Abstract

The Cretaceous mudstone undergoes significant argillization and disintegration when in contact with water due to its high content of clay minerals, posing a severe challenge to the stability of roadways in coal mines during construction and operation. This research aimed to prepare water-sensitive mudstone–like materials by the method of clay mineral composition similar to that of natural Cretaceous mudstone to reproduce the mechanical and hydraulic properties of natural rocks and meanwhile reveal the deteriorating effect of clay minerals on its microstructure and macroscopic properties. Using binary clay-gypsum mixtures and considering the aggregate-binder ratio, the clay-gypsum ratio, the iron sand content in fine sand, and the powder sand content in aggregate as controlling factors, 16 groups of proportioning schemes were established using the orthogonal test method and a series of physic mechanical experiments were conducted to determine its mechanical and hydraulic properties. Subsequently, sensitivity analysis was applied to characterize the effects of different influencing factors on mudstone-like materials’ mechanical and hydraulic properties. The result shows that the distribution ranges of physical, mechanical, and hydraulic parameters of the newly prepared similar material overlap noticeably with those of the natural mudstone, suggesting that this new material can better meet the requirements of modeling natural mudstone. In addition, the range analysis showed that the aggregate-binder ratio was the dominant factor for the material’s UCS, E, and cohesion, while the clay-gypsum ratio had a significant effect on its density and disintegration time. Then, qualitative and quantitative microstructural analysis was carried out on the SEM images of the four samples based on kaolinite-gypsum binary mixtures by Avizo software via the dynamic threshold segmentation method. The result indicates that the material microscopic parameters, such as pore size distribution, equivalent diameter, porosity, fractal dimension, etc., are significantly altered with the increase of kaolinite content, resulting in a marked deterioration of the material’s micromechanical properties. This mineralogical and microstructural change transforms the cementation type from homogeneous and dense crystalline cementation to anisotropic and loose argillaceous cementation, exhibiting strong water sensitivity and extremely weak macro mechanical properties, which explains the deterioration and disintegration mechanism of natural mudstones from a micro mineralogical point of view. Importantly, the synthesis and microstructural analysis method based on mineralogy proposed in this study may be widely employed in rock mechanics and engineering.

Similar content being viewed by others

Introduction

The Cretaceous mudstone of the Bayanhua Formation is widely distributed in extremely weakly cemented rock formations in the eastern part of Inner Mongolia, China. Due to the richness of clay minerals, the mudstone exhibits strong water disintegration properties, causing many difficulties in coal mine roadway operation, including excessive deformation, failure of support system or even complete collapse, which can not only impact roadway safety operation but also impede normal coal mining activities from an economic perspective1,2,3. Compared to theoretical analyses and numerical simulations, the model tests are now considered a viable option to effectively reveal the evolution laws of geotechnical structures’ deformation and failure under complex geological conditions(e.g., water-rock interaction under dynamic stress field)4,5,6. However, the capability of model tests to accurately reproduce engineering problems relies on the selection and proportion of similar materials used in such models7,8,9. Therefore, the synthesis of Cretaceous mudstones in a laboratory is quite fundamental for the study of the physical and mechanical properties of the original rock and the prevention of deformation hazards of the roadway.

Many studies have demonstrated that the mineralogy and microstructure of rock materials have a significant impact on their macroscopic physic-mechanical and hydrological properties10,11,12,13,14, especially clay-mineral-rich rock types such as mudstone15,16,17,18,19,20. This is because mudstone contains numerous soluble salts, such as carbonate, sulphate, nitrate, and halide, as well as diverse types of clay minerals with swelling capability, playing a significant function in cementing the particles together and strengthening the mudstone’s strength. When in contact with water, a series of physical-chemical actions occur in mudstone, including soluble salt dissolution, clay mineral dilation, and disintegration. The former results in numerous dissolution micropores, and the latter leads to multiple microcracks due to the clay minerals’ different expansion capability and their heterogeneous distribution. These physical-chemical actions finally damage the material’s microstructure and deteriorate its mechanical properties18,21,22,23,24,25,26,27,28. Existing research experimentally confirmed this deterioration effect in mudstone when subjected to different environments. Vergara et al. assessed the effect of water on the swelling behavior and mechanical properties of a partially saturated argillaceous swelling rock. The experimental results exhibited a strong decrease in strength and stiffness with increasing saturation or decreasing suction, accompanied by obvious accumulated swelling strain16. Liu et al. experimentally proved that the various strengths of the mudstone samples showed a negative exponential relationship with water content17. Song et al. and Zhu et al. also drew the same findings when studying the mudstone’s uniaxial mechanical behavior and damage evolution mechanism under gaseous water sorption18,19. Wang et al. verified this relationship aforementioned between the mechanical properties and water content via the coupling model20. These findings make it imperative to consider the clay minerals’ deterioration effect when developing mudstone-like materials to better model their physical and mechanical response.

Given the remarkable influence of mineralogical properties and microstructure of mudstone on its macroscopic mechanical properties, more and more scholars started to employ clay materials as one of the raw materials to develop the desired mudstone-like materials11,29. Mondol et al. synthesized mudstone-like materials by mixing known amounts of brine, smectite, and kaolinite via mechanical compression (different vertical stress) to study their physical properties11. Nooraiepour et al. prepared artificial mudstone by mixing and compressing quartz grains with kaolinite and smectite to investigate the effect of grain size distribution and mineralogical composition on the permeability of natural and synthetic mudstones29. Besides the conventional mechanical properties, some studies also reproduced the creep properties and hydraulic properties of the natural mudstones through the rock-like materials5,30,31,32,33,34,35. For example, Arora et al. and Xu et al. recreated the compression and shear creep properties of the natural rock using different clay materials, respectively5,30. Fu et al. discovered that the water absorption and expansibility properties of similar materials with a clay mineral ratio of 12% were highly similar to those of natural mudstone31. By adjusting the proportion of red clay, Guo et al. obtained a rock-like material with the same permeability coefficient as the Class IV weak surrounding rock typically encountered in tunnel cavities32. Cui et al. and Liu et al. separately tested the effect of Montmorillonite minerals on the disintegration properties of similar swelling rocks, improving the understanding of the disintegration mechanism of natural rocks33,34. However, the mineral composition and proportions of these synthetic mudstone–like materials, reported in the above-mentioned literature, are only partially similar to those of natural rock samples, which may result in the deviation of synthetic mudstone properties. Therefore, Cui et al. prepared red mudstone-like materials using a method similar to the mineral composition and proportion of natural rock samples. The result showed that the red mudstone–like materials are consistent with the natural rocks in terms of mineral composition and physical and mechanical properties, proving the technical reasonability of the synthetic method35.

