Abstract

Regarding the asymmetric large deformation occurring in the No. 13,313 return airway of the Sunjiagou Coal Mine due to multiple mining disturbances, research methods including numerical simulation and field measurements were employed, considering the engineering geological conditions, to analyze the main influencing factors of roadway instability and to obtain the energy-stress distribution characteristics of the surrounding rock.The results of the study show that: (1) The main controlling factors for the deformation and instability of the 13,313 return airway are the dynamic pressure excavation of the neighbouring working face and the influence of the concentrated stress on the coal pillar of the No.11 coal seam section above the working face. (2) Rock damage and failure primarily occur in areas where plastic dissipated energy accumulates. The extent of plastic dissipated energy accumulation shows a clear correlation with the distribution of the plastic zone. Under the action of accumulated elastic strain energy, potential plastic failure zones exist in the surrounding rock of the tunnel. (3) Based on the full-cycle evolution law of the energy-plasticity zone of the tunnel perimeter rock, combined with the numerical simulation results and on-site support conditions, the tunnel perimeter rock zoning control system is proposed to strengthen the support for the concentrated area of the mining influence.Reinforcement support was applied to key sections, providing valuable reference for the engineering practice of similar mining conditions in the future.

Similar content being viewed by others

Introduction

Along-air tunneling technology has the advantages of reducing coal loss and increasing coal extraction rate, and is widely used in China1,2,3. However, the traditional roadway excavation along the air is carried out after the neighbouring working face has been mined and stabilised, which is prone to cause the problem of tense mining and excavation succession. Meet the adjacent back to mining face tunneling roadway by the action of mining and lateral support pressure, tunneling roadway peripheral rock stress rises significantly, the roadway deformation also increases, in the face of back to mining face tunneling roadway, the reasonable width of the coal pillar to stay on the roadway deformation has a significant effect4,5,6. In different periods to meet the mining face digging roadway, roadway peripheral rock stress evolution law and the stability of the section of the coal pillar is different, the required support intensity is different, the support is extremely difficult to support, according to the different digging period, the need to develop the corresponding support mode influence7,8,9. As a result, maintenance of this type of roadway is extremely difficult and requires the use of a new roadway in the area of influence of the oncoming mining10,11. Coal pillar width retention12,13. Roadway Support Parameters14,15,16 and many other aspects are analysed.At present, scholars at home and abroad have carried out a lot of research for this kind of strong mine pressure roadway.Hao Xiaoqi17 researched on the mechanism of impact ground pressure of small coal pillars along the hollow digging road under the condition of thick and hard rock layer in Ordos mine, and clarified that the most obvious area of subsidence is 25–53 m of lagging digging face; Liu Hongtao18 deduced the distribution equation of plastic dissipative energy of circular roadway perimeter rock with non-uniform stress field and obtained the energy evolution law of roadway perimeter rock under the influence of quarrying, and correlated the plastic zone with the plastic dissipative energy, which revealed the evolution law of the plastic zone of the roadway perimeter rock under the effect of energy dissipation.Zhangcun19 quantitatively characterised the degree of energy dissipation of the scale effect of the indicator parameters by defining the damage degree index, and simulated and analysed the influence of the length of the working face and the advancing speed on the degree of overburden damage by combining with the geological conditions of the working face of Qinglongsi Coal Mine.Wu Yu20 took the impact manifestation accident in the tunnel of Mengcun No.4 coal seam as an engineering case, and obtained that the rate of change of impact deformation energy increased 10 times compared with the rate of change in the shallow part of the coal seam after the mining depth exceeded 500 m. The reason for the nonlinear increase of impact hazard is that the growth rate of coal and rock body energy accumulation and release increases significantly after 500 m.The reason for the nonlinear increase of impact hazard is that the growth rate of coal and rock body energy accumulation and release increases significantly after 500 m.Jiang Pengfei21 reveals that the lagging mining influence stage of adjacent workings is the main stage of mining stress increase in the roadway perimeter rock and the temporal and spatial evolution of the mining stress field, support body force and displacement field are related to each other.Based on on-site measured data, combined with theoretical analysis and numerical simulation results, Park Jianbiao22 reveals the mining-excavation stress superposition effect and dynamic pressure disturbance spatial distribution law when digging along the empty roadway on the face of facing mining, and puts forward three control measures, namely, setting a reasonable width of the coal pillar, determining the timing of stopping and resuming digging of the roadway, and adopting the concept of dynamic segmentation control.Guo Chongtuo23 speculated that the influence range of oncoming mining disturbance is 80 m to 100 m by analysing the influence law of lateral support stress and forward over-mining stress, M.D.G.Salamon24,25 based on a large amount of field measurement data (covering more than 2,000 cases of coal pillars) from gold mines in South Africa, has developed empirical equations for the strength of coal pillars and a mechanism for the influence of denudation effects on the long-term stability of coal pillars.Schumacher26 Forrest P made a study based on the roof control engineering of deep coal mines (> 600 m depth) in the western United States, which provided a theoretical basis for the design of support under complex geological conditions. By studying the case of Bowen Basin mine in Australia, R. Frith27 found that there was a 45% deviation between the safety factor predicted by the empirical formula (FS = 1.6) and the result of FLAC3D simulation (FS = 1.1), and put forward a three-in-one risk assessment framework of ‘geomechanics, numerical simulation and on-site monitoring’.Coggan J28 systematically investigated the influence mechanism of weak roof lithology on the stability of coal mine roadway through numerical simulation methods, focusing on the role of different locations of soft and weak interlayers on the stress distribution, displacement field evolution and plastic zone extension law of the roadway surrounding rock.Esterhuizen E29 systematically investigated the numerical model calibration method for coal pillar-air zone-overburden system in coal mines, and established a multi-scale coupled model considering the progressive destruction of coal pillars, the fracture and expansion characteristics of the air zone, and the overburden stiffness degradation by integrating the measured data of the Appalachian mine in the United States, which included microseismic monitoring, surface subsidence, and the load distribution of the coal pillars, with the numerical simulation of FLAC3D. The calibration framework is successfully applied to predict the long-term stability of the remaining coal pillar groups, providing a reliable theoretical model for mine surface subsidence prevention and control.

These research results all reveal the surrounding rock stress environment when digging along the empty roadway in the oncoming mining face to a certain extent, and put forward different control measures30,31,32.

However, there are fewer studies on the mechanism of stress and energy evolution of the meet-mining roadway during the influence of multiple mining disturbances. In this paper, Shanxi Shide Sunjiagou coal mine 13313 backwind face excavation, meet the intersection, the perimeter rock energy - stress evolution law, the proposed roadway perimeter rock zoning control system, on the mining side of the large-scale laying of the site, the more blind to support comments, This paper not only provides theoretical guidance for the reasonable support of 13313 return roadway in Sunjiagou coal mine, but also provides reference cases for the support of roadway under similar geological mining conditions.

Engineering background

Mine overview

Sunjiagou coal mine is located in Baode County, Shanxi Province, 13313 back to the wind tunnel in the process of digging and 13311 face head to meet, the middle interval of 25 m section of coal pillar, in the meeting section and even the local also take grouting reinforcement treatment, however, the support effect is not ideal, the roadway mining pressure is very obvious, the anchor bar (rope) broken and failure, deformation is very serious, due to the adjacent 13311 face of the return mining influence, 13313 back to the roadway during the digging of roof and slice gang collapse phenomenon. Due to the influence of the neighbouring 13311 working face, the 13313 return air lane had the phenomenon of roofing and collapsing of sheet gangs during the digging period, and the roadway was seriously deformed. During the mining of this working face, under the influence of the overrun pressure, the two gangs moved in a large amount; the top plate sinking and the bottom plate bottom drum are also obvious.

