Abstract

α-Sn and SnGe alloys are attracting attention as a new family of topological quantum materials. However, bulk α-Sn is thermodynamically stable only below 13∘C. Moreover, scalable integration of α-Sn quantum materials and devices on silicon is hindered by their large lattice mismatch. Here, we grow compressively strained α-Sn doped with 2-4 at.% germanium on a native oxide layer on a silicon substrate at 300–500∘C. Growth is found to occur by a reversed β-Sn to α-Sn phase transformation without relying on epitaxy, with germanium-rich GeSn nanoclusters in the as-deposited material acting as seeds. The size of α-Sn microdots reaches up to 200 nm, which is approximately ten times larger than the upper size limit for α-Sn formation reported previously. Furthermore, the compressive strain makes it a candidate 3D topological Dirac semimetal with possible applications in spintronics. This process can be further optimized to achieve optically tunable SnGe quantum material and device integration on silicon.

Similar content being viewed by others

Introduction

The phase transformation from ductile metallic β-Sn to brittle α-Sn1 at low temperatures (<13 °C)2 has long been known as “tin pest” or “tin plaque” in early literature. Legends of this transformation range from the crumbled tin buttons of Napoleon’s Grande Armée in Russia3 to the leaky tin cans of Robert Scott’s Antarctica expedition4. In the 21st century, the old “pest” has made a “quantum leap” in that α-Sn has been identified as a very interesting topological quantum material5. Relaxed or compressively strained α-Sn is a topological Dirac semimetal (TDS)5, a 3D counterpart of graphene with the Dirac cone protected by crystal symmetry and spin-orbit coupling. Recently, topological surface states in α-Sn TDS has been utilized to demonstrate current-induced magnetization switching and damping enhancement for spintronics6,7. Under a moderate tensile strain of 0.7%, on the other hand, α-Sn turns into a topological insulator (TI) with a topological gap of ~50 meV. Recently, theory has predicted that SnGe alloys with >40% Sn composition can be a TDS under compressive strain8. If verified experimentally, this wide range of SnGe alloys could greatly enrich the family of 3D TDS since only a few of them have been discovered so far5,9,10. They are also naturally compatible with Si-based integrated circuits as Group IV alloys.

However, integrating α-Sn and SnGe quantum materials on Si poses a significant challenge. Limited by lattice matching for hetero-epitaxy, so far most of the α-Sn thin films have been grown on InSb instead of Si because the latter has a large lattice mismatch of ~ 20%. Ge-rich GeSn alloys on Si have been extensively explored in optoelectronics community11,12,13,14, but high Sn composition SnGe alloys have been rarely studied experimentally since they are well beyond the solubility limit2. Note that throughout this paper we will use “SnGe” to represent Sn-rich alloys while “GeSn” for Ge-rich alloys. Furthermore, the thermal stability is also limited by the phase transition to β-Sn at elevated temperatures. For example, the thickness of α-Sn grown on Si is limited to ~6 nm at room-temperature before it transforms completely to β-Sn6,7. Since the transition between TI and TDS of α-Sn is thickness dependent with the borderline ranging from 8 to 40 nm depending on strain15,16, such a limited thickness makes it hard to control the exact topological quantum state of the material. Therefore, it would be ideal to find a solution to grow thermally stable α-Sn and SnGe in a relatively large thickness range for well-controlled topological quantum material integration on Si substrates.

To obtain metastable α-Sn, most previous literature adopted the strategy of low-temperature growth and introduced different mechanisms to retard its transition to β-Sn at elevated temperatures. For example, previous studies have shown that impurities could help stabilize α-Sn at elevated temperatures. α-Sn containing 0.75 wt.% Ge or 0.6 wt.% Si were observed to be stable at 60 °C or 90 °C, respectively17,18. Impurities could also affect the β → α-Sn transition at low temperatures19,20,21,22,23,24,25, but previous studies on the effect of Ge gave inconsistent observations. One work showed that Ge could act as secondary nuclei for α-Sn and help the preparation of compact α-Sn specimens from β-Sn26. Other studies showed that impurities such as Ge and Si inhibit the β → α-Sn transition at low temperatures27,28. Hetero-epitaxy on lattice-matched substrates is another approach to stablize α-Sn. For example, epitaxial α-Sn thin films grown on InSb could be stable above room temperature up to ~180 °C, yet the thickness is limited to 8 nm29,30,31. It was thought that the epitaxial interface helps to stabilize α-Sn, and the α → β-Sn transition temperature depends on the thickness of the film: the thicker the film, the lower the α → β-Sn transition temperature. The slight lattice mismatching between α-Sn and InSb leads to an in-plane compressive strain which was thought to enhance the thermal stability of the α-Sn films in some literature7,32,33. However, another study showed that negative pressure, or tensile strain, is required to stabilize α-Sn beyond 13 °C34. Furthermore, some recent studies on Sn nanoparticles have revealed that the stability of α-Sn is size-dependent. The critical size beyond which α → β-Sn transition starts is reported to be 8, 17, and 1.6 nm for Sn nanoparticles fabricated by epitaxy, chemical reduction, and microplasma methods, respectively35,36,37. Overall, none of the previous literature observed any reversed transformation from β-Sn to α-Sn at >13 °C.

Here we report a remarkable finding that α-Sn alloyed with ~2–4 at.% Ge can be grown and stabilized on native oxide layers on Si substrates without hetero-epitaxy from the substrate. The size of α-Sn microdots reaches up to 280 nm, which is ~10x larger than the previously reported critical size mentioned above. Completely unexpected and exactly opposite to the bulk phase diagram, we find that the as-deposited β-Sn reversely transforms into α-Sn upon rapid thermal annealing (RTA) at 300–500 °C, while such transformation does not occur at all at low temperatures, in sharp contrast to pure Sn microdots. Based on detailed microstructure analyses, we propose that the Ge-rich GeSn nanoclusters in the as-deposited materials have served as the seeds for α-Sn nucleation and growth at elevated temperatures. To the best of our knowledge, this work is the first demonstration of compressively strained α-SnGe grown at >300 °C without epitaxial interface stabilization towards 3D TDS integration on Si. The TDS Sn microdots could potentially be coupled through graphene or quantum dots towards quantum device applications38,39,40. They also demonstrated optical absorption at ~1250–1750 nm wavelength, which may enable quantum state switching by optical excitation41 at 1310–1550 nm telecommunication wavelengths, potentially through integration with silicon photonics. This reversed β → α-Sn phase transition can potentially be scaled up using selective epitaxy process for quantum device integration on Si.