To gain a deeper understanding of the mechanism by which clay mineralogy and microstructure affect the macroscopic physic-mechanical properties of materials, scanning electron microscope (SEM) technology has been widely employed to perform a comprehensive mineralogical and microstructure analysis to argue the influence of a material’s micromorphology on its macro properties recent year12,17,18,21,25,28,36. Liu et al. analyzed the microstructure of swelling mudstones in the dry and saturated states by SEM tests to investigate the reason for the deterioration of the mechanical properties of swelling mudstones17. Tang et al. studied the changes in the macroscopic and microscopic structure of mudstone samples with different moisture contents during the immersion test28.

However, these studies only qualitatively evaluated the transformations in the microstructure of the rock material. Considering the materials’ pore size distribution (PSD), geometrical features, and fractal dimensions of the pore network are the key parameters governing their macro properties, continuous efforts have been made to quantify these microscopic parameters of rock materials based on SEM images19,23,37,38,39. Zhou et al. calculated the fractal dimensions in MATLAB, based on the box-counting method, to quantify the intensity of sandstone cracks after different wetting-drying cycles38. Liu et al. developed Pores (Particles) and Cracks Analysis System (PCAS) software on the basis of a series of image processing technologies and geometric measurement methods that can automatically quantify the SEM images of clay samples in the computer39. Zhu et al. performed the pore network characterization of the swelling mudstones during gaseous water absorption via the commercial software Avizo19. However, the threshold used for pores segmentation is an artificially set constant value, which may reduce the accuracy of pore segmentation. Yang et al. accurately determined the characteristic parameters(i.e., the pore area, average diameter, area ratio, and fractal dimensions) of the pore network from the SEM images of the chlorite–amphibolite rock samples by Image Pro Plus image processing software23. In conclusion, accurate segmentation of the pore structure inside the material is an important prerequisite for quantitative analysis of pore networks. Determining a reasonable segmentation threshold will help to segment the pore structure accurately.

The main purpose of this study is to provide a method to accurately synthesize the mudstone-like materials of natural Cretaceous mudstone in a certain range. Based on the main mineralogical composition of Cretaceous mudstones, kaolin and rectorite were selected as the raw materials, and an orthogonal experimental scheme incorporating four factors with four levels was designed to investigate the physical, mechanical, and hydraulic properties of the new material. Afterward, the influence of different controlling factors on its macro properties is detailed evaluated by sensitive analysis subsequently. To better understand how one single clay mineral affects the microstructure and macroscopic properties of the material, we accurately extracted the pore network of four samples with different cementitious minerals ranging from pure kaolinite to pure gypsum by using the dynamic Interaction Thresholding method in Avizo. We then quantitatively analyzed the micro-parameters of the four samples, i.e., the porosity, fractal dimensions, and the pore size distribution. Additionally, the practicability of the synthetic method was verified by comparing the properties of the mudstone-like materials with those of the natural Cretaceous mudstone, helping to expand the methodology developed in this study for a wide range of applications in rock mechanics and engineering.

Materials and methods

Description of cretaceous mudstone

The Cretaceous mudstone samples investigated in this study were collected from the Bayanhua Formation in the eastern part of Inner Mongolia, China. Moreover, several investigations have been performed regarding its mineralogical composition, microstructural analysis, and mechanical and hydraulic properties.

Table 1 lists the mineralogical composition of three typical kinds of Cretaceous mudstones using the X-ray diffraction (XRD) technique. The results show that the clay mineral content of the three mudstones varies from 21 to 51%, typically clay-rich. The dominant clay minerals are kaolinite and mixed-layer illite-smectite, with a high average content of 16.49% and 16.27%, respectively.

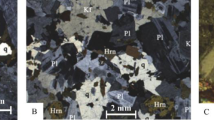

The microstructural changes of the three mudstones under different clay mineral content were observed through SEM tests with a magnification of 5000× (see Fig. 1). The SEM images demonstrate that characteristics of pores, such as pore size, shape and distribution changed obviously with the increase of clay mineral content. Furthermore, we can visually see that the microporosity and connectivity of the pore network increased continuously, changing its microstructure from dense into a loose and muddy one. In short, clay minerals exhibited a deterioration effect on rock samples’ microstructure, which will negatively affect their macroscopic physical and mechanical properties.

The effect of water content on the macroscopic mechanical properties of Cretaceous mudstone was investigated by Uniaxial compression test, and the results are shown in Table 2; Fig. 2. With the increased water content, the mechanical parameters of both mudstones are negatively linear with the water content. The UCS and E of the grey mudstone with 10.53% water content reduced by 80.10% and 80.93%, respectively, compared to the dry sample with 4.37% water content. The UCS and E of the sandy mudstone with 9.82% water content decreased by 59.06% and 66.12%, respectively, compared to the dry sample 2 − 1, indicating that these materials have the characteristics of strong water reactivity. Additionally, the fitted curves and their mathematical equations presented in Fig. 2 show that the degradation of the mechanical parameters of the grey mudstone is more pronounced than that of the sandy mudstone, exhibiting a stronger water-reactive property due to its higher clay mineral content. In contrast to SEM tests, these experimental results reveal, from a macroscopic point of view, that clay minerals have a significant deteriorating effect on the macroscopic properties of Cretaceous mudstones (water-rock interaction, to be precise).

