Abstract

Chemical control using pesticides remains an essential component of crop pest and disease management, while precision pesticide application is a core element for achieving sustainable agriculture. Precision spraying technology—integrating UAV-based detection, real-time pesticide mixing, and adaptive variable-rate spraying—provides a critical pathway for sustainable crop protection by establishing a “perception-decision-execution” closed-loop framework.While previous reviews have predominantly focused on compartmentalized analyses of individual technologies (e.g., sensing or actuation), this study establishes a unified Perception-Decision-Execution (PDE) framework to, for the first time, quantitatively assess the synergistic interactions and systemic Bottlenecks across all three layers.This paper systematically reviews 168 core publications from 2013 to 2024, proposing for the first time and quantitatively assessing the synergistic effects of technologies within this closed-loop framework. The findings reveal that: (1) UAV-deep learning systems achieve pest identification accuracy rates of 89–94%, but this significantly declines to 60–70% under strong light or occlusion conditions; (2) Real-time mixing systems attain a mixing homogeneity coefficient (γ) > 85% for liquid pesticides, while for suspension concentrates (SCs), γ decreases to 70–75% due to particle sedimentation effects; (3) PWM-based variable-rate spraying reduces pesticide usage by 30–50% and off-target drift by > 30%, though sensor errors can cause positioning deviations of 0.3–0.8 m. Despite considerable promise, this integrated technology faces challenges in large-scale applications, including perception degradation under environmental disturbances, limitations in algorithm generalization, poor pesticide formulation adaptability in mixing, and system coordination issues. To overcome these barriers, this review proposes interdisciplinary solutions: (i) Deploying lightweight edge devices and pruned neural networks to address decision-making delays and enhance real-time responsiveness; (ii) Optimizing mixer structures (e.g., helical baffle angles) based on computational fluid dynamics (CFD) simulations to reduce dead zones and improve mixing homogeneity for SCs; (iii) Integrating multi-sensor technology for drift compensation to enhance UAV spraying stability. By integrating and optimizing these key technologies, the closed-loop framework holds significant potential to markedly improve pesticide utilization efficiency, minimize environmental impact, and offer a practical framework for achieving on-demand application, thereby advancing sustainable smart agriculture.

Similar content being viewed by others

Introduction

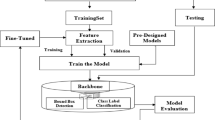

Global food demand is projected to increase by 60% by 2050, yet crop losses due to pests and diseases remain alarmingly high, reaching 35%−50%1. Conventional pesticide application models, characterized by significant overuse (exceeding 4 million tons annually), exacerbate pesticide resistance and environmental pollution, with off-target drift accounting for > 30% of contamination. This undermines the goals of sustainable agriculture and underscores the urgent need for precision pesticide application technology as an effective solution to these drawbacks2. This technology achieves a 30%−50% reduction in pesticide usage through the “Perception-Decision-Execution (PDE)” closed-loop framework in Figure. 13,4. Its major breakthroughs are manifested in three core aspects: (1) Unmanned Aerial Vehicle (UAV) platforms enable terrain adaptability (operational efficiency: 10–15 hectares/hour) and real-time sensing capabilities (e.g., multispectral disease identification coupled with edge computing), reducing off-target drift by 62%5,6,7; (2) Spraying systems integrated with real-time pesticide mixing technology utilize jet/static mixing devices to dynamically optimize chemical formulation ratios, mitigating operator poisoning risks and enhancing efficacy against complex disease complexes8,9,10,11; (3) The integrated system incorporates variable-rate spraying technology, significantly shortening the system response time to 10–50 ms via Pulse Width Modulation (PWM) control12,13,14,15,16.

Precision pesticide application technology facilitates pest/disease control and field management through intelligent sensing, dynamic decision-making, and precise execution17,18,19. Its core objective is to realize “on-demand application”—dynamically regulating spray mixture ratios, droplet parameters, and application paths based on the spatiotemporal distribution of pests and diseases—thereby achieving sustainable crop protection. However, scaling this technology faces three primary bottlenecks3,20,21,22,23: (1) Technological Fragmentation: Current research predominantly focuses on isolated components (e.g., pest identification or spray mechanisms), lacking holistic synergistic optimization. Environmental interference degrades sensing accuracy by > 30% under challenging conditions like strong light or occlusion4,24,25 data silos at the decision layer lead to application rate errors26,27,28 and cost imbalances at the execution layer hinder adoption by smallholder farmers29,30,31. To address these challenges, this study pioneers the construction of an PDE closed-loop framework and quantifies the synergistic effects of its constituent technologies through a meta-analysis of 168 core publications. The framework specifically targets overcoming the three bottlenecks: (i) Implementing lightweight edge computing solutions to minimize decision latency; (ii) Enhancing mixing uniformity, particularly for suspension formulations, via Computational Fluid Dynamics (CFD)-optimized mixer designs to improve precision application efficiency32,33; (iii) Developing multi-sensor fusion algorithms to reduce drift error margins. By establishing a reusable technical paradigm for sustainable smart agriculture, this study advances precision pesticide application technology. The systematic Literature retrieval process that underpins this meta-analysis, which identified and selected the 168 core publications (2013–2024), is visually summarized in Fig. 2.

Precision pesticide application technology represents a pivotal advancement in modern agriculture for enhancing crop protection efficiency. Through the synergistic integration of Unmanned Aerial Vehicle (UAV) platforms, real-time pesticide mixing technology, and adaptive spraying systems, this approach achieves precise chemical delivery and optimized utilization34,35,36. As a core component of precision application systems, the real-time pesticide mixing system ensures dynamic homogenization and mixture uniformity, providing essential support for efficient field operations37.

Materials and methods

This study employs a systematic literature review and meta-analysis approach, rigorously adhering to the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) Guidelines. It conducts a multidimensional assessment of precision pesticide application research spanning the period 2013–2024. As illustrated in Fig. 3, the research workflow comprises four key phases: literature retrieval, screening, data extraction, and analysis. The analysis specifically quantifies the synergistic effects within the “Perception-Decision-Execution (PDE)” technological closed-loop framework in Fig. 138.

Literature search strategy

This study employs a systematic literature review methodology. A structured keyword search strategy was implemented to comprehensively gather research findings on precision pesticide application technology within the domain of pest and disease control. A reproducible research framework was constructed based on the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines, ensuring process transparency and conclusion reliability. The specific implementation steps are detailed below.

Literature screening process

Systematic literature searches were conducted across databases including Web of Science, Science Direct, CNKI, and Google Scholar to map research progress in the field of precision pesticide application technology. The search strategy utilized Boolean operators (AND/OR), with core query terms as follows: (“precision agriculture” OR “site-specific management”) AND (“variable-rate spraying” OR “targeted pesticide application”) AND (“pest control” OR “disease management”) This was supplemented with Chinese keyword combinations, such as “real-time mixing”, “UAV spraying systems”, “variable spraying and control”, and “ field pest and disease management”7,8,17,39 to comprehensively capture relevant literature while minimizing irrelevant results. The literature screening criteria were as follows:

Publication Date: 2013–2024;(2) Document Type: Research articles; (3) Research Focus: Explicit involvement of precision pesticide application control technologies (e.g., UAV variable spraying, PWM real-time variable spraying, field pest/disease control, real-time pesticide mixing); (4) Research Setting: Pest and disease control in agricultural crops; (5) Language: Chinese and English prioritized; other languages included if necessary.

Priority during screening was given to publications where the title and abstract were clearly relevant to the research topic. The following exclusion criteria were simultaneously applied:

(1) Document Type: Conference abstracts, patents, non-technical studies (e.g., economic evaluations, purely policy analyses); (2) Research Content: Solely discussing conventional application techniques; (3) Data & Methodology: Case reports lacking quantitative data or with ambiguous method descriptions; (4) Technical Discussion: Merely mentioning relevant technologies without in-depth exploration.

Initial searches in the Web of Science and Science Direct databases yielded 1,876 and 1,675 records, respectively. The literature screening workflow is illustrated in Fig. 3.

Data extraction and classification

This study employed Microsoft Excel 2019 to construct structured tables for systematic data extraction and classification of the included literature. Table 1 outlines the data extraction protocol, which was designed based on the PRISMA framework and focused on the core technological components of precision pesticide application.