Results

Fabrication and surface morphology

We first start with a description of the fabrication process. Nominally, 50 nm-thick SnGe thin films containing ~5 at.% Ge are deposited on single-side polished Si(001) substrates by co-evaporating Sn and Ge using a physical vapor deposition (PVD) system. There is a thin layer of native oxide (~10 nm) on the surface of the Si substrate, as will be detailed later. Note that the Sn-rich SnGe dewets the surface of the native oxide, hence the 50-nm thickness based on the deposition rate is nominal. After the deposition, the as-deposited SnGe thin films are annealed for 2 min at a variety of temperatures ranging from 300 to 500 °C by a RTA process.

Scanning electron microscope (SEM) images of the SnGe film annealed at 350 °C are shown in Fig. 1a, b. It is clear that the film is not continuous, showing a textured surface with the presence of microdots of different sizes up to ~500 nm in diameter. Figure 1c shows a histogram of the diameters of the dots in Fig. 1a. A two-peak (bimodal) Gaussian fit is applied to the histogram, giving the average diameter of the small nanodots and large microdots to be 34 nm and 223 nm, respectively. The bimodal distribution indicates Oswald ripening process, i.e. bigger SnGe dots grow at the cost of shrinking smaller dots due to surface energy minimization. Further analysis using energy-dispersive X-ray spectroscopy (EDS) shows that the big microdots contain mostly Sn, while the Ge is more abundant in the gaps between the big microdots or in the small nanodots. An EDS line-scan is shown in Fig. 1d. The EDS result we show here only includes Ge and Sn atoms to avoid the effect of the Si substrate, and their total is normalized to 100 at.%. On average there is 2.1 at.% Ge within the big microdots and 5.9 at.% Ge in the gaps or small nanodots. This observation is also consistent with Oswald ripening since Sn is likely the dominant surface-diffusion species from small nanodots to large microdots due to the low melting point, thereby leading to a higher Sn composition (lower Ge composition) in big microdots.

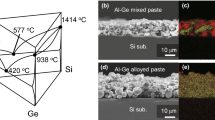

Mechanism of reversed β → α-Sn transformation upon RTA

The transition from β-Sn to α-Sn upon RTA were studied via Raman spectroscopy and X-ray diffraction (XRD). Figure 2a shows the β → α-Sn transition after RTA annealing at 300 °C and at 350 °C for 2 minutes in comparison with the as-deposited sample. Interestingly, in addition to the Sn-Sn vibration mode in β-Sn at 125.6 cm−1,42 the as-deposited sample actually showed characteristic features of Ge-rich GeSn alloys43, with Ge-Ge and Ge-Sn vibration modes clearly visible at 288.2 cm−1 and 250.2 cm−1, respectively. The Ge-Ge and Ge-Sn peaks are both relatively broad, indicating tiny GeSn nanoclusters in the as-deposited samples. Note that the diffraction peaks from nanoclusters are usually too weak to be observed in XRD data. On the other hand, the cross-sectional EDS mapping and high-resolution transmission electron microscopy (HRTEM) analyses in panels c and d clearly revealed these Ge-rich nanoclusters at the microdot/oxide interface of the as-deposited samples. From the Ge-Ge and Ge-Sn Raman peak positions, the average Sn composition in these GeSn nanoclusters is estimated to be ~17 at.%43. This is also supported by the EDS and HRTEM analyses in c and d showing GeSn nanoclusters with ~10–30 at.% Sn. These Ge-rich GeSn nanoclusters are formed spontaneously via Ge-Sn intermixing during the deposition, indicating that the solubility of Sn in Ge in nanostructures may well exceed that of the bulk phase diagram (~1 at.%). After annealing at 300 °C, a peak corresponding to the Sn-Sn vibration mode in α-Sn appears at ~ 195.9 cm−1 in addition to the β-Sn, Ge-Sn and Ge-Ge peaks42,43. Correspondingly, the Ge-Ge peak is blue-shifted, indicating that the Sn composition in the GeSn nanoclusters is decreased significantly upon the formation of α-Sn. This observation strongly suggests that α-Sn is segregated from the GeSn nanoclusters. Annealing at 350 °C further increases the intensity of the α Sn-Sn peak and further blue-shifts the Ge-Ge peak. This is in good agreement with the corresponding XRD data in Fig. 3, which also showed the transition of β to α-Sn starting at 300 °C as well as a better crystallization/larger fraction of α-Sn after RTA at 350 °C. It is important to note that the appearance of α Sn-Sn peak concurs with the blue-shift of the Ge-Ge peak upon RTA. This concurrence indicates that the phase separation of the GeSn nanoclusters upon RTA leads to heterogeneous nucleation of Sn-rich α-SnGe on Ge-rich nanoclusters and initiates β → α-Sn transition at elevated temperatures.

a Raman spectra of as-deposited (blue) and annealed SnGe samples at 300 °C (red) and 350 °C (green) (RTA for 2 min). b Raman spectra of an as-deposited SnGe sample at room temperature (blue) and after cooling to −50 °C for 45 min (red). c EDS mapping of the as-deposited sample, showing Ge-rich nanoclusters at the microdot/oxide interface. d HRTEM image of the as-deposited sample. Several Ge or Ge-rich GeSn nanoclusters are clearly identified, with the (111) interplanar spacing and estimated Sn compositions labeled individually. e Schematic mechanism of β → α-Sn transition upon annealing at elevated temperature. The average Sn composition in GeSn nanoclusters is derived from the Ge-Ge and/or Ge-Sn peak positions in the Raman spectra.

a XRD patterns of as-deposited and annealed SnGe samples. The Si(200) peak from the single crystal substrate is due to multiple diffraction60. b Mass fraction of α-Sn versus annealing temperature.

