Abstract

Ganoderma formosanum, an edible medicinal fungus renowned for its bioactive metabolites, faces challenges in traditional cultivation due to prolonged timelines and elevated costs, hindering its integration into functional food formulations. This study introduces an innovative, sustainable fermentation platform by immobilizing G. formosanum mycelia (GFM) on plastic composite support (PCS) within an airlift bioreactor, utilizing agricultural byproducts to foster eco-efficient production of natural anti-melanogenesis compounds with potential as functional food ingredients. Initial shake-flask evaluations identified the SY-PCS matrix, comprising soybean hulls, polypropylene, and yeast extract, as optimal for mycelial immobilization, yielding anti-melanin activity equivalent to 79.78% of kojic acid (KA) efficacy. Upscaling to a 5 L bioreactor with 1% SY-PCS supplementation on day 8 elevated this to 81.7% of KA’s potency, while repeated-batch fermentation amplified second-batch biomass productivity by 2.7-fold, promoting resource-efficient yields suitable for food-grade applications. Cell-based assays in B16-F10 models demonstrated potent suppression of intracellular melanin accumulation, akin to KA, and zebrafish trials revealed a 31% reduction in melanin content. LC-MS/MS analysis identified 15 bioactive compounds, corroborated by molecular docking studies showing enhanced tyrosinase-binding affinities and synergistic effects, underscoring their promise as natural additives in functional foods for skin health support.

Similar content being viewed by others

Introduction

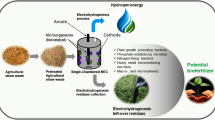

Microbial fermentation is widely employed to enhance bioactive metabolite production, with immobilization technology improving microbial stability, secondary metabolite biosynthesis, and process efficiency1. This approach is particularly beneficial for filamentous fungi, susceptible to shear stress in liquid culture. Immobilized systems provide a structured matrix that supports fungal adhesion, biofilm formation, and metabolic regulation, creating favorable conditions for continuous and repeated-batch fermentation2. These advantages contribute to sustainable bioprocessing by increasing biomass retention, reducing waste generation, and minimizing the need for frequent reinoculation2. Among immobilization carriers, PCS has been widely applied due to its porosity, mechanical stability, and suitability for fungal attachment. Using polypropylene and agricultural byproducts, PCS aligns with circular economy principles by incorporating biodegradable components, promoting more sustainable fermentation practices3. Previous studies have demonstrated that PCS-based immobilization enhances fermentation efficiency, increasing vitamin K production by 2.3-fold in Bacillus subtilis4. However, its impact on secondary metabolite biosynthesis in filamentous fungi requires further investigation.

ALBs have been increasingly adopted for low-shear fungal cultivation, providing enhanced oxygen transfer while minimizing mycelial fragmentation. Compared to STRs, which rely on mechanical agitation, ALBs prevent biomass loss, improve energy efficiency, and optimize fungal growth conditions. Integrating immobilization with ALB fermentation is expected to enhance metabolite biosynthesis while reducing energy consumption, supporting a more sustainable fermentation model5.

Among filamentous fungi, G. formosanum, a medicinal species native to Taiwan, has been widely studied for its antioxidant, anti-inflammatory, anti-fibrotic, anti-pro-apoptotic and skin-anti-melanin properties6,7. Its mycelial extracts contain bioactive compounds that inhibit tyrosinase, a key enzyme in melanin biosynthesis7. Tyrosinase catalyzes L-tyrosine oxidation to dopaquinone, which polymerizes into melanin. Unregulated tyrosinase activity leads to hyperpigmentation, increasing demand for natural inhibitors with high biocompatibility8. Sustainable production of these bioactive compounds through immobilized fermentation may enhance yield while reducing the environmental footprint compared to traditional extraction methods. Although GFE have been shown to inhibit tyrosinase activity, regulate melanogenic gene expression, and mitigate oxidative stress-induced pigmentation, the effects of immobilized fermentation on these bioactivities remain unclear7.

This study aims to evaluate the impact of immobilized fermentation on GFM growth and bioactive compound production. Biomass yield, mycelial morphology, and metabolite composition will be compared between immobilized and suspension cultures, while the physicochemical properties of immobilization matrices and their effects on fungal adhesion, proliferation, and metabolite synthesis will be analyzed. The anti-melanin potential will be assessed through tyrosinase inhibition, oxidative stress modulation, and melanogenesis suppression mechanisms.

Results and discussion

Optimizing G. formosanum immobilization and anti-melanogenesis activity through PCS composition and agitation speed

The effect of PCS composition on G. formosanum immobilization was evaluated using six nutrient containing PCS formulations, PP, and a control without carriers. At 120 rpm, high shear stress disrupted biofilm formation, limiting mycelial adhesion across PCS groups (Fig. 1A), with no significant differences in total biomass (p > 0.05) among PCS groups (7.5–9.6 g/L), while PP (8.75 g/L) and the control (11.75 g/L) showed no enhancement (Fig. 1C). As illustrated in Supplementary Fig. 1A, B, SEM images of PCS surfaces under high agitation, corresponding to the condition shown in Fig. 1G, revealed smooth particle surfaces without visible hyphal adhesion. These SEM observations confirmed that excessive shear stress impeded mycelial attachment and prevented biofilm formation on the PCS surface.

A, B Biomass distribution on PCS surfaces under 120 rpm and 60 rpm, respectively. C, D Biomass distribution in the culture medium at 120 rpm and 60 rpm. E, F Tyrosinase inhibitory activity of culture filtrates at 120 rpm and 60 rpm. G, H Mycelial attachment morphology on SY-PCS at 120 rpm and 60 rpm. All experiments were performed in triplicate, and results are expressed as mean ± standard deviation. Different letters indicate significant differences (p < 0.05).

