Abstract

Trapped-ion applications, such as in quantum information processing1, precision measurements2,3,4,5, optical clocks6 and mass spectrometry7, rely on specialized high-performance ion traps. The last three of these applications typically use traditional machining to customize macroscopic 3D Paul traps8, whereas quantum information processing experiments usually rely on photolithographic techniques to miniaturize the traps and meet scalability requirements9,10. Using photolithography, however, it is challenging to fabricate the complex 3D electrode structures required for optimal confinement. Here we demonstrate a high-resolution 3D printing technology based on two-photon polymerization (2PP)11 that is capable of fabricating large arrays of high-performance miniaturized 3D traps. We show that 3D-printed ion traps combine the advantages, such as strong radial confinement, of traditionally machined 3D traps with on-chip miniaturization. We trap calcium ions in 3D-printed ion traps with radial trap frequencies ranging from 2 MHz to 24 MHz. The tight confinement eases ion cooling requirements and allows us to implement high-quality Rabi oscillations with Doppler cooling only. Also, we demonstrate a two-qubit gate with a Bell-state fidelity of 0.978 ± 0.012. With 3D printing technology, the design freedom is greatly expanded without sacrificing scalability and precision, so that ion trap geometries can be optimized for higher performance and better functionality.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. All other data supporting the plots in this paper and other findings of this study are available from the corresponding authors on request.

References

Bruzewicz, C. D., Chiaverini, J., McConnell, R. & Sage, J. M. Trapped-ion quantum computing: progress and challenges. Appl. Phys. Rev. 6, 021314 (2019).

Brown, L. & Gabrielse, G. Geonium theory: physics of a single electron or ion in a Penning trap. Rev. Mod. Phys. 58, 233–311 (1986).

Smorra, C. et al. A parts-per-billion measurement of the antiproton magnetic moment. Nature 550, 371–374 (2017).

Scielzo, N. D. et al. The β-decay Paul trap: a radiofrequency-quadrupole ion trap for precision β-decay studies. Nucl. Instrum. Methods Phys. Res. A 681, 94–100 (2012).

Roussy, T. S. et al. An improved bound on the electron’s electric dipole moment. Science 381, 46–50 (2023).

Ludlow, A. D., Boyd, M. M., Ye, J., Peik, E. & Schmidt, P. Optical atomic clocks. Rev. Mod. Phys. 87, 637–701 (2015).

Douglas, D. J., Frank, A. J. & Mao, D. Linear ion traps in mass spectrometry. Mass Spectrom. Rev. 24, 1–29 (2005).

Paul, W. Electromagnetic traps for charged and neutral particles. Rev. Mod. Phys. 62, 531–540 (1990).

Chiaverini, J. et al. Surface-electrode architecture for ion-trap quantum information processing. Quantum Inf. Comput. 5, 419–439 (2005).

Seidelin, S. et al. Microfabricated surface-electrode ion trap for scalable quantum information processing. Phys. Rev. Lett. 96, 253003 (2006).

Baldacchini, T. Three-Dimensional Microfabrication Using Two-Photon Polymerization (William Andrew, 2016).

Leibfried, D., Blatt, R., Monroe, C. & Wineland, D. Quantum dynamics of single trapped ions. Rev. Mod. Phys. 75, 281–324 (2003).

Wesenberg, J. H. Electrostatics of surface-electrode ion traps. Phys. Rev. A 78, 063410 (2008).

Nguyen, L. M. A., Bowers, B. & Mouradian, S. The effect of trap design on the scalability of trapped-ion quantum technologies. Entropy 27, 576 (2025).

Brownnutt, M., Kumph, M., Rabl, P. & Blatt, R. Ion-trap measurements of electric-field noise near surfaces. Rev. Mod. Phys. 87, 1419–1482 (2015).

Brown, K. R., Chiaverini, J., Sage, J. M. & Häffner, H. Materials challenges for trapped-ion quantum computers. Nat. Rev. Mater. 6, 892–905 (2021).

Blakestad, R. B. et al. High-fidelity transport of trapped-ion qubits through an X-junction trap array. Phys. Rev. Lett. 102, 153002 (2009).

Ragg, S., Decaroli, C., Lutz, T. & Home, J. P. Segmented ion-trap fabrication using high precision stacked wafers. Rev. Sci. Instrum. 90, 103203 (2019).

Decaroli, C. et al. Design, fabrication and characterization of a micro-fabricated stacked-wafer segmented ion trap with two X-junctions. Quantum Sci. Technol. 6, 044001 (2021).

See, P., Wilpers, G., Gill, P. & Sinclair, A. G. Fabrication of a monolithic array of three dimensional Si-based ion traps. J. Microelectromech. Syst. 22, 1180–1189 (2013).

Auchter, S. et al. Industrially microfabricated ion trap with 1 eV trap depth. Quantum Sci. Technol. 7, 035015 (2022).

Biener, J. et al. Miniature ion traps for fast, high-fidelity and scalable quantum computations. US patent US20230274174A1 (2023).