Based on the experimental data and analyses discussed above, Fig. 2e summarizes the mechanism of β → α-Sn transition. The Ge-rich GeSn nanoclusters in the as-deposited samples initiate the nucleation and growth of α-Sn upon RTA, which leads to the reversed β → α-Sn transition, exactly opposite to the bulk phase diagram. With the increase of RTA temperature from 300 °C to 350 °C, α-Sn grows both vertically and laterally from the Ge-rich GeSn nuclei, extending across the width of the microdots. As will be discussed later, this mechanism is further supported by the HRTEM data showing that each α-Sn region in a microdot is dominated by a single crystal grain, indicating growth from a single nucleus upon β-to-α-Sn transition. Moreover, the volume expansion upon β-to-α-Sn transition also leads to in-plane compressive strain in α-Sn because the microdots’ adhesion to the substrate constrains the lateral expansion. In addition, nucleation and growth from Ge-rich GeSn nuclei (with a smaller lattice constant) further helps to enhance the compressive strain in α-Sn towards a 3D TDS. The strain analyses will be detailed in our XRD and HRTEM data.

Furthermore, contrary to the bulk phase diagram again, we note that the β-to-α-Sn transition no longer occurs at low temperatures when Ge is incorporated. As shown in Fig. 2b, while pure β-Sn readily started to transform into α-Sn at −20 °C (see Supplementary Note 1 and Supplementary Fig. 1), with a few percent Ge incorporation we do not see such a transition any more even after cooling down the sample to −50 °C and waiting for 45 min. Note that the absence of β → α-Sn transition at low temperature and its presence after RTA at 300–500 °C is completely unexpected, given that β-Sn is known to transform into α-Sn at temperatures below 13 °C and α-Sn is rarely observed at above 150 °C even with coherent epitaxial interface to enhance its stability.30,44. Our observation shows that Ge doping enhances β → α-Sn transition at high temperatures while retards it at low temperatures. This result helps to reconcile some seemingly contrary results mentioned earlier.

XRD and strain measurement

The XRD patterns of as-deposited and annealed samples are shown in Fig. 3a to further evaluate the phase transformation upon RTA. In the XRD pattern of the as-deposited sample, all the diffraction peaks are attributed to polycrystalline β-Sn, and no α-Sn peak is observed. Consistent with the Raman data discussed earlier, after RTA at 300–500 °C the XRD patterns clearly show the peaks of α-Sn. Especially, samples annealed at 325–400 °C show relatively strong α-Sn peaks. Zoomed-in XRD patterns are shown in Supplementary Note 2 and Supplementary Fig. 2. Theoretically, the peak intensity ratio of α-Sn and β-Sn Iα/Iβ depends on their mass ratio wα/wβ45

where RIR is the relative intensity ratio. Iα and Iβ could be calculated by an integral of each peak with a range of ± 0.5∘. Then the mass fraction of α-Sn wα/(wα + wβ) is derived from Eq. (1) and shown in Fig. 3b. According to α-Sn (01-071-4637) and β-Sn (98-001-3770) powder diffraction files, the RIR of β-Sn is 10.78 while the RIR of α-Sn is 16.6536. The mass fraction of α-Sn versus annealing temperature shown in Fig. 3(b) indicates that the optimal annealing temperature for β → α-Sn transition is ~325–400 °C. The sample annealed at 375 °C contains more than 50 wt.% α-Sn. The low amount of α-Sn formed at temperature(s) lower than 325 °C and higher than 400 °C indicates that low temperature cannot overcome the activation energy barrier for α-Sn nucleation on Ge-rich nanoclusters, while high temperature degrades its stability.

A further measurement of residual strain in the sample annealed at 325 °C using asymmetric scans of α-Sn(400) peak vs. tilting angle indicates that the in-plane stress is compressive, as detailed in the Supplementary Note 3 and Supplementary Fig. 3. With 95% confidence, the average in-plane strain ϵ∥ = (−0.63 ± 0.44)% across the Sn microdots, and the stress-free lattice constant of α-Sn phase is a0 = 6.4540 ± 0.027 Å. Then using Vegard’s law, we can estimate that the atomic percent of Ge in α-Sn phase is (4.2 ± 3.3) at.%, consistent with the EDS measurement within the error range. The level of Ge composition and compressive strain falls into the category of TDS as predicted theoretically5,8, offering a facile approach for 3D TDS material integration on Si.

HRTEM and four-dimensional scanning transmission electron microscopy (4D-STEM)