Reducing agitation to 60 rpm significantly increased fungal attachment (p < 0.05), particularly on SF-PCS (0.47 g/L), SFB-PCS (0.43 g/L), and SFY-PCS (0.41 g/L), while PP showed no adhesion (Fig. 1B). This enhanced immobilization under low shear stress was further supported by SEM analysis. As shown in Supplementary Fig. 1C, D, corresponding to the PCS conditions visualized in Fig. 1H, PCS surfaces exhibited dense hyphal entanglement and extensive wrapping of G. formosanum mycelia. Moreover, Supplementary Fig. 1E provided a high-magnification view of the PCS interface, revealing direct interaction between fungal hyphae and the PCS matrix. The presence of filamentous structures anchored tightly to the carrier surface indicated successful immobilization and enhanced stability of the biofilm. These microstructural features likely contributed to improved nutrient accessibility and more efficient colonization.

No significant differences in suspended biomass were observed (p > 0.05). The increased adhesion was attributed to greater hydrophilicity and surface roughness in PCS containing yeast extract (Y) and soy hull (S), which facilitated fungal attachment9. Total biomass was significantly higher (p < 0.05) in PCS cultures (1.30–1.62 g/L) than in PP (0.99 g/L) and the control (1.04 g/L) (Fig. 1D). Similar results were reported in ethanol fermentation, where A. niger exhibited increased biomass on SFY-Salt PCS, while S. cerevisiae remained unaffected10. These results suggest PCS enhances fungal adhesion and biomass accumulation, with minimal influence from nutrient composition.

The ethanol extract of G. formosanum mycelium was previously shown to inhibit tyrosinase activity, with the ethyl acetate fraction exhibiting the strongest effect (IC₅₀ = 118.26 ± 13.34 ppm)7. Mycelia were cultivated using different PCS formulations under different agitation speeds to evaluate their effect on tyrosinase inhibition. As shown in Fig. 1E, F, tyrosinase inhibition was highest under 120 rpm in SY-PCS, SFB-PCS, and SFY-PCS groups (59.87%, 51.77%, and 67.97%, respectively, p > 0.05). At 60 rpm, SY-PCS exhibited the strongest inhibition (79.78%, p < 0.05), representing a more favorable condition under the tested parameters and therefore applied in subsequent experiments. These findings align with studies on fungal extracts, where G. lucidum, G. resinaceum, and G. pfeifferi mycelial extracts showed tyrosinase inhibition of 50.53%, 45.31%, and 29.18%, respectively11, while G. weberianum chloroform and ethyl acetate extracts achieved 41.46% and 57.52% inhibition, respectively9. Lower agitation improved mycelial adhesion to PCS (Fig. 1H), which may have contributed to enhanced anti-melanogenesis activity by facilitating nutrient access and mass transfer. Similar effects of shear on fungal morphology and metabolite synthesis have been reported.12–14,15. Compared to high agitation (Fig. 1G), the SY-PCS formulation, composed of soy hull and yeast extract, was particularly effective in enhancing mycelial growth. Yeast extract-based PCS has been shown to release 51–60% of total nitrogen, enriching the medium. Additionally, soy hull and yeast extract in PCS reduced hydrophobicity, promoting fungal adhesion12. Since carbon and nitrogen sources significantly influence fungal metabolism and secondary metabolite production, nitrogen availability likely played a key role in enhancing G. formosanum anti-melanogenesis compounds.

PCS composition and agitation speed influenced G. formosanum mycelial growth and anti-melanin activity, with shear stress affecting mycelial development. While higher agitation improved nutrient distribution, oxygenation, and heat transfer, excessive shear stress disrupted mycelial structure and altered metabolite production15. This study’s lower shear stress promoted SY-PCS biofilm formation, yielding stronger tyrosinase inhibition. Based on these findings, a low-shear airlift bioreactor was selected for scale-up experiments. As biofilm thickness increased on SY-PCS, outer layers detached while new biofilms formed after medium replacement, supporting continuous fermentation feasibility.

Optimizing SY-PCS concentration and repeated-batch fermentation for enhanced G. formosanum biomass and anti-melanin activity

The impact of SY-PCS supplementation (0.5% and 1% w/v) on G. formosanum fermentation was assessed in a 5 L bioreactor over 10 days. These two concentrations were selected as representative low-load and high-load conditions to examine whether supplementation exerts functional effects on biomass and metabolite production, rather than to define a universal optimum. Biomass stabilized between days 3 and 8 without SY, reaching 7.45 g/L on day 9 (Fig. 2A). Supplementation with 0.5% SY produced 7.34 g/L on day 6 (Fig. 2B), whereas 1% SY-PCS significantly increased biomass to 8.62 g/L on day 8 (p < 0.05) before a decline was observed (Fig. 2C). The increased biomass yield was attributed to nitrogen release from PCS, facilitating fungal growth. Yeast extract, a known nitrogen source, has been reported to enhance G. lucidum biomass accumulation16. PCS supplementation significantly enhanced tyrosinase inhibition (p < 0.05), with 1% SY-PCS group yielding the highest inhibition at 81.74%, 86.47%, and 85.25% on days 8, 9, and 10, respectively (Fig. 2F), representing a 1.34-fold increase compared to the control. No significant differences were observed between 0.5% SY-PCS and the control (p > 0.05) (Fig. 2E). This trend aligned with findings in S. cerevisiae, where ethanol yield increased from 45.9% to 48.59% in biofilm reactors17. Since PCS released nitrogen into the medium, promoting both biomass and metabolite production, 1% SY-PCS was adopted for repeated-batch fermentation as the more favorable supplementation level under the tested conditions, supported by its consistent enhancement of biomass (8.62 g/L on day 8) and tyrosinase inhibition (81.74–86.47% on days 8–10) compared with 0.5% and the control.

Biomass distribution of GFM under different SY-PCS ratios (Control (A), 0.5% (w/v) (B), 1% (w/v) (C)). Anti-melanogenesis effects at the corresponding SY-PCS ratios (Control (D), 0.5% (w/v) (E), 1% (w/v) (F)). Under 1% (w/v) SY-PCS and repeated batch fermentation, panels show biomass distribution (G), anti-melanin effects (H), and anti-melanin compound content per unit time (I).