Screening (Title/Abstract Level)

Within the systematic review, an initial screening of retrieved records was performed, primarily excluding obviously irrelevant publications based on title examination. This stage prioritized studies fulfilling the following core criteria: (1) Technical Relevance: Explicit application of core precision pesticide application technologies in pest/disease control practice, such as variable-rate spraying, UAV precision application, online mixing technology, and PWM variable-rate control systems44,45. (2) Application Setting: Research context focused on the intelligent detection and precision management of agricultural crops or field weeds. (3) Research Significance: Examination of the current status, challenges, and future development of precision pesticide application technology (including relevant sensors and intelligent algorithms) to promote its adoption in precision agriculture. From the initial pool of 5,010 retrieved records, 1,462 publications met these criteria and were included for subsequent analysis. All included publications were uniformly managed using reference management software (Zotero/EndNote) to facilitate organization and citation. The detailed workflow for screening included literature is presented in Fig. 3.

Eligibility screening (Abstract/Full-Text Level)

Publications passing the initial screening underwent further eligibility assessment based on abstract review. Records meeting any of the following criteria were excluded:

(1) Inaccessible via link or subject to paywall restrictions.(2) Irrelevant content: Not addressing core research on precision pesticide application technology, or unrelated to pest/disease control or precision agriculture field applications.Following this screening stage, 168 publications were definitively identified as meeting the inclusion criteria. These proceeded to the full-text review phase, forming the core basis for analysis and exposition in this systematic review.

Data analysis

A systematic analysis and synthesis were performed on the 168 included publications. The extracted structured data in Table 1 were processed and analyzed using Microsoft Excel, with data visualization facilitated by software including PowerPoint.The analysis focused on the following aspects:

(1) Publication Basic Characteristics: Year of publication, research methodology, research objectives.(2) Technical Application Details: Crop type, UAV models, types of precision pesticide application technology, sensor types, control methods, pesticide usage volume, crop monitoring approaches, research/testing platforms, and other specific parameters.Through in-depth analysis of this data, the study aims to systematically elucidate research findings and technological trends, identify current research gaps, and propose recommendations and future prospects.

Based on the aforementioned literature analysis, the subsequent sections of this review will discuss the three core modules of precision pesticide application technology: (1) Sensing Layer Technologies (Pest/disease identification and monitoring); (2) Decision Layer Technologies (Intelligent decision models (e.g., deep learning) and prescription map generation); (3) Execution Layer Technologies (Variable spraying control (e.g., PWM) and real-time pesticide mixing systems).This discussion will systematically evaluate their current development status and performance.

Technology classification and current status

Sensing layer technologies

Sensor-based pest and disease identification

Amidst the rapid advancement of precision agriculture, Unmanned Aerial Vehicle (UAV) has emerged as the core platform for precision pesticide application technology. By integrating multi-source sensors and intelligent algorithms, UAV significantly enhance the accuracy of pest/disease identification and spraying efficiency2,44,46. Although UAV spraying systems have demonstrated a 46%−75% reduction in pesticide usage compared to conventional ground-based application47 their adoption among smallholder farmers remains constrained by high initial equipment costs (e.g., LiDAR, multispectral sensors) and technical operational barriers6,48. Accelerating deployment necessitates cost-reduced hardware and standardized operator training.

UAV enable precise field pest/disease management, offering significant cost benefits through reduced spray coverage while simultaneously improving operational efficiency, lowering production costs, and increasing crop yields49,50,51,52. However, several challenges persist in application: standardization of operational parameters (e.g., flight altitude, speed), control of spray drift, and adaptability to diverse pesticide formulations27,53,54. To address these, advanced technologies are integrated into UAV spraying systems: Multi-sensor fusion combines RTK-GPS positioning, computer vision, and multi-source sensors (LiDAR, ultrasonic)55,56,57,58 enabling real-time optimization of flight paths (altitude: 1–3 m, speed: 2–5 m/s) and nozzle flow rates (0.5–1.2 L/min), reducing off-target contamination by 30%−50%59,60,61. Real-time monitoring of crop growth status and environmental parameters (temperature, humidity, light) facilitates dynamic spraying strategy adjustments, enhancing data accuracy for informed decision-making62,63. Integration of deep learning models (e.g., YOLO-Fi) with multispectral vegetation indices (NDVI, SAVI) significantly improves recognition accuracy in complex environments, achieving synergistic algorithmic optimization for precise target-oriented spraying through field crop information capture16,64,65,66.

To enhance system robustness, researchers employ diverse multi-sensor fusion strategies. At the hardware level, prevalent sensors include: LiDAR (e.g., 905–1550 nm wavelength models like Velodyne VLP-16) for high-resolution canopy structural point clouds (> 100,000 points/sec within 2 m range); multispectral cameras (e.g., DJI P4M’s RedEdge-MX, covering Blue, Green, Red, Red-edge, NIR bands) for calculating vegetation indices (NDVI, SAVI) to monitor crop stress; hyperspectral imagers (e.g., Headwall Nano-Hyperspec) for continuous spectral information, albeit with substantial data volume and processing costs; alongside RGB optical cameras and ultrasonic sensors. Algorithmically, fusion strategies encompass data-level (pixel-wise registration of LiDAR point clouds with multispectral images), feature-level (concatenating or weighting spatial features from point clouds and spectral features via attention mechanisms), and decision-level fusion (voting or weighted averaging of recognition results from different sensors). Kalman filtering is commonly used to synchronize GNSS/RTK and IMU data, ensuring stable, high-frequency positioning.

High-fidelity sensor data acquisition for crop pests and diseases is fundamental to UAV precision application. Representative case studies validate the technical efficacy of the UAV-perception linkage system. Common precision spraying UAV models, such as the DJI P4M and Matrice 300 RTK (Fig. 4a, b), achieve perception-decision coupling via multi-sensor fusion. Their effectiveness is evidenced by: Maritan et al. utilizing RGB image analysis from an XAG P100 UAV (Figure 4c, g)for quantitative spraying in Greek vineyards, reducing pesticide volume by 46%−75%70. Han et al. developing a PWM intelligent system on UAV platforms DJI P4M(Fig. 4d, h) for precise pear tree canopy structure and paddy field weed distribution detection via canopy image feature analysis16.

Early pest/disease control in orchards using UAV-mounted intelligent spraying systems integrating multispectral-deep learning decision-making: Peng Wei combining mRMR feature selection with the YOLO-Fi model and an MS 600 V2 multispectral camera for early pest/disease identification and targeted spraying in apple trees20,71. Pengchao Chen integrating UASS centrifugal nozzles with multispectral remote sensing to establish a cotton canopy spectral index-spray volume prediction model, optimizing defoliant variable-rate application43,72.

Evaluation of 3D modeling-enabled variable spraying: Wang employing a DJI T40 to quantitatively assess the impact of mango tree canopy structural parameters (Leaf Area Index - LAI, porosity) on spray quality46. Rayamajhi dynamically adjusting maple tree pesticide dosage based on DJI Matrice 300 RTK(Fig. 4b, k) canopy volume measurement using a zero-shot segmentation method73.

These studies demonstrate that UAVs significantly enhance positioning accuracy, minimize localization errors, and markedly improve dynamic control capabilities through high-resolution imaging and multi-source data fusion.

Advancements in sensor technology, particularly high-resolution imaging and multi-source data fusion, have substantially improved the positioning accuracy and dynamic control of UAV spraying systems, garnering significant attention in precision application19,40,58,74,75. Nevertheless, intelligent decision-making remains a critical bottleneck for technological advancement. UAV operational parameter settings still heavily rely on manual expertise, and decision logic varies significantly across intelligent spraying systems60,61,62,76. To overcome this limitation, researchers are actively developing data-driven decision models. For instance, Chen et al. fused RGB and multispectral imagery with a Backpropagation (BP) neural network and Bayesian regularization algorithm to establish a droplet distribution prediction model correlating cotton canopy structure with UASS spray volume, enabling dynamic spraying strategy optimization51,72,77.