Other physico-mechanical parameters of the Cretaceous mudstone, including density (\(\:\rho\:\)), water content (ω), porosity (\(\:{\Phi\:}\)), cohesion and angle of internal friction (c and \(\:\phi\:\)), and disintegration time (t) are listed in Table 3. The experimental results show that the natural water content of the Cretaceous mudstones was 6.17% ∼ 10.09%, their natural porosity was 17.53% ∼ 25.79%, and the cohesion was only 0.45 MPa ∼ 0.98 MPa. In addition, the time consumed for complete disintegration of the three mudstones decreased dramatically from 40 to 10 min with increasing clay mineral content.

Taken together with the previous analyses, the micro- and macro-physical and mechanical properties of Cretaceous mudstones are strongly influenced by the clay minerals, and the discovery of this conclusion will guide the development of Cretaceous mudstone-like materials.

Raw material selection

In this study, a method similar to the mineral composition of natural rock samples was used to synthesize Cretaceous mudstone-like materials. In order to exclude the interference of secondary clay minerals, based on the main minerals of Cretaceous grey mudstone (see Table 1), we designed a new mudstone-like material formulation scheme by choosing a clay-gypsum binary mixture as cementing agent and quartz sand as aggregate. The binary clay-gypsum mixtures varied from pure clay to pure gypsum to characterize the different extent of water-induced softening and disintegration properties of the natural rock. In this case, the clay mixture consists of kaolinite (84.40% purity), which characterizes the non-swelling clay minerals in the grey mudstone, i.e., kaolinite and illite, and rectorite (75.02% purity), which is used to represent the swelling clay minerals, i.e., mixed-layer illite-smectite minerals. The ratio of the two is approximately 61:39, equal to that of the non-swelling clay minerals to the swelling clay minerals in the grey mudstone. Aggregate is a mixture of quartz sand of two different grain sizes, i.e., fine and powder sand, to optimize the gradation. In addition, iron tetraoxide sand was used to regulate the density of the material. The physical parameters of the selected raw materials and the corresponding photos are shown in Table 4; Fig. 3a, respectively.

Synthesis of cretaceous mudstone–like materials

Due to the uniformity and representativity of the distribution of test points, the orthogonal experimental method was adopted to design the experiment in this paper. Four influencing factors were selected as follows: Factor A—the aggregate-binder ratio (the mass ratio of aggregate to cementing agent), Factor B—the clay-gypsum ratio (the mass ratio of clay mixtures to gypsum), Factor C—the iron sand content in fine sand, and Factor D—the powder sand content in aggregate. Afterward, we set four levels for each influencing factor (Table 5). Finally, 16 groups of mudstone-like material proportions were obtained, as presented in Table 6.

Samples were prepared using the standardized procedure shown in Fig. 3b to eliminate as much as possible the influence of human factors on the experimental results. The amounts of raw materials required for the experiments were accurately weighed using an electronic balance with a precision of 0.001 g. (see Table 6) and mixed at a constant rate for 5 min in a container. Then, distilled water was added to the solid materials and mixed again for 5 min. During this process, the water mixing ratio was determined to be 23% for all proportion schemes in order to minimize the effect of the initial water content on the physical and mechanical properties of the specimens. Afterwards, the formed mixtures were loaded into standard molds and vibrated densely on a vibrator. After polishing the two end faces of the specimens, the samples were placed in a curing box with the molds for 24 h at a temperature of 20 ± 3 °C and a humidity of 65%. After demolding, the specimens were numbered, weighed, and then cured for seven days until the moisture content remained constant at room temperature. Finally, the standard cylindrical specimens (φ 50 mm × 100 mm) employed in uniaxial compression test and water immersion test and standard ring cutter specimens (φ 61.8 mm × 20 mm) used in direct shear test (Fig. 3b) were prepared in order to investigate the different parameters of the specimens containing 16 different proportions, respectively.

Physical and mechanical property testing

A series of experiments were performed to determine mudstone-like materials’ physical and mechanical parameters in this research, including the water content(ω), density (ρ), uniaxial compressive strength (UCS), elastic modulus (E), cohesion (c), internal friction angle (φ) and the complete disintegration consumption time (t), as shown in Fig. 3c.

The density (ρ) of each sample was calculated based on the volume determined by a vernier caliper with a precision of 0.01 mm and the mass by using an electronic balance with a precision of 0.001 g before mechanical tests. The samples were dried in an oven at 110 °C for 24 h to determine their water content(ω) based on the Standard for Test Methods of Engineering Rock Mass (GB/T 50266 − 2013). To obtain the mineral composition of the specimens, X-ray diffraction (XRD) analysis was carried out on the processed powder of these dried samples using a D8 ADVANCE instrument. Then qualitative and quantitative analyses of each mineral were performed in Jade 9.0 software based on the XRD test data. In addition, the complete disintegration consumption time (t) of each sample was determined by water immersion test in a container filled with pure water to characterize its disintegration properties.

The uniaxial compression tests were carried out on the specimens using MTS816 Rock Mechanics Test Systems with the test procedure recommended by Standard for Test Methods of Engineering Rock Mass (GB/T 50266 − 2013). The maximum axial load of the testing machine is 1490kN with ± 0.5% accuracy of applied load, equipped with a data acquisition system that can automatically record axial load and displacement in real-time. In the uniaxial compression tests, the axial stress is applied using the strain control mode at 0.18 mm/min loading rate until the sample is damaged. Based on the test data, the uniaxial compressive strength (UCS) and elastic modulus (E) were calculated by the method suggested by GB/T 50,266 − 2013.

Direct shear tests were also conducted on similar materials by a GJY-II strain-controlled direct shear apparatus in accordance with the Standard for Geotechnical Testing Method (GB/T 50123 − 2019). In the shear tests, the samples are horizontally sheared under different vertical pressures of 100 kPa, 200 kPa, 300 kPa and 400 kPa at a shear rate of 1.0 mm/min. The displacement was recorded manually and the shear strength (c and φ) of similar materials was determined according to the method recommended by GB/T 50,123–2019. The direct shear apparatus and the damaged samples are illustrated in Fig. 3(c).