The choice of fermentation mode significantly influences metabolite production. While batch fermentation is simple and minimizes contamination risk, nutrient depletion limits productivity. Continuous fermentation maintains a steady-state culture, extending microbial exponential growth and increasing metabolite yield, though sterility remains challenging18,19. Repeated-batch fermentation, where part of the culture broth is replaced while active biomass is retained, has been shown to reduce downtime, lower operational costs, and sustain metabolite production17. Given these advantages, immobilized fungal mycelium is well suited for repeated-batch or continuous fermentation, ensuring a more resource efficient and environmentally sustainable approach. To improve fermentation efficiency and biomass stability, repeated-batch fermentation was implemented to address limitations associated with batch fermentation, such as reinoculation delays and reduced biomass stability17. Without PCS, Ganoderma mycelia formed dense aggregates that restricted oxygen and nutrient diffusion20.

In this study, mycelial growth stabilized by day 4, reaching 7.67 g/L on day 13 (Fig. 2G), similar to observations in G. lucidum, where biomass yield declined with aging20,21. Tyrosinase inhibition remained stable in the second batch, with peak inhibition comparable to that observed between days 6 and 8 of the first batch (Fig. 2H). The rapid recovery of metabolic activity in the second batch was likely due to high biomass density in biofilm reactors, shortening the lag phase and facilitating metabolite accumulation. Immobilized cell systems have been widely adopted in industrial fermentation to improve bioproduct yields. Similarly, immobilized G. lucidum demonstrated a 1.55-fold increase in extracellular polysaccharide yield18. In this study, anti-melanin compound productivity peaked at 2.09 g/L/day on day 11, 2.7 times higher than in the first batch (Fig. 2I). However, productivity declined in the third batch, consistent with findings in C. militaris, where polysaccharide yield decreased due to cell aging22. These results suggest that while SY-PCS IFS enhances metabolite production, with 1% supplementation surpassing a functional threshold not achieved at 0.5%, thereby sustaining higher productivity in repeated-batch mode. Comparable observations have been reported in Ganoderma cultures where yeast extract supplementation significantly increased triterpenoid accumulation23, and in PCS-based biofilm reactors where adequate carrier loading was required to maintain lactic acid productivity during repeated fed-batch fermentation24. Such findings reinforce that our selection of 1% SY-PCS reflects a practically favorable condition rather than an absolute optimum.

Cytotoxic effects and melanogenesis inhibition of GFE-EA from SY-PCS IFS in B16-F10 cells and zebrafish embryos

B16-F10 cell viability was assessed after exposure to GFE-EA at 50–200 µg/mL (Fig. 3A). At 24 h, viability remained above 80% (p > 0.05), but at 48 h, significant reductions were observed at 150 and 200 µg/mL (p < 0.05), with PCS-treated cells showing greater cytotoxicity at 200 µg/mL (p < 0.05) (Fig. 3B). Previous studies reported cytotoxicity at 200 ppm25, supporting the decision to conduct subsequent melanogenesis assays at concentrations below 200 µg/mL. Melanin levels were quantified after 48 h of treatment with 100 and 150 µg/mL GFE-EA (Fig. 3C). KA (100 µM) was a positive control, with α-MSH (1 µM) used to induce melanogenesis. GFE-EA significantly reduced melanin levels compared to the α-MSH-induced control (p < 0.05), confirming its inhibitory effect. However, no significant differences were detected between SY-PCS and non-PCS groups (p > 0.05). This lack of statistical difference between SY-PCS and non-PCS extracts in B16-F10 cells is mechanistically plausible. Once the metabolites are extracted into a soluble ethanolic fraction, the matrix effect of PCS during fermentation is largely normalized at the assay stage, so both groups deliver comparable concentrations of active compounds to the cells. Moreover, melanogenesis in B16-F10 cells is regulated at multiple levels beyond direct tyrosinase inhibition, including MITF-driven transcription and post-translational regulation of TYR/TYRP enzymes, which can dampen incremental differences in metabolite composition26. Similar plateau effects have been described in B16-F10 melanogenesis assays, where different plant extracts suppress pigmentation to a similar extent despite compositional variability27. In addition, the limited permeability of some polyphenolic compounds may restrict intracellular availability, capping functional differences even when docking analyses suggest stronger binding affinity28. These considerations explain why PCS versus non-PCS extracts showed no significant differences in cellular melanin assays, despite their divergent fermentation-phase metabolite profiles.

Cell viability of B16-F10 cells treated with different concentrations of GFE-EA (obtained from the SY) for 24 h (A) and 48 h (B). Intracellular melanin content in B16-F10 cells following GFE-EA treatment (C). Effect of GFE-EA on zebrafish heart rate (D). Zebrafish melanogenesis assays, including tyrosinase activity (E) and melanin content (F). Phenotypic observations of zebrafish under GFE-EA treatment (G). All data are expressed as mean ± SD (n ≥ 3). Different letters indicate significant differences according to Duncan’s multiple range test (p < 0.05). NC Negative control, KA Kojic acid (100 µg/mL); SY-PCS contains PP, dried ground soybean hulls, and yeast extract, GFE-EA Hexane fraction of GFM.

Before evaluating melanogenesis inhibition, GFE-EA toxicity was tested in zebrafish embryos. KA (100 µg/mL) was a positive control, while GFE-EA was tested at 50–200 µg/mL. At 72hpf, the heart rate significantly declined at 200 µg/mL (p < 0.05), indicating potential toxicity (Fig. 3D). This was likely due to triterpenoids and polyphenols in G. formosanum25,29, as phenolic compounds have been shown to alter zebrafish metabolism30. Morphological assessment (Fig. 3G) revealed normal development at 50–150 µg/mL, while pericardial edema occurred at 200 µg/mL, suggesting developmental toxicity. Consequently, melanin assays were conducted at lower concentrations. Tyrosinase activity and melanin content were analyzed at 50–150 µg/mL GFE-EA, with KA (100 µg/mL) as the positive control. As shown in Fig. 3E, tyrosinase activity significantly decreased in the 150 µg/mL PCS-treated group (151.07 units/mg) compared to the control (340.39 units/mg), a 2.25-fold reduction (p < 0.05). Other groups showed no significant differences from kojic acid. Melanin content (Fig. 3F) declined dose-dependently, with 100 µg/mL PCS and non-PCS groups reducing melanin levels to 50.15% and 57.26%, respectively, with no significant difference from KA (p > 0.05). At 150 µg/mL, melanin content decreased to 31.33% and 32.10%.