Such intelligent decision models demonstrate substantial benefits in field management: Gao et al.‘s deep learning model, trained on enhanced field image data channels, achieved precise weed identification at 1.78 × 1.78 cm²resolution, yielding a remarkable 90% pesticide saving rate7,21,78. Han et al. utilized UAV (Fig. 4a, e,i, j,f) to generate 3D prescription maps and execute offline variable-rate application, validating the accuracy of terrain measurement across different flight altitudes, significantly boosting operational efficiency and reducing labor costs16.

The generation of UAV remote sensing prescription maps is intrinsically linked to sensor-derived field crop data. As depicted in the prescription map construction flowchart in Fig. 5, the process relies on the sensor data chain: acquisition via remote sensing imagery, point cloud segmentation, feature extraction (LAI/porosity), and voxel-based 3D mapping for optimized spray parameter generation. These cases indicate that the “Perception-Decision” closed loop is progressively advancing UAV from automated execution towards intelligent decision-making. However, widespread adoption is still constrained by limitations in algorithm generalizability, operational standardization, and cost-benefit equilibrium44,79,80,81.

Workflow for constructing voxel-based prescription maps from UAV remote sensing data16.

UAV remote sensing for field monitoring

Unmanned Aerial Vehicle (UAV) remote sensing technology utilizes multi-source sensors (RGB, multispectral, hyperspectral, LiDAR) to acquire data on crop spectral responses and spatial heterogeneity, providing critical support for precision pesticide application decisions48,82,83,84,85. Low-altitude, low-speed flight operations (1–3 m Height, 2–5 m/s speed) significantly enhance data quality. Research indicates that reducing flight speed to 2 m/s decreases the coefficient of variation (CV) for the deposition uniformity of organic Liquid fertilizer by 23% (P < 0.05)6. Furthermore, when flight altitude is maintained below 2m, multispectral imagery achieves a spatial resolution of 2 cm/pixel, elevating weed identification accuracy to 95%18,19,41,75,84,86. Variable-rate spraying decisions are driven by vegetation indices, while LiDAR point clouds facilitate canopy structure reconstruction (e.g., Leaf Area Index (LAI), porosity), guiding the optimization of droplet parameters. This integrated approach enables precise three-dimensional prescription map-based spraying and field detection13,17,45,87,88. Illustrating the efficacy of typical remote sensing applications, targeted spraying based on canopy vigor maps has reduced pesticide usage in vineyards by 45%.

Figure 6(b, c,d, e)depicts commercial UAV currently predominant in field monitoring and precision spraying. While contemporary commercial UAV (e.g., DJI P4M, Matrice 300 RTK) integrate GNSS-RTK positioning (± 1 cm accuracy) and edge computing modules66,89,90,91 they encounter several persistent challenges in complex environments. Notably, spectral saturation and dense canopies can lead to environmentally induced perturbations and errors6,18,58,84. Under rainy or foggy conditions, the effective LiDAR point cloud acquisition rate in the field drops below 50%, presenting a significant bottleneck for edge computing capabilities92,93,94,95. Moreover, the technical-economic analysis of current systems reveals limitations.

Commercial UAV systems have evolved distinct technological pathways, offering precision solutions tailored to different crop growth stages. The DJI Agras T30(Figure 6a), equipped with high-definition RGB and multispectral imaging modules, enables early disease identification through canopy-penetrating spray technology, achieving an 89% accuracy rate for pest and disease detection in rice seedlings83. Its low-altitude hovering capability ensures effective deposition onto lower leaves, overcoming traditional spraying blind spots. The XAG P100(Fig. 6f) integrates RTK precision positioning and a binocular obstacle avoidance system, maintaining flight stability via anti-interference algorithms under wind speeds below 8 m/s. Its extended 30-minute endurance supports continuous operation over 15 Hectares per flight, coupled with Centrifugal atomization nozzles that achieve a 40% reduction in pesticide usage70 establishing it as a core asset for large-scale rice field management during the maturity stage. Technical-economic analysis demonstrates that UAV systems, through vertical integration of “sensing-decision-making” (e.g., T30 for seedling diagnosis, P100 for maturity-stage scheduling), reduce management costs per unit area by 23–41%. However, marginal benefits are constrained by operational scale and field fragmentation86,87.

Perception enhancement strategies under environmental disturbances

Although deep learning methods on UAV demonstrate high accuracy rates (89–94%) in pest and disease identification, their performance significantly declines to 60–70% under complex field environments such as strong illumination and partial occlusion. To address this critical issue, a systematic multi-level solution strategy is implemented. At the sensing level, a cost-optimized multi-sensor fusion scheme is adopted, which systematically integrates low-cost thermal imaging sensors with RGB cameras. Thermal features compensate for the loss of visible light information, and vision-based depth estimation methods replace high-cost LiDAR, significantly reducing system costs. At the algorithm level, a lightweight dual-branch network architecture, specifically optimized for agricultural environments, can be employed. It incorporates a dynamic feature selection mechanism that automatically adjusts the weight ratio of each branch based on environmental conditions, reducing computational complexity while maintaining accuracy. At the system level, a confidence-level feedback-based real-time adaptive acquisition system is developed. When a confidence drop is detected, it automatically triggers countermeasures: activating built-in polarizing filters and adjusting exposure parameters under strong light conditions; performing path re-planning to obtain multi-angle observation data under occlusion scenarios, realizing perception-decision closed-loop control. Furthermore, a distributed training framework based on federated learning is designed to fully leverage diverse environmental data, significantly enhancing the model’s generalization capability across different field conditions.

Deploying sensor fusion systems reduces the identification accuracy degradation of UAV in complex environments, and strengthening the development and integration of adaptive information acquisition systems provides a practical technical pathway for the large-scale application of UAV precision pesticide application technology.

Decision-layer technologies

Deep learning-based target recognition

Data acquired from the aforementioned perception layer serves as input for the decision layer. Deep learning facilitates precise crop-weed discrimination through multi-scale feature fusion and semantic segmentation mechanisms, which is pivotal for targeted spraying decisions. For instance, in distinguishing crops from weeds within vegetable fields, Raja et al.98 developed a spraying robot that integrates crop signals and machine vision, achieving crop detection accuracy of 99.75% and weed recognition accuracy of 98.11%. While effectively addressing weed identification, further improvements are required for adaptability across diverse weather conditions. To tackle multi-weather adaptability, Hussain et al.‘s99,100 intelligent variable-rate sprayer employs the small-YOLOv3 model, enabling real-time weed/disease detection under various weather conditions and reducing Herbicide usage by 42%.

Adaptive spraying based on crop density has also seen significant application in deep learning-based target recognition. For example, He et al.17 utilized an improved DeepLab V3 + model to dynamically analyze weed density in wheat fields. Combined with Pulse Width Modulation (PWM) technology, this approach reduced pesticide costs by 46.3%, effectively addressing crop-driven spraying in high-density environments. However, limitations persist for large-scale row-crop cultivation using this method. Alam’s tobacco field spraying system achieved a 98% crop row recognition rate and a 52% pesticide reduction using a Faster R-CNN/YOLOv5 dual-model framework101.

Optimization of offline prescription maps is also crucial for the core application of this technology. Allmendinger et al. implemented site-specific Herbicide spraying in cornfields using georeferenced UAV imagery, reducing chemical usage by 47% while maintaining 86% weed control efficacy102.

Leveraging their flexible controllability, high operational efficiency (10–15 ha/h), and lightweight characteristics, UAV has become central decision-making platforms for crop disease and pest management. Compared to manned agricultural aircraft, their significant advantages include overcoming terrain limitations in hilly, mountainous, and low-lying fields, thereby achieving superior environmental adaptability. Furthermore, UAV equipped with high-precision sensors acquire high-resolution crop imagery under low-altitude, low-speed conditions, enabling high-resolution data acquisition essential for deep decision-making. Real-time UAV decision-making necessitates integrating lightweight sensors (e.g., LiDAR, multispectral cameras) to expand monitoring dimensions and provide multi-source inputs for deep learning models. Table 2 presents supporting application cases for UAV multi-sensor fusion decision-making.

Deep learning has substantially enhanced target recognition capabilities, yielding substantive breakthroughs in crop identification, multi-weather adaptability, and variable-rate spraying. The UAV platform effectively supports real-time decision-making through multi-sensor fusion, demonstrating exceptional terrain adaptability and precise control potential.