To further analyze the α-Sn vs. β-Sn regions in the microdots as well as their interfaces, cross-sectional samples of the SnGe microdots annealed at 325 °C were prepared and analyzed by HRTEM, EDS, and scanning nanobeam diffraction acquired through 4D-STEM. Figure 4a, b show two big microdots, both being α-Sn capped with β-Sn. Figure 4c shows a small β-Sn dot. Our further analysis found that small dots with size up to 50 nm diameter mostly remain in β-Sn phase, suggesting that the critical size for nucleating β → α-Sn transformation might be >50 nm at 325 °C. The contrast between α-Sn and β-Sn regions in the two big microdots (in panels a and b) are also clearly shown in the high-angle annular dark-field (HAADF) STEM images in panels d and g. These two examples indicate that the reversed transformation from β-Sn to α-Sn started at the Sn microdot/oxide interface and grew toward the top surface. The α-Sn phase in both microdots have similar size of ~200-nm-diameter and ~100-nm-thickness. These images also clearly show a native oxide layer between the SnGe microdots and the Si substrate. Therefore, the observed α-Sn formation is completed unrelated to hetero-epitaxy on Si. The EDS analysis in Fig. 4d–i clearly shows Ge-rich regions near the corner of the microdots, which serve as seeds for α-Sn nucleation and growth, as we have indicated earlier in the Raman analyses. The average Ge composition is 1.4-1.8 at.% inside the α-Sn regions of the microdots, while that in β-Sn regions is slightly lower. Figure 4j–l are HRTEM images of the microdot in a, while the insets show fast Fourier transform (FFT) of the boxed region with Miller indices labeled for the corresponding crystal planes. Figure 4j corresponds to the α-Sn region at the bottom of the microdot (near the SiO2 interface). Since α-Sn[1\(\bar{3}\bar{1}\)] direction is parallel to Si surface, the in-plane strain ϵ∥ = ( − 1.4 ± 0.4) is directly measured using the d-spacing of α-Sn(1\(\bar{3}\bar{1}\)) planes and 3.9 at.% Ge composition near the SiO2 interface from EDS analyses. Within the error range, this level of compressive strain is also consistent with average in-plane strain from XRD analyses (ϵ∥ = ( − 0.63 ± 0.44)%). The strain measured using different techniques are also summarized in Table 1, confirming compressive strain in α-Sn.

a, b Two microdots, both being α-Sn capped with β-Sn. c A small β-Sn dot. d–f are high-angle annular dark-field (HAADF) STEM image and EDS analysis of the microdot in a, while g–i are corresponding analyses of the microdot in b. j–l are HRTEM images of the microdot in a. The insets show FFT of the boxed regions. Panel j corresponds to the α-Sn region at the bottom of the microdot (near SiO2 interface). Panel k corresponds to the relatively Ge-rich region at the corner of the microdot. Panel l corresponds to the boundary between α-Sn and β-Sn phase.

Figure 4k shows the Ge-rich region at the corner of the microdot, which also echoes the Ge-rich region observed in the as-deposited sample (see Fig. 2c, d). The d-spacing of (111) planes in the boxed region is 0.323 nm, indicating that this region is almost pure Ge after RTA. This observation is fully consistent with the blue-shift of the Ge-Ge peak observed in Raman spectroscopy earlier, showing that the average Sn composition in the Ge nanoclusters is drastically reduced from ~17 at.% to zero after RTA. Figure 4l corresponds to the phase boundary between α-Sn and β-Sn. This phase boundary is relatively sharp, some regions approaching coherent interface with α-Sn(111) almost perpendicular to β-Sn(200) planes. The zone axis of α-Sn[11\(\bar{2}\)] is parallel to β-Sn[010]. The larger d-spacing of α-Sn(111) near the phase boundary compared with that in 4j near the microdot/oxide interface is likely due to the difference in strain considering that the Ge compositions are similar.

Furthermore, scanning nanobeam diffraction analyses from 4D-STEM data in Fig. 5 also clearly distinguishes α-Sn from β-Sn phase regions in a microdot. Figure 5a is the bright field image of this microdot, while Fig. 5b is the corresponding reconstructed phase map, showing α-Sn capped with β-Sn. This map was generated by analyzing the spatial evolution of the Bragg disk positions; examples of indexing from different grains are shown in Fig. 5c–g (regions shown are depicted by red rectangles in the corresponding generated dark-field images). The corresponding conventional dark-field TEM images of this microdot are also given in the Supplementary Note 4 and Supplementary Fig. 4. From this analyses, we can see that the α-Sn region is dominated by a large grain shown in Fig. 5(c), ~200 nm wide and 100 nm thick. It is indeed ~10x larger than the largest critical size for α-Sn formation reported earlier35,36,37. The small α-Sn region at the top right corner in Fig. 5d has a different orientation, overlapping with a small piece of β-Sn region (see Fig. 5g) in the vertical direction. The β-Sn “cap” region is consisted of three small grains, as shown in Fig. 5e–g. Overall, the results further confirm the formation of large α-Sn microdots capped with β-Sn. α-Sn occupies ~70% of the volume in this microdot, which equals to ~65% weight percentage. This is largely consistent with the ~50% mass ratio estimated from XRD results in Fig. 3b, considering that there are also small β-Sn dots.

a Bright-field image obtained by masking only the (0,0,0) disk for the convergent-beam electron diffraction (CBED) patterns at each pixel. b Phase map showing the spatial distribution of the alpha and beta phases, produced by indexing the diffracted disks and thereby identifying the dominant phase at each pixel. c–g are example dark-field images generated from the corresponding indexed disks (shown as red circles) in h–l (these CBED patterns were generated from various locations over the nanodot as indicated by red rectangles in c–g).

We also confirmed the presence of both α and β-Sn microdots in the sample annealed at 350 °C via HRTEM analyses, as shown in Fig. 6. Figure 6a shows a trapezoid-shaped microdot dominated by a single-crystalline α-Sn grain extending throughout the microdot with ~280-nm-diameter and ~150-nm-thickness. Again, these dimensions are ~10x greater than the upper size limit for stable α-Sn nanodots reported earlier.35,36,37. In contrast, Fig. 6b shows a dome-shaped microdot dominated by β-Sn. The difference in shape between α and β-Sn microdots could due to the different surface energy. Previous studies show that diamond cubic structures (corresponding to α-Sn) tend to form facets on top46.

a A SnGe microdot with a “trapezoid” morphology dominated by α-Sn. b A SnGe microdot with a “dome” morphology dominated by β-Sn. c A zoomed-in HRTEM image of a pure α-Sn region in the SnGe microdot shown in Figure a. To show the crystal planes more clearly, the boxed region in c is highlighted in d by converting the brightness contrast into color contrast, i.e., red for brighter and blue for darker regions. Panel e shows a Fourier transform of d in order to obtain the d spacing and the corresponding Miller indices, as labeled in d and e. Panels f–h zoomed into an α/β overlapped region of Figure a, showing Moiré fringes due to vertical overlapping of α-Sn planes with β-Sn(200) planes. Panels i–k correspond to a pure β-Sn microdot.