Fungal secondary metabolites have been recognized for tyrosinase inhibition. A. silvaticus ethanol extracts suppressed zebrafish melanogenesis dose-dependently31, while A. cinnamomea mycelium hexane fractions reduced melanogenesis by inhibiting tyrosinase32. These compounds penetrate the zebrafish chorion and regulate melanogenesis by downregulating tyrosinase, MITF, TYRP1, and TYRP233. In this study, tyrosinase activity did not show a clear dose-dependent trend, suggesting additional pathways may be involved. These results highlight G. formosanum mycelium extracts as potential melanogenesis regulators, warranting further investigation.

Molecular docking analysis of multi-ligand interactions with tyrosinase and the effect of SY-PCS IFS on binding affinity

LC–MS/MS profiling revealed that fermentation under SY-PCS conditions generated additional metabolites, including flavonoids such as chrysin and kaempferol and fatty acids such as linoleic acid, which were absent or less abundant in PCS-only cultures. This study then investigated the molecular interactions between these metabolites and tyrosinase, particularly under SY-PCS IFS. Previous studies demonstrated that combining multiple ligands enhances tyrosinase inhibition33. A prior analysis of six anti-melanin compounds from GFM, including gluconic acid, mesalamine, L-pyroglutamic acid, esculetin, 5-hydroxyindole, and salicylic acid, showed a combined binding energy of −16.36 kcal/mol, contributing to enzyme inhibition. At the same time, some metabolites chelate copper ions, further disrupting melanin synthesis34. Following fermentation optimization in an SY-PCS, multi-ligand docking analysis revealed an increased binding energy of −20.20 kcal/mol compared to −17.38 kcal/mol in the non- SY-PCS group (Table 1), indicating that fermentation conditions influenced metabolite composition and strengthened tyrosinase binding. Molecular docking analysis (Fig. 4A) revealed that in the SY-PCS group, several compounds formed hydrogen bonds with tyrosinase, with the strongest interactions observed for linoleic acid (Fig. 4B), chrysin (Fig. 4C), kaempferol (Fig. 4D), succinic acid (Fig. 4E), paracetamol (Fig. 4F), norfloxacin (Fig. 4G), and C2-ceramide (Fig. 4H), contributing to 16 hydrogen bonds. It should be noted that annotations such as paracetamol and norfloxacin were derived from LC–MS/MS spectral matching and are presented here for transparency. These signals do not necessarily originate from Ganoderma formosanum; rather, they may reflect exogenous background compounds whose relative abundance was amplified during extraction and concentration. For this reason, they are regarded as tentative identifications and were not emphasized in the mechanistic interpretation. However, 2-aminophenol (Fig. 4I), glycyrrhetic acid (Fig. 4J), and nicotinic acid (Fig. 4K) primarily exhibited hydrophobic interactions without hydrogen bonding. These findings were consistent with docking studies on known tyrosinase inhibitors. Arbutin and its derivatives formed hydrogen bonds with His178 and Lys15835, similar to the binding pattern observed for Linoleic acid. 6,7-bis-(2-methoxyethoxy)-4(3H)-quinazolinone, a potent quinazolinone-based tyrosinase inhibitor, interacted with Thr360 and Val11 through hydrophobic forces, altering tyrosinase conformation34, aligning with succinic acid binding in this study. Additionally, carotenoids such as bixin, norbixin, and crocin were reported to interact with Asp130, Asn29, and Asp36936, resembling the binding sites of PCS-derived compounds. Another study demonstrated that salicylic acid derivatives formed hydrogen bonds with TRP357, Ser363, Asn80, His84, and His24337, which differed from the binding sites identified in this study.

Further analysis identified embelin, a natural benzoquinone with tyrosinase inhibitory properties, forming hydrogen bonds with Asn19, Glu359, Asp369, and Lys372, with a binding energy of −6.56 kcal/mol. Cinnamic and ferulic acids also inhibited tyrosinase, interacting with Arg301, Asn22, and Lys37938. These findings were consistent with the binding patterns observed in SY-PCS-derived compounds. Traditional medicinal plant extracts contain flavonoids and terpenoids that act as tyrosinase inhibitors, with hydroxyl groups playing a crucial role in hydrogen bond formation at the enzyme’s active site7. The inhibitory effect of these compounds is influenced by the number and position of hydroxyl groups, with higher hydroxylation enhancing tyrosinase inhibition. In this study, fermentation under SY-PCS conditions led to the production of flavonoids such as Chrysin (Fig. 4C) and Kaempferol (Fig. 4D), which interacted with tyrosinase through hydroxyl-mediated hydrogen bonding. These findings reinforced the significance of flavonoids in tyrosinase inhibition and highlighted the impact of fermentation on metabolite composition. The greater metabolite diversity observed in the SY-PCS group can be explained by the nutrient-enriched matrix: yeast extract in SY-PCS provides amino acids, vitamins, and nitrogenous precursors that stimulate secondary metabolism in Ganoderma, thereby enabling the production of additional bioactive compounds. This nutrient effect, combined with improved immobilization on the PCS surface, created a more favorable microenvironment for metabolite biosynthesis than PCS alone22. A comparative docking site analysis (Fig. 4L, M) evaluated tyrosinase interactions in SY-PCS and non-SY-PCS groups. The binding residues identified in this study, shown in red and pink, were compared with previously reported tyrosinase inhibitors. Green lines indicate binding sites shared with documented anti-melanin compounds34,39, while yellow lines highlight additional sites reported in previous studies, including TRP357, Ser363, Asn80, His84, and His24337. These results suggested that the compounds produced under PCS fermentation may interact with novel tyrosinase binding residues, offering potential opportunities to develop sustainable anti-melanin agents.

