average energies Eo and Ed of 10.58 eV and 23.33 eV with relaxation times of 82.71 µs (from tan δ plot), 0.69–10.62 µs (from M″ plot), and 15.92–40.94 µs (from Z″ plot) after annealing at 500 °C are greatly suitable for high-frequency and nonlinear optical device applications. The unique behavior of defect density (D), polarizability (PZ), and grain size (d) make Cd0.40Ni0.60ZnO2 superior for tunability and performance in various applications. Future studies will target doping concentration optimization, hybrid nanocomposite evaluation, process upscaling for industrial applications in sectors such as energy storage, optoelectronics, and environmental remediation.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Kalpanadevi, K., Sinduja, C. R. & Manimekalai, R. Characterisation of Zinc Oxide and Cadmium Oxide Nanostructures Obtained from the Low Temperature Thermal Decomposition of Inorganic Precursors, ISRN Inorg. Chem. (2013). (2013) https://doi.org/10.1155/2013/823040

Dippong, T., Levei, E. A. & Cadar, O. Formation, structure and magnetic properties of mfe2 o4 @sio2 (M = co, Mn, Zn, Ni, cu) nanocomposites. Mater. (Basel). 14 https://doi.org/10.3390/ma14051139 (2021).

Yang, Y., Xu, D., Wu, Q. & Diao, P. Cu2O/CuO bilayered composite as a high-efficiency photocathode for photoelectrochemical hydrogen evolution reaction. Sci. Rep. 6 https://doi.org/10.1038/srep35158 (2016).

Barvinschi, P., Stefanescu, O., Dippong, T., Sorescu, S. & Stefanescu, M. CoFe2O4/SiO2 nanocomposites by thermal decomposition of some complex combinations embedded in hybrid silica gels. J. Therm. Anal. Calorim. https://doi.org/10.1007/s10973-012-2704-9 (2013).

Masjedi-Arani, M. & Salavati-Niasari, M. A simple solid-state approach for synthesis and characterization of CdO–ZrO2–CdZrO3 nanocomposites. J. Mater. Sci. Mater. Electron. 26 https://doi.org/10.1007/s10854-015-2686-z (2015).

Sharma, A. K. et al. The selective ethanol gas sensing performance of CdO1 – XZnOX nanocomposite. J. Mater. Sci. Mater. Electron. 28 https://doi.org/10.1007/s10854-016-5984-1 (2017).

Anitha, S. et al. Synthesis and characterization of NiO-CdO composite materials towards photoconductive and antibacterial applications. Mater. Chem. Phys. 211 https://doi.org/10.1016/j.matchemphys.2018.01.048 (2018).

Mohamed, M., Sedky, A. & Kassem, M. A. Gradual growth of ZnO nanoparticles from globules-like to nanorods-like shapes: effect of annealing temperature. Optik (Stuttg). 265, 169559. https://doi.org/10.1016/j.ijleo.2022.169559 (2022).

Sedky, A., El-Brolossy, T. A. & Mohamed, S. B. Correlation between sintering temperature and properties of ZnO ceramic varistors. J. Phys. Chem. Solids. 73, 505–510. https://doi.org/10.1016/j.jpcs.2011.11.035 (2012).

Senthilkumar, N. et al. Two step synthesis of ZnO/Ag and ZnO/Au core/shell nanocomposites: structural, optical and electrical property analysis. J. Alloys Compd. 750, 171–181. https://doi.org/10.1016/j.jallcom.2018.03.348 (2018).

Jiang, H. L., Akita, T., Ishida, T., Haruta, M. & Xu, Q. Synergistic catalysis of Au@Ag core-shell nanoparticles stabilized on metal-organic framework. J. Am. Chem. Soc. 133 https://doi.org/10.1021/ja1099006 (2011).

Douvalis, A. P. et al. A facile synthetic route toward air-stable magnetic nanoalloys with Fe-Ni/Fe-Co core and iron oxide shell. J. Nanoparticle Res. 14 https://doi.org/10.1007/s11051-012-1130-z (2012).