Quinn, A., Brown, M., Gardner, T. J. & Allcock, D. T. C. Geometries and fabrication methods for 3D printing ion traps. Preprint at http://arxiv.org/abs/2205.15892 (2022).

Xia, X. et al. Electrochemically reconfigurable architected materials. Nature 573, 205–213 (2019).

Gao, H. et al. High-resolution 3D printed photonic waveguide devices. Adv. Opt. Mater. 8, 2000613 (2020).

Oellers, M., Lucklum, F. & Vellekoop, M. J. On-chip mixing of liquids with swap structures written by two-photon polymerization. Microfluid. Nanofluidics 24, 4 (2019).

Fendler, C. et al. Microscaffolds by direct laser writing for neurite guidance leading to tailor-made neuronal networks. Adv. Biosyst. 3, 1800329 (2019).

Wineland, D. J. et al. Experimental issues in coherent quantum-state manipulation of trapped atomic ions. J. Res. Natl Inst. Stand. Technol. 103, 259–328 (1998).

Sutherland, R. T., Yu, Q., Beck, K. M. & Häffner, H. One- and two-qubit gate infidelities due to motional errors in trapped ions and electrons. Phys. Rev. A 105, 022437 (2022).

Schindler, P. et al. A quantum information processor with trapped ions. New J. Phys. 15, 123012 (2013).

Mølmer, K. & Sørensen, A. Multiparticle entanglement of hot trapped ions. Phys. Rev. Lett. 82, 1835–1838 (1999).

Jefferts, S. R., Monroe, C., Bell, E. W. & Wineland, D. J. Coaxial-resonator-driven rf (Paul) trap for strong confinement. Phys. Rev. A 51, 3112–3116 (1995).

Home, J. P. & Steane, A. M. Electrode configurations for fast separation of trapped ions. Quantum Inf. Comput. 6, 289–325 (2006).

Pino, J. M. et al. Demonstration of the trapped-ion quantum CCD computer architecture. Nature 592, 209–213 (2021).

Moses, S. A. et al. A race-track trapped-ion quantum processor. Phys. Rev. X 13, 041052 (2023).

Low, G. H., Herskind, P. F. & Chuang, I. L. Finite-geometry models of electric field noise from patch potentials in ion traps. Phys. Rev. A 84, 53425 (2011).

Niffenegger, R. J. et al. Integrated multi-wavelength control of an ion qubit. Nature 586, 538–542 (2020).

Mehta, K. K. et al. Integrated optical multi-ion quantum logic. Nature 586, 533–537 (2020).

Bushev, P. et al. Electrons in a cryogenic planar Penning trap and experimental challenges for quantum processing. Eur. Phys. J. D 50, 97–102 (2008).

Goldman, J. & Gabrielse, G. Optimized planar Penning traps for quantum-information studies. Phys. Rev. A 81, 052335 (2010).

Yu, Q. et al. Feasibility study of quantum computing using trapped electrons. Phys. Rev. A 105, 022420 (2022).

An, D. et al. Surface trap with dc-tunable ion-electrode distance. Rev. Sci. Instrum. 89, 093102 (2018).

Acknowledgements

We acknowledge the inspiration of C. Matthiesen at the start of the project and J. Oakdale for printing the first demonstration objects. We would also like to acknowledge N. Greene for the help on chamber assembly, W.-T. Chen for the useful guidance on the measurements, B. Saarel for providing the surface trap image, M. Brzeczek and J. Philips for providing preliminary trapping results on horizontal traps, A. L. Castillo for electron-beam deposition, W. L. Smith for creating CAD models, M. M. Biener for the AFM surface roughness measurements and X. Liu for performing the XCT experiments. This work is supported by the UC Multicampus-National Lab Collaborative Research and Training under award no. LFR-20-653698, as well as the Army Research Laboratory under award no. W911NF-23-1-0323, by the U.S. Department of Energy, Office of Science, National Quantum Information Science Research Centers, Quantum Systems Accelerator (QSA), by the Noyce Initiative and received some institutional support by NSF grant no. 2016245. Part of this work was performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under contract DE-AC52-07NA27344 and was supported by the LLNL-LDRD Program under project no. 23-ERD-021. A.J. acknowledges the support of ONR grant nos. N00014-21-1-2597 and N00014-21-1-2720.

Author information

Authors and Affiliations

Contributions

J.B., H.H., X.X., S.X. and E.M. conceived the project. X.X., A.P. and S.X. fabricated and prepared the traps. S.X., Q.Y. and S.K. performed the ion trap measurements. B.Y. carried out structural simulations. K.B., J.B., H.H., B.H. and A.J. coordinated research and provided scientific guidance. All authors participated in interpreting and planning of the experiments. All authors participated in writing the manuscript.

Corresponding authors

Ethics declarations

Competing interests

J.B., H.H., E.M. and X.X. are named inventors on US patent no. US20230274174A1 and the corresponding PCT application no. WO2022046306A2, titled ‘Miniature ion traps for fast, high-fidelity and scalable quantum computations’.