Roof-floor lithology

The 13# seam is the main coal seam with an average thickness of 13 m. The top plate is mainly mudstone and sandy mudstone, the average thickness of mudstone is 3.0 m, and the average thickness of sandy mudstone is 5.72 m. The bottom plate is medium sandstone and grey mudstone, the average thickness of medium sandstone is 1.82 m, and the average thickness of grey mudstone is 0.58 m. The average inclination angle of the seam is 6°, which is a near-horizontal seam. The Geological map of coal beds is shown in Fig. 1.

Roadway support situation

In order to cope with the difficult support situation during the mining process, the mine has adopted the following support scheme. The Mining relationship and rock layer histograms is shown in Fig. 2.

Roof support:5 short anchor cables of 5200 mm in each row, spacing 1000 mm, row spacing 1000 mm; the material of short anchor cables is 21.8 mm, 1 × 19 strands of high-strength low relaxation prestressing strand. 8200 mm long anchor cables are arranged in the middle of two rows of 5 200 mm anchor cables, 2 cables in each row, spacing 2000 mm, row spacing 1000 mm. all of them are arranged vertically in the top plate. The initial tensioning of the anchor cable should not be less than 300kN.

Roadside support: Before and after the roadway intersects with the adjacent working face, the same anchor support scheme is adopted, with 4 anchors in each row for each of the left and right gangs, and the spacing between rows of anchors is 900 mm×1000 mm, and all of them are arranged vertically on the coal gangs. The 20 mm HRB500 high-strength left-handed non-longitudinal rebar is used, and the pre-tensioning torque of the anchor rods is 400 N-m. Before the roadway intersects with the 13,311 working face, 2 anchor ropes are installed in each row of the coal pillar gangs, and the row spacing between the anchor ropes is 1,800 mm×1,000 mm.

After the roadway meets the 13,311 working face, the spacing between rows is adjusted to 1800 mm×2000 mm. the anchor cables used are all 17.8 mm, 1 × 17 strands of high-strength, low-relaxation prestressing strand, with a carrying capacity of ≥ 353 kN, and the initial tensioning of the anchor cables is not less than 200 kN.

Mines choose large-scale, high-cost support materials in the face after meeting to the working face to open the cutting eye position for the continuous arrangement of support, resulting in a large number of manpower, material and financial resources are wasted, in order to make a clear control programme for the regional strengthening of support, which this paper based on the conditions to carry out a series of work. The Roadway support layout diagram is shown in Fig. 3.

Deformation monitoring analysis of roadway surrounding rock

The boundary of the rectangular roadway is mapped to the circumference of the unit circle. Based on the plane strain mechanical model for circular openings, the mathematical expression for the plastic zone boundary radius R0 in circular roadways under non-uniform stress fields is derived as33:

Herein, P1 and P3 denote the maximum and minimum principal stresses of the regional stress field, respectively. C and φ represent the cohesion and internal friction angle of the coal-rock mass, while a denotes the roadway radius. The Circular roadway surrounding rock force model in the inhomogeneous stress fieldis shown in Fig. 4.

Circular roadway surrounding rock force model in the inhomogeneous stress field. The distribution of plastic zone boundaries in roadway surrounding rock under different confining pressure conditions reveals distinct patterns. When the regional stress field exhibits biaxial equal pressure, the plastic zone forms a circular shape. As the stress ratio gradually increases, the failure zone evolves into elliptical and butterfly-shaped configurations, with its extent continuously expanding. Both loading in the direction of maximum principal stress and unloading in the direction of minimum principal stress contribute to an increase in stress ratio, thereby creating conditions for the expansion and evolution of butterfly-shaped failure zones. When the roadway stress field is subjected to mining disturbances—if equivalent to maximum principal stress loading or minimum principal stress unloading—the confining pressure ratio increases. This subsequently induces changes in both the extent and morphology of the failure zone.

The distribution of plastic zone boundaries in roadway surrounding rock under different confining pressure conditions reveals distinct patterns. When the regional stress field exhibits biaxial equal pressure, the plastic zone forms a circular shape. As the stress ratio gradually increases, the failure zone evolves into elliptical and butterfly-shaped conurations, with its extent continuously expanding. Both loading in the direction of maximum principal stress and unloading in the direction of minimum principal stress contribute to an increase in stress ratio, thereby creating conditions for the expansion and evolution of butterfly-shaped failure zones. When the roadway stress field is subjected to mining disturbances, if equivalent to maximum principal stress loading or minimum principal stress unloading, the confining pressure ratio increases. This subsequently induces changes in both the extent and morphology of the failure zone.

Roadway deformation characteristics. The roadway shown in Fig. 4 is a photograph taken by Zi-Long Hui and Xiao-Xiang Wei at the underground site of the 13313 return airway of the Sunjiagou coal mine. We confirm that we are the photographer of the photo. The roadway as a whole shows asymmetric deformation and damage, and the deformation and damage trend of the right side of the roadway is larger than that of the left side. We hold the full copyright of this image and grant Springer Nature Ltd permission to publish it under the Creative Commons Attribution 4.0 International License (CC BY 4.0).This authorization covers all publication formats, including print and digital versions.

According to the on-site research and observation, the asymmetric deformation trend of the roadway is obvious, The 13313 return airway is subjected to multiple mining disturbances. Stress redistribution around the mined-out area induces varying degrees of principal stress rotation in surrounding rock, placing the roadway within an anisotropic stress field that triggers asymmetric failure phenomena.

The Roadway deformation characteristics is shown in Fig. 5. 13313 return-airway top and bottom plates are moved closer to each other by more than 70 m in the overrun and more than 130 m in the lagging, and the whole length of 200 m is affected by the mining stress of the neighbouring 13311 working face more drastically; the top plate crushing mainly occurs in 0 ~ 3 m, and the destruction of the top plate is more obvious in the interval from 3 to 6 m. The top plate above 6 m is relatively intact. The top plate breakage mainly occurs in 0 ~ 3 m, the top plate is more obvious in the range of 3 ~ 6 m, and the top plate above 6 m is relatively intact.The roadway as a whole shows asymmetric deformation and damage, and the deformation and damage trend of the right side of the roadway is larger than that of the left side. The Peeping view of mine borehole is shown in Fig. 6.

Peeping view of mine borehole. Drill hole peeping is able to show the lithological characteristics and dynamic damage characteristics of coal seams more intuitively. The top plate breakage mainly occurs in 0~3m, the top plate is more obvious in the range of 3~6m, and the top plate above 6m is relatively intact. The roadway as a whole shows asymmetric deformation and damage, and the deformation and damage trend of the right side of the roadway is larger than that of the left side.

Industrial tests and mine pressure observation were carried out in the 13313 return airway. Anchor cable pressure gauge and cross observation method were used to monitor the anchor cable force and peripheral rock surface displacement, The Tunnel Surface Displacement Monitoring Curve is shown in Fig. 7.

