Abstract

In urban concentrated area, the disturbance caused by construction affects significantly the sustainability of adjacent existing structures. It is essential to capture the mechanical response of existing structures to adjacent deep excavation. The objective of this paper is to investigate the displacement and internal force behavior of elevated bridge piles (BP) subject to influence of deep excavation. A three-dimensional finite element model is established by taking the project of a deep excavation near elevated bridge as an example. The numerically calculated results agree well with the measured data, which verifies the established numerical model. On the basis of this model, the influence of deep excavation on the mechanical characteristics of adjacent piles is captured. The results show that the displacement, bending moment, and shear force of piles are sensitive to the excavation depth. Their magnitudes increase with the increase of excavation depth. When the excavation is completed, the maximum displacements of piles in horizontal direction and vertical direction are 2.3 mm and 10.05 mm, respectively. The maximum bending moment is 1,140.8 kN·m. The maximum and minimum shear forces are 1,206 kN and -2,282 kN, respectively. The piles are mainly under pressure. The maximum pressure is -13,116 kN. The axial force is not sensitive to the depth of excavation. The deformation and internal force of piles exhibit obvious spatial distribution characteristics, and the closer the distance to the middle of the long side of the deep excavation, the greater the value. The research results have a positive effect on the optimization of related engineering structures and the promotion of sustainable development in urban concentrated area.

Similar content being viewed by others

The excavation of foundation pit can cause the deformation of supporting structure and the movement of nearby soil. This has a certain impact on the safety of the foundation pit and nearby buildings and structures1,2,3,4. Therefore, it is very important to accurately evaluate the stress and deformation of adjacent piles caused by foundation pit excavation. In practice, various problems may arise. Then some serious engineering accidents occurred in some foundation pits5,6,7,8. This may cause great economic losses and negative social impacts9,10,11,12. This will be detrimental to environmental protection and sustainable development13,14. Therefore, the choice of reliable and economic support is crucial. The underground diaphragm wall is made use of some special trenching machinery. With the help of mud wall protection, narrow and deep pits are dug into the ground. And the appropriate material is poured into it to form an underground wall. It has the functions of seepage prevention, soil retention and load bearing15,16,17. Because of its characteristics of large stiffness, good anti-seepage performance, less land area, and small impact on urban environmental disturbance, it has become the preferred type of foundation pit retaining structure18,19,20,21,22,23. This type of excavation support structure is widely used in engineering practice, for examples, in the Shenzhen Ping-An International Financial Center building foundation pit, Shanghai Center Building foundation pit, and so on.

At present, domestic and foreign scholars have carried out a lot of research on geotechnical problems caused by foundation pit excavation14,15,16,17,18,19,20,21,22,23,24,25,26,27. Wang28 proposed a calculation method for the safety factor of foundation pit supporting system. Shaaban et al.29 used the finite element model to study the influence of piles near the foundation pit. Yeh et al.30 designed an envelope structure with continuous wall as the main component. Van Nguyen et al.31 established a model that included the interaction between the structure and the surrounding soil, and on this basis studied the influence of excavation on the building performance. Zhang et al.32 used numerical simulation to study the effect of excavation depth on the internal force of support. The research results of Rao et al.33 show that excavation depth has a relatively large influence on displacement. Al-ne ‘Aimi et al.18 studied the response of continuous wall under load change by using Plaxis 2D software. Wang et al.34 studied soil displacement, internal force and deformation of supporting structure by using the method of field monitoring. Peng et al.35 and Ganesh et al.36 studied the deformation rule of foundation pit.