Quantitative and microstructural analysis

In order to better reveal the deterioration mechanism of single clay minerals on the microstructure and macroscopic properties of the materials, we eliminated the use of rectorite and iron powder from the original proportioning scheme (see Sect. 2.2) and adopted a more simplified proportioning scheme, as shown in Table 7. It should be noted that the four influencing factors here, except for factor B, which is the mass ratio of kaolinite to gypsum, the other three influencing factors represent the same meaning as in the previous section. Subsequently, we performed SEM tests on each of the four samples using a TESCAN GAIA3 FIB-SEM system (see Fig. 3(c)), and obtained their 500x and 1000x images, respectively.

SEM image of sample S1 and associated segmentation method: (a) original images, (b) pore segmentation using Interactive Thresholding module, blue represents pores, (c) pore segmentation based on dynamic thresholding method, purple represents pores; (d), (e) and (f) are the step-by-step instructions of the pore segmentation.

Firstly, after creating labels of the SEM image in the Project interface of AVIZO software, the system will automatically enter the Segmentation interface. After activating the Brush tool at the bottom of Segmentation’s control panel and enable the Masking module, adjust the threshold value to 0-16100, so that the pores around the sand particles can be accurately marked out, as shown in Fig. 4(d). Use the Brush tool, whose default state is the Add Selection function, to manually paint the pore structure around the sand particles to create a selection, and then press the Add button in the control panel to add the selection to the pre-created labels. So far, the pore around the sand particles has been segmented precisely (see Fig. 4(e), pores in red color).

Secondly, adjust the threshold value in the Masking module until all the unsegmented pores are accurately characterized (here, the threshold value is 0-18370), and then use the Brush tool again to manually paint the marked pores to create another selection. Then, the remaining pores can be segmented out by repeating the previous operation (see Fig. 4(f), pores in green color).

Finally, check whether the segmentation result has split all the pores. If a pore is over-segmented, use the Subtract selection function of the Brush to remove the over-segmented part; else if a pore is not yet fully segmented, raise the threshold until the pore is accurately identified, and then use the Brush tool again with the Add button to accurately segment it. At last, the micropores of the four samples were precisely defined using this method (see Fig. 4c).

To further investigate the characteristics of pores in the samples with different kaolin contents, “Volume Fraction” and “Fractal Dimension” commands were used to calculate the porosity and fractal dimension of the specimens, respectively. Furthermore, the “Label Analysis” command was employed to obtain the equivalent diameter of the pore networks.

Results and discussion

Test results of mudstone-like material

The physical, mechanical, and hydraulic properties of 16 groups of specimens are presented in Table 8. The results suggest that the material’s mineral composition was the same as that of natural Cretaceous mudstone, and the synthesis process was a reaction between minerals and water that did not cause chemical changes in the sample, which has been confirmed by the SEM tests. Additionally, the material’s water content (\(\:\omega\:\)), density (\(\:\rho\:\)), uniaxial compressive strength (UCS), elastic modulus(E), cohesion and angle of internal friction (c and \(\:\phi\:\)), and disintegration time (t) are mainly distributed in the ranges of 5.65–12.59%, 1.62–2.08 g/cm3, 0.09–3.59 MPa, 24.71–505.93 MPa, 97.43–495.32 kPa, 6.28–64.26° and 21–90 mi. While the distributions of natural Cretaceous mudstones listed in Sect. 2.1 are 2.73–10.53%, 1.97–2.16 g/cm3, 1.21–5.79 MPa, 131–687 MPa, 450–980 kPa, 9.26–27.82° and 10–40 min respectively. Figure 5 illustrates a detailed comparison of the range of distributions of these parameters between the two materials. It shows that the physical, mechanical and hydraulic parameter distributions of the newly-prepared mudstone-like materials have an apparent overlap with those of the natural mudstone, indicating that this new material can better meet the requirements of simulating natural mudstone. Furthermore, according to the demands of specific projects, we can flexibly adjust the mix proportions of base materials to customize the mudstone-like materials for stress-seepage coupling model test under certain similarity scales.

Comparison of physical and mechanical properties between mudstone-like materials and natural Cretaceous rocks: (a) Comparison of physical properties of the mudstone–like materials with that of natural mudstone samples; (b) Comparison of mechanical properties of the mudstone–like materials with that of natural mudstone samples.

In conclusion, the mudstone–like materials in this study are consistent well with the natural Cretaceous mudstones in terms of mineral composition, water content (ω), density (ρ), uniaxial compressive strength (UCS), elastic modulus(E), cohesion and angle of internal friction (c and φ), and disintegration time (t), proving that the prepare method of this kind of mudstone–like materials is quite practicable.

Sensitivity analysis

The aforementioned experimental studies have demonstrated that the newly synthetic mudstone-like materials can accurately simulate the disintegration property of natural rock and instability mechanisms of coal mine roadways under long-term water-induced strength deterioration. However, the complexity of the in-situ geotechnical engineering disaster mechanism may be beyond one’s imagination. Therefore, to improve its applicability to more practical geotechnical engineering problems, sensitivity analyses were carried out to identify the main controlling factors affecting the physical, mechanical and hydraulic properties of this mudstone-like material.

Analysis of factors affecting the density

Based on orthogonal experimental results, Fig. 6 presents the range R and impacts of 4 factors on density of the specimens. It can be observed that the influence degree of each factor on the density of mudstone-like materials is B ≈ C > D > A. This implies that the clay minerals and iron sand content exert a more significant influence on the density of the materials than that of the binder and powder sand content. Specifically, the density tends to increase linearly with increasing clay-gypsum ratio and iron sand content, while linearly decreasing with the increase of powder sand content. In addition, the density was least affected by the aggregate-binder ratio, fluctuating with changes in this influencing factor.

Analysis of factors affecting UCS

Based on orthogonal experimental results, Fig. 7 exhibits the range R and impacts of 4 factors on UCS of the specimens. We can obtain that the sensitivity extent of each factor on the UCS is A > C > D ≈ B, suggesting that the aggregate-binder ratio exerts a more significant influence on the UCS of mudstone-like materials than that of the other three factors. Specifically, UCS grows rapidly with decreasing aggregate-binder ratio but decreases slightly with increasing clay mixtures and powder content. In addition, UCS increases gradually with increasing iron sand content, but the increase is clearly smaller than that of UCS with decreasing aggregate-binder ratio.