Tunnel surface displacement monitoring curve. This figure depicts a roadway surface displacement monitoring graph. The monitoring curves of roadway surface displacement can be divided into three areas, in area A, i.e., outside the range of 80m before the intersection, the displacement of top and bottom plates and two gangs shows a slow rising trend, in area B, i.e., within the range of 80m before the intersection and 120m after the intersection, the displacement shows a fast rising trend, in area C, i.e., outside the range of 120m after the intersection, the displacement curve tends to stabilise. Outside the range, the displacement curve tends to stabilise as a whole.

The monitoring curves of roadway surface displacement can be divided into three areas, in area A, i.e., outside the range of 80 m before the intersection, the displacement of top and bottom plates and two gangs shows a slow rising trend, in area B, i.e., within the range of 80 m before the intersection and 120 m after the intersection, the displacement shows a fast rising trend, in area C, i.e., outside the range of 120 m after the intersection, the displacement curve tends to stabilise. outside the range, the displacement curve tends to stabilise as a whole.

Comprehensive mine pressure observation data show that: in the 13313 return airway from the front of 13311 face to face digging to along the 13311 face along the edge of the hollow area during the whole period, the maximum amount of the two gangs of the roadway moving closer to 400 mm or less. Due to the roadway roof and the two gangs of high-strength support role, high stress will be released through the weak parts of the bottom plate, resulting in some parts of the bottom plate appeared to a certain degree of bottom drum, and eventually through the adoption of the bottom of the pull to release the pressure, the later did not appear again obvious bottom drum.During the roadway excavation, the force of top and gang anchor rods (ropes) is stable, and there is no sudden change of the force value. The top 5.2 m anchor cable force is between 150k N ~ 200k N, the top 8.2 m anchor cable force is basically stable at about 170KN, the gang anchor bar force is between 54KN ~ 136KN, and the gang anchor cable force is between 82kN ~ 96kN. The Roadway anchor cable force monitoring curve is shown in Fig. 8.

Comprehensive mine pressure observation data show that: in the 13313 return airway from the front of 13311 face to face digging to along the 13311 face along the edge of the hollow area during the whole period, the maximum amount of the two gangs of the roadway moving closer to 400 mm or less. Due to the roadway roof and the two gangs of high-strength support role, high stress will be released through the weak parts of the bottom plate, resulting in some parts of the bottom plate appeared to a certain degree of bottom drum, and ultimately through the adoption of pulling the bottom to release the pressure, the later did not appear again obvious bottom drum. Among them, I is the force curve of the top plate of the anchor cable, II is the force curve of the gang part of the anchor cable, during the roadway excavation, the force of the top gang anchor rod (cable) is stable, and there is no sudden change of the force value. The top plate 5.2 m anchor cable force is between 150k N ~ 200k N, the top plate 8.2 m anchor cable force is basically stable at about 170KN, the gang anchor rod force is between 54 KN ~ 136 KN, and the gang anchor cable force is between 82 kN ~ 96 kN.

The establishment and correction of numerical model

Numerical modeling

To investigate the failure patterns of surrounding rock in the 13313 return airway, the excavation of the 13313 haulage roadway will be subjected to multiple mining-induced disturbances. The numerical model will be excavated in three sequential steps: First, the upper mining face of the 11# coal seam will be excavated to simulate the initial mining disturbance. Subsequently, the lower mining face of panel 13311 will be excavated to simulate the secondary mining disturbance. Finally, the 13313 return airway will be excavated in sections to simulate the deformation and failure of roadway surrounding rock within the influence zone of advanced abutment pressure at different advance positions.

Now considering that the stress field characteristics around actual roadways are influenced by numerous complex factors—including overburden movement patterns, lithological combinations of the coal seam roof, backfill extent of goaf areas, among others—it is challenging to comprehensively incorporate all these elements solely through numerical simulation. Therefore, during modeling, only primary factors such as the spatial geometry of excavation engineering, structural characteristics of overlying strata, and regional stress environment were considered. This approach aims to capture the vector characteristics of the stress field in the vicinity of the mined-out space.

The mechanical parameters of each rock layer in the model were derived experimentally.Through uniaxial compression tests, the axial stress-strain curves were measured to calculate Young’s modulus and Poisson’s ratio. These values were then used to derive the bulk modulus and shear modulus. Additionally, the internal friction angle and cohesion of the coal-rock mass were determined via direct shear tests.The parameter settings were obtained from the rock mechanics experimental data provided by the coal mine, and the final rock mechanics parameters were determined by averaging the measured surrounding rock mechanics parameters, with some adjustments for consistency.Determination of rock tensile strength through the Brazilian test.The experimental figure for mechanical parameter testing is shown in Fig. 9.

Experimental figure of mechanical parameter testing. The mechanical parameters of each rock layer in the model were derived experimentally. Through uniaxial compression tests, the axial stress-strain curves were measured to calculate Young’s modulus and Poisson’s ratio. These values were then used to derive the bulk modulus and shear modulus. Additionally, the internal friction angle and cohesion of the coal-rock mass were determined via direct shear tests. The parameter settings were obtained from the rock mechanics experimental data provided by the coal mine, and the final rock mechanics parameters were determined by averaging the measured surrounding rock mechanics parameters, with some adjustments for consistency. Determination of rock tensile strength through the Brazilian test.

According to the geological conditions of the site, the numerical model was established with the help of FLAC3D, as shown in Fig. 10.The length×width×height of the model is 500 m×250 m×82 m, There are a total of 2969056 zones and 3048375 Gridpoints, and the bottom and side displacements of the model are fixed, The average depth of the modelled roadway is 400 m, and a vertical stress of 9.8 MPa is applied to the top of the model, Lateral pressure coefficient is taken as 1.3.In order to restore the mechanical properties of the rock layers as much as possible, the Double-yield model was used to simulate the air-mining zone, the Strain-softening model was used to simulate the coal pillar, and the Mohr-Coulomb model was used to simulate the other rock layers.In order to optimise the calculation efficiency and accuracy of the model, the mesh is locally encrypted in the area of 20 m to the left of the 13313 return trench and 20 m to the right of the 13311 inlet trench. The grid size is 1 m×0.5 m×0.5 m.

Based on the physical and mechanical parameters of the rock mass listed in Table 1, particular emphasis was placed on restoring the stress field in key areas during the model construction process: Through precise parameter assignment and boundary condition setting, the vertical stress distribution at the target coal seam location within the model was ensured to be highly consistent with the in-situ stress field obtained from downhole measurements or theoretical inferences.

Meanwhile, strictly adhering to mine geological exploration data and rock mechanics test results, the mechanical parameters assigned to each simulated rock layer fully reflect the actual rock mass properties under the specific geological conditions of the mine.

Based on a comprehensive analysis of the verification results of the model’s stress field and the authenticity of the rock layer parameters, this study concludes that: The established numerical model demonstrates robust stress reproduction capability in the core area of the 13313 return airway, and the key steps involved in equivalently converting actual complex rock mass materials into numerical model media were handled appropriately. Overall, the model can relatively realistically and reasonably reflect the geomechanical environment of the original mine prototype.

Numerical three-dimensional model diagram. The pictures depict that the X direction of the model represents the direction of the working face, whose length is 500m; the Y direction represents the tendency, whose length is 250m; the Z direction represents the direction of the overburden, whose length is 82m.