Pung, S. Y., Chan, Y. L., Sreekantan, S. & Yeoh, F. Y. Photocatalytic activity of ZnO-MnO2 core shell nanocomposite in degradation of RhB dye. Pigment Resin Technol. 45 https://doi.org/10.1108/PRT-08-2015-0082 (2016).

Mohamed, M., Jayiz, M., Alshammari, A. S., Sedky, A. & Khan, Z. R. Comparative study on structural, morphological, optical and photocatalytic properties of Mn3O4/ZnO, CuO/ZnO and Fe2O3/ZnO nanocomposites, opt. Quantum Electron. 55 https://doi.org/10.1007/s11082-023-04858-x (2023).

Mohamed, M., Sedky, A., Alshammari, A. S. & Gandouzi, M. Optical, photoluminescence and ferromagnetic properties of Ni-doped ZnO for optoelectronic applications. J. Mater. Sci. Mater. Electron. 32, 5186–5198. https://doi.org/10.1007/s10854-021-05250-9 (2021).

Zhao, J. et al. Energy-efficient fabrication of a novel multivalence Mn3O4–MnO2 heterojunction for dye degradation under visible light irradiation. Appl. Catal. B. 202, 509–517 (2017).

Wang, G. et al. Valence state heterojunction Mn3O4/MnCO3: photo and thermal synergistic catalyst. Appl. Catal. B. 180, 6–12 (2016).

Ghigna, P. et al. Synthesis, stoichiometry, and electrical transport properties of (Cd1 – xMnx)Mn2O4. J. Solid State Chem. 153 (2), 231–236 (2000).

Sedky, A., Afify, N., Abbas, A. & Abd-Elrahim, A. G. Cooperative effects due to Zn–Sn replacement by Co-ions on the optical and magnetic properties of (ZnSn)1- xCoxO nanocomposites. Mater. Chem. Phys. 313, 128776. https://doi.org/10.1016/j.matchemphys.2023.128776 (2024).

Mohamed, M. et al. Structural, morphological, optical, photocatalytic activity investigations of Bi doped ZnO nanoparticles. Opt. Mater. (Amst). 136. https://doi.org/10.1016/j.optmat.2022.113347 (2023).

Sedky, A., Ali, A. M., Somaily, H. H. & Algarni, H. Electrical, photoluminescence and optical investigation of ZnO nanoparticles sintered at different temperatures. Opt. Quantum Electron. 53 https://doi.org/10.1007/s11082-021-02849-4 (2021).

Abd-Elrahim, A. G., Sedky, A., Afify, N. & Abbas, A. The effect of composition on the structure, optical, and room-temperature ferromagnetic properties of hydrothermally synthesized (ZnSn)1-xCuxO nanocomposites. Phys. B Condens. Matter. 674, 415568. https://doi.org/10.1016/j.physb.2023.415568 (2024).

Nouha Mastour, K., Ramachandran, S., Ridene, K., Daoudi & Gaidi, M. Tailoring the optical band gap of In–Sn–Zn–O (ITZO) nanostructures with co-doping process on ZnO crystal system: an experimental and theoretical validation. Eur. Phys. J. Plus. 137, 1137. https://doi.org/10.1140/epjp/s13360-022-03351-w (2022).

Jahura, F. T., Mazumder, N. U. S., Hossain, M. T., Kasebi, A. & Girase, A. Bryan Ormond exploring the prospects and challenges of Fluorine-Free firefighting foams (F3) as alternatives to aqueous Film-Forming foams (AFFF): A review. ACS Omega. 9, 37430–37444. https://doi.org/10.1021/acsomega.4c03673 (2024).

Ghori, M. Z. et al. A comparative study of photocatalysis on highly active columnar TiO2 nanostructures in-air and in-solution. Sol Energy Mater. Sol Cells. 178, 170–178. https://doi.org/10.1016/j.solmat.2018.01.019 (2018).