Analysis of factors affecting E

Based on orthogonal experimental results, Fig. 8 illustrates the range R and impacts of 4 factors on the elasticity modulus (E) of the specimens. It can be seen that the sensitivity rank of the four factors on the E is A > C > B > D, demonstrating that the aggregate-binder ratio plays a more dominant role on the E of mudstone-like materials than that of the other three factors. Specifically, the E increases sharply and linearly with decreasing aggregate-binder ratio but decreases slightly with increasing clay and powder content. Moreover, with increasing iron sand content, the E value also increases, but significantly less than the E that increases with decreasing aggregate-binder ratios.

Analysis of factors affecting cohesion

Based on orthogonal experimental results, Fig. 9 shows the range R and impacts of 4 factors on cohesion of the specimens. It can be concluded that the influence degree of each factor on the cohesion of mudstone-like materials is A ≈ B > C > D, which reveals that both the aggregate-binder ratio and clay-gypsum ratio exert a more obvious influence on the cohesion of mudstone-like materials than that of the content of iron sand and powder sand. However, the trend of the effect of Factor A and B on cohesion is diametrically opposed. Specifically, the cohesion rises quickly with decreasing of aggregate-binder ratio, whereas it decreases rapidly with increasing clay minerals content, demonstrating a clear deterioration effect. Additionally, iron and chalk content had a small effect on cohesion, and there was no significant linear relationship between the two factors and cohesion.

Analysis of factors affecting internal friction angle

Based on orthogonal experimental results, Fig. 10 presents the range R and impacts of 4 factors on internal friction angle of the specimens. The conclusion can be drawn that the order of sensitivity of each factor on the internal friction angle is D > A > B > C, implying that the powder sand content exerts a more significant influence on the internal friction angle of mudstone-like materials than that of the other three factors. Nevertheless, the internal friction angle changed irregularly as the powder sand content increased, indicating no obvious relationship between them, and the same holds true for Factor A and C. Moreover, with increasing clay content, the internal friction angle tended to decrease linearly, which could be explained by the addition of clay minerals weakening the frictional characteristics of the mudstone-like materials.

Analysis of factors affecting disintegration time

Based on orthogonal experimental results, Fig. 11 depicts the range R and impacts of 4 factors on the complete disintegration consumption time (t) of the specimens. The result shows that the sensitivity rank of the four factors on the complete disintegration consumption time is B > A > C > D, suggesting that the clay-gypsum ratio plays a more major part in the disintegration time of mudstone-like materials than that of the other factors. Specifically, the disintegration time decreases rapidly and linearly with increasing clay-gypsum ratio while increases moderately with decreasing aggregate-binder ratio. This finding suggests that the presence of clay mineral additions, especially swelling clay minerals, leads to the disintegration of the material in water. Moreover, with increasing iron and powder sand content, the disintegration time fluctuated within a small range, indicating that the parameter is less sensitive to these two factors.

In summary, the findings of the range analysis showed that the aggregate-binder ratio significantly impacted the UCS, E and cohesion, while the clay-gypsum ratio content strongly influenced the density and disintegration time of mudstone-like materials. From the mineralogical point of view, gypsum significantly enhances the material’s mechanical properties, i.e., as the aggregate-binder ratio decreases, the UCS, E, and cohesion of the material show a significant increase. In contrast, clay minerals have a remarkable deterioration effect on the material’s mechanical properties, i.e., as its content rises, all the strength parameters display the same linear decreasing trend. Besides, the disintegration property of the materials also increased linearly with the increase in clay minerals. These findings imply that the mineralogy of the materials has a significant effect on the material’s macroscopic physic-mechanical parameters.

microstructural analysis based on micromineralogy

The sensitivity analyses of similar materials described above indicate that clay minerals significantly impact the macroscopic physical properties (including disintegration) and macroscopic mechanical properties of the materials. In order to reveal the mechanism of this influence, we carried out micromorphological observations based on micromineralogy and quantitative microstructural analyses based on Avizo software on four samples with different gypsum-kaolinite ratios (referred to as G: K).

Qualitive microstructural analysis

Figure 11 shows the micro-morphological images of four different gypsum-kaolinite ratios for samples S1-S4 (see Fig. 12(a1) -(d1), with the yellow dashed box as the selected ROI region), the zoomed-in images of the corresponding ROI regions (see Fig. 12(a2) -(d2)) and the results of pore segmentation of the (a1) -(d1) images based on the dynamic threshold segmentation method of Avizo (see Fig. 12(a3) -(d3)).

SEM images and the corresponding pore segmentation results of the 4 samples (S1, S2, S3 and S4): (a1) -(d1) are the SEM images of the S1-S4 specimens respectively; (a2) -(d2) depict the magnified views of the ROI marked with golden dashed-line boxes in (a1) -(d1); (a3) -(d3) present the corresponding pore segmentation results of (a1) -(d1).

Figure 12(a1), (a2), and (a3) show the typical crystal cementation microstructural morphology of the S1 sample and the corresponding pore segmentation results, respectively. From (a1) and (a2), it can be seen that the S1 sample is a typical crystalline cementation, with a large number of needle-like gypsum crystals interlaced with each other, which effectively bonded the quartz sand particles together to form a dense micromechanical structure. Its pore segmentation results show that when G: K = 4: 0, the material, the pores are mostly uniformly distributed isolated tiny pores; although the number of pores is relatively large, the pore size and the total area of the pores are small.

Figure 12(b1), (b2) shows the microstructural morphology of the S2 sample (G: K = 3:1). Due to the presence of a small amount of kaolinite minerals (near-pristine flake minerals adhering to the surface of the gypsum crystals, blue-circled area in Fig. 12(b2)), large isolated pores begin to grow in the vicinity of the kaolinite minerals, attributed to the water-loss and shrinkage properties of kaolinite. The micro-mechanical structure formed by gypsum crystals starts to deteriorate in S2 sample compared to S1. Its pore segmentation results show (see Fig. 12(b3)) that the overall uniformly distributed isolated tiny pores are still dominant within the S2 sample compared to S1, but the generation of larger diameter pores results in a moderate increase in the average pore size and total pore area of the S2 sample.