Double yield model correction of goaf

Roof rock characteristics

After mining the working face, the roof slab above the mining hollow area collapses and fills the hollow area, and the part of the rock belt where the roof slab collapses is called the collapse zone. The height of the fall zone is related to the top plate lithology, mining height and other factors, and can be calculated by the following formula34:

Above equation:

ℎc is the height of the collapse zone, m;

ℎm is the mining height of the coal seam, m;

c1 and c2 are the correction coefficients, and the values of the parameters are shown in Table 2.

The mining height of the coal seam is 13 m, and the average strength of the roof plate is medium strength rock layer According to Table 2, selecting the appropriate parameters and substituting them into the calculation, the collapse zone is 16.2 m.

After the working face is mined, with the collapse of the rock layer above, the rock body in the mining area is gradually compacted, and the mechanical properties of the rock body in this process will show a dynamic change process.The Salamon theoretical model is used to describe the stress-strain relationship of rock bodies in the extraction zone and is widely used in engineering.

Above equation:

σ is the vertical stress applied to the rock mass in the extraction zone, MPa;

εg is the strain occurring in the rock mass in the extraction zone under the effect of vertical stress;

E0 is the initial modulus of the rock mass in the extraction zone, GPa.

The maximum strain occurring in the rock mass of the extraction zone under vertical stress can be calculated by Eq. (5)35:

Above equation:

bg is the fragmentation coefficient of the rock mass in the extraction zone;

Εgmax is the maximum strain of the rock mass in the extraction zone.

The Stress-strain relationship of materials in the extraction zone are shown in Table 3.

Determination of model parameters

The built-in Double-yield model of FLAC 3D can be used to describe the gradual recovery of rock stress in the extraction zone more accurately.A 1 m×1 m×1 m model was built in FLAC 3D for calibration, the bottom and peripheral displacements of the model were fixed, and a vertical load of 10-5m/step was applied at the top36.The trial-and-error method is used to continuously correct the model parameters, and the correction results are shown in Fig. 10, and the stress-strain curve of the corrected numerical model is in good agreement with the theoretical calculation results. The stress-strain relationship of the rock body in the extraction zone is shown in Table 3, and the finalised mechanical parameters of the rock body in the extraction zone are shown in Table 4. The Double yield model correction flow chart is shown in Fig. 11.

Double yield model correction flow chart. The images show the overall process of strain softening the model and a model with dimensions of 1m x 1m x 1m was created in FLAC3D for calibration, with constraints imposed on the displacements at the bottom and around the model. In addition, a vertical load of 10-5/step was applied at the top. The trial-and-error method was used to continuously correct the model parameters.

Verification of stress environment in goaf

In order to verify the reasonableness of the stress environment of the mining hollow zone, the rock layers of the mined working face and the collapse zone above are given Double-yield model and then run to equilibrium, and the measurement lines are arranged along the working face strike, and the monitoring results are shown in Fig. 12. After the compaction of the working face, the stress is gradually recovered, The red line in the graph indicates the stress in the original rock, and at 70 m from the edge of the working face, the stress is close to that of the original rock, and there is a stress concentration at 7 m from the working face, with the maximum value of 32 MPa, and the stress concentration coefficient is 3.2.

Vertical stress distribution in goaf of 13,311 working face. After verifying the reasonableness of the stress environment of the working face’s hollow zone, running to equilibrium after assigning the Double-yield model to the rock layer of the working face 13311 and the collapsed zone above, and arranging the measuring line along the working face, the vertical stress recovered to 9.7MPa at 70m from the edge of the hollow zone, close to the original rock stress.

Coal pillar strain softening model correction

Correction results of double yield model. This image shows the double yield model with the overall trend and peak point of the stress-strain graphs from numerical simulations and laboratory tests being essentially close to each other. The FLAC 3D software was used to model a cylinder with a diameter of 2 m and a height of 4 m at a fixed speed of 2.5 × 10(-1) ,0-5 m/step was applied simultaneously to the top and bottom.

The FLAC 3D software was used to model a cylinder with a diameter of 2 m and a height of 4 m at a fixed speed of 2.5 × 10(-1) ,0–5 m/step was applied simultaneously to the top and bottom. The material parameters were continually adjusted and the final set of mechanical parameters determined for the model are listed in Tables 5 and 6. Figure 11 shows the resulting calibration results. The stress-strain curves obtained through numerical simulation agree with those obtained from laboratory tests, thus confirming the validity of the strain softening model37.The Correction results of double yield model is shown in Fig. 13.

Energy model

When performing energy analyses, the energy numerical model needs to be re-established for the calculations and the Null model is assigned to the extraction zone38.From the energy point of view, when a rock is deformed by an external force, assuming that there is no heat exchange between this physical process and the outside world, the total input energy produced by the external work is U. According to the principle of conservation of energy we get:

Above equation:

Ue is the releasable elastic strain energy of the rock, can be expressed as:

Above equation:

µ is the modulus of elasticity;σ is Poisson’s ratio;σ1, σ2 and σ3are the maximum, intermediate and minimum principal stresses respectively.

The total strain energy of element i :

In the formula : Ui is the strain energy density of the i th unit body ; Vi is the volume of the ith unit cell39.

The Energy conversion relationship diagram for coal and rock bodies is shown in Fig. 14. In the process of roadway forming, the stable stress state of the surrounding rock is destroyed, and its energy is continuously transformed with the rebalancing of the stress field of the coal and rock body. According to the law of conservation of energy, the energy change of the unit body is approximately equal to the energy difference before and after mining when other factors are ignored.Define Wa,Wb respectively, where a is pre-mining and b is post-mining.Wi is the strain energy density of the ith cell before and after harvesting, then the energy change W is:

The energy-stress full-cycle evolution law of surrounding rock of roadway

Influencing factors of asymmetric failure in roadways

Based on the investigation of on-site engineering geological conditions, it is concluded that the influencing factors of deformation and failure in roadways of fully mechanized top-coal caving mining in extra-thick coal seams are:

-

(1)

Roadway Layout. After the extraction of Coal Seam 11, stress redistribution occurs in the surrounding rock strata of the mined-out area. The destressed zone formed in the working face floor and the stress concentration phenomenon over the remaining section pillars place the 13313 return airway within a stress concentration zone induced by the overlying remaining coal pillar. Consequently, the stability of this roadway is significantly impacted by the overlying coal pillar.

-

(2)

Stress Environment.The 13313 return airway is subjected to a composite stress field primarily composed of in-situ stress, stress induced by the overlying remaining coal pillar, and mining-induced dynamic loads.

-

(3)

Unreasonable Support Design. Conventional cable bolts of 5.2 m and 8.2 m lengths were employed, with 5.2 m bolts installed in fractured roof zones where inadequate reinforcement compromised roadway stability, ultimately resulting in poor ground control.

Main influencing factors of roadway instability

On the one hand, due to the influence of over-supporting stress caused by the upper section working face, the deformation of the roadway peripheral rock shows a gradual increasing trend with the proximity of the digging working face and the upper section working face. With the digging face and the upper section of the mining face will meet, the overlying rock structure drastically adjusted, the working face pushed through the direct top of the irregular collapse, the basic top of the bending and sinking in turn, slewing, broken, until the gangue tended to stabilise after compaction.

Thickness of direct roof required to form a filled void after mining No. 11 coal.

Above equation:

∑h is the thickness of the direct roof, m;M is the thickness of No.11 coal seam, m;K is the crushing expansion coefficient of the bubbling direct roof, and is taken as 1.3 according to the lithological data of the mine; Calculated ∑h is 9.3 m.