Anju Chanu, L., Joychandra Singh, W., Jugeshwar Singh, K., Nomita, K. & Devi Effect of operational parameters on the photocatalytic degradation of methylene blue dye solution using manganese doped ZnO nanoparticles. Results Phys. 12 https://doi.org/10.1016/j.rinp.2018.12.089 (2019).

Hassan, N., Shahat, A., El-Didamony, A., El-Desouky, M. G. & El-Bindary, A. A. Synthesis and characterization of ZnO nanoparticles via zeolitic imidazolate framework-8 and its application for removal of dyes. J. Mol. Struct. 1210, 128029. https://doi.org/10.1016/j.molstruc.2020.128029 (2020).

Ding, J. et al. Aerosol assisted chemical vapour deposition of nanostructured ZnO thin films for NO2 and ethanol monitoring. Ceram. Int. 46 https://doi.org/10.1016/j.ceramint.2020.03.051 (2020).

Wang, N., Cheng, L., Liao, Y. & Xiang, Q. Effect of functional group modifications on the photocatalytic performance of g-C3N4. Small 19 https://doi.org/10.1002/smll.202300109 (2023).

Li, F. et al. Understanding the unique S-scheme charge migration in triazine/heptazine crystalline carbon nitride homojunction. Nat. Commun. 14 https://doi.org/10.1038/s41467-023-39578-z (2023).

Chidhambaram, N. & Ravichandran, K. Fabrication of ZnO/g-C3N4 nanocomposites for enhanced visible light driven photocatalytic activity. Mater. Res. Express. 4 https://doi.org/10.1088/2053-1591/aa7abd (2017).

Sedky, A., Ali, A. M. & Algarni, H. Structural, FTIR, optical and dielectric properties of Zn1-xAlxO ceramics for advanced applications. Opt. Quantum Electron. 54 https://doi.org/10.1007/s11082-022-03769-7 (2022).

Saadi, H. et al. Electrical conductivity improvement of Fe doped ZnO nanopowders. Mater. Res. Bull. 129 https://doi.org/10.1016/j.materresbull.2020.110884 (2020).

Sedky, A. et al. Structural, optical, and dielectric properties of M/SnO2 (M = Al2O3, NiO, Mn3O4) nanocomposites, Ceram. Int 50, 3409–3421. https://doi.org/10.1016/j.ceramint.2023.11.088 (2024).

Sedky, A., Afify, N., Ali, A. M. & Algarni, H. On the dielectric behaviors of Zn1 – x–yFexMyO ceramics for nonlinear optical and solar cell devices. Appl. Phys. Mater. Sci. Process. 128 https://doi.org/10.1007/s00339-022-05260-2 (2022).

Singh, S., Dey, P., Roy, J. N. & Mandal, S. K. Tunable dielectric constant with transition metals doping in Zn1-x(MnTM)xO (TM = Co, Fe) nanocrystals. J. Alloys Compd. 642. (2015).

Zamiri, R., Kaushal, A., Rebelo, A. & Ferreira, J. M. F. Er doped ZnO nanoplates: synthesis, optical and dielectric properties. Ceram. Int. 40 https://doi.org/10.1016/j.ceramint.2013.07.054 (2014).

Irshad, K., Khan, M. T. & Murtaza, A. Synthesis and characterization of transition-metals-doped ZnO nanoparticles by sol-gel auto-combustion method. Phys. B Condens. Matter. 543. https://doi.org/10.1016/j.physb.2018.05.006 (2018).

Singh, J. & Singh, R. C. Structural, optical, dielectric and transport properties of ball mill synthesized ZnO–V2O5 nano-composites. J. Mol. Struct. 1215 https://doi.org/10.1016/j.molstruc.2020.128261 (2020).