However, sensor inaccuracies within the perception layer (e.g., positioning deviations, point cloud distortion, image recognition errors) directly introduce decision-making biases, consequently compromising spraying precision. For instance, GNSS/RTK signal attenuation in multi-obstacle environments can lead to positioning errors exceeding 0.5 m; LiDAR point cloud density degradation under intense light or rainy/foggy conditions results in canopy volume estimation errors greater than 15%109; the recognition reliability of vision sensors decreases under shadow or backlight conditions. If unaddressed, these errors cause the decision system to generate incorrect prescription maps or real-time commands, resulting in missed spraying or over-application.

However, scaling this technology faces three core constraints: (1) Insufficient Algorithmic Environmental Robustness: Models exhibit limited generalization capability in complex field scenarios. (2) Latency in Edge Computing: Current systems struggle to meet millisecond-level response requirements. (3) High Economic Cost of Data Annotation: This impedes application in small-scale scenarios. Future development requires synergistic breakthroughs in environment-adaptive algorithms, optimized edge-cloud collaborative architecture, and low-cost annotation technologies to realize the closed-loop decision-making paradigm for smart agriculture.

To address the challenges posed by sensor errors, future research requires synergistic breakthroughs in multi-sensor fusion algorithms (e.g., LiDAR and vision fusion), online adaptive calibration techniques (e.g., Kalman filter-based real-time error compensation), and digital twin-based simulation testing platforms. These advancements are crucial for enhancing the system’s robustness and reliability in real-world environments, ultimately realizing the closed-loop decision-making paradigm for smart agriculture5,18,40,41,58,84.

Execution-layer technologies

PWM-based variable-rate spraying

Variable-rate spraying control technology represents the core execution component of precision agriculture pesticide application. It aims to dynamically adjust application rates based on the spatiotemporal heterogeneity of pest, disease, and weed distribution within fields, thereby reducing pesticide waste and enhancing control efficiency. This technology has been widely adopted across various agricultural platforms, including UAV, boom sprayers, and orchard sprayers, in recent years.

The key to achieving variable-rate spraying lies in regulating the spraying system. Pulse Width Modulation (PWM) variable-rate spraying control technology is a pivotal execution-layer technique for precise flow regulation. Its core mechanism involves precisely controlling the opening and closing duration of solenoid valves by adjusting the duty cycle of the PWM signal, enabling nonlinear continuous adjustment of spray flow rate4,22,84,110. Compared to traditional constant-pressure spraying systems, PWM offers significantly faster response times (reaching 10–50 ms), substantially enhancing dynamic adaptability to complex field environments50.

Experimental studies and literature data consistently demonstrate that this technology can significantly improve application efficiency and reduce off-target drift. For example, Seol et al.111 conducting experiments in pear orchards, showed that PWM-based variable-rate control reduced pesticide usage from 25 L/row to 12.7 L/row, a reduction of 49.2%, while the deposition proportion in non-target areas decreased from 58.8 to 8.08%, a reduction of 86.3%. Research by Grella et al.112 in vineyards indicated that under optimized PWM duty cycles (70–100%), insecticide application rates were maintained at 200–250 L/ha and Fungicides at 300–370 L/ha. Compared to conventional uniform spraying (often exceeding 370 L/ha), insecticide usage was reduced by 32.4–46%. The UAV-based variable-rate system developed by Wen et al.62 adjusted flow rates in real-time based on prescription maps with a deviation of less than 2.16%. Within a duty cycle range of 40–100%, the flow rate per nozzle was regulated from 0.16 L/min to 0.54 L/min, enabling on-demand spraying and significantly reducing over-application113,114.

Regarding drift control, evaluations by Grella et al.112 using water-sensitive paper (WSP) showed that under actual field conditions, the PWM system did not significantly increase spray coverage heterogeneity while substantially reducing deposition in non-target areas. Seol et al.111 reported a decrease in non-target deposition from 58.8% (fully open) to 8.08% (variable control), a reduction exceeding 86%. Studies by Butts et al.115 indicated that PWM systems can adjust flow rates without altering droplet spectra, resulting in lower drift potential compared to traditional pressure regulation methods, with significantly reduced drift particularly at low duty cycles.

Typically, a complete variable-rate spraying system comprises several critical stages: information perception, decision generation, execution control, and ultimately, variable-rate spraying. It relies on sensors such as multispectral cameras, LiDAR, ultrasonic sensors, vision sensors, and GNSS/RTK17,45,62,63,74,75,86,110,116 to acquire real-time spatial information on crop canopy structure (density, volume, height) and pest/disease or weed distribution28,55,117. Based on GIS prescription maps or intelligent algorithms like machine learning and object detection models (e.g., YOLO/CNN), the system analyzes this data and generates decision signals specifying the required pesticide application rate10,18,40,118. The PWM controller receives these decision signals and generates drive signals with specific duty cycles and frequencies to control the rapid opening and closing of solenoid valves. Pressure-compensated nozzles are often employed in conjunction to ensure stable atomization during flow variations. Finally, the actuation mechanism dynamically adjusts the solenoid valve’s duty cycle according to the PWM signal, enabling dynamic spraying operations119. PWM variable-rate spraying technology has been successfully applied in diverse scenarios and platforms, as summarized in Table 3.

The case studies in Table 3 clearly demonstrate that variable-rate spraying technology, through the integration of advanced perception, decision-making, and execution modules, has been successfully applied for precise pest and disease control in both field crops and orchards. This approach significantly improves pesticide utilization efficiency and reduces environmental risks, showcasing substantial potential for advancing precision agriculture. Its core principle involves utilizing the perception layer (e.g., multispectral cameras, LiDAR, ultrasonic sensors) to acquire real-time spatial heterogeneity information on canopy structure and pest/disease/weed distribution18,51. Based on this, the decision layer (relying on GIS prescription maps or machine learning algorithms like YOLO, CNN) generates precise pesticide application rate commands64,125,126,127. Finally, the execution layer’s PWM controller drives the solenoid valves, working in tandem with pressure-compensated nozzles to achieve dynamic and precise flow regulation128,129. This “Perception-Decision-Execution” closed-loop effectively addresses the challenges of pesticide overuse and non-target contamination prevalent in conventional spraying practices. These representative studies provide clear direction for the further development of variable-rate spraying technology.

To enhance weed control efficiency and reduce pesticide usage, He et al.17 developed a weed-density-driven variable spraying system for wheat fields. This system integrates an improved DeepLab V3 + semantic segmentation model (perception/decision) with PWM control (execution), significantly reducing pesticide costs. Grella et al.112 validated the adaptability of a tower air-assisted sprayer equipped with PWM for 3D crop spraying in vineyards, demonstrating that it did not compromise spray deposit uniformity within the canopy (SC). Salcedo et al.119 integrated laser guidance (perception) with PWM control (execution) on an orchard sprayer, achieving higher canopy coverage uniformity in apple orchards, reducing environmental impact, and ensuring consistent application across replicated canopies.

Regarding precise canopy volume modeling and on-demand spraying applications, Liu et al.54,130 developed a prototype system based on LiDAR canopy profile sensing (perception) and the α-shape algorithm (decision). This system accurately calculates canopy volume and drives PWM to enable volume-dose spraying (execution). To verify the feasibility of precision spraying, Darbyshire et al.131 simplified the control model by integrating multiple machine detection technologies (perception/decision) and validated the feasibility of target-detection-based precision spraying (execution) across multiple datasets, providing crucial evidence for precise weed management. Figure 7 illustrates a typical example of such integrated application. Qiao et al.120 developed an intelligent variable-rate spray system for corn canopies by combining 3D LiDAR scanning (perception) with PWM control (execution), embodying the core concept of perception data directly driving the execution mechanism.

LiDAR-guided PWM spraying system for corn canopy120.

Although the aforementioned research demonstrates the significant efficacy of PWM variable-rate spraying technology in precision application, its implementation still faces several critical challenges, particularly concerning spray drift control and the real-time responsiveness of the perception-decision-execution loop:

(1) Persistent Challenge of Spray Drift Control: PWM parameter settings directly influence droplet behavior. Li et al.132 systematically investigated the effects of duty cycle and frequency on spray drift characteristics using a wind tunnel system. Employing a tracer method, they quantified air drift and deposit drift, calculating the drift potential reduction percentage relative to a 100% duty cycle reference condition. Their results indicate that while optimizing PWM parameters can reduce drift, droplet drift risk remains significant under high wind speeds or complex airflow conditions, demanding even more precise duty cycle control.