The HRTEM images in Fig. 6c, f further zoom into a pure α-Sn region and an α/β vertically overlapped region of Fig. 6a, respectively. Figure 6d, g convert the boxed regions of c and f from grayscale into RGB color scale for better visibility. In the pure α-Sn region, Fig. 6d and the corresponding FFT in e show an α-Sn(111) inter-planar spacing of d = (0.367 ± 0.03) nm, which is used to derive the in-plane strain ϵ∥ = ( − 2.0 ± 1.0) given the Ge composition and an uniaxial Poisson ratio of ν = 0.31 (biaxial Poisson ratio of 0.9)47. This is also consistent with the compressive strain measured in the sample annealed at 325 °C, as shown in Table 1. In the α/β overlapped region, Fig. 6f–h show Moiré patterns48,49 due to the vertical overlapping of the predominant α-Sn(111) planes with β-Sn(200) planes at an angle of ~11.5∘. Finally, Fig. 6i–k show a pure β-Sn microdot with its (101) planes almost parallel to the surface of the Si substrate. Overall, these data not only confirm the formation of α-Sn at hundreds of nm scale after RTA at 350 °C, but also capture adjacent α and β-Sn grains during the reversed phase transformation process from β to α-Sn.

Optical properties

To investigate the optical transitions in these 3D TDS microdots, the optical absorptance spectra of the as-deposited and annealed SnGe samples are plotted in Fig. 7. The absorption edge at ~1100 nm is due to the Si substrate. Samples with a significant amount of α-Sn (annealed at 350 °C and 375 °C) show an additional absorption feature at 1250–1750 nm wavelength compared to those with no or little α-Sn. This feature also disappears with the disappearance of α-Sn, such that the absorption spectrum of the 500 °C RTA sample is approaching that of the as-deposited sample again. Clearly, it is strongly correlated to β-to-α-Sn transition. SEM images show that the as-deposited sample and annealed samples have very similar morphology (see Supplementary Note 5 and Supplementary Figure 5). Particularly, the microdot size distributions are almost identical for the samples annealed at 375 °C vs. 500 °C, yet the former has the addition absorption feature at 1250–1750 nm while the latter does not. Therefore, this absorption feature is unlikely due to morphology change. Furthermore, both α-Sn and β-Sn are semimetals with refractive index n greater than the extinction coefficient k in this wavelength range, so it is unlikely due to plasmonic resonance, either. Instead, this additional optical absorption feature at ~0.7–1 eV is consistent with a recent work50 on the optical properties of α-Sn, attributed to a transition corresponding to the spin-orbit splitting energy of Δ0 = Γ8v − Γ7v ≈ 0.7 eV1,50. Since it has been recently demonstrated that pulsed laser can be used to change the quantum states of 3D TDS41, the measured absorption spectrum of α-SnGe suggests that commonly used lasers for telecommunications at 1310–1550 nm may be used for quantum state switching with potential for integration with silicon integrated photonics. For example, these α-Sn microdots can be easily deposited on Si or silicon nitride waveguides or microresonators, where the input optical power can be evanescently coupled to α-Sn 3D TDS to switch the quantum states. This feature may offer an approach to achieve optically tunable quantum materials and devices on silicon.

Towards further optimization

We also grew SnGe samples with higher and lower nominal Ge composition and found a nominal Ge composition of 5-8 at.% in the as-deposited microdots is optimal for seeding β → α-Sn transformation. This is briefly summarized in the Supplementary Note 6 and Supplementary Fig. 6. We also found that the β → α-Sn transition can be further enhanced by directly growing SnGe on Si (i.e. etching away the native oxide on the Si by HF). More than 80 wt.% α-Sn was achieved upon RTA51. We will further optimize this reversed phase transition in our future work. On the other hand, since β-Sn is at the top, it can also be readily removed by timed etching (e.g. using dilute HCl or reactive ion etching) whenever needed, such that the remaining ~100-nm-thick α-Sn can be used for quantum device fabrication.

Discussion

In summary, we demonstrate that Ge-doped α-Sn can be grown on native oxide on Si substrate via a reversed phase transformation from β to α-Sn at 300–500 °C, seeded by Ge-rich GeSn nanoclusters in the as-deposited materials. Such a reversed phase transformation has not been reported in previous literature. Referring to Fig. 2e, this reversed phase transformation is implemented via the following steps. (1) Ge-rich GeSn nanoclusters (with ~17 at.%.) are spontaneously formed via Ge-Sn intermixing during the deposition process. From HRTEM analyses, they are mostly located near the microdot/oxide interface and the corners of the microdots. (2) Upon RTA at 300–500 °C, the GeSn nanoclusters undergo phase separation into Ge and Sn, driven by thermodynamic solubility limit of Sn in Ge at these elevated temperatures. Furthermore, this phase separation favors heterogeneous nucleation of diamond cubic α-Sn, rather than tetragonal β-Sn, to minimize the interface energy with the Ge-rich GeSn nanocluster seeds due to the same crystal structure. This process initiates the reversed β to α-Sn transition, as strongly evidenced by the Raman spectra showing that the appearance of α-Sn coincides with the decrease of Sn composition in the Ge-rich GeSn nanoclusters. (3) During the heterogeneous nucleation process, α-Sn also dissolves ∼2–4 at.% Ge, as evidenced by our EDS analyses. This Ge doping in α-Sn reduces its Gibbs free energy by increasing the mixing entropy, which further drives the transformation of adjacent β-Sn regions into (Ge-doped) α-Sn. This mechanism is strongly evidenced by the TEM and EDS analyses, showing that the β-to-α-Sn transition is dominated by a single crystal α-Sn grain propagating from the Ge-rich interface upward to the top of the microdots. (4) In relatively large microdots with diameters >50 nm, α-Sn can reach the critical size for nucleation and grow both laterally and vertically from the interface towards the surface, transforming β-Sn into α-Sn during the growth process. This process tends to result in α-Sn microdots capped with β-Sn (e.g. Figs. 4a, b and 5), and some big microdots can be almost fully transformed to α-Sn (e.g. Fig. 6a). The volume expansion upon β-to-α-Sn transition also leads to in-plane compressive strain because the adhesion of the microdots to the substrates constrains the lateral expansion. The lattice mismatch between α-Sn and the Ge-rich GeSn nuclei further helps to enhance the compressive strain in the α-Sn towards 3D TDS materials integrated on Si. (5) Small dots <50 nm in diameter cannot reach the critical size for nucleating α-Sn, thereby mostly remaining β-Sn. According to nucleation theory, this critical size is determined by the ratio of the interface energy (γ) to the change in Gibbs free energy (ΔG) upon β-to-α-Sn phase transition. Since ΔG of this transition is relatively small52 while γ is relatively large due to the different crystal structures between α and β phases, the critical size of nucleation for α-Sn is also relatively large. Such size-limited phase transformation has indeed been observed in other material systems such as silicides53.