Acharya, A. D. & Sarwan, B. Tunability of electronic properties and magnetic behaviour of nickel oxide: A review. Curr. Nanosci. 15 https://doi.org/10.2174/1573413714666180820124910 (2018).

Sedky, A., Afify, N., Hakamy, A. & Abd-Elnaiem, A. M. Structural, optical, and dielectric properties of hydrothermally synthesized SnO2 nanoparticles, Cu/SnO2, and Fe/SnO2 nanocomposites. Phys. Scr. 98, 125929. https://doi.org/10.1088/1402-4896/ad081a (2023).

Parveen, A., Ahmad, S. A., Agrawal, S. & Azam, A. Room temperature variation in dielectric and electrical properties of Mn doped SnO2 nanoparticles, in: Mater. Today Proc., (2017). https://doi.org/10.1016/j.matpr.2017.06.198

Ahmed, A., Tripathi, P., Naseem Siddique, M. & Ali, T. Microstructural, optical and dielectric properties of Al-Incorporated SnO2 nanoparticles, IOP Conf. Ser. Mater. Sci. Eng. 225, 012173. https://doi.org/10.1088/1757-899x/225/1/012173 (2017).

[44], S., Muy, R., Schlem, Y., Shao-Horn, W. G. & Zeier Phonon–Ion interactions: designing ion mobility based on lattice dynamics. Adv. Energy Mater. 11 https://doi.org/10.1002/aenm.202002787 (2021).

Gupta, R. et al. Advances in micro and nano-engineered materials for high-value capacitors for miniaturized electronics. J. Energy Storage. 55 https://doi.org/10.1016/j.est.2022.105591 (2022).

Ben Taher, Y., Oueslati, A., Maaloul, N. K., Khirouni, K. & Gargouri, M. Conductivity study and correlated barrier hopping (CBH) conduction mechanism in diphosphate compound. Appl. Phys. Mater. Sci. Process. 120 https://doi.org/10.1007/s00339-015-9353-3 (2015).

Singh, J. & Singh, R. C. Structural, optical, dielectric and transport properties of ball mill synthesized ZnO–V2O5 nano-composites. J. Mol. Struct. 1215 https://doi.org/10.1016/j.molstruc.2020.128261 (2020).

Belkhaoui, C., Mzabi, N., Smaoui, H. & Daniel, P. Enhancing the structural, optical and electrical properties of ZnO nanopowders through (Al + Mn) doping. Results Phys. 12 https://doi.org/10.1016/j.rinp.2019.01.085 (2019).

Sedky, A. et al. Enhancement of mechanical and ferromagnetic properties of Cd0.4Mn0.6XO nanocomposites (X = ZnO, SnO, CuO, Al2O3, Fe2O3, CoO, NiO). Mater. Sci. Engineering: B. 310 https://doi.org/10.1016/j.mseb.2024.117737 (2024).

Abbady, G., Afify, N., Sedky, A. & Hamad, D. Effect of annealing temperature on structural, optical and magnetic properties of Cd1-xMnxZnO2 nanocomposites: an investigation for ferromagnetic. Ceram. Int. 49 https://doi.org/10.1016/j.ceramint.2023.02.172 (2023).

Sedky, A. et al. Annealing temperature effect on structural, mechanical, and magnetic properties of Cd0.40M0.60ZnO2 (M = Mn, Ni) nanocomposites. Mater. Chem. Phys. 309 (2023).

Naglaa, A., Al & et. An investigation for optical, photocatalytic, photoluminescence and dielectric properties of Cd0.40Mn0.60ZnO2 annealed nanocomposites. J. Alloys Compd. 990, 174432 (2024).

El-Fadl, A. A. et al. Syntheses of new spinels Zn1 – xFexAl2O4 nanocrystallines structure: Optical and magnetic characteristics. J. Alloys Compd. 795, 114–119 (2019).