(2) Perception Accuracy and Environmental Vulnerability: The target identification accuracy reliant on sensors like LiDAR is susceptible to environmental conditions. Qi et al. utilized an R-Fans-32 3D LiDAR to study the relationship between tomato plant point clouds and leaf area, constructing a target detection system109. Although point cloud data was acquired at a 1 m detection distance and 10 Hz scan frequency, insufficient point cloud density under complex canopy structures or rainy/foggy conditions can lead to missed detection of small targets (e.g., early-stage diseased leaves or weeds), directly impacting subsequent spraying precision. GNSS signal obstruction or multipath effects can also introduce positioning deviations. These perception-layer errors are directly transmitted to the decision layer, leading to miscalculations of the target location and required dosage for application, which directly impacts the precision of subsequent spraying operations6,18,40.

(3) System Response Latency: An inherent delay exists between perception and execution. Yuan et al.63 addressed this issue by designing a real-time target-activated spray system. It employed 2D LiDAR detection combined with a Traveling Ground Speed Sensor (TGSS) to establish an adaptive delay model for dynamically adjusting spray timing.This strategy compensates to some extent for the composite delays arising from sensor scan frequency, data processing time, and mechanical transmission16,51,63. Efforts to reduce latency and enhance response speed are evident in various systems: Yang’s greenhouse trials using ROS robots and LiDAR122 Zhao et al.‘s field vegetable target-activated system133 Li et al.‘s self-propelled target-following system (reported to reduce water consumption by 26.70% and drift loss by 53.50%)134 Liu’s orchard LiDAR automatic target-activated robot requiring 3D ROI conversion to 2D centroid coordinates58,130 and Shu et al.‘s canopy volume-PWM control system94. However, inherent sensor delays (e.g., limited LiDAR scan frequency), data processing time, communication latency, and the mechanical response time of actuators (solenoid valves) collectively cause overall system response lag. This makes achieving true instantaneous on-target spraying difficult, particularly during high-speed operations or with rapidly changing targets40,58,109,120.

(4) Stability Under Environmental Interference: Natural environmental factors (e.g., light variation, temperature/humidity fluctuations, dust) not only impair sensor accuracy (affecting LiDAR point cloud quality and visual recognition reliability), leading to positioning deviations, but can also exacerbate the aforementioned drift and latency issues. These factors pose ongoing challenges to spray positioning accuracy and introduce potential environmental impacts.

To enhance system robustness against sensor errors and improve its accuracy, the following solutions can be considered:

(1) Multi-Sensor Fusion Technology: Adopting a multi-source heterogeneous sensor fusion strategy integrating LiDAR, vision, IMU, and RTK-GNSS can mitigate the risk of single-sensor failure or error through informational complementarity5,40,41,55,58.

(2) Advanced Algorithms & Online Calibration: Introducing online calibration and adaptive filtering algorithms (e.g., Kalman Filter) enables real-time estimation and compensation for sensor errors and motion delays16,51,106.

(3) High-Precision Actuation & Closed-Loop Control: Utilizing high-response actuators (e.g., high-speed solenoid valves) combined with real-time feedback from sensors like flow and pressure meters to construct a closed-loop control system can effectively suppress the propagation of upstream perception and decision errors. This ensures end-point execution accuracy and maintains stable flow control deviation12,62,116,119.

(4) System-Level Simulation & Digital Twin: Technologies such as CFD drift models, ROS-Gazebo simulation, or digital twins can simulate and predict the impact of sensor errors under various environmental conditions before deployment. This allows for optimization of system parameters and control strategies, providing pre-validation for field applications33,135.

In summary, addressing sensor errors requires a systematic solution encompassing the entire technological chain from perceptual fusion and intelligent algorithms to precise execution. This ensures that variable-rate spraying systems can maintain high-precision operational capability even within complex field environments5,18,40,84.

Real-time mixing system: the dynamic proportioning interface for decision-execution

The real-time chemical mixing system serves as a critical execution component within the “Perception-Decision-Execution” closed-loop of precision pesticide application. It acts as the direct interface bridging the prescription map generated by the decision layer and the variable-rate spraying executed by the actuation layer in Fig. 8. Its core function is to dynamically adjust the chemical mixture ratio in response to decision-layer commands (e.g., pest/disease severity, crop growth stage), ensuring precise matching between chemical concentration (C) and spray flow rate (Q)11,136,137.

The mixing uniformity coefficient (γ) is a key performance indicator, directly influencing the deposition efficiency of PWM spraying and the resultant control efficacy128. For instance, while jet mixers achieve γ > 85% for oil-soluble pesticides, γ can drop to 70–75% for suspension concentrates due to particle sedimentation138. Similarly, in static mixers, the mixing efficiency for high-viscosity chemicals decreases by up to 40% owing to the “dead zone effect”139.

The integration of this technology offers significant synergistic value for precision application systems and is crucial for advancing the adoption of precision spraying techniques. By enabling UAV perception data to drive dynamic adjustment of mixture ratios via prescription maps, the system facilitates PWM spraying execution based on concentration-flow rate requirements, thereby closing the loop. Field trials in rice paddies demonstrated that such systems reduce pesticide usage by 30–50% and mitigate non-target pollution10.

To address the decline in mixing uniformity caused by particle sedimentation in suspension concentrates, breakthroughs can be pursued in two key areas: mixer structural innovation and material pretreatment.

In mixer design, Computational Fluid Dynamics (CFD) simulation can optimize the flow field structure32,33: (1) Introduce swirl generators or helical baffles into jet mixers to generate three-dimensional turbulent flow that enhances particle suspension140,141; (2) Implement asymmetric mixing elements in static mixers to disrupt sedimentation flow patterns, thereby reducing dead zones139,142; (3) Develop pulsed jet technology, where intermittent high-frequency flow pulses prevent particle deposition143,144.

In pretreatment, an online viscosity adjustment system can be constructed. This system would inject eco-friendly thickeners (e.g., xanthan gum) to dynamically regulate the rheological properties of the suspension, reducing the settling velocity145. Furthermore, an ultrasonic disruption unit can be utilized to pretreat the high-concentration stock solution before it enters the main mixer, effectively breaking particle agglomerates and significantly enhancing mixing uniformity146.

Real-time mixing system146.

Integrated optimization of mixing control and detection devices

Traditional pre-mixed spraying suffers from low pesticide utilization efficiency and high operational risks. In contrast, real-time mixing technology, dynamically adjusting chemical ratios, serves as a core execution component in precision application systems147. This technology leverages intelligent algorithms and multi-source sensors to achieve real-time concentration detection and closed-loop control, significantly enhancing pesticide utilization efficiency.

The evolution of concentration detection technology is central to system optimization. Early infrared spectroscopy methods, such as the FT-NIR spectrometer employed by Koller et al.148, analyzed solution volumetric concentration but exhibited > 15% identification error for suspension concentrates and poor weak-signal stability. To overcome these limitations, Han et al.149 developed a dye-doped PWM sensor combining fluorescence indication and image analysis, enabling visual concentration monitoring. This reduced detection error for oil-soluble pesticides to < 5% and improved the signal-to-noise ratio by 40%145. Recently, machine learning has further revolutionized detection precision. Liang et al.150 integrated hyperspectral imaging with PCA algorithms, while Pfezer et al.151 utilized plasma-enhanced infrared absorption spectroscopy, achieving pesticide residue identification rates > 90% and reducing response time to 0.5 s.

Intelligent assessment of mixing uniformity (γ) directly determines prescription map execution efficacy. Dai et al. proposed an image-processing-based uniformity analysis method, correlating CFD flow field simulations with supervised machine learning to dynamically predict pesticide mixing uniformity in real-time (γ prediction error < 8%)33,135,143. Chen et al. captured pesticide mixing flow fields under varying flow rates using high-speed cameras and quantified γ values via principal component analysis, validating γ > 85% at 3 L/min, thereby providing parameter benchmarks for field variable-condition regulation10.