An important result of this work is that ~10x thicker α-Sn is achieved on Si compared to previous literature, which greatly facilitates robust TDS integration. In fact, the topological phase of α-Sn depends on the thickness15,16, apart from strain. α-Sn transforms from TI to TDS as the thickness increases. For epitaxial α-Sn grown on CdTe (with −0.126% in-plane compressive strain), the crossover from TI to TDS occurs when the thickness exceeds ~38 nm15. For α-Sn grown on InSb (with −0.67% in-plane compressive strain), the transition between 2D-TI and quantized TDS occurs as the thickness exceeds 8 nm 16. Therefore, compared with the recently reported 6 nm α-Sn grown on Si6,7, our α-Sn microdots with ~100–200 nm thickness provide a much larger margin from the critical thickness of TI/TDS transition for more robust TDS integration on Si. Our thicker α-Sn could also potentially be used to study magneto-transport properties or the transition of transport type, which has been observed for α-Sn with thickness >40 nm grown on CdTe54,55.

Another important implication of this work is that Ge-rich GeSn with ~17 at.% Sn can effectively serve as a template for α-Sn quantum material growth at elevated temperatures. Since such GeSn virtual substrate have already been developed for mid-infrared optoelectronic device integration on 8-inch Si wafers56, they can be readily applied to implement monolithic Sn-rich SnGe quantum material and device integration on Si. Another implication, especially interesting for the GeSn infrared material and device community, is that the actual room-temperature solubility of Sn in Ge nanostructures can reach as high as ~17 at.% Sn since such a high Sn composition was spontaneously achieved during physical vapor deposition at room-temperature, indicating that it is thermodynamically favored. This is a favorable result for the stability of GeSn mid infrared materials and devices that require ~10–20 at.% Sn composition.

Our work also clarifies a couple of questions related to previous literature: (1) We showed that the formation of α-Sn at elevated temperatures does not have to rely on epitaxy from single-crystal substrates. Therefore, although lattice-matching epitaxy is preferred, actually it is not a necessary condition to stabilize α-Sn; (2) We found that the incorporating Ge facilitates α-Sn formation at elevated temperatures while retards its formation at low temperatures. This results reconciles some of the seemingly contradictory reports in previous literature26,27,28. (3) We confirm that a moderate compressive strain on the order of −0.5 to −1.5% does not necessarily retard the formation of α-Sn.

Conclusion

In conclusion, we show that Ge-doped α-Sn can be stabilized up to ~200 nm in dimensions at room temperature without the help of coherent epitaxial interface as in the common case of α-Sn growth on InSb substrates. A compressive strain is introduced to Ge-doped α-Sn, which makes it one of the few candidates for 3D TDS according to theoretical predictions. To the best of our knowledge, this work presents the first instance of α-Sn grown at relatively high temperature on Si without epitaxy, breaking through the long-existing constraints in substrate selection, size/thickness limit, and thermal stability of α-Sn growth towards topological quantum material/device integration on Si. Furthermore, α-SnGe’s optical absorption at ~1250–1750 nm wavelength suggests a potential possibility to achieve optically tunable quantum materials and devices on silicon when integrated with silicon photonic circuits. Since we found that Ge-rich GeSn nanoclusters can effectively seed the growth of Sn-rich α-SnGe in this study, this process could potentially be scaled up using selective epitaxial growth on GeSn virtual substrates on Si56 for high-quality quantum device integration.

Methods

Fabrication

Kurt J. Lesker Lab 18 PVD system was used to grow SnGe on single-side polished Si(001) substrates. Sn and Ge atoms are co-evaporated at a rate of 0.7 Å/s and 0.037 Å/s, respectively, for 11 min 20 s. Therefore, the nominal Ge composition is ~5 at.%. Note that the Sn-rich SnGe dewets the surface of the native oxide on Si, hence the 50-nm thickness based on the deposition rate is also nominal. After deposition, the as-deposited SnGe samples are annealed in Argon for 2 min at a variety of temperatures by SOLARIS 100 rapid thermal processor.

Characterization

The Raman spectra of as-deposited and annealed samples at different temperatures were obtained using a Horiba LabRAM HR spectrophotometer. The spectra were taken using a 633-nm laser and a ×50 microscope objective lens at an excitation power of 0.5 mW. Si peak at 520.5 cm−1 was used to calibrate the Raman spectra57,58. The XRD data were taken by Rigaku x-ray diffractometer with 40 kV and 300 mA at 1°/min speed. Si (400) peak was used to calibrate the XRD data. Cross-sectional TEM samples were prepared by focus ion beam milling. HRTEM images were taken by JEOL ARM-CF TEM/STEM and FEI Tecnai F20ST FEG TEM. 4D-STEM data were acquired using a Direct Electron DE-16 detector with a 2 mrad probe. The lattice images of the silicon substrate was used to calibrate the d-spacings. LiberTEM59 software was used to process 4D-STEM data. The absorptance spectra were taken by a Jasco V570 UV-Vis-IR spectrophotometer.