The unique binding residues suggested that compounds identified in SY-PCS cultures may offer novel tyrosinase inhibition mechanisms, providing opportunities for developing more effective anti-melanogenesis agents. This study demonstrated that SY-PCS IFS enhanced the production of tyrosinase-inhibiting metabolites, leading to increased binding affinity and diverse interaction mechanisms. The presence of multiple ligands with synergistic binding indicated that SY-PCS IFS optimized metabolite profiles for improved anti-melanogenesis potential. Furthermore, comparative docking analysis highlighted distinct binding residues, suggesting the potential for discovering novel tyrosinase inhibitors. These findings contributed to developing sustainable and biologically active anti-melanogenesis agents, emphasizing the role of fermentation optimization in functional metabolite production.

In this study, G. formosanum mycelia were successfully immobilized using PCS in an airlift bioreactor, significantly enhancing anti-melanogenesis activity and fermentation efficiency. Among the PCS variants, the SY-PCS based carrier, composed of soybean hulls, polypropylene, and yeast extract, demonstrated the highest efficacy in promoting mycelial growth and anti-melanogenesis activity. Shake flask screening confirmed that an agitation speed of 60 rpm facilitated optimal adhesion of G. formosanum to SY-PCS group, leading to a stable biomacromolecule matrix. This matrix exhibited 79.78% of the anti-melanogenesis effect of Kojic acid (100 µg/mL). Scale-up experiments in a 5 L airlift bioreactor further validated these findings, with 1% SY-PCS supplementation on day 8 yielding anti-melanogenesis efficacy comparable to 81.7% of Kojic acid. Additionally, repeated-batch fermentation significantly improved productivity, reaching 2.09 g/L/day on day 11 of the second batch, a 2.7-fold increase over the first batch.

Cell-based assays demonstrated that the ethyl acetate extract of G. formosanum remained non-cytotoxic at concentrations below 150 µg/mL while effectively inhibiting intracellular melanin accumulation, achieving anti-melanogenesis activity comparable to 100 µg/mL Kojic acid. Zebrafish experiments confirmed a 31% melanin reduction at 150 µg/mL, reinforcing the anti-melanogenesis potential of the SY-PCS group. LC-MS/MS analysis identified 15 active anti-melanogenesis compounds: gluconic acid, mesalamine, L-pyroglutamic acid, esculetin, 5-hydroxyindole, salicylic acid, linoleic acid, chrysin, kaempferol, succinic acid, paracetamol, norfloxacin, C2-ceramide, 2-aminophenol, and glycyrrhetic acid. Molecular docking analysis revealed high tyrosinase-binding affinities, with a maximum binding energy of -20.20 kcal/mol in the SY group, indicating strong synergistic effects among the identified compounds. By integrating immobilization with sustainable fermentation strategies, this study demonstrates that SY-PCS is the most effective immobilization matrix for G. formosanum fermentation, enhancing both mycelial growth and anti-melanogenesis activity. Combining SY-PCS IFS in an airlift bioreactor provides a sustainable and scalable strategy for producing natural anti-melanogenesis agents.

Methods

Materials

G. formosanum (ATCC 76537) was obtained from the American Type Culture Collection (ATCC, Rockville, MD, U.S.A.), while the B16-F10 murine melanoma cell line (BCRC 60031) was provided by the Bioresource Collection and Research Center (BCRC, Hsinchu, Taiwan). Zebrafish (AB strain) embryos were acquired from NTU Tech Comm., National Taiwan University (Taipei, Taiwan). The culture medium for G. formosanum consisted of glucose, yeast extract, peptone, potato dextrose broth, and agar, all obtained from BioShop Canada Inc. (Ontario, Canada). For cell culture, Dulbecco’s Modified Eagle Medium (DMEM, high glucose, phenol red-free, and L-glutamine supplemented) and fetal bovine serum (FBS) were purchased from GE Healthcare Life Science (Logan, Utah, U.S.A.), while penicillin, streptomycin, and trypsin-EDTA solution were sourced from the same supplier. Radio-Immunoprecipitation Assay (RIPA) Buffer (10X) was obtained from Cell Signaling Technology (Beverly, MA, U.S.A.), and Cell Counting Kit-8 (CCK-8) was acquired from Cyrus Bioscience (Neihu, Taiwan). Zebrafish embryos were maintained in Danieau’s buffer, which was prepared using NaCl, KCl, MgSO₄, Ca(NO₃)₂, and HEPES, all sourced from Sigma-Aldrich (St. Louis, MO, U.S.A.). Chemicals used for mycelial extraction and compound fractionation, including ethanol, n-hexane, and ethyl acetate, were of analytical grade and purchased from Merck (Burlington, MA, U.S.A.). The Tyrosinase Activity Assay Kit (ab252899) was purchased from Abcam (Cambridge, U.K.). High-performance liquid chromatography (HPLC)-grade solvents, including acetonitrile, methanol, and formic acid, were obtained from JT Baker (Phillipsburg, NJ, U.S.A.). All chemicals and reagents were of analytical grade and used without further purification.

Preparation of Plastic Composite Support (PCS)

PCS was produced by twin-screw extrusion based on a modified method37. The agricultural byproducts used included defatted soybean powder, soy hull, hydrolyzed protein, yeast extract, and dried porcine red blood cells, with PP serving as the polymer matrix. Before extrusion, the extruder was preheated in multiple stages. Once the desired temperature was reached, the agricultural byproducts and PP were gradually introduced into the feeding port of the extruder at a screw speed of 13 rpm. The extruded PCS was cooled and cut into the appropriate lengths for further experiments3.

Selection and optimization of PCS for immobilization

To evaluate the suitability of PCS for G. formosanum immobilization, a modified protocol from researches were applied38,39. A 10% (v/v) inoculum of G. formosanum was introduced into 100 mL of culture medium in 250 mL shake flasks, each containing four pre-sterilized PCS strips (4 cm × 3.5 cm × 1.7 mm). The PCS was sterilized twice at 121 °C for 20 min before use. The cultures were incubated at 25 °C under high-speed (120 rpm) and low-speed (60 rpm) agitation for seven days. Mycelial growth and anti-melanogenesis activity were assessed after incubation.