The closed-loop integration of detection and control modules is the critical link between the decision and execution layers. This system receives ratio commands from the prescription map in real-time (e.g., pest/disease severity level → target concentration Ct). It compares the measured concentration (Cm) using deep learning models, dynamically adjusts jet/static mixer parameters, and coordinates PWM spraying for flow compensation (e.g., increasing flow by 10% when γ < 80%)145,152,153. Rice field trials demonstrate that this integrated strategy improves pesticide utilization efficiency by 35%, confines ratio errors within ± 5%, and advances precision spraying technology towards greater intelligence and lower risk154.

Design and optimization of mixing devices

The jet mixer, a core proportioning device in the precision spraying execution layer, utilizes high-speed jet-induced negative pressure to draw pesticide into a mixing chamber for dynamic fluid mixing in Fig. 937,137,140,155. Its key advantages include no moving parts, compact structure, and effective separation of pesticide concentrate from carrier water, minimizing residual contamination. Compared to direct injection mixing, jet mixing technology achieves forced turbulent mixing within the Venturi tube mid-section. Combined with buffer detection tube designs to increase contact area, it significantly enhances mixing uniformity (γ)23,140,146. Computational Fluid Dynamics (CFD) simulation technology has become a core tool for mixer design and optimization. By constructing digital models of the internal flow field within mixers, CFD enables the visualization and quantitative analysis of flow velocity, pressure distribution, turbulence intensity, and chemical concentration fields. This allows for performance prediction before manufacturing physical prototypes, significantly reducing trial-and-error costs and development cycles32,33. For instance, commonly used CFD turbulence models like RNG k-ε and the Discrete Phase Model (DPM) are employed to simulate droplet trajectory and deposition patterns in airflows112,135.

Recently, CFD flow field simulation based on Venturi principles has become crucial for optimization. Addressing the challenge of low solubility in oil-soluble pesticides, Xu’s team utilized Computational Fluid Dynamics (CFD) simulation to analyze the internal flow field, specifically focusing on pressure distribution and vortex generation patterns. Their investigation revealed that the mixing efficacy of swirling jet mixers is strongly correlated with key structural parameters, namely the contraction angle, mixing tube length, and diffuser angle135. Dai et al. further proposed an image-processing-based uniformity analysis method, validating the effectiveness of structural optimization through variable-condition experiments135,146,156. Furthermore, uniformity evaluation for viscous water-soluble pesticides in long straight mixing tubes has expanded the technology’s applicability. For diverse pesticide types, Yuan et al. developed a helical honeycomb plate, the design of which was confirmed through CFD simulation to effectively enhance turbulent disturbance. By employing an alternating left/right rotation installation, this design triples the pesticide mixing ratio range through intensified turbulence, achieving a detection error of less than 5% at low flow rates157. Additionally, Chen’s team integrated PWM technology to regulate liquid flow, enabling real-time ratio adjustments for UAVs based on prescription maps .

However, pesticide formulation compatibility remains a bottleneck. Particle sedimentation in suspension concentrates reduces γ to 70–75% (compared to γ > 85% for oil-soluble pesticides), while powders and emulsions face dissolution challenges135,140. CFD simulation has revealed the mechanisms behind these issues: suspension concentrate particles are prone to sedimentation and accumulation in mixer dead zones (e.g., corners of plate-type static mixers); high-viscosity liquids, due to their higher Reynolds numbers, struggle to achieve adequate turbulence, resulting in mixing inhomogeneity33,135,139,146. Current optimization focuses on CFD-driven structural parameter tuning of the contraction angle (30°–45°), mixing tube length-to-diameter ratio (L/D = 8–10), and diffuser angle (7°–10°)141,152. The use of alternately installed helical honeycomb plates enhances turbulence, reduces pesticide deposition in precision systems, and improves mixing uniformity158. Dai et al.‘s variable-condition tests revealed a 40% decay in mixing uniformity for suspension concentrates at flow rates exceeding 8 L/min, highlighting insufficient dynamic adaptability143. This highlights the persistent challenges CFD models face in simulating multiphase flow (gas-liquid-solid) and highly dynamic operating conditions. Complex models require substantial computational resources, and their predictive accuracy heavily relies on accurate material property parameters (e.g., viscosity, particle size distribution). Difficulties in obtaining or inaccuracies in these parameters can significantly impact simulation results32,135. Current mainstream jet mixers employed in agricultural precision application equipment are summarized in Table 4.

Enhancing the mixing performance of suspension formulations requires a multi-modal mixing strategy: (1) Design a Venturi-static combinatorial mixer, where the initial Venturi section achieves preliminary mixing and particle crushing, and the subsequent static mixing unit enhances turbulence and prolongs residence time; (2) Integrate an online ultrasonic disruption device to pretreat the high-concentration stock solution before pesticide intake, breaking up particle agglomerates146; (3) Develop adaptive pulsed flow technology that adjusts pulse frequency based on feedback from flow sensors, preventing particle sedimentation under low-flow conditions143. CFD simulations indicate that the combinatorial design can increase the γ-value for suspensions, while pulsed flow technology reduces mixing uniformity fluctuations at low flow rates32,33,135.

CFD technology has demonstrated successful cases in improving existing mixer designs. For example, CFD analysis of a Venturi injector mixer identified significant low-pressure dead zones inside it as the key cause of suspension deposition. By optimizing the Venturi tube’s geometry and injection port angle, the dead zone volume was successfully reduced by 40%, significantly improving mixing uniformity135,152. For static mixers, CFD simulation can precisely evaluate the fluid splitting and recombination efficiency of different mixing elements (e.g., Kenics helical elements, perforated plates), thereby guiding the selection of optimal element structures and arrangements to achieve the best balance between pressure drop and mixing effectiveness33,139,142.

Despite the current application of jet technology in agriculture, significant challenges persist in its synergy with execution-layer technologies. Temporal mismatch between mixing uniformity detection and PWM spray control introduces system-wide response delays. The integration level requires further research due to numerous vulnerabilities; multi-protocol interfaces cause data flow asynchrony, leading to substantial dynamic proportioning errors. As the critical interface bridging “prescription maps - variable-rate spraying” in precision application, the dynamic optimization of jet mixers can Boost pesticide utilization efficiency by 35%, driving the evolution towards a closed-loop “on-demand proportioning” paradigm with significant implications for sustainable crop protection146.

Static mixers: powerless pesticide mixing solutions and agricultural adaptation bottlenecks

Static mixers, characterized by no moving parts, low energy consumption, and easy maintenance, are key mixing devices in the precision spraying execution layer in Fig. 10(a, b,c, d)10,159,160. They utilize flow-disturbing elements (e.g., helical blades, perforated plates) to split fluid streams and generate turbulence for efficient chemical mixing. They are particularly suitable for high-viscosity chemicals (> 50 MPa·s) and low-pressure drop scenarios, reducing maintenance costs by over 60% compared to jet mixers. Predominant types include helical Kenics, plate-type, SX multi-layer cross-bar, and perforated Kenics mixers142,161,162,163 each with distinct agricultural adaptation characteristics:

Helical Kenics, Employs 90°−270°twisted blades for low-shear mixing, protecting chemical activity but suffering > 30% clogging rates for suspension concentrates.Plate-type, Features inclined baffles and Central through-holes, reducing pressure drop by 25% but exhibiting > 15% dead zones139. SX Multi-layer Cross-bar, Achieves > 90% mixing efficiency but is difficult to clean due to its enclosed structure.Perforated Kenics, Reduces the coefficient of variation by 15% via micro-jet flows but requires ± 0.01 mm machining precision, limiting field deployment142.

Computational Fluid Dynamics (CFD) simulation plays a Central role in agricultural-oriented optimization. Yu et al. validated that dual co-flow water injection reduces energy consumption by 30%, but vortex dead zones decrease mixing efficiency by 40%. Chen et al., using Box-Behnken experiments, determined the optimal baffle inclination angle (35°±5°), achieving γ > 82% and response delay < 0.3 s65. Tang’s team developed a perforated Kenics mixer that significantly reduced suspension concentrate deposition rates by 53% by adjusting perforation spacing (S/d = 1.5). Field synergy theory Further reveals that internal multi-vortex blade designs can enhance the synergy angle between velocity and pressure fields by 5.9%−11.9%, making them especially suitable for high-viscosity fluid mixing142.