Figure 12 (c1) and (c2) show the microstructural morphology characteristics of the S3 sample (G: K = 1:3). The results show that a large number of cemented associations are distributed inside the sample, consisting of larger-sized cement formed by the absorption and fusion of the dominant kaolinite minerals and a small proportion of needle-like gypsum crystals. Compared to S2, larger-sized water-loss shrinkage pores begin to be formed and interconnected, resulting in a significant deterioration of the microstructure within the material. The pore segmentation results of the S3 sample showed (see Fig. 12(c3)) that larger-sized interconnected pores were distributed non-uniformly within the S3 sample compared to S2, resulting in a significant increase in the average pore size and total pore area within the material.

Figure 12(d1) -(d2) show the typical microstructural morphology of loose argillaceous cementation for S4 sample (G: K = 0:4). Compared with S3, not only the shrinkage pores inside the material further expanded and connected to form larger-size pores, but the large-size cracks began to generate and connected with the surrounding pores and formed a complex pore-crack network with higher connectivity, resulting in an extremely loose microstructure of the material. The pore segmentation results of S3 (see Fig. 12(d3)) showed that the internal pores of the material are mostly non-uniformly distributed and connected large-sized types, leading to a high average diameter and total area of pore cleavage (although the number of pores is significantly lower).

Quantitative microstructural analysis

Understanding the variation of pore size distribution with clay content in geotechnical materials is important for revealing the deterioration mechanism of clay minerals. The frequency distribution of pore number and area of the four samples in Fig. 12(a3) -(d3) were detailed quantified by using the Label Analysis module in Avizo, and the results are shown in Fig. 12. Overall, the total pore counts of the four samples from S1-S4 were 1640, 1407, 1218, and 323, respectively, which decreased significantly with the increase of kaolinite content. Meanwhile, the total pore areas of the S1-S4 samples were 2265.13, 2540.15, 3239.52, and 3827.69 µm2, respectively, exhibiting a noticeable increase. As can be seen from the pore size distribution (PSD), most of the pores of all the samples were distributed in the range of 0–3 μm, indicating that a large number of micropores were distributed within all four samples. However, the incorporation of kaolinite significantly changed the PSD characteristics. Specifically, the pore number, number frequency, and area frequency within 0–3 μm decreased from 1573, 95.91%, and 52.75% of S1 samples to 283, 87.68%, and 7.14% of S4. And the corresponding parameters of pores > 10 μm in equivalent diameter increased from 0 in S1 and S2 to 5, 0.41%, 17.25% in S3, and 8, 3.10%, 74.19% in S4. In addition, the number, number frequency, and area frequency of 3–10 μm pores in S3 (96,7.88%,66.57%) also showed a significant increase compared to S1 (66, 4.08%, 47.25%) and S2 (89,6.32%, 60.63%), indicating that tiny pores gradually expanded and merged into larger-sized ones, which can be regarded as a transitional pattern of pore structure in S4 samples.

To further investigate the change in other characteristics of pores with increasing kaolinite content, the Volume Fraction and Fractal Dimension modules in Avizo were used to calculate the porosity and fractal dimension of the specimens, respectively, as shown in Fig. 13. below. It indicated that the samples’ equivalent diameter, porosity, and fractal dimension increased to different degrees with the increase of kaolinite content. That is, the equivalent diameter and porosity of the samples increased exponentially from 0.93 μm to 11.82% to 1.87 μm and 20.57%, respectively, while the fractal dimension increased linearly from 1.639 to 1.675. Analyzed in conjunction with Fig. 14(b)-(d) as well as Fig. 12, this can be attributed to the strong development of 10–15 μm pores in the S3 sample and > 10 μm pores in the S4 sample. These large pores are interconnected with other pores to form a more complex pore network with greater connectivity. In conclusion, the incorporation of kaolinite obviously changed the pore structure characteristics and strongly weakened the cementation strength of the material, transforming the material from a dense crystalline cementation to a porous clay cementation, showing an obvious deterioration effect.

Equivalent diameter, fractal dimension and Porosity of the 4 samples (S1, S2, S3 and S4): (a) presents the overall porosity, fractal dimension and equivalent diameter of the 4 samples; (b) -(d) are the equivalent diameters, fractal dimensions, and porosity of pores with different pore size range, respectively, and they use the same Graph legend illustrated in (b).

In conclusion, with the increase of kaolinite content, the PSD of the pores within the samples, as well as the micro-mechanical parameters, such as porosity and fractal dimension, changed significantly, causing the rock microstructure to gradually change from a homogeneous and dense crystalline cement to an anisotropic and loose argillaceous cement. Combined with the conclusion of the sensitivity analysis in Sect. 3.2, we can conclude that the presence of clay minerals completely changes the mineralogical properties and micro-mechanical properties of the material, which in turn causes the degradation of the macro-mechanical properties of the material and the enhancement of water sensitivity.

Conclusion

In this study, a novel Cretaceous mudstone-like material was developed based on the similarity of mineral compositions. All physical, mechanical, and hydraulic properties were obtained on the basis of orthogonal experiments. At the same time, qualitative and quantitative analyses of the microstructure were carried out based on SEM tests and Avizo software to reveal the deterioration mechanisms of the clay minerals. Some of the major findings are presented below.

-

(1)

The parameter distributions of the synthetic mudstone-like material overlap well with those of the natural Cretaceous mudstone, indicating a similar physico-mechanical property, including disintegration characteristics, as the natural mudstone.

-

(2)

Aggregate-binder ratio dominated the UCS, E, and cohesion, while the clay-gypsum ratio content significantly affected mudstone-like materials’ density and disintegration time. Moreover, all the mechanical properties of the materials decreased obviously with the increase in clay minerals.