Mycelial Extraction and Fractionation

Freeze-dried GFM were thermally disrupted at 121 °C for 20 min and extracted three times using ethanol at a 1:15 (w/v) ratio at 60 °C. The extract was concentrated under reduced pressure to remove ethanol, yielding the crude GFE. The GFE was then redissolved in 20 volumes of double-distilled water and partitioned with Hex by vigorous shaking, followed by centrifugation at 9000 × g for 5 min. The upper hexane layer was collected, and the process was repeated three times to obtain GFE-Hex. The aqueous phase was further extracted with ethyl acetate using the same procedure, yielding GFE-EA25,32.

In vitro tyrosinase activity assay

Tyrosinase inhibitory activity was assessed following the method described by the study25. Tyrosinase powder was dissolved in PBS to prepare a 480 unit/mL solution, while L-DOPA solution (0.86 mM) was prepared in PBS. Samples, including KA (positive control), were dissolved in methanol at 400 µg/mL. A 96-well microplate was used, where 20 μL of KA or test samples were added to each well, followed by 140 μL of PBS. Subsequently, 20 μL of the tyrosinase solution was added, and the reaction was incubated for 10 min in the dark. After incubation, 20 μL of L-DOPA solution was introduced, followed by another 10-min incubation in the dark. Absorbance was measured at 475 nm using a microplate reader. The tyrosinase inhibition rate was calculated using the following equation.

Where A and B represent the absorbance of the control group with and without tyrosinase, respectively, and C and D represent the absorbance of the sample group with and without tyrosinase, respectively.

Airlift bioreactor fermentation and repeated-batch process

Fermentation was performed in a 5 L ALB following a modified method described by previous research22. The bioreactor was sterilized at 121 °C for 40 min before inoculation with G. formosanum at 10% (v/v). PCS was introduced at 0%, 0.5%, and 1% (w/v) to evaluate its effect on mycelial growth and metabolite production. The cultures were maintained at 25 °C with an aeration rate of 1 vvm for 10 days. For repeated-batch fermentation, the spent medium and mycelia were removed at the optimal fermentation time, and fresh medium was introduced for the second and third batch fermentations. Collected mycelia were freeze-dried and analyzed for dry weight, anti-melanogenesis activity, and production efficiency, calculated using the following equation Eq. 2

Cell-based tyrosinase activity assay

The B16-F10 melanoma cells were seeded into 96-well plates at a density of 1 × 10⁴ cells per well and incubated at 37 °C with 5% CO₂ overnight. After removing the medium, different concentrations of GFE-EA (200, 150, 100, and 50 µg/mL) were added, and cells were incubated for 48 h. Subsequently, 120 µL of CCK-8 reagent mixed with DMEM was added to each well and incubated for 1 h in the dark. Cell viability was measured at 450 nm using a microplate reader7. For melanin quantification, cells were seeded into 24-well plates at a density of 1 × 10⁵ cells per well and incubated overnight. After removing the old medium, DMEM without phenol red was used to prepare different concentrations of GFE-EA. Kojic acid served as the positive control, and 1 µMα-MSH was used as the negative control. The samples, along with α-MSH, were added to the wells and incubated for 48 h. The cells were then washed twice with PBS, detached with 200 µL of Trypsin, and incubated for 3 min. The reaction was stopped by adding 800 µL of DMEM, followed by centrifugation at 6000 × g for 10 min at 4 °C. The supernatant was discarded, and cells were resuspended in 1 mL PBS, centrifuged again, and dissolved in 250 µL of 1 N NaOH containing 10% DMSO. The samples were incubated at 60 °C for 60 min, centrifuged at 12,000 × g for 20 min, and the melanin content was measured at 405 nm25.

Zebrafish tyrosinase activity and melanin content assay

Zebrafish embryos at the same developmental stage were transferred into 96-well plates, with three embryos per well in 200 µL of Danieau’s buffer. The samples, including GFE-EA (200, 150, 100, and 50 µg/mL) and 100 µg/mL KA (positive control), were added at 7 hpf. The medium was replaced every 24 h until 72 hpf, at which point heart rate and viability were recorded using a stereomicroscope40. For the tyrosinase activity assay, approximately 60 zebrafish embryos were collected, rinsed with PBS, and lysed using 300 µL of Lysis Buffer from the Tyrosinase Activity Assay Kit (ab252899). The lysates were sonicated on ice and centrifuged at 120,00 × g for 10 min at 4 °C. The supernatant was used for protein quantification via the Bradford assay, while tyrosinase activity was assessed using SBC Mix (45 µL Tyrosinase Assay Buffer, 5 µL Tyrosinase Probe) and Reaction Mix (35 µL Tyrosinase Assay Buffer, 10 µL Tyrosinase Substrate, 5 µL Tyrosinase Probe). The reaction was monitored by measuring absorbance at 510 nm every 1 min for 15 min40. Melanin content was measured by dissolving the pellet in 250 µL of 1 N NaOH containing 10% DMSO, followed by incubation at 100 °C for 60 min. After centrifugation at 12,000 × g for 10 min, 100 µL of the supernatant was transferred into a 96-well plate and absorbance was measured at 405 nm. The melanin content was determined using a standard curve generated from synthetic melanin standards13. All experiments were performed according to the regulations and guidelines issued by National Taiwan University Institutional Animal Care and Use Committee (NTU-108-EL-147).

Identification of anti-melanin compounds using UHPLC-MS/MS

Anti-melanin compounds in GFE were analyzed using UHPLC-MS/MS in collaboration with the Department of Chemistry, National Taiwan University. The extracts were dissolved in methanol at 10 mg/mL, filtered through a 0.22 µm PES membrane, and injected into a Promisil C18 column (5 µm, 250 × 4.6 mm). A mobile phase of 0.1% formic acid in water (Solvent A) and 0.1% formic acid in acetonitrile (Solvent B) was used at a flow rate of 0.5 mL/min. Detection wavelengths were set at 254 nm, 300 nm, and 365 nm39. Mass spectrometry analysis was performed using an ESI source in both positive and negative ion modes. Precursor ions with strong intensities were selected for fragmentation, and MS/MS spectra were obtained using CID. The generated fragmentation spectra were compared with the mzCloudTM database for compound identification7,41.