The height Dmax of the bottom slab damage caused by No.11 coal mining can be calculated by the following formula.

Above equation:

γ is the rock bulk weight, take25kN/m3;

H is the depth of the coal seam, take 250 m;

L is the length of the working face, take 160 m;

Rrmc is the uniaxial compressive strength of the rock body of the bottom plate, take 25 MPa.

Calculated to be 3.9 m.

No.11 coal seam, No.13 coal seam mining filled with the direct roof thickness required by the formula, taking into account that the working face is a roof coal mining, the working face roof coal extraction rate is calculated at 90%, the direct roof fall height required to fill the full mining area is 39 m.

The thickness of the rock layer between No.11 coal seam and No.13 coal seam is only 8.72 m, and when No.11 coal seam is opened, the depth of the bottom plate destruction is up to 3.9 m, so this rock layer will be mined along with the No.13 coal seam working face, so that the upper and lower two air-mining zones are connected.Because No.11 coal seam is only 2.19 m, and the height of its collapse zone is only 7.9 m, the sum of both of them still can’t reach the required 39 m direct roof fall height, at this time, part of the rock layer in the fissure zone of No.11 coal seam will be destabilised, and will become a new rock layer in the collapse zone until it can fill up the air-sea area, and then the fissure zone and part of the curved downward sinking zone on it will become the new rock layer of the fissure zone as shown in Fig. 15.

After the 13311 working face is recompacted, lateral support pressure will be formed on the coal pillar in the section, and if it is a single-seam mining, the lateral support pressure is shown as the red curve in Fig. 15; as it moves away from the edge of the coal pillar, the support pressure grows significantly, and after reaching the maximum value, it slowly returns to the original stress value. Sunjiagou mine is close multi-seam mining, and the coal pillar of the lower coal is located 25 m below the mining airspace of the upper coal, and above it is the rock of the collapse zone of the upper working face, which has a low capacity of carrying and transferring the self-weight of the overlying rock layer before re-compacting, resulting in the transfer of the stress of the overlying rock layer to a more distant place, and the lateral bearing pressure is shown as the blue curve in Fig. 15 after the mining of the 13311 working face.Compared with the lateral support pressure of single seam mining, the main features are: low peak support pressure; slow pressure drop and large influence range. Under the action of dynamic pressure, the large thickness of top coal is easy to occur away from the layer of damage, the lower No. 13 coal seam 13311 working face back to mining, due to the influence of the No. 11 coal seam section above the working face of the coal pillar concentration of stress, increasing the difficulty of the 13313 back to the wind lane support.

Full-cycle evolution law of surrounding rock stress in roadway

The 13313 roadway is excavated and supported at the edge of unstable mining zone and under strong dynamic pressure conditions, which is affected by the mining of the neighbouring working face, and the lateral roof breakage and slewing of the neighbouring working face as well as the strong dynamic pressure will directly affect the stability of the roadway, and the numerical simulation is used in this section to reveal the full-cycle evolution law of the roadway peripheral rock energy-stress.

The stress cloud diagram of roadway surrounding rock under different mining-excavation positions. This picture shows the three-dimensional stress distribution map at each stage, the vertical stress reaches the peak point about 30m before the intersection, and then the vertical stress inside the coal pillar starts to decrease gradually, and the internal stress state of the coal pillar shows the trend of rising and then decreasing in the whole evolution cycle.

The stress cloud diagram of roadway surrounding rock under different mining-excavation positions is shown in Fig. 16. With the advancement of 13311 working face, the coal column bearing state, the stress peak all appeared in the right gang of the roadway, which was 25.3 MPa; the right side of the figure shows the vertical stress curve of the coal column under different mining-excavation positions, under the superposition of over-advanced supporting stress in the excavation face and lateral supporting stress in the back-mining face, the internal stress in the coal column gradually rises and reaches a peak point about 30 m before the intersection with the continuous advancement of excavation face, followed by a gradual decline in the internal vertical stress. After that, the vertical stress inside the coal pillar starts to decrease gradually, and the internal stress state of the coal pillar shows the trend of rising and then decreasing in the whole evolution cycle.

Before the intersection, the working face mining has a greater impact on the roadway, including in the top plate and two gangs, are in different degrees affected by the mining, focusing on the expansion of the plastic zone and the asymmetric deformation of the roadway, and after the intersection, the peripheral rock around the roadway is less affected by the mining activities of the working face. In the vertical stress curves of the coal pillar under different mining positions, the whole shows a saddle shape, and the stress concentration coefficient inside the coal pillar reaches a peak of 2.25 at 30 m in front of the intersection, and starts to decrease gradually with the advance of the boring face.Stresses are more concentrated in the area from 80 m before the intersection to 20 m after the intersection.

Cloud diagram of plastic zone in roadway under different mining-excavation positions. This picture shows the plastic zone of the roadway at various stages as shown in the cloud diagram; within the interval from 80m before the intersection to 20m after the intersection, the stability of the roadway perimeter rock is greatly reduced by the influence of the over-supporting pressure of the neighbouring working face, leading to serious deformation of the perimeter rock in this area.13313 The plastic zone of the right gang of the return roadway is extended, with a destructive depth of about 2m.

The Cloud diagram of plastic zone in roadway under different mining-excavation positions is shown in Fig. 17. From the above figure in different mining-excavation position under the roadway plastic zone cloud map shows that under the influence of multiple extractions, especially the 80 m before the meeting of the digging face and the mining face back to meet the 20 m after the meeting of the roadway, by the influence of the neighbouring working face of the over-excavation support pressure, the stability of roadway peripheral rock greatly reduced, resulting in serious deformation of the peripheral rock of the region. 13313 back to the wind roadway plastic zone of the right gang expansion, damage to the depth of 2 m or so.

Comprehensive analysis of the plastic zone and the stress map of the surrounding rock of the roadway shows that in the roadway area from 80 m before the meeting of the mining face to 20 m after the meeting, the stress of the coal pillar increases significantly compared with other areas, and the damage of the plastic zone expands, i.e., the surrounding rock in this area has a large range of stress concentration and plastic damage, so it needs to focus on the support.

Dissipative energy cloud diagram of roadway surrounding rock under different mining-excavation positions. This picture shows the dissipated energy cloud map of the surrounding rock at each stage of the roadway, in the whole evolution cycle, the dissipated energy is mainly concentrated in the top and bottom plates of the roadway; the area of plastic dissipated energy accumulation is the main area of damage to the surrounding rock, and the degree of damage to the surrounding rock at the right gang of the roadway increases, while the damage to the surrounding rock at the deep part of the roadway is small, where a large amount of elastic strain energy is accumulated; the range of the dissipated energy accumulation in the roadway is obviously correlated with the distribution of the plastic zone.

The Dissipative energy cloud diagram of roadway surrounding rock under different mining-excavation positions is shown in Fig. 18. The dissipated energy of the surrounding rock in different relative positions; in the whole evolution cycle, the dissipated energy is mainly concentrated in the top and bottom slabs of the roadway; according to the definition of the degree of energy dissipation damage, the larger the value of which indicates that the overlying rock is more serious in energy dissipation, and the degree of damage of the fracture is also larger, which can be seen that the peak of the released energy at different mining-excavation positions occurs at the top and bottom slabs of the roadway, which is mainly manifested in the top plate subsidence and the bottom plate bottom bulge.