Data availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files). The numerical datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Küfner, S., Furthmüller, J., Matthes, L., Fitzner, M. & Bechstedt, F. Structural and electronic properties of α-tin nanocrystals from first principles. Phys. Rev. B 87, 235307 (2013).

Predel, B. Ge-Sn (germanium-tin): datasheet from landolt-börnstein - group iv physical chemistry volume 5f: “Ga-Gd – Hf-Zr” in SpringerMaterials https://doi.org/10.1007/10501684.1506. (Springer-Verlag, 1996).

Le Couteur, P. & Burreson, J. Napoleon’s Buttons: 17 Molecules That Changed History (Penguin, 2004).

Menzies, A. W. Tin plague and Scott’s antarctic expedition. Nature 108, 496–496 (1921).

Xu, C.-Z. et al. Elemental topological Dirac semimetal: α-Sn on InSb (111). Phys. Rev. Lett 118, 146402 (2017).

Ding, J. et al. Switching of a magnet by spin-orbit torque from a topological Dirac semimetal. Adv. Mater. 33, 2005909 (2021).

Ding, J. et al. Large damping enhancement in Dirac-semimetal–ferromagnetic-metal layered structures caused by topological surface states. Adv. Funct. Mater. 31, 2008411 (2021).

Lan, H.-S., Chang, S. & Liu, C. Semiconductor, topological semimetal, indirect semimetal, and topological dirac semimetal phases of Ge1−xSnx alloys. Phys. Rev. B 95, 201201 (2017).

Wang, H. et al. Observation of superconductivity induced by a point contact on 3d Dirac semimetal Cd3As2 crystals. Nat. Mater. 15, 38–42 (2016).

Liu, Z. et al. Discovery of a three-dimensional topological Dirac semimetal, Na3Bi. Science 343, 864–867 (2014).

Wang, X. et al. GeSn on insulators (GeSnOI) toward mid-infrared integrated photonics. Front. Phys. 7, 134 (2019).

Moutanabbir, O. et al. Monolithic infrared silicon photonics: the rise of (Si) GeSn semiconductors. Appl. Phys. Lett. 118, 110502 (2021).

Al-Kabi, S. et al. An optically pumped 2.5 μm GeSn laser on Si operating at 110 k. Appl. Phys. Lett. 109, 171105 (2016).

Elbaz, A. et al. Reduced lasing thresholds in GeSn microdisk cavities with defect management of the optically active region. ACS Photon. 7, 2713–2722 (2020).

de Coster, G., Folkes, P., Taylor, P. & Vail, O. Effects of orientation and strain on the topological characteristics of CdTe/α-Sn quantum wells. Phys. Rev. B 98, 115153 (2018).

Anh, L. D. et al. Elemental topological Dirac semimetal α-Sn with high quantum mobility. Adv. Mater. 33, 2104645 (2021).

Ewald, A. W. Germanium-stabilized gray tin. J. Appl. Phys. 25, 1436–1437 (1954).

Gallerneault, W. M. T., Vnuk, F. & Smith, R. W. Silicon-stabilized grey tin. J. Appl. Phys. 54, 4200–4201 (1983).

Becker, J. On the quality of gray tin crystals and their rate of growth. J. Appl. Phys. 29, 1110–1121 (1958).

Joo, Y. J. & Takemoto, T. Transformation of Sn–Cu alloy from white tin to gray tin. Mater. Lett. 56, 793–796 (2002).

Semenova, O., Flandorfer, H. & Ipser, H. On the non-occurrence of tin pest in tin–silver–indium solders. Scr. Mater. 52, 89–92 (2005).

Plumbridge, W. Tin pest issues in lead-free electronic solders. In Lead-Free Electronic Solders, 307–318 (Springer, 2006).

Plumbridge, W. Recent observations on tin pest formation in solder alloys. J. Electron. Mater. 37, 218–223 (2008).

Plumbridge, W. Further observations on tin pest formation in solder alloys. J. Electron. Mater. 39, 433–440 (2010).

Di Maio, D. & Hunt, C. Investigation Methods Of The Beta To Alpha Tin Allotropic Transformation. NPL Report. MAT 21 (2008).

Vnuk, F. Preparation of compact α-tin specimens. J. Cryst. Growth 48, 486–488 (1980).

Matvienko, A. & Sidelnikov, A. The influence of relaxation of stresses occurring during the β → α transformation of tin on the kinetics of the transformation. J. Alloys Compd 252, 172–178 (1997).

Zeng, G., McDonald, S. D., Gu, Q., Sweatman, K. & Nogita, K. Effects of element addition on the β → α transformation in tin. Philos. Mag. Lett. 94, 53–62 (2014).

Farrow, R. et al. The growth of metastable, heteroepitaxial films of α-Sn by metal beam epitaxy. J. Cryst. Growth 54, 507–518 (1981).

Menéndez, J. & Höchst, H. Study of the phase transition in heteroepitaxially grown films of α Sn by raman spectroscopy. Thin Solid Films 111, 375–379 (1984).

Mason, B. & Williams, B. On the stability of pseudomorphic α-Sn on InSb (001) to temperature and film thickness. Surf. Sci. 273, L472–L476 (1992).

Song, H. et al. Thermal stability enhancement in epitaxial alpha tin films by strain engineering. Adv. Eng. Mater. 21, 1900410 (2019).

Madarevic, I. et al. Structural and electronic properties of the pure and stable elemental 3d topological Dirac semimetal α-Sn. APL Mater. 8, 031114 (2020).

Olson, D. & Matlock, D. Diamond cubic phase of lead. J. Phys. Chem. Solids 42, 805–808 (1981).

Arslan, I., Yates, T., Browning, N. & Midgley, P. Embedded nanostructures revealed in three dimensions. Science 309, 2195–2198 (2005).