Molecular docking analysis

Molecular docking was conducted to assess the binding affinity of tyrosinase with bioactive compounds identified in GFE. The 3D structure of tyrosinase (PDB ID: 2Y9W) was obtained from the RCSB Protein Data Bank. The structure was processed using AutoDock Tools, where water molecules were removed, hydrogen atoms were added, and Kollman charges were assigned. Ligands were retrieved from PubChem, converted to PDB format, and processed by AutoDock Tools, which included hydrogen addition, Gasteiger charge assignment, and torsional flexibility setting. Docking simulations were carried out using AutoDock Vina, with the docking grid set at X: -1.83/40, Y: 30.70/40, Z: 81.89/40. Ligand binding interactions with tyrosinase active sites were analyzed using LigPlot + software for 2D interaction mapping, while PyMOL software was employed to visualize 3D structural interactions7.

Morphology of PCS samples

The morphology of PCS samples was observed using a scanning electron microscopy (SEM) at an accelerating voltage of 10 kV (FESEM S-4800 model, Hitachi, Tokyo, Japan), then lyophilized and coated with a thin layer of gold nanoparticles and captured at 30-350X magnification41.

Statistical analysis

All experiments were performed in triplicate. Data were expressed as mean ± standard deviation (SD). Statistical analyses were conducted using IBM SPSS Statistics 20 (IBM, New York, USA). Differences among groups were assessed using one-way ANOVA, followed by Duncan’s multiple range test, with statistical significance set at p < 0.057.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Yi, G. et al. Repeated batch fermentation for surfactin production with immobilized Bacillus subtilis BS-37: two-stage pH control and foam fractionation. J. Chem. Technol. Biotechnol. 92, 530–535 (2017).

Ogawa, M., Bisson, L. F., García-Martínez, T., Mauricio, J. C. & Moreno-García, J. New insights on yeast and filamentous fungus adhesion in a natural co-immobilization system: proposed advances and applications in wine industry. Appl. Microbiol. Biotechnol. 103, 4723–4731 (2019).

Hou, S. J. et al. Improvement of extracellular polysaccharides production from Cordyceps militaris immobilized alginate beads in repeated-batch fermentation. LWT 193, 115752 (2024).

Mahdinia, E., Demirci, A. & Berenjian, A. Utilization of glucose-based medium and optimization of Bacillus subtilis natto growth parameters for vitamin K (menaquinone-7) production in biofilm reactors. Biocatal. Agric. Biotechnol. 13, 219–224 (2018).

Ramonet, F., Haddadi, B. & Harasek, M. Optimal design of double stage internal loop air-lift bioreactor. Energies 16, 3267 (2023).

Hou, C. Y. et al. Evaluation of the amelioration effect of Ganoderma formosanum extract on delaying PM2.5 damage to lung macrophages. Mol. Nutr. Food Res. 68, 2300667 (2024).

Hsieh, C. C. et al. Aromatic compounds and organic acids identified from Ganoderma formosanum exhibit synergistic anti-melanogenic effects. J. Food Drug Anal. 32, 532 (2024).

Zhao, W. et al. Potential application of natural bioactive compounds as skin-anti-melanin agents: a review. J. Cosmet. Dermatol. 21, 6669–6687 (2022).

Lai, Y. J. et al. Anti-melanogenic effect from submerged mycelial cultures of Ganoderma weberianum. Mycobiology 47, 112–119 (2019).

Izmirlioglu, G. & Demirci, A. Ethanol production in biofilm reactors from potato waste hydrolysate and optimization of growth parameters for Saccharomyces cerevisiae. Fuel 181, 643–651 (2016).

Sułkowska-Ziaja, K. et al. Bioactivity and mycochemical profile of extracts from mycelial cultures of Ganoderma spp. Molecular 27, 275 (2022).

Ho, K. L., Pometto, A. L., Hinz, P. N., Dickson, J. S. & Demirci, A. Ingredient selection for plastic composite supports for L-(+)-lactic acid biofilm fermentation by Lactobacillus casei subsp. rhamnosus. Appl. Environ. Microbiol. 63, 2516–2523 (1997).

Fan, X., Zhu, S. S., Zhang, X. X., Ren, H. Q. & Huang, H. Revisiting the microscopic processes of biofilm formation on organic carriers: a study under variational shear stresses. ACS Appl. Bio Mater. 4, 5529–5541 (2021).

Rathore, H., Prasad, S., Kapri, M., Tiwari, A. & Sharma, S. Medicinal importance of mushroom mycelium: mechanisms and applications. J. Funct. Foods 56, 182–193 (2019).

Zhixia, J. et al. Effect of agitation intensity on the mycelial morphology and cephalosporin C production in Cephalosporium acremonium. Chin. J. Antibiot. 30, 392–395 (2005).

Shah, P. & Modi, H. Optimization of culture conditions for biomass production of Ganoderma lucidum. Int. J. Curr. Microbiol. Appl. Sci. 7, 1882–1889 (2018).

Germec, M., Turhan, I., Karhan, M. & Demirci, A. Ethanol production via repeated-batch fermentation from carob pod extract by using Saccharomyces cerevisiae in biofilm reactor. Fuel 161, 304–311 (2015).

López-Gómez, J. P., Alexandri, M., Schneider, R. & Venus, J. A review on the current developments in continuous lactic acid fermentations and case studies utilising inexpensive raw materials. Proc. Biochem. 79, 1–10 (2019).

Supramani, S. et al. Pellet diameter and morphology of European Ganoderma pfeifferi in a repeated-batch fermentation for exopolysaccharide production. Biocatal. Agric. Biotechnol. 19, 101118 (2019).