Younis, N., Abd-Elrahman, M., Afify, N., Abu El-Fadl, A. & Abu-Sehly, A. Structural, optical and magnetic characterizations of nanoparticles spinel Zn(1–x)MxAl2O4 (M = Co and Ni) synthesized by microwave combustion method. Mater. Sci. Engineering: B. 271, 115316 (2021).

Ariga, K., Vinu, A., Yamauchi, Y., Ji, Q. & Hill, J. P. Nanoarchitectonics for mesoporous materials. Bull. Chem. Soc. Jpn. 85. https://doi.org/10.1246/bcsj.20110162 (2012).

Saeid, Y. A. & Ateia, E. E. Efficient removal of Pb (II) from water solution using CaFe2 – x–yGdxSmyO4 ferrite nanoparticles. Appl. Phys. Mater. Sci. Process. 128 https://doi.org/10.1007/s00339-022-05718-3 (2022).

Cazetta, A. L. et al. Synthesis and application of N-S-doped mesoporous carbon obtained from Nanocasting method using bone Char as heteroatom precursor and template. Chem. Eng. J. 300. https://doi.org/10.1016/j.cej.2016.04.124 (2016).

Muthreja, I. L., Agarwal, A. K., Kadu, M. S. & Pandhurnekar, C. P. Adsorption and kinetic behavior of fly Ash used for the removal of lead from an aqueous solution. J. Chem. Technol. Metall. 52 (2017).

Tauc, J., Grigorovici, R. & Vancu, A. Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi. https://doi.org/10.1002/pssb.19660150224 (1966).

Frederichi, D., Scaliante, M. H. N. O. & Bergamasco, R. Structured photocatalytic systems: photocatalytic coatings on low-cost structures for treatment of water contaminated with micropollutants—a short review. Environ. Sci. Pollut Res. 28, 23610–23633. https://doi.org/10.1007/s11356-020-10022-9 (2021).

El Mesoudy, A. et al. Band gap narrowing induced by oxygen vacancies in reactively sputtered TiO2 thin films. Thin Solid Films. 769, 139737. https://doi.org/10.1016/j.tsf.2023.139737 (2023).

Khan, R. et al. Effect of Sn-doping on the structural, optical, dielectric and magnetic properties of ZnO nanoparticles for spintronics applications. J. Mater. Sci. Mater. Electron. 32 https://doi.org/10.1007/s10854-021-06675-y (2021).

Modwi, A., Ghanem, M. A., Al-Mayouf, A. M. & Houas, A. Lowering energy band gap and enhancing photocatalytic properties of Cu/ZnO composite decorated by transition metals. J. Mol. Struct. https://doi.org/10.1016/j.molstruc.2018.06.082 (2018).

[64], A., Sedky, A. M., Ali, H. H., Somaily & Algarni, H. Electrical, photoluminescence and optical investigation of ZnO nanoparticles sintered at different temperatures. Opt. Quant. Electron. 55, 243 (2021).

[65], E., Davis & Mott, N. Conduction in non-crystalline systems V. Conductivity, optical absorption and photoconductivity in amorphous semiconductors. Phil. Mag. 22, 0903–0922 (1970).

Sedky, A., Afify, N., Almohammedi, A., Ibrahim, E. & Ali, A. M. Structural, optical, photoluminescence and magnetic investigation of doped and Co-doped ZnO nanoparticles. Opt. Quant. Electron. 55, 5 (2023).

Sedky, A., Ali, A. M. & Algarni, H. Structural, FTIR, optical and magnetic investigation of Zn1 – xMxO ceramics with m = cu, Mn: comparative study. J. Alloys Compd. 912, 165139 (2022).

Singh, P. & Kumar, R. Investigation of refractive index dispersion parameters of Er doped ZnO thin films by WDD model. Optik 246, 167829 (2021).

Yang, W. J. et al. The structure and photocatalytic activity of TiO2 thin films deposited by Dc Magnetron sputtering. Superlattices Microstruct. 52, 1131–1142. https://doi.org/10.1016/j.spmi.2012.08.013 (2012).