Nevertheless, static mixers face significant bottlenecks for agricultural adaptation. While they are commonly used in precision spraying for uniform pesticide-water mixing to enable fine-scale pest management33,145 their reliance on physical mixing via internal elements (inclined plates, helical blades, perforated structures) to split fluid flow and generate turbulence, thereby shortening mixing paths, exhibits notable limitations. Compatibility varies significantly with pesticide type:

High-Viscosity Suspension Concentrates: Prone to internal scaling, causing clogging and efficiency decay (γ attenuation > 20% compared to γ > 85% for oil-soluble pesticides). Particle sedimentation further reduces γ to 70–75%, requiring > 5 Hz pulsed flushing to maintain flow146.

(2) Dynamic Operating Conditions: Adaptability is limited. Significant pressure fluctuations (± 0.2 MPa) cause dynamic coordination failure, leading to mixing efficiency variations up to 35%. Temporal errors (> 50 ms) relative to PWM spraying cycles result in prescription map execution deviations of ± 5%.

(3) Synergistic Control: Major challenges exist in coordinating static mixers with spraying equipment control systems.

UAV-Ground equipment collaborative spraying

The UAV-Ground Collaborative Spraying System integrates aerial perception capabilities with ground-based precision execution, establishing an enhanced “Perception-Decision-Execution” closed-loop framework. This system leverages the UAV’s advantage in rapid large-area perception (operational efficiency: 10–15 hectares/hour) and the ground robot’s capability for localized precision operations, effectively overcoming the limitations of single-platform operations. It significantly improves pesticide utilization efficiency while reducing environmental risks (pesticide drift reduced by 40–60%6,52,164. Collaborative operation has emerged as a key development direction for enhancing spraying efficacy in complex agricultural scenarios21,38,61.

The coordination architecture and technological integration between UAVs and ground equipment are primarily realized through three layers: the Aerial Perception Layer, the Decision Relay Layer, and the Ground Execution Layer.

UAVs equipped with multispectral/hyperspectral sensors (e.g., DJI P4M, Matrice 300 RTK) acquire Centimeter-resolution crop data at flight altitudes of 1–3 m. Deep learning models (e.g., YOLO-Fi, DeepLab V3+) identify pest/disease/weed hotspots and generate spatial prescription maps64,165,166. RTK-GPS positioning ensures geocoordinate errors below 0.1 m97,108. Cloud or edge computing platforms integrate UAV perception data. Utilizing GIS spatial analysis, they generate targeted operation commands, which are transmitted to ground units via low-latency communication protocols (e.g., LoRa, 5G)67,167. Typical response latency is controlled within 200 ms. Autonomous navigation ground robots (GNSS/LiDAR positioning accuracy: ±2 cm) receive the prescription maps. They employ machine vision for precise target localization and drive PWM variable-rate spraying systems for localized application41,101,130,168. For instance:

The Ecorobotix AVO robot implements site-specific Herbicide spraying based on UAV prescription maps, reducing chemical usage by 90%169. Laser weeding robots (e.g., Carbon Robotics) achieve millimeter-precision weed eradication through coordinate mapping170. Representative collaborative platforms include the UAV-ground weeding system robots depicted in Fig. 11. Table 5 provides a performance comparison of these typical robotic collaboration platforms across different scenarios.

Figure 11 showcases multiple ground-based weeding robot systems, including: (a) The Oz weeding robot from Naio Technology, France168; (b) The Ecorobotix AVO weeding robot from Agtech, Switzerland (Figure. 11b); (c) Bosch Deepfield Robotics’ BoniRob (Figure. 11c)25,78,95,170; (d) AgBot II (Figure. 11d)172; (e) Andela Robotic Weeder ARW–912 (Figure. 11e); (f) Ekobot WEAI (Figure. 11f); (g) Carbon Robotics LaserWeeder (Figure. 11 g); (h) Farm Droid FD-20 (Figure. 11 h); (i) Hortibot (Figure. 11i).

Analyzing the synergy and advantages of this ground equipment reveals significant benefits: UAVs rapidly scan for hotspot areas (10–15 ha/h), enabling ground robots to perform targeted treatments. This reduces operational time by 30–50% compared to blanket spraying173.Close-proximity operation by ground platforms effectively reduces droplet drift and non-target pesticide deposition. Ground robots featuring four-wheel drive with independent steering designs (e.g., KUMAR slope climbing system) support operations on slopes and in high canopy density environments (LAI > 4), overcoming environmental constraints faced by UAVs68,77.

The UAV-Ground Collaborative Spraying System, operating through its three-tier architecture of Aerial Perception - Edge Decision - Ground Execution in Fig. 11, achieves end-to-end optimization of crop protection operations—from wide-area monitoring to localized precision intervention. This system significantly enhances spraying efficacy in complex environments (operational efficiency + 30–50%, pesticide drift − 40–60%)59,106. However, current implementations are still constrained by:

Spatiotemporal Synchronization Errors (0.3–0.8 m); Dynamic Decision-Making Latency (Conflict Rate > 22%);System Economic Bottlenecks16,129.

These challenges fundamentally stem from the systemic coupling of issues across layers: environmental disturbances at the perception layer, Limited algorithm generalization at the decision layer, and control coordination deficiencies at the execution layer. This analysis naturally leads to the in-depth examination of cross-layer Bottlenecks in precision spraying technology presented in Chap. 4.

Challenges and limitations of precision spraying technology

Perception layer challenges: environmental sensitivity and Real-time processing bottlenecks

As the core component for information acquisition in precision spraying systems, the reliability of the perception layer directly impacts the accuracy of decision-making and execution. However, current multi-source sensing technologies (LiDAR, multispectral cameras, RGB sensors, etc.) face significant challenges in complex field environments, primarily manifested in performance degradation under environmental interference and bottlenecks in real-time data processing.

Sensor performance degradation induced by environmental disturbances

Dynamic changes in field conditions severely challenge sensor accuracy. Under overcast or hazy conditions, low illumination compromises the efficacy of optical sensors. Transmittance in the visible light spectrum (450–650 nm) decreases by over 40%52, causing the Signal-to-Noise Ratio (SNR) of RGB cameras to drop from 28 dB to 18 dB. This phenomenon directly reduces pest/disease identification accuracy from 90% to 60–70%, with the missed detection rate increasing by 35%, particularly in early disease spot detection tasks73.

During rainy or foggy conditions, moisture induces LiDAR point cloud distortion. The 905nm laser wavelength is absorbed by water molecules, resulting in a point cloud density loss rate > 50%174. As shown in Table 3, LiDAR tests on tracked chassis platforms revealed a leaf area density inversion error of 22% at a 1 m detection distance40leading to distorted canopy 3D reconstruction in Fig. 7.

When the Leaf Area Index (LAI) exceeds 4, ultrasonic sensors generate false echoes due to multipath reflection, causing target height detection offsets of ± 15 cm109. Simultaneously, dense canopy occlusion leads to saturation of vegetation indices (e.g., NDVI) in multispectral imagery, diminishing disease differentiation capabilities77. These factors collectively induce canopy structure interference on multi-source sensors.

Bottlenecks in Real-time processing of high-resolution data

For UAV-based precision spraying technology, a significant technical bottleneck exists at the perception layer: the inability of single sensors to adapt to complex environments and the obstacles encountered in fusing multi-source data. This is primarily manifested in:

Multi-source Data Fusion Obstacles: Clock asynchrony between GNSS positioning and LiDAR scanning causes canopy volume calculation offsets of 0.3 m6creating spatiotemporal registration errors that induce spraying delays.

Feature Space Heterogeneity: Spatial heterogeneity in features across spectral bands (e.g., soil reflectance surge in the NIR band) reduces the F1-score for early disease classification by 0.155, leading to feature fusion failure.

(3) Lack of Adaptive Algorithms: Existing Fusion models lack embedded environmental compensation mechanisms. Under hazy conditions, multispectral-LiDAR Fusion accuracy plummets by 32%51.