An analysis of the energy dissipation evolution reveals that the energy disturbance zone formed by roadway excavation exhibits significant spatial coupling characteristics with the surrounding rock plastic zone. As the excavation face advances, the energy dissipation density field demonstrates a gradient distribution: within 10 m from the mining intersection, an energy concentration effect occurs with a peak density reaching 5.5 kJ/m³ (this zone corresponds to the fracture development zone of surrounding rock). With increasing distance from the intersection, the energy dissipation density follows an exponential decay trend, consistent with the typical attenuation pattern of excavation-induced energy propagation.

Similarly, in the range of 80 m ahead of the working face and 20 m behind the working face, the dissipation of energy in the right gangway of 13313 return roadway is more and more significant than that in other areas, and compared with other areas, the total amount of dissipation in the current range of the roadway is increased, and the non-equilibrium characteristics of the energy transfer process are more prominent.

Within 80 m ahead of the working face and 20 m behind the working face, the range of energy dissipation area gradually expands, and the range of plastic zone injury also expands synchronously; the plastic zone and dissipated energy show consistency in the scope and degree of influence, and the damage of the surrounding rock mainly occurs in the area of plastic dissipated energy accumulation, and the process of formation and development of the plastic zone is accompanied by the dissipation of energy, and the range of plastic energy accumulation has an obvious correlation with the distribution of plastic zones, i.e. Plastic dissipative energy accumulation area is the main area of surrounding rock damage.

Numerical simulation is used to reveal the full-cycle evolution law of the energy change of the surrounding rock in the 13313 return roadway. Lay out the flanks under different mining and digging positions, and get the energy density and energy change diagram of the surrounding rock under different mining and digging positions.

Energy density variation diagram of roadway surrounding rock under different mining-excavation positions. This picture shows the distribution of energy density change in the surrounding rock; at the vertical slice position 10m after the intersection, its energy density reaches the peak value of 27kj/m3; after the intersection, as the spacing increases, the density change peak value also decreases gradually, and the rate of decline is relatively smooth, showing a progressive decay trend. In the intersection of 0m along the roadway roof location to do horizontal slicing, its energy density influence range of the right gang is obviously larger than the left gang. The energy density change is mainly concentrated in the roadway roof and the right gang, in the working face 80m ahead of the lagging 20m range, the surrounding rock energy change density began to increase rapidly, that is, in the surrounding rock gradually accumulate energy at the same time, plastic deformation is also occurring synchronously.

The Energy density variation diagram of roadway surrounding rock under different mining-excavation positions is shown in Fig. 19. Arrange the measurement surface under different mining and digging positions in the mining and digging intersection face, and get the distribution of surrounding rock density and energy changes. The above figure shows the distribution of surrounding rock energy density changes, in the process of converging to the intersection surface, the peak energy density will show a gradual increase in the trend. In the 10 m vertical slice position after the intersection, the energy density reaches the peak value of 27kj/m3; after the intersection, with the increase of the spacing, the density change peak value also decreases gradually, the rate of decline is relatively gentle, showing a progressive decay trend. In the intersection of 0 m along the roadway roof location to do horizontal slicing, the energy density influence range of the right gang is obviously larger than the left gang. The energy density change is mainly concentrated in the roadway roof and the right gang, in the working face 80 m ahead, lagging 20 m range, the surrounding rock energy change density began to increase rapidly, that is, in the surrounding rock gradually accumulate energy at the same time, plastic deformation is also occurring synchronously.

Energy change diagram of roadway surrounding rock under different mining-excavation positions. This picture shows the distribution of the energy change of the surrounding rock; before the intersection the energy change shows an increasing trend with the indentation of the relative position, and its energy change reaches a peak at the position of the 10m vertical slice after the intersection; then its cut-off peak shows a slow decreasing trend with the increase of the relative distance. The energy dissipation area is mainly concentrated in the left and right gangs, and the energy change area in the right gang of the roadway is larger than that in the left gang.

The Energy change diagram of roadway surrounding rock under different mining-excavation positions is shown in Fig. 20. Before the intersection, the energy change shows an upward trend with the indentation of the relative position, and its energy change reaches the peak at the vertical slicing position of 10 m after the intersection; and then its cut-off peak shows a slow downward trend with the increase of the relative distance. Doing horizontal slicing at the 0 m position of the intersection, its energy dissipation area is mainly concentrated in the left and right gangs, with a peak value of 20.72kj, and the energy change area of the right gang of the 13313 tunnel is larger than that of the left gang.

Under the influence of excavation disturbance in 13313 return trench, the top and bottom plates and the two gangs of surrounding rocks, in order to reach a stable state, convert the strain energy into dissipative energy for release, resulting in plastic deformation and damage of the surrounding rocks in this area; the deeper the energy of the unit is the bigger, indicating that the energy transfer is the less. The energy accumulation area is mainly distributed in the top and right side of the roadway, and the further away from the intersection surface, the energy accumulation area also appears in the top and bottom plates of the roadway and the right gang, and the two are gradually connected to form a larger energy accumulation area; the energy release area is generally distributed in the peripheral surrounding rocks of the roadway.

The influence distance of energy density and energy change is mainly concentrated in the range of 120 m after the intersection of digging face and 80 m before the intersection, and the trend of both of them is basically the same, and on the whole, both of them are irregularly shaped before the intersection, and after the intersection, with the increase of distance after the intersection, the influence range is gradually reduced. The trend of energy density and energy change of surrounding rock is shown in Fig. 21.

The overall change trend diagram of surrounding rock energy. This picture shows the full-cycle evolution law of the energy-plasticity zone of the roadway surrounding rock, in which the influence range of the plasticity zone of the roadway surrounding rock is mainly concentrated in the area from 80m before the meeting of the back-mining face to 20m after the meeting, which is shown as the orange area in the picture; the influence range of the energy of the roadway surrounding rock is obviously larger than the plasticity zone, and the surrounding rock is accumulating energy under the action of the accumulated elastic strain energy, and according to the above picture of the trend of the energy change. According to the energy change trend graph above, the energy change is also obvious after 20m of meeting, and there is a potential plastic damage zone under the action of accumulated elastic strain energy of the tunnel surrounding rock, which is shown as blue area in the graph.

Comparing the full-cycle evolution law of the stress and energy change of the tunnel surrounding rock, in the full-cycle evolution law of the stress of the tunnel surrounding rock, the plastic zone and the dissipated energy show the consistency in the scope and degree of influence, in which the influence range of the plasticity zone of the roadway surrounding rock is mainly concentrated in the area from 80 m before the meeting of the mining face to 20 m after the meeting, In the full-cycle evolution of the energy of the roadway surrounding rock, the energy density and energy in the influence of the scope and degree of consistency, in which the influence of the plastic zone of the roadway surrounding rock is mainly concentrated in the area from 80 m before the meeting of the digging workface to 120 m after the meeting.

The influence range of the energy change of the surrounding rock of the roadway is obviously larger than the influence range of the plastic zone and dissipation energy, the surrounding rock is constantly storing energy under the action of the accumulated elastic strain energy, according to the energy change trend graph above, the energy change is also obvious after the intersection of the working face for 20 m, and there will be a potential plastic damage zone under the action of the accumulated elastic strain energy.