-

(3)

Qualitative analyses based on micromineralogy indicate that the presence of kaolinite completely changes the micromechanical parameters, such as the number, diameter, and distribution of pores as well as the total pore area within the samples, which changes the type of cementation from a homogeneous and dense crystalline to anisotropic and loose argillaceous cementation.

-

(4)

Quantitative analysis results showed that with the increase of kaolinite content, the number of pores, number frequency, and area frequency in the range of 0–3 μm diameter decreased from 1573, 95.91%, and 52.75% in the S1 sample to 283, 87.68%, and 7.14% in S4. In contrast, the corresponding pore parameters with diameters > 10 μm increased from 0 for S1 to 8, 3.10%, and 74.19% for S4. The latter is the main factor for increased equivalent diameter, porosity, and fractal dimension.

The developed mineralogically-based synthetic methods and microstructural analyses may be widely used in rock mechanics studies.

Data availability

The data used to support the findings in this study are available from the corresponding author upon request.

References

Wang, S., Han, L., Meng, Q., Jin, Y. & Zhao, W. Water absorption/dehydration by NMR and mechanical response for weakly cemented mudstones subjected to different humidity conditions. Bull. Eng. Geol. Environ. 79, 1275–1288. https://doi.org/10.1007/s10064-019-01629-5 (2020).

Jin, Y. et al. Experimental study of the spontaneous imbibition characteristics of mudstone extracting water from cement grout. Bull. Eng. Geol. Environ. 79, 1333–1347. https://doi.org/10.1007/s10064-019-01663-3 (2020).

Meng, L. et al. Study on characteristic and energy of Argillaceous weakly cemented Rock under Dynamic Loading by Hopkinson Bar experiment. Energies 13 (2020).

Wang, Z. et al. New Type of similar material for simulating the processes of water inrush from roof Bed separation. ACS Omega. 5, 30405–30415. https://doi.org/10.1021/acsomega.0c03535 (2020).

Arora, K., Gutierrez, M., Hedayat, A. & Cruz, E. C. Time-Dependent Behavior of the tunnels in Squeezing Ground: an experimental study. Rock Mech. Rock Eng. 54, 1755–1777. https://doi.org/10.1007/s00603-021-02370-w (2021).

Xu, Z. et al. Mechanical properties and reasonable proportioning of similar materials in physical model test of tunnel lining cracking. Constr. Build. Mater. 300, 123960. https://doi.org/10.1016/j.conbuildmat.2021.123960 (2021).

Sun, P. et al. Experimental study on the ratio model of similar materials in the simulation test of coal and gas outburst. Sci. Rep. 11, 13513. https://doi.org/10.1038/s41598-021-92880-y (2021).

Zhu, X., Guo, G., Liu, H., Chen, T. & Yang, X. Experimental research on strata movement characteristics of backfill–strip mining using similar material modeling. Bull. Eng. Geol. Environ. 78, 2151–2167. https://doi.org/10.1007/s10064-018-1301-y (2019).

Zan, W. et al. Experimental and applied research on similar materials to granular mixtures for solid-liquid coupling model test of an underwater tunnel. Constr. Build. Mater. 416, 135170. https://doi.org/10.1016/j.conbuildmat.2024.135170 (2024).

Lindqvist, J. E., Åkesson, U. & Malaga, K. Microstructure and functional properties of rock materials. Mater. Charact. 58, 1183–1188. https://doi.org/10.1016/j.matchar.2007.04.012 (2007).

Mondol, N. H., Bjørlykke, K., Jahren, J. & Høeg, K. Experimental mechanical compaction of clay mineral aggregates—changes in physical properties of mudstones during burial. Mar. Pet. Geol. 24, 289–311. https://doi.org/10.1016/j.marpetgeo.2007.03.006 (2007).

Chen, H. B., Wang, Y. Z., Sánchez-Soto, M. & Schiraldi, D. A. Low flammability, foam-like materials based on ammonium alginate and sodium montmorillonite clay. Polymer 53, 5825–5831. https://doi.org/10.1016/j.polymer.2012.10.029 (2012).

Yao, W. et al. Multiscale Study of Physical and Mechanical Properties of Sandstone in Three Gorges Reservoir Region Subjected to cyclic wetting–drying of Yangtze River Water. Rock Mech. Rock Eng. 53, 2215–2231. https://doi.org/10.1007/s00603-019-02037-7 (2020).

SUN, C., LI, G., XU, J., RONG, H. & SUN, Y. Rheological characteristics of mineral components in sandstone based on nanoindentation. Chin. J. Rock Mechan. Eng. 40, 77–87. https://doi.org/10.13722/j.cnki.jrme.2020.0477 (2021).

Hu, D. W., Zhang, F., Shao, J. F. & Gatmiri, B. Influences of Mineralogy and Water Content on the Mechanical properties of Argillite. Rock Mech. Rock Eng. 47, 157–166. https://doi.org/10.1007/s00603-013-0413-8 (2014).

Vergara, M. R. & Triantafyllidis, T. Influence of Water Content on the Mechanical properties of an Argillaceous Swelling Rock. Rock Mech. Rock Eng. 49, 2555–2568. https://doi.org/10.1007/s00603-016-0938-8 (2016).

Liu, C. D. et al. Experimental study on the effect of water on mechanical properties of swelling mudstone. Eng. Geol. 295, 106448. https://doi.org/10.1016/j.enggeo.2021.106448 (2021).

Song, Y. et al. Study on Uniaxial Mechanical Behavior and damage evolution mechanism of Water-Immersed Mudstone. Sustainability 15, 12499 (2023).

Zhu, H., Fu, Z., Yu, F. & Li, S. Study on Deterioration Characteristics of Uniaxial Compression Performance and Microstructure Changes of Red-Bed Mudstone during Gaseous Water Sorption. Buildings 12, 1399 (2022). https://www.mdpi.com/2075-5309/12/9/1399

Wang, T. & Yan, C. Investigating the influence of water on swelling deformation and mechanical behavior of mudstone considering water softening effect. Eng. Geol. 318, 107102. https://doi.org/10.1016/j.enggeo.2023.107102 (2023).