Current research primarily attempts to enhance sensor synergy and algorithm robustness to improve spectral-spatial joint compensation for precision spraying. Examples include:

Fusing LiDAR point clouds (resistant to low-light interference) with the Red-Edge Inflection Point (REIP) index to construct Light-humidity adaptive models, restoring grape downy mildew identification accuracy to 82% under foggy conditions174.Implementing adaptive spray pattern adjustment through dynamic band selection, switching to optimal band combinations (e.g., SWIR 1550 nm under haze) based on real-time atmospheric transmittance, reducing dependence on visible light108.

However, perception failure under extreme environments persists. Dust conditions drastically reduce LiDAR point cloud SNR and severely blur multispectral images. Furthermore, existing algorithms fail to account for reflection fluctuation errors caused by leaf inclination angle changes, lacking coupling with such physiological traits. Consequently, unresolved core challenges persist at the perception layer. Breaking through the “Environment-Crop-Sensor” coupling mechanism and developing field-deployable adaptive fusion frameworks are essential to support the all-weather operation of precision spraying systems.

Decision layer challenges: algorithm generalization and edge computing bottlenecks

The decision layer of precision spraying systems relies on deep learning algorithms for pest/disease recognition and spraying decision-making. However, its application in complex field scenarios faces significant challenges, primarily manifested in three areas: algorithm generalization, real-time performance, and multi-source data fusion.

Current deep learning-based recognition models (e.g., YOLO, CNN) are highly sensitive to illumination variations and occlusion interference. Research indicates that under strong Sunlight, the missed detection rate for grape powdery mildew increases by 40%52, while Haar-like feature-based detectors exhibit false detection rate fluctuations of ± 10% in occlusion scenarios105. A more severe issue is cross-crop transfer failure: a model trained for grape black rot (mAP 0.92) drops to 0.68 accuracy when transferred to apple orchards5. Similarly, a cotton field weed detection model shows a 15% rise in false detection rates in rice paddy scenes due to morphological similarities108. The root cause lies in the insufficient incorporation of agricultural image background complexity (soil texture, overlapping foliage) into model training paradigms and the lack of mechanisms for extracting crop morphology-invariant features.

The computational Limitations of edge devices result in decision delays far exceeding the requirements of precision spraying. Inference latency for mainstream models running on Jetson Nano platforms reaches 205–228 ms65significantly surpassing the < 50 ms response threshold for PWM control173. Concurrently, high computational loads cause drastic energy consumption spikes: continuous operation of MobileNetV3 reduces UAV endurance by 40%2. Under this dual constraint of latency and energy consumption, existing edge devices struggle to support millisecond-level decision-making loops in the field.

The decision layer needs to fuse high-resolution remote sensing imagery with historical agronomic data to generate prescription maps. However, the absence of standardized fusion mechanisms for multi-source heterogeneous data leads to decision biases. For instance: scale mismatch between hyperspectral imagery (5 cm resolution) and gridded historical records (1 km²units) causes cotton defoliant application rate deviations of ± 20%175. Furthermore, the lack of a “spectral-environmental-agronomic” correlation rule base prevents models from dynamically responding to environmental stressors (e.g., changes in pesticide diffusion rate under drought conditions), further compromising decision reliability.

To overcome these bottlenecks, recent research proposes three innovative solutions: Employing channel pruning reduced YOLO-Fi parameters by 68%, maintaining mAP 0.89 for early disease detection in apple trees175. Introducing spectral attention modules to enhance near-infrared band weighting improved F1-score by 12% under low-light conditions. Hierarchical decision-making (coarse classification at edge layer + fine-grained diagnosis in cloud) compressed end-to-end latency to 45 ms and reduced bandwidth usage by 80%101. Constructing a trinity feature library integrating “LiDAR canopy volume + NDVI disease index + historical weather” reduced cotton prescription map generation error to ± 7%175.

Despite these advances, core problems remain unresolved and require future breakthroughs: (1) Insufficient Robustness to Agricultural Adversarial Samples: Spray residue reflections can increase false detection rates by + 50%.(2) Undefined Pareto Frontier for Edge Device Energy-Accuracy: The theoretical mAP Limit under a 5W power budget is estimated < 0.8.(3) Cross-temporal Image Registration Errors > 20 Pixels: Caused by non-rigid deformation of crops during growth.

Future research must focus on designing intrinsically safe learning frameworks for agriculture, developing crop deformation compensation models, and exploring theoretical accuracy limits under edge computing constraints.

Execution layer challenges: physical limitations of precision control

As the terminal component of the “Perception-Decision-Execution” closed-loop in precision spraying systems, the control accuracy of the execution layer directly determines pesticide utilization efficiency and ecological environmental risk. However, current technologies still face three fundamental physical bottlenecks: insufficient mixing uniformity, control synergy failure, and environmental disturbance amplification.

Formulation adaptability deficiencies in mixing devices

The attenuation of the mixing uniformity coefficient (γ) is a core constraint for precision application.Significant Formulation Dependence: Jet mixers achieve γ > 85% for oil-soluble pesticides, but particle sedimentation reduces γ to 70–75% for suspension concentrates145. Suspension concentrates form a “pesticide mud layer” at the bottom of mixing tubes, requiring high-frequency pulsed flushing (> 5 Hz) to maintain flow146. Static mixers (e.g., plate-type) exhibit dead zones accounting for up to 15% of the volume, causing mixing efficiency (ψ) to decline by 40% for high-viscosity chemicals (> 50 mPa·s)139.

Discrepancies exist between CFD simulations and field measurements. Despite being a powerful design tool, CFD still faces accuracy challenges in agricultural applications. Simplified models, such as the standard k-ε turbulence model, often neglect particle sedimentation effects and complex multiphase interactions, leading to overestimation of the predicted mixing uniformity (γₐ) for suspension concentrates by up to 12%135. Furthermore, CFD simulations are typically based on ideal steady-state conditions and struggle to fully replicate the extreme dynamic conditions of field operations, such as severe flow fluctuations and highly variable physicochemical properties of pesticides, creating a gap between simulation results and practical performance146. Although the perforated Kenics mixer design was optimized using CFD to improve the coefficient of variation, the required machining precision (± 0.01 mm) increases costs by 300%161, highlighting the gap between optimized design and manufacturing practicality.

Nonlinear control synergy failure and environmental disturbance amplification

Decision-execution synergy in variable-rate spraying systems faces physical constraints. PWM variable-rate spraying technology imposes high demands on sensor data acquisition (e.g., LiDAR) and end-point actuator responsiveness, yet struggles to effectively handle pressure-flow nonlinearities during spraying. Pressure fluctuations of ± 0.2 MPa alter the duty cycle-flow rate curve slope by 35%, increasing the spray volume coefficient of variation from 5 to 12%176. GNSS-LiDAR temporal errors (> 50 ms) cause canopy volume matching offsets in Fig. 7, resulting in spraying trajectory deviations of up to 0.8 m120. This phenomenon leads to pressure-flow nonlinearity loss of control, while dynamic field conditions exacerbate UAV execution errors. Wind speeds exceeding 4 m/s increase turbulence intensity in the rotor downwash airflow by 200%, elevating droplet drift rates beyond 30%82. CFD simulations indicate that nozzle orifices < 0.8 mm reduce drift but incur a 40% loss in canopy penetration rate112.

System integration and socioeconomic scaling challenges

The large-scale deployment of precision spraying technology faces bottlenecks stemming from both technical fragmentation and socioeconomic constraints. Key integration barriers include protocol disparities and hardware-software mismatches, which lead to asynchronous data flow and dynamic proportioning errors (± 8%). Beyond technical issues, significant socioeconomic barriers impede adoption, particularly among smallholder farmers. The high initial investment required for advanced sensor systems and automated equipment creates economic hurdles, while operational complexity demands technical expertise that may not be readily available in resource-limited contexts. Policy support mechanisms—such as targeted subsidies, green financing initiatives, and integration into ecological compensation schemes—are crucial to lower adoption barriers and enhance economic viability. Furthermore, the technology’s potential extends beyond field applications to enhancing overall supply chain sustainability. By significantly reducing crop losses and improving quality consistency, precision spraying contributes to stronger closed-loop supply chains, minimizing food waste and enabling transparent traceability through data integration. Achieving scalable deployment requires a coordinated effort to develop cost-effective solutions, promote standardized protocols, and implement training programs, ultimately facilitating the transition toward productive and sustainable agricultural systems.