Partition control system of roadway surrounding rock in working face

According to on-site research and observation, 13313 return airway shows asymmetric deformation characteristics under the influence of mining in the adjacent working face: the top and bottom plates are shifted more than 70 m in front of the mining face and more than 130 m in behind, and the whole length of 200 m is affected by the stress of mining in the adjacent 13311 working face; in the roadway area from 80 m in front of the meeting of the mining working face to 20 m after the meeting, the coal column stress is obviously increased compared with other areas, and the concentration coefficient of coal column stress reaches 2.4, and the damage range of plasticity zone is enlarged; during the evolution of the whole cycle of energy change of the roadway surrounding rock, the influence range of energy change is concentrated in the area from 80 m before to 120 m after the meeting, the damage range of plasticity zone is enlarged; during the whole cycle evolution of the energy change of the surrounding rock in the roadway, the influence area of energy change is concentrated in the area from 80 m before to 120 m after the meeting of the mining face, which is highly consistent with the actual influence area of mining.

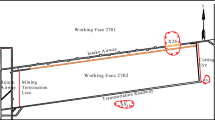

In this regard, it is proposed that according to the arrangement of the roadway and the energy stress evolution characteristics of the surrounding rock, the 13313 return wind tunnel is divided into three zones: mining influence concentrated zone, mining influence over the front zone, mining influence lagging zone. As shown in Fig. 22. According to the three different sections of the roadway use cycle, surrounding rock environment, section size, etc., the roadway perimeter rock zoning control system is proposed.

The first stage : The area within 80 m from the digging face to the front of the meeting is less affected by the mining stress, and the stress on both sides of the roadway is symmetrically distributed.

The second stage: from 80 m before meeting to 120 m after meeting, the mining stress has a strong influence on the surrounding rock. In this area, the stress on both sides of the roadway gradually changes from symmetrical distribution to asymmetrical distribution, and the deformation damage of the right gang of the return airway is larger than that of the left gang. As the relative distance decreases, this asymmetric phenomenon becomes more and more obvious.

The third stage: 120 m after the intersection to the working face range, with the increase of the relative distance, the internal energy of the coal pillar is gradually reduced and tends to be stable, the effect of mining influence is also reduced, with appropriate support programme, can effectively control the deformation of the roadway peripheral rock damage.

Roadway surrounding rock partition control system. This picture shows the roadway perimeter rock zoning control system; according to the roadway layout and the energy-stress evolution characteristics of the perimeter rock, the 13313 backwind tunnels are divided into 3 zones. The first stage: the area within 80m from the digging face to the front of meeting is less affected by the mining stress, and the stress on both sides of the roadway is symmetrically distributed. The second stage: from 80m before meeting to 120m after meeting, the influence of mining stress on the surrounding rock is strong. In this area, the stress on both sides of the roadway gradually changes from symmetric distribution to asymmetric distribution, and the deformation damage of the right gang of the return airway is larger than that of the left gang. As the relative distance decreases, this asymmetric phenomenon becomes more and more obvious. The third stage: 120m after the intersection to the working face range, with the increase of the relative distance, the internal energy of the coal column gradually reduces and tends to be stable, the effect of mining influence is also reduced, with the appropriate support programme, it can effectively control the deformation and damage of the roadway peripheral rock.

For the complex geological conditions of the roadway, high stress, large deformation of the roadway, poor support effect and other issues, the mine used high prestressing strong anchor rods (ropes) combination of support technology for large-scale laying, blind support, resulting in a large number of manpower, material and financial resources wasted, which is proposed to strengthen the support of the concentrated area of the impact of the mining movement, that is, only in the area to set the anchor rods row spacing of 900 mm × 1000 mm, it is proposed that 13313 back to the wind tunnel at different stages of the specific support distribution shown in Fig. 21. 1000 mm, it is suggested that the specific support distribution of 13313 return-airway at different stages of the roadway is shown in Fig. 23.

Results and discussion

-

(1)

13313 return roadway top plate crushing mainly occurs in 0 ~ 3 m, top plate 3 ~ 6 m crushing degree is weaker than the range of 0 ~ 3 m, the two gangs are generally moved in the amount of more than 2 m, the top plate sinking, the bottom plate bottom drum obvious, the roadway as a whole presents asymmetric deformation damage. 13313 return roadway deformation instability of the main control factors for the neighbouring working face back to the mining dynamic pressure digging and the working face above the No.11 coal seam section of the coal column concentration of stress. The main controlling factors of the deformation and instability of 13313 back-air tunnel are the dynamic pressure digging in the neighbouring working face and the concentration of coal pillar in the section of No.11 seam above the working face.

-

(2)

The internal stress of the coal pillar reaches the peak at about 30 m before the intersection, which is 25Mpa, and shows the trend of rising and then falling in the whole evolution cycle. The area of plastic dissipative energy accumulation is the main area of surrounding rock damage, and the damage degree of surrounding rock in the right gang of the roadway increases, while the damage degree of surrounding rock in the deep part of the roadway is small, and a large amount of elastic strain energy is accumulated here; the range of plastic dissipative energy accumulation in the roadway has obvious correlation with the distribution of plasticity zone.

-

(3)

The distribution trend of the energy density and energy change map of the surrounding rock of the roadway is basically the same, which shows irregular shape before meeting, and after meeting, with the increase of the distance after the intersection, the range also decreases gradually. The energy accumulation area is mainly distributed in the top plate and right side of the roadway, and near the intersection surface, the energy accumulation area gradually appears in the top and bottom plate of the roadway and the deep area of the right gang, and both of them are gradually connected to form a larger energy accumulation area, and there will be a potential plastic damage area under the effect of the accumulated elastic strain energy of the roadway enclosing rock.

-

(4)

Combining the numerical simulation results and site conditions, the tunnel perimeter rock zoning control system is proposed, which divides the tunnel into 3 zones and strengthens the support for the concentrated area of mining influence, avoiding the excessive waste of a large amount of manpower, material and financial resources.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Wang, W., Wu, Y., Lu, X. & Zhang, G. Study on small coal pillar in gob-side entry driving and control technology of the surrounding rock in a high-stress roadway. Front. Earth Sci. 10, 1020866 (2023).

Meng, W. et al. A study on the reasonable width of narrow coal pillars in the section of hard primary roof hewing along the air excavation roadway. Energy Sci. Eng. 12, 2746–2765 (2024).

Zhai, W. et al. Roof cutting mechanism and surrounding rock control of small pillar along-gob roadway driving in super high coal seam. Bull. Eng. Geol. Environ. 82, 151 (2023).

Duan, H. & Zhao, L. Gob-side entry driving with small-coal-pillar for carboniferous extra Thick coal seam under jurassic coal pillar. Arab. J. Geosci. 15, 935 (2022).

Gu, W., Xu, D., Han, Z. & Zhang, H. Research on the reasonable width of coal pillar driving along Goaf under Thick hard roof. Appl. Sci. 14, 6381 (2024).

Chang, Q. et al. Determination of narrow coal pillar width and roadway surrounding rock support technology in gob driving roadway. Sustainability 14, 4848 (2022).

Li, G., Wang, X., Bai, J., Wu, B. & Wu, W. Research on the failure mechanism and control technology of surrounding rock in gob-side entry driving under unstable overlying strata. Eng. Fail. Anal. 138, 106361 (2022).

Xie, S., Guo, F. & Wu, Y. Control techniques for Gob-Side entry driving in an Extra-Thick coal seam with the influence of upper residual coal pillar: A case study. Energies 15, 3620 (2022).