Wang, L. et al. S-scheme MOF-on-MOF heterojunctions for enhanced photo-Fenton Cr(VI) reduction and antibacterial effects. Chemosphere 344, 140277. https://doi.org/https://doi.org/10.1016/j (2023).

Du, H. et al. Plasmonic ag modified ag3VO4/AgPMo S-scheme heterojunction photocatalyst for boosted Cr(VI) reduction under visible light: performance and mechanism. Sep. Purif. Technol. 304. https://doi.org/10.1016/j.seppur.2022.122204 (2023).

Toporovska, L. R. et al. Photocatalytic properties of zinc oxide nanorods grown by different methods. Opt. Quantum Electron. 49, 408. https://doi.org/10.1007/s11082-017-1254-6 (2017).

Zamiri, R. et al. Influence of Mg doping on dielectric and optical properties of ZnO nano-plates prepared by wet chemical method. Solid State Commun. 195 https://doi.org/10.1016/j.ssc.2014.07.011 (2014).

Cole, R. H. Theory of dielectric constant and dielectric loss. J. Am. Chem. Soc. 80 https://doi.org/10.1021/ja01551a071 (1958).

Ojha, S. K., Purkait, P., Chatterjee, B. & Chakravorti, S. Application of Cole-Cole model to transformer oil-paper insulation considering distributed dielectric relaxation. High. Volt. 4 https://doi.org/10.1049/hve.2018.5079 (2019).

Krishna Reddy, G., Jagannatha Reddy, A., Hari Krishna, R., Nagabhushana, B. M. & Gopal, G. R. Luminescence and spectroscopic investigations on Gd 3 + doped ZnO nanophosphor. J. Asian Ceram. Soc. 5, 350–356. https://doi.org/10.1016/j.jascer.2017.06.008 (2017).

Van Dijken, A., Makkinje, J. & Meijerink, A. The influence of particle size on the luminescence quantum efficiency of nanocrystalline ZnO particles. J. Lumin. 92 https://doi.org/10.1016/S0022-2313(00)00262-3 (2001).

Mehedi Hassan, M., Khan, W., Azam, A. & Naqvi, A. H. Influence of cr incorporation on structural, dielectric and optical properties of ZnO nanoparticles. J. Ind. Eng. Chem. 21 https://doi.org/10.1016/j.jiec.2014.01.047 (2015).

Mututu, V., Sunitha, A. K., Thomas, R., Pandey, M. & Manoj, B. An investigation on structural, electrical and optical properties of GO/ZnO nanocomposite. Int. J. Electrochem. Sci. 14, 3752–3763. https://doi.org/10.20964/2019.04.49 (2019).

Farheen, A. & Parveen Dielectric and electrochemical analysis of graphene nanosheets and tin oxide nanocyrstals explored as electrode material in pseudocapacitor, in: AIP Conf. Proc., (2020). https://doi.org/10.1063/5.0001688

Eroǧlu, A., Tataroǧlu, A. & Altindal, Ş. On the temperature dependent dielectric properties, conductivity and resistivity of MIS structures at 1 mhz. Microelectron. Eng. 91 https://doi.org/10.1016/j.mee.2011.07.016 (2012).

Joshi, J. H., Kanchan, D. K., Joshi, M. J., Jethva, H. O. & Parikh, K. D. Dielectric relaxation, complex impedance and modulus spectroscopic studies of mix phase rod like Cobalt sulfide nanoparticles. Mater. Res. Bull. 93 https://doi.org/10.1016/j.materresbull.2017.04.013 (2017).

Sinclair, D. C. & West, A. R. Impedance and modulus spectroscopy of semiconducting BaTiO3 showing positive temperature coefficient of resistance. J. Appl. Phys. 66, 3850–3857. https://doi.org/10.1063/1.344049 (1989).