Wan, W. A. A. Q. I., Latif, N. A., Harvey, L. M. & McNeil, B. Production of exopolysaccharide by Ganoderma lucidum in a repeated-batch fermentation. Biocatal. Agric. Biotechnol. 6, 91–101 (2016).

Yalcin, O. U., Sarikurkcu, C., Cengiz, M., Gungor, H. & Ćavar Zeljković, S. Ganoderma carnosum and Ganoderma pfeifferi: Metal concentration, phenolic content, and biological activity. Mycologia 112, 1–8 (2020).

Lin, S. P. et al. Enhanced exopolysaccharide production of Cordyceps militaris via mycelial cell immobilization on plastic composite support in repeated-batch fermentation. Int. J. Biol. Macromol. 250, 126267 (2023).

Cui, M. L. & He, G. Q. Optimization of the submerged fermentation conditions of Ganoderma lucidum with high triterpenoids production by response surface analysis. Adv. Mater. Res. 621, 259–262 (2013).

Velázquez, A., Pometto Iii, A. L., Ho, K. L. G. & Demirci, A. Evaluation of plastic-composite supports in repeated fed-batch biofilm lactic acid fermentation by Lactobacillus casei. Appl. Microbiol. Biotechnol. 55, 434–441 (2001).

Hsu, K. D. et al. Extract of Ganoderma formosanum mycelium as a highly potent tyrosinase inhibitor. Sci. Rep. 6, 32854 (2016).

Kim, T., Kim, K. B. & Hyun, C. G. A 7-hydroxy 4-methylcoumarin enhances melanogenesis in B16-F10 melanoma cells. Molecular 28, 3039 (2023).

Vidyalakshmi, S. & Sahithya, D. Preliminary screening of selected plant extracts for anti tyrosinase activity. J. Nat. Remedies, 16, 18–21 (2016).

Pavlović, N. et al. Principal Component Analysis (PCA) of molecular descriptors for improving permeation through the blood–brain barrier of quercetin analogues. Int. J. Mol. Sci. 25, 192 (2023).

Cui, M. & He, G. Enhanced production of mycelia biomass and bioactive metabolite of the American Ganoderma lucidum in submerged culture. ICBEB, 252–255. (IEEE, 2012).

Mahmood, I. et al. Mutated Shiitake extracts inhibit melanin-producing neural crest-derived cells in zebrafish embryo. Comp. Biochem. Physiol. C. Toxicol. Pharmacol. 245, 109033 (2021).

Pavic, A., Ilic-Tomic, T. & Glamočlija, J. Unravelling anti-melanogenic potency of edible mushrooms Laetiporus sulphureus and Agaricus silvaticus in vivo using the zebrafish model. J. Fungi. 7, 834 (2021).

Chen, H. Y., Cheng, K. C., Wang, H. T., Hsieh, C. W. & Lai, Y. J. Extracts of Antrodia cinnamomea mycelium as a highly potent tyrosinase inhibitor. J. Cosmet. Dermatol. 20, 2341–2349 (2021).

Ferreira, A. M. et al. Anti-melanogenic potential of natural and synthetic substances: application in zebrafish model. Molecular 28, 1053 (2023).

Yin, Z. H. et al. Synergistic effects and antityrosinase mechanism of four plant polyphenols from Morus and hulless barley. Food Chem. 374, 131716 (2022).

Chai, W. M., Bai, Q., Pan, Q., Wang, L. & Zhu, D. 6,7-Bis-(2-methoxyethoxy)-4(3H)-quinazolinone as a novel inhibitor of tyrosinase and potential anti-browning agent of fresh-cut apples. J. Biosci. Bioeng. 137, 165–172 (2024).

Anantharaman, A. et al. Inhibitory effect of apocarotenoids on the activity of tyrosinase: multi-spectroscopic and docking studies. J. Biosci. Bioeng. 121, 13–20 (2016).

Korkmaz, A. & Bursal, E. Synthesis, biological activity and molecular docking studies of novel sulfonate derivatives bearing salicylaldehyde. Chem. Biodivers. 19, e202200140 (2022).

Yu, Q., Fan, L. & Duan, Z. Five individual polyphenols as tyrosinase inhibitors: inhibitory activity, synergistic effect, action mechanism, and molecular docking. Food Chem. 297, 124910 (2019).

Salih, E. Y. et al. LC-MS/MS tandem mass spectrometry for analysis of phenolic compounds and pentacyclic triterpenes in antifungal extracts of Terminalia brownii (Fresen). Antibiotics 6, 37 (2017).

Liu, Y. W. et al. Optimal production of Ganoderma formosanum mycelium with anti-melanogenic activity. Fermentation 9, 372 (2023).

Hsieh, C. C. et al. Production and analysis of metabolites from solid-state fermentation of Chenopodium formosanum (Djulis) sprouts in a bioreactor. Food Res. Int. 168, 112707 (2023).

Acknowledgements

This project was funded by the National Science and Technology Council, Taiwan (R.O.C.) (NSTC 112-2320-B-002-013-MY3; 112-2221-E-002-040-MY3; 113-2222-E-992 -009 -MY2). Yi-Wen Chen and Yi-Cheng Huang had the same contribution in this study. This article serves as a tribute to Chan's significant contributions in exploring the anti-melanogenesis properties of G. formosanum.

Author information

Authors and Affiliations

Contributions

Chen-Che Hsieh: Writing Original Draft, Conceptualization, Writing–review & editing. Yi-Wen Chen, Yi-Cheng Huang, hin-Ping Lin, Kai-Wen Cheng, Cheng-Chih Hsu, Chang-Wei Hsieh, Artik Elisa Angkawijaya, and Shella Permatasari Santoso: Data Curation, Formal Analysis. Kuan-Chen Cheng and Hui-Wen Lin: Conceptualization, Funding acquisition, Writing–review & editing, Project Administration, and Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hsieh, CC., Chen, YW., Huang, YC. et al. Sustainable repeated-batch fermentation of immobilized Ganoderma formosanum for enhanced production of anti-melanogenic bioactive compounds. npj Sci Food 9, 247 (2025). https://doi.org/10.1038/s41538-025-00608-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41538-025-00608-3