Peer review

Peer review information

Nature thanks Rajibul Islam and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

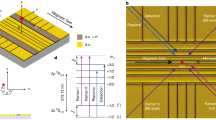

Extended Data Fig. 1 SEM image of an array of 200 3D-printed ion trap central regions.

Each region contains RF and DC electrodes only, with no electrical paths. This image is created by stitching together 50 individual 2 × 2 ion trap section images; slight contrast variations between panels reflect the composite assembly.

Extended Data Fig. 2 Optical profilometry measurement on 200 3D-printed ion trap central regions.

Colour bar represents height in the out-of-plane direction (z-axis).

Extended Data Fig. 3 Repeatability of 3D-printed feature dimensions in ion trap central regions.

a, Measured dimensions of printed structures in an ion trap compared with the CAD model dimensions. Blue dots (red triangles) represent in-plane (out-of-plane) dimensions. Grey line represents the ideal one-to-one relationship between the measured dimension to the CAD dimension. b, Variation in measured in-plane, out-of-plane and angular dimensions of selected trap features relative to the CAD model across 90 samples. In-plane measurements (blue) correspond to DC electrode dimensions parallel to the sapphire substrate; out-of-plane measurements (red) to RF electrode heights; angular measurements (yellow) to angles between RF electrodes. Grey bars denote the minimum and maximum values of each feature and coloured area outlined in grey show kernel density estimation. c, Variation in feature dimensions along two orthogonal in-plane directions (x and y) over ten repeated measurements per axis for four independent experiments, each involving sample repositioning, mounting and imaging. Blue (red) dots denote measurements along the x-axis (y-axis).

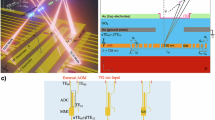

Extended Data Fig. 4 SEM images of fabrication defects.

a, SEM image of the RF electrode surface at a 45° angle, revealing layer-by-layer 2PP-printing-induced roughness. b, Stitch lines between adjacent fields of view on DC electrodes and electrical paths. c, Dust particle on an electrical path, potentially shorting to the ground plane. d, Residual solvent-impurity contamination on 3D-printed structures. e, Surface roughness of the 3D-printed polymer after electron-beam Au deposition.

Extended Data Fig. 5 AFM images of Au coatings.

a,b, 1-μm-thick Au coating deposited on a sapphire substrate. c,d, 1-μm-thick Au coating deposited on a 3D-printed polymer DC electrode. Average roughness is 9.1 nm on sapphire and 6.5 nm on polymer. Peak-to-valley roughness is 58.5 nm on sapphire and 30.6 nm on polymer.

Extended Data Fig. 6 XCT images.

Reconstructed 3D XCT image (top left) of the RF electrode structure, with a horizontal slice (top right) and vertical slices (bottom row) through the electrodes. Bright regions denote the Au coating and colour scales represent the local coating thickness. The low atomic number polymer substrate is not detected, so only the metal layer appears.

Extended Data Fig. 7 FIB SEM cross-sections of two trench designs used in trap 3D-100-Au-V.

a, Secondary electron SEM image of the trench design for the electrical paths. b, The corresponding BSE SEM image. Surface roughness and curtaining artefacts arise from FIB milling and the lighter-grey layer at the trench base reflects Au–C redeposition during the milling process. c,d, Secondary electron SEM image (c) and BSE SEM image (d) of the trench design used in the central region of the ion trap. The thin top layer is a protective carbon coating applied before FIB milling.

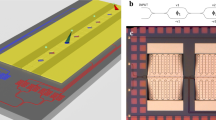

Extended Data Fig. 8 3D-printed RF electrodes on microfabricated substrates.

a,b, Photographs of microfabricated Si substrates featuring surface DC electrodes, electrical paths and wire-bonding pads. The substrates are processed on 6-inch wafers and diced into individual chips. c,d, SEM images (top-down and angled views) of a 3D-printed ion trap mounted on these substrates.

Extended Data Fig. 9 Vertical trap iteration 17 (3D-75-Al-V).

a, SEM image of the ion trap central region. The electrodes are annotated in the image. The distance between each pair of opposite RF electrodes is 150 μm, which leads to 75 μm ion–RF electrode distance. b, Design showing the CAD model of printed structures, including electrical paths.

Extended Data Fig. 10 Configuration for two-qubit gate measurement.

Magnetic field is tilted by 45° relative to the substrate. 397 nm laser beam propagates parallel to the substrate, whereas 729 nm and 866 nm beams propagate perpendicular to it. Two ion images are overlaid on the SEM image of trap 3D-75-Al-V.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, S., Xia, X., Yu, Q. et al. 3D-printed micro ion trap technology for quantum information applications. Nature 645, 362–368 (2025). https://doi.org/10.1038/s41586-025-09474-1

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41586-025-09474-1

This article is cited by

-

Quantum simulation of oscillatory Unruh effect with superposed trajectories

Science China Physics, Mechanics & Astronomy (2026)

-

Femtosecond Laser Direct Writing of Biopolymeric Nanocomposite for Biocompatible 3D Features

Chinese Journal of Polymer Science (2026)

-

3D nanolithography with metalens arrays and spatially adaptive illumination

Nature (2025)