Singh, K. N. & Bajpai, P. K. Dielectric relaxation in pure columbite phase of SrNb2O6 ceramic material: impedance analysis. World J. Condens. Matter Phys. 1, 37–48. https://doi.org/10.4236/wjcmp.2011.12007 (2011).

Raymond, O., Font, R., Portelles, J., Suárez-Almodovar, N. & Siqueiros, J. M. Frequency-temperature response of ferroelectromagnetic Pb(Fe 1/2Nb1/2)O3 ceramics obtained by different precursors. III. Dielectric relaxation near the transition temperature. J. Appl. Phys. 99 https://doi.org/10.1063/1.2201853 (2006).

Dielectrics in electric fields. Chem. Eng. News 34 https://doi.org/10.1021/cen-v034n020.p2370. (1956).

Ojha, S. K., Purkait, P. & Chakravorti, S. Modeling of relaxation phenomena in transformer oil-paper insulation for Understanding dielectric response measurements. IEEE Trans. Dielectr. Electr. Insul. 23 https://doi.org/10.1109/TDEI.2016.7736885 (2016).

Dzhioev, R. I. et al. Low-temperature spin relaxation in n-type GaAs. Phys. Rev. B - Condens. Matter Mater. Phys. 66 https://doi.org/10.1103/PhysRevB.66.245204 (2002).

Yakushiji, K. et al. Enhanced spin accumulation and novel magnetotransport in nanoparticles. Nat. Mater. 4 https://doi.org/10.1038/nmat1278 (2005).

Ramesh Babu, N. C. et al. Low temperature dielectric dispersion and electrical conductivity studies on Fe2O3 mixed lithium yttrium silicate glasses. J. Non Cryst. Solids. 358, 3175–3186. https://doi.org/10.1016/j.jnoncrysol.2012.09.011 (2012).

Sedky, A., Afify, N., Almohammedi, A., Ibrahim, E. M. M. & Ali, A. M. Structural, optical, photoluminescence and magnetic investigation of doped and Co-doped ZnO nanoparticles. Opt. Quantum Electron. 55 https://doi.org/10.1007/s11082-023-04718-8 (2023).

Mahapatra, T., Halder, S., Bhuyan, S. & Choudhary, R. N. P. Dielectric and electrical characterization of lead-free complex electronic ceramic: (Bi1/2Li1/2)(Zn1/2W1/2)O3. J. Mater. Sci. Mater. Electron. 29 https://doi.org/10.1007/s10854-018-9998-8 (2018).

Nasrallah, D. A., El-Metwally, E. G. & Ismail, A. M. Structural, thermal, and dielectric properties of porous PVDF/Li4Ti5O12 nanocomposite membranes for high-power lithium-polymer batteries. Polym. Adv. Technol. 32 https://doi.org/10.1002/pat.5171 (2021).

Yuan, R., Dong, Y., Hou, R., Zhang, S. & Song, H. Review—Influencing factors and suppressing strategies of the Self-Discharge for carbon electrode materials in supercapacitors. J. Electrochem. Soc. 169 https://doi.org/10.1149/1945-7111/ac56a1 (2022).

Author information

Authors and Affiliations

Contributions

The photocatalytic measurement and analysis, XRD and TEM analysis, and first draft of the article were done Mansour Mohamed; A. Sedky is responsible for the investigated problem, optical and dielectric measurements, and the final copy of the article submission; Abdullah F. Al-Naim is responsible for analyzing the optical data; Abdullah Almohammedi is responsible for analyzing the dielectric data; and N. Afify is responsible for sample synthesis and surface area measurements. All authors have read and reviewed the manuscriptand, and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

The present manuscript is original work and has never been under evaluation for any other journal.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Mohamed, M., Sedky, A., Al-Naim, A.F. et al. Comprehensive study of optical, photocatalytic and dielectric properties of Cd0.40Mn0.60ZnO2 annealed nanocomposites. Sci Rep 15, 15524 (2025). https://doi.org/10.1038/s41598-025-97449-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-97449-7