Ciantia, M. O., Castellanza, R., Crosta, G. B. & Hueckel, T. Effects of mineral suspension and dissolution on strength and compressibility of soft carbonate rocks. Eng. Geol. 184, 1–18. https://doi.org/10.1016/j.enggeo.2014.10.024 (2015).

Hassine, M. A., Beck, K., Brunetaud, X. & Al-Mukhtar, M. Strain measurements during capillary water infiltration in porous limestones. Constr. Build. Mater. 175, 439–447. https://doi.org/10.1016/j.conbuildmat.2018.04.182 (2018).

Yang, X., Wang, J., Zhu, C., He, M. & Gao, Y. Effect of wetting and drying cycles on microstructure of rock based on SEM. Environ. Earth Sci. 78, 183. https://doi.org/10.1007/s12665-019-8191-6 (2019).

Zeng, L., Luo, J. T., Liu, J., Gao, Q. F. & Bian, H. B. Disintegration characteristics and mechanisms of carbonaceous mudstone subjected to load and cyclic drying–wetting. J. Mater. Civ. Eng. 33, 04021195. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003817 (2021).

Chen, C., Zhao, B., Zhang, L. & Huang, W. Mechanism of strength deterioration of red sandstone on reservoir bank slopes under the action of dry–wet cycles. Sci. Rep. 13, 20027. https://doi.org/10.1038/s41598-023-47397-x (2023).

Yang, Y., Li, W. & Lu, Q. Acoustic Emission characteristics of the water weakening effect on cretaceous weakly cemented sandstone. Sustainability 15, 8390 (2023).

Zhang, Z. et al. Study on the cracking mechanism of strongly weathered purple mudstone under wetting and drying effect through experiments and molecular dynamics simulation. Constr. Build. Mater. 403, 133104. https://doi.org/10.1016/j.conbuildmat.2023.133104 (2023).

Tang, J., Lan, T., Lai, Y., Li, M. & Ma, Q. Softening mechanism and characteristics of mudstone after absorbing moisture. Appl. Clay Sci. 254, 107398. https://doi.org/10.1016/j.clay.2024.107398 (2024).

Nooraiepour, M., Mondol, N. H. & Hellevang, H. Permeability and physical properties of semi-compacted fine-grained sediments – A laboratory study to constrain mudstone compaction trends. Mar. Pet. Geol. 102, 590–603. https://doi.org/10.1016/j.marpetgeo.2019.01.019 (2019).

Xu, C. et al. Experimental study on mechanical properties and failure behaviours of new materials for modeling rock bridges. J. Mater. Res. Technol. 23, 1696–1711. https://doi.org/10.1016/j.jmrt.2023.01.128 (2023).

Fu, H. Y., Qi, S. X., Shi, Z. N. & Zeng, L. Mixing Ratios and Cementing Mechanism of Similar Silty Mudstone Materials for Model Tests. Advances in Civil Engineering 2426130, doi: (2021). https://doi.org/10.1155/2021/2426130 (2021).

Guo, Y., Yang, Y., Kong, Z. & He, J. Development of similar materials for liquid-solid coupling and its application in Water Outburst and Mud Outburst Model Test of deep tunnel. Geofluids 2022 (8784398). https://doi.org/10.1155/2022/8784398 (2022).

Cui, Y., Xu, C., Xue, L., Dong, J. & Jiang, T. Experimental study on the reasonable proportions of rock-like materials for water-induced strength degradation in rock slope model test. Sci. Rep. 13, 9288. https://doi.org/10.1038/s41598-023-36511-8 (2023).

Liu, X., Jiang, D., Jia, Q., Xu, H. & Wang, T. Preparation Method of similar materials for the Progressive disintegration of Red-Bedded Soft Rock based on Diagenesis Simulation. Buildings 13 (2023). https://www.mdpi.com/2075-5309/13/4/875

Cui, G., Zhou, C., Liu, Z., Xia, C. & Zhang, L. The synthesis of soft rocks based on physical and mechanical properties of red mudstone. Int. J. Rock Mech. Min. Sci. 151, 105037. https://doi.org/10.1016/j.ijrmms.2022.105037 (2022).

Huang, K. et al. Relationship between capillary water absorption mechanism and pore structure and microfracture of red-layer mudstone in central Sichuan. Bull. Eng. Geol. Environ. 82, 100. https://doi.org/10.1007/s10064-023-03115-5 (2023).

Gaboreau, S., Robinet, J. C. & Prêt, D. Optimization of pore-network characterization of a compacted clay material by TEM and FIB/SEM imaging. Microporous Mesoporous Mater. 224, 116–128. https://doi.org/10.1016/j.micromeso.2015.11.035 (2016).

Zhou, Z. et al. Dynamic tensile properties of sandstone subjected to wetting and drying cycles. Constr. Build. Mater. 182, 215–232. https://doi.org/10.1016/j.conbuildmat.2018.06.056 (2018).

Liu, C., Shi, B., Zhou, J. & Tang, C. Quantification and characterization of microporosity by image processing, geometric measurement and statistical methods: application on SEM images of clay materials. Appl. Clay Sci. 54, 97–106. https://doi.org/10.1016/j.clay.2011.07.022 (2011).

Acknowledgements

This work is financially supported by Basic Science (Natural Science) Research Projects in Higher Education Institutions in Jiangsu Province (22KJB130008,23KJD170002,23KJD440001) and Natural Science Research of Jiangsu College of Engineering and Technology (GYKY20213,GYKY20235).

Author information

Authors and Affiliations

Contributions

S.Y. conceived and wrote the main manuscript with feedback from all authors. L.H. contributed to the ideas and general guidance for the article. W.Z. analyzed the experiment results. L.M. finished the translation of the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yan, S., Han, L., Meng, L. et al. Application of clay minerals in the synthesis of cretaceous mudstones and microstructural analysis of their deterioration mechanism. Sci Rep 14, 29414 (2024). https://doi.org/10.1038/s41598-024-81202-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-81202-7