To sum up, the influence of various factors on foundation pit excavation has gradually been paid attention by many scholars. And significant research results have been obtained. However, previous researches mainly focused on the deformation and mechanical properties of foundation pits37,38,39,40. Few scholars have studied in detail the influence of deep foundation pit excavation on the construction mechanical behavior of adjacent piles. It should be noted that with the large-scale development of underground space, there are more and more phenomena and problems involving foundation pit close to existing buildings. For example, deep foundation pits may be dug near viaducts. The appearance of this situation makes the surrounding environment of construction relatively complicated41,42,43. Therefore, in order to ensure the safe construction of foundation pit engineering and the normal use of adjacent buildings and structures. It is of great significance to carry out research on the influence of deep foundation pit construction on close piles for efficient development and utilization of underground space. In addition, issues related to the impact of foundation pit excavation on adjacent piles are also very important issues faced by urban construction and sustainable development. However, due to the complexity of the situation, the research is difficult44,45,46. Therefore, it is necessary to conduct in-depth research on the influence of deep foundation pit excavation on the construction mechanical behavior of adjacent piles.

In view of this, this paper investigates the mechanical response of existing piles supporting elevated bridge to nearby deep foundation pit excavation. The research content mainly includes three parts: Firstly, based on the modified Mohr-Coulomb constitutive model, a three-dimensional finite element model is established by MIDAS GTS NX software (See reference 49 for an introduction of the software). Secondly, the reliability of the model is verified by comparing the simulated with the measured results. Finally, the influence of deep foundation pit excavation on the mechanical behavior of adjacent piles is studied. The research results will play a positive role in the further optimization of related engineering structures and the promotion of sustainable development.

Project overview

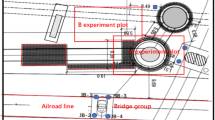

The research object of this paper is the deep foundation pit engineering of typical strata in a certain area of Zhengzhou City, China. The piles of the elevated bridge are near the foundation pit. Engineering geological conditions, surrounding environment and construction technology are complicated. This brings great challenges to the construction technology and the surrounding environment safety. The foundation pit is constructed by open excavation method. In accordance with the principle of “longitudinal segmentation, vertical stratification, and timely installation of excavation support structure”, the excavation is carried out in layers. The length of the foundation pit is 120 m, the width is 10 m, and the excavation depth is 18 m. The excavation support structure is mainly composed of underground diaphragm wall, crown beam, steel enclosing purlin, and internal support. The foundation supporting the elevated bridge is composed of cap and pile. The closest distance between the cap and the underground diaphragm wall is 6 m. The distance between caps is 18 m. The width of the underground diaphragm wall is 0.6 m, the height is 24 m, and the embedment depth is 6 m.

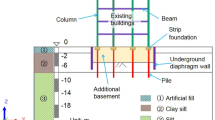

The foundation pit was excavated in six steps. The first three excavation depths were all 4 m. The last three excavation depths were all 2 m. According to the geotechnical investigation report, the simplified soil layer is 5 layers. From top to bottom, they are: mixed fill, silty clay, silt, fine sand and clay silt. The influence range of excavation depth is mainly mixed fill soil and silty clay. Each excavation is carried out after the water has fallen 3 m below the excavation face. Therefore, the influence of groundwater on excavation is not considered in this study. Figure 1 shows the cross-section of the foundation pit. Schematic diagram of foundation pit section.

The foundation of bridge pier is composed of cap and pile. There are four piles (named piles) under each cap. The height of the cap is 2 m, and the length and width are 6 m. Both cap and pile are made of reinforced concrete. The diameter of the pile is 1.5 m. The distance between piles is 3 m. The distance between pile and cap edge is 1.5 m. Figure 2 shows the schematic diagram of cap and pile.

In addition, the underground diaphragm wall is made of concrete. There are three internal supports, located 2 m, 7 m, and 13 m below the surface. Among them, the first inner supporting material is reinforced concrete. The cross-section shape is square. The material supported in the second and third channels is steel. The cross-section shape is a ring. The horizontal distance of the inner support is 5 m. The material parameters of envelope structure, cap and pile are shown in Table 1. The mechanical parameters related to soil layer are shown in Table 2. The relevant mechanical parameters are derived from the engineering geological survey report. The meanings of the letters in Table 2 are consistent with reference 49.

Model building and numerical calculation.

Basic assumptions.

The construction process and site engineering conditions are complicated. In order to facilitate the calculation study, the numerical model needs to be simplified to some extent. The basic hypothesis of this study is consistent with reference 49.

Simulated construction.

Calculation model.

In this study, MIDAS GTS NX (version 2022) software was used to establish a three-dimensional finite element model. The numerical simulation method is used to study the influence of deep foundation pit excavation on the construction mechanical behavior of adjacent piles. The size of the model will have a certain impact on the calculation speed and results29,31. For example, if the size is too small, there will be a boundary effect. The simulation results cannot fully reflect the influence range of foundation pit excavation. This can adversely affect the results of the calculation. On the contrary, if the size is too large, then the number of cells and nodes will increase significantly. This in turn makes the calculation time even longer. Therefore, proper model size is important18,36. The proper model size is not only faster to calculate, but also can reflect the influence range of excavation well. In this study, several attempts were made to calculate the model by changing the size. The appropriate model size is obtained by comparing the calculated results.

It should be noted that the object of this study is symmetrical structure. Therefore, one half can be modeled23. Finally, it is determined that the length (X), height (Y) and height (Z) of the model established in this study are 100 m, 80 m and 50 m respectively. The calculation model is shown in Fig. 3. Considering the complexity of the model and the accuracy of the calculation results. Fine-grained elements are used in excavated soil, envelope structure, cap and surrounding soil. The size of the fine unit is 0.5 m. The unit size of the pile is 1 m. The number of units and nodes is 227,515 and 165,985, respectively. The model coordinate system is shown in Fig. 3: the positive direction of X axis points to the width of the foundation pit. The positive direction of the Y axis points to the long foundation pit. The positive Z-axis points straight up. The boundary conditions of the model are consistent with those in the reference 23. Relevant studies have shown that the deformation response of soil around foundation pit has obvious small-strain characteristics18. The modified Molar coulomb constitutive relation can be used to better simulate the small strain characteristics of soils [49]. In this study, the modified Molar coulomb constitutive relationship was used for the soil in the numerical model.

In addition, both the envelope structure and the inner support adopt elastic constitutive relation. Soil and cap in the model are 3D solid units. The underground diaphragm wall is a 2D surface unit. The inner support, crown beam, and steel enclosing purlin are all 1D beam units. The pile is a 1D implantable beam unit.

It should be noted that there are four caps near the foundation pit in this study. There are four piles under each cap, for a total of 16 piles. The spatial position relationship and numbering of cap and pile are shown in Fig. 4. Obviously, the closest distance from the center of the foundation pit is cap 1 and pile 1–1. The farthest distance from the middle of the foundation pit is cap 4 and pile 4 − 3.

Simulated construction.

The process of foundation pit excavation mainly involves the construction of underground continuous wall, soil excavation, and the setting of internal support. In addition, the specific operation process of excavation is consistent with reference 49. The specific process of simulated construction consists of 10 parts. The details are shown in Table 3. It should be noted that the deep excavation in this study was completed at stage 10.

Comparative of simulation and field measurements.

The actual situation in the construction process can be directly fed back through the on-site monitoring data34,35,36. For example, by arranging monitoring points, relevant monitoring instruments can be used to obtain displacement and axial force data simultaneously. The monitoring data plays an important role in verifying the rationality of the calculation model. However, field monitoring is not predictive in advance. This has some limitations to the optimization and guidance of the construction site. In addition, if there is a lot of monitoring in the field. On the one hand, it may affect the construction process. On the other hand, it will increase the project cost. It should be noted that this method cannot monitor all parts of the construction site.

The numerical model has the characteristics of fast calculation speed and low cost29,30. In addition, full range simulation of the site can be carried out44,45,46. The presentation of simulation results is characterized by diversification31. Both detailed data and vivid cloud maps (including internal forces and displacements) can be generated32. It can even visually show the deformation of the structure33. It is convenient for us to find certain laws and then draw relevant conclusions. In addition, the calculation result of this method has a certain predictability. This is conducive to better effective guidance for construction. However, the established model may not accurately reflect the real situation of the construction site. If the model differs greatly from the real situation of the construction site, then the results will have no reference value. Therefore, it is very important to establish a reasonable calculation model. By combining these two methods, the rationality of the numerical model can be tested through the field monitoring results. This allows us to make appropriate adjustments to the model. This makes the model better reflect the real situation of the construction site. Therefore, the rationality of numerical models is crucial.

The main controlling factor of urban deep foundation pit is the horizontal displacement of supporting structure48. In this study, the displacement calculation results of the underground diaphragm wall (stage 10) were selected to verify the rationality of the parameter values of the model. It should be noted that according to the research results of scholars49, excavation will have a great adverse impact on the middle part of the supporting structure. Therefore, it is necessary to select a representative place to arrange monitoring points. There are three monitoring locations selected in this study. They are: the middle of the long side of the underground continuous wall (A-A), the middle of the short side (B-B), and the corner (C-C). See Fig. 5 for specific locations. The calculation results of Y-direction displacement of three monitoring positions were extracted. At the same time, the values were compared with the corresponding field monitoring values, and the contrast map was drawn. Figure 5 shows the displacement comparison diagram of (A-A), (B-B), and (C-C).

Obviously, the simulated results of the three monitoring locations are close to the field monitoring results. The monitoring site (A-A) was taken as an example to explain. It can be seen that the monitoring value of the maximum Y-direction displacement is about 8.5 mm. The simulated value is about 7.9 mm. All of them appear near the excavation face. In addition, the results of both methods show a changing trend of “small at both ends and large in the middle”. This shows that the numerical simulation results are in good agreement with the monitoring results. The rationality of the numerical model established in this paper is verified. In addition, the maximum horizontal displacement value is relatively small. The foundation pit is in a safe state. This also reflects that the selection of the supporting structure is reasonable. At the same time, it also shows that the construction process of this excavation is reasonable.

At the same time, it can also be found that the field monitoring results of the monitoring site (A-A) are different from the numerical simulation results. By comparison, the results of field monitoring are about 7.5% higher than those of numerical simulation. But the difference between the two is small. The reasons for the differences may be: the numerical simulation can not fully consider the complexity of the actual construction conditions, which will lead to certain differences in the results. For example, the disturbance of excavators, earth-moving vehicles, long-term rainfall and so on. However, these factors are not fully taken into account in the numerical simulation. This may lead to the field monitoring data is too large. In summary, the results of the two methods are close. And the pattern of change is similar. Therefore, the design of this model has certain rationality and reliability. On this basis, the influence of excavation on the construction mechanical behavior of adjacent piles can be studied.

Numerical result.

The excavation may have some influence on the nearby piles. The study of the influence of excavation on the deformation characteristics and mechanical properties of piles is helpful to clarify the deformation process and the specific conditions of the load. The general rule is obtained through analysis. This helps to better guide the design and construction of foundation pit and piles. The main object of this study is piles. The content includes five parts: XY displacement, Z displacement, bending moment, shear force, and axial force. The details are as follows.

Displacement of piles and caps in XY direction.

The displacement in XY direction can reflect the deformation of piles in horizontal direction. If the displacement is too large, it will cause the horizontal displacement of the cap to increase. This may cause the viaduct surface to be tilted. It may even cause a security incident. Therefore, the XY direction displacement analysis of piles has important reference value for evaluating the stability and safety of adjacent viaducts during excavation. Figure 6 shows the displacement cloud image in the XY direction. To be clear, the red numbers in results of this study represent the proportions of the calculated results. In order to facilitate the analysis and study, the maximum displacement of piles and cap is marked (including position and value) in Fig. 6. Obviously, excavation will have a certain influence on the displacement of nearby piles. The displacement of piles will change with different excavation depth. This shows that the excavation of foundation pit will indeed have a certain impact on nearby piles.

It can be seen that the excavation of foundation pit will also have a certain impact on the cap. With different excavation depth, the displacement of cap will change constantly. Specifically: with the increase of excavation depth. Both the displacement of piles and the displacement of cap show an increasing trend in general. In the first phase of excavation, the