Oehl, N. et al. Critical size for the β-to α-transformation in tin nanoparticles after lithium insertion and extraction. CrystEngComm 17, 3695–3700 (2015).

Haq, A. U. et al. Size-dependent stability of ultra-small α-/β-phase tin nanocrystals synthesized by microplasma. Nat. Commun. 10, 817 (2019).

Wu, Z. et al. Coupling topological insulator SnSb2Te4 nanodots with highly doped graphene for high-rate energy storage. Adv. Mater. 32, 1905632 (2020).

Castro-Enriquez, L., Quezada, L. & Martín-Ruiz, A. Optical response of a topological-insulator–quantum-dot hybrid interacting with a probe electric field. Phys. Rev. A 102, 013720 (2020).

Cho, S. et al. Topological insulator quantum dot with tunable barriers. Nano Lett. 12, 469–472 (2012).

Hübener, H., Sentef, M. A., De Giovannini, U., Kemper, A. F. & Rubio, A. Creating stable floquet–weyl semimetals by laser-driving of 3D Dirac materials. Nat. Commun. 8, 13940 (2017).

Olijnyk, H. Pressure dependence of Raman phonons of metallic β-Sn. Phys. Rev. B 46, 6589–6591 (1992).

D’Costa, V. et al. Raman scattering in Ge1−ySny alloys. Solid State Commun. 144, 240–244 (2007).

Nogita, K. et al. XRD study of the kinetics of β ↔ α transformations in tin. Philos. Mag. 93, 3627–3647 (2013).

Hubbard, C. R. & Snyder, R. L. RIR-measurement and use in quantitative XRD. Powder Diffraction 3, 74–77 (1988).

Liu, J. et al. Ge-on-Si optoelectronics. Thin Solid Films 520, 3354–3360 (2012).

Price, D., Rowe, J. & Nicklow, R. Lattice dynamics of grey tin and indium antimonide. Phys. Rev. B 3, 1268 (1971).

Tu, J. F. TEM nano-Moiré pattern analysis of a copper/single walled carbon nanotube nanocomposite synthesized by laser surface implanting. C 4, 19 (2018).

Zhang, H., Wen, H., Liu, Z., Zhang, Q. & Xie, H. TEM nano-Moiré evaluation for an invisible lattice structure near the grain interface. Nanoscale 9, 15923–15933 (2017).

Carrasco, R. A. et al. The direct bandgap of gray α-tin investigated by infrared ellipsometry. Appl. Phys. Lett. 113, 232104 (2018).

Liu, S. et al. Reversed Phase Transformation of β → α-Sn At Elevated Temperatures Towards Quantum Material Integration On Silicon. (Presentation in MRS Fall Meeting, 2021).

Legrain, F. & Manzhos, S. Understanding the difference in cohesive energies between alpha and beta tin in DFT calculations. AIP Adv. 6, 045116 (2016).

Liu, J., Feng, J. & Zhu, J. Film thickness dependence of the NiSi-to-NiSi2 transition temperature in the Ni/Pt/Si (100) system. Appl. Phys. Lett. 80, 270–272 (2002).

Vail, O. et al. Growth and magnetotransport in thin-film α-Sn on CdTe. Phys. Stat. Solidi (b) 257, 1800513 (2020).

Ding, Y. et al. Multiple carrier transport in high-quality α-Sn films grown on CdTe (001) by molecular beam epitaxy. J. Vac. Sci. Technol. A Vac. Surf. Films 39, 033408 (2021).

Dou, W. et al. Optically pumped lasing at 3 μm from compositionally graded GeSn with tin up to 22.3%. Opt. Lett. 43, 4558–4561 (2018).

Lu, Z., Quinn, T. & Reehal, H. Polarization-dependent Raman spectra of thin crystalline silicon films. J. Appl. Phys. 97, 033512 (2005).

Lukin, S., Užarević, K. & Halasz, I. Raman spectroscopy for real-time and in situ monitoring of mechanochemical milling reactions. Nat. Protoc. 16, 3492–3521 (2021).

Clausen, A. et al. LiberTEM/LiberTEM: 0.5.0. No. FZJ-2020-05025. Physik Nanoskaliger Systeme. https://doi.org/10.5281/zenodo.3763313 (2020).

Zaumseil, P. High-resolution characterization of the forbidden Si 200 and Si 222 reflections. J. Appl. Crystallogr. 48, 528–532 (2015).

Acknowledgements

The authors thank Dr. Maxime J. Guinel for his support in transmission electron microscopy analyses. This research has been supported by the Air Force Office of Scientific Research under the award number FA9550-19-1-0341 managed by Dr. Gernot Pomrenke. This work was performed in part at the Harvard University Center for Nanoscale Systems (CNS); a member of the National Nanotechnology Coordinated Infrastructure Network (NNCI), which is supported by the National Science Foundation under NSF award no. ECCS-2025158.

Author information

Authors and Affiliations

Contributions

J.L. conceived the experiments. A.C.C. further proposed to investigate the possibility of α-Sn formation at elevated temperatures. S.L. and A.C.C. conducted the experiments, collected, and analyzed the data. J.G., A.A., and B.D.A.L. contributed to TEM/EDS/4D-STEM measurements. X.W. contributed to the analysis of the data. All authors contributed to the write-up of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Margriet Van Bael and the other, anonymous, reviewer for their contribution to the peer review of this work. Primary Handling Editor: John Plummer. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, S., Covian, A.C., Gardener, J.A. et al. Growth of α-Sn on silicon by a reversed β-Sn to α-Sn phase transformation for quantum material integration. Commun Mater 3, 17 (2022). https://doi.org/10.1038/s43246-022-00241-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-022-00241-7

This article is cited by

-

Enhancing SiGeSn nanocrystals SWIR photosensing by high passivation in nanocrystalline HfO2 matrix

Scientific Reports (2024)

-

Group IV topological quantum alloy and the role of short-range order: the case of Ge-rich Ge1–xPbx

npj Computational Materials (2024)