Xue, Y. Optimization of small coal pillar width and control measures in gob-side entry excavation of Thick coal seams. Sci. Rep. 14, 23304 (2024).

Zhang, G. et al. Squeezing failure behavior of roof-coal masses in a gob‐side entry driven under unstable overlying strata. Energy Sci. Eng. 8, 2443–2456 (2020).

Ma, Z., Chen, C., Liang, X., Chen, A. & Song, W. Field and numerical investigation on the stability of coal pillars of gob-side entry driving with top coal. Arab. J. Geosci. 13, 1193 (2020).

Wang, C., Yao, H. & Huang, Y. Stability control of goaf-driven roadway surrounding rock under interchange remaining coal pillar in close distance coal seams. Energy Sci. Eng. 12, 2553–2567 (2024).

Li, L., Qian, D., Yang, X. & Jiao, H. Pressure relief and bolt grouting reinforcement and width optimization of narrow coal pillar for Goaf-Side entry driving in deep Thick coal seam: A case study. Minerals 12, 1292 (2022).

Jianjun, S., Jicheng, F., Rui, P. & Quanjie, Z. The research on stability of surrounding rock in Gob-Side entry driving in deep and Thick seam. Geotech. Geol. Eng. 40, 3357–3364 (2022).

Zhang, B. et al. Simulation and On-Site monitoring of deformation characteristics of roadway excavation along Goaf in soft and Thick coal seams in Western mining areas. Appl. Sci. 14, 7760 (2024).

Yun, Q. L. et al. Characteristics of deformation and damage of surrounding rock along the top roadway in the working face of an isolated Island and its evolution law. Sci. Rep. 14, 15092 (2024).

Hao, X. et al. Rock burst mechanism of roadway excavation along Goaf with small coal pillar in Ordos mining area. J. Min. Strata Control Eng. 5, 36–45 (2023).

Liu, H. et al. Research on energy evolution law and control method of deformation of high stress roadway surrounding rock. J. China Coal Soc. 1–15 (2024).

Zhang et al. cun Research on the main controlling factors and characterization of overburden fracture damage based on energy conduction mechanism. J. China Coal Soc. 1–13 (2024).

Wu,Yu et al. Energy evolution model and rock burst risk assessment for deformation and failure of Coal-Rock mass. J. Min. Saf. Eng. 39, 1177–1186 (2022).

Jiang,Pengfei et al. Research on evolution of integrated stress field of surrounding rock of mining while digging opposite roadway in deep and ultra-thick coal seam. Coal Sci. Technol. 48, 26–36 (2020).

Bai, J., Shen, W., Guo, G., Wang, X. & Yu, Y. Roof deformation, failure characteristics, and preventive techniques of Gob-Side entry driving heading adjacent to the advancing working face. Rock. Mech. Rock. Eng. 48, 2447–2458 (2015).

Guo,Zhongtuo et al. Surrounding rock control for gob-side entry driving toward mining disturbance in extra-thick coal seam. Coal Eng. 52, 42–46 (2020).

Salamon, M. D. G. & Munro, A. H. A study of the strength of coal pillars. J. South Afr. Inst. Min. Metall. 68 (2), 55–67 (1967).

Salamon, M. D. G., Ozbay, M. U. & Madden, B. J. Life and design of Bord-and‐Pillar workings affected by pillar scaling. J. South Afr. Inst. Min. Metall. 98 (3), 135–145 (1998).

Schumacher Forrest, P. & Kim, E. Modeling the pipe umbrella roof support system in a Western US underground coal mine. Int. J. Rock. Mech. Min. Sci. 60, 114–124 (2013).

Frith, R. & Reed, G. Limitations and potential design risks when applying empirically derived coal pillar strength equations to Real-Life mine stability problems. Int. J. Min. Sci. Technol. 29, 17–25 (2019).

Coggan, J., Gao, F., Stead, D. & Elmo, D. Numerical modelling of the effects of weak immediate roof lithology on coal mine roadway stability. Int. J. Coal Geol. 90–91, 100–109 (2012).

Esterhuizen, E., Chris, M., Michael, M. & Murphy Numerical model calibration for simulating coal pillars, gob and overburden response. In: Proceedings of the Twenty-ninth International Conference on Ground Control in Mining. 46–57 (2010).

Peng,Yujie et al. Mechanisms and influential factors of rock bursts in tunneling roadways ofextra-thick coal seams. Coal Geol. Explor. 52, 25–39 (2024).

Zhang, J. et al. Study on roadway roof deformation and coal pillar energy accumulation instability. Sci. Rep. 14, 27603 (2024).

Lv, J. et al. Effect of multi-factor dynamic loading on gob-side entry driving during Longwall face extraction: a case study. Bull. Eng. Geol. Environ. 81, 409 (2022).

Zhi-qiang Zhao,Nian-jie Ma, Xiao-fei Guo. et al. Falling principle and support design of butterfly-failure roof in large deformation mining roadways. 41 (12), 2932–2939. https://doi.org/10.13225/j.cnki.jccs.2016.1146 (2016).

Wei, X. X. et al. Study on the law of stress distribution in the presence of remaining coal pillar in a close-distance coal seam and the reasonable location of the roadway. Sci. Rep. 15, 8737. https://doi.org/10.1038/s41598-025-91370-9 (2025).

Wang, Y. et al. Deformation mechanism and control technology of gob-side entry retaining with roadside backfilling: a numerical analysis and field investigation. Geomech. Geophys. Geo-energ. Geo-resour 10, 175. https://doi.org/10.1007/s40948-024-00901-7 (2024).

Chen, D. et al. Study on stability mechanism and control techniques of surrounding rock in gob-side entry retaining with flexible formwork concrete wall. J. Cent. South. Univ. 30, 2966–2982 (2023).

Wei, X., Yun, Q., Wu, J., Wang, X. & Wang, Y. Study on the Full-Cycle stress evolution law and reasonable size of isolated coal pillar. Energy Sci. Eng. https://doi.org/10.1002/ese3.1987 (2024). ese3.1987.

Li, Z., Fan, J., Feng, G., Qi, C. & Zhang, J. A new method for identifying coal pillar instability based on energy and stress correlation characteristics and its engineering application. Minerals 13, 1507 (2023).

Chen, D. et al. The full cycle evolution law of energy-stress in the surrounding rock of thegob-side entry driving for adjacent advancing working facegob-side entry driving for adjacent advancing working face Coal Science and Technology. 1–14. http://kns.cnki.net/kcms/detail/11.2402.TD.20240307.1034.001.html (2025).

Acknowledgements

The authors extend their appreciation to the Prof. Zhiqiang Zhao of the School of Energy and Mining, China University of Mining and Technology (Beijing) for funding this research work through project number U22A20165.

Funding

Zhi-Qiang Zhao—Funded by the National Natural Science Foundation of China Joint Foundation Programme (U22A20165).

Author information

Authors and Affiliations

Contributions

Zi-Long Hui. Zhi-Qiang. and Xiao-Xiang Wei. wrote the text of the main manuscript, and Yao Li. prepared figures 3. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hui, ZL., Zhao, ZQ., Wei, XX. et al. The energy and stress evolution law of surrounding rock in gob side entry driving of adjacent mining faces. Sci Rep 15, 34488 (2025). https://doi.org/10.1038/s41598-025-10977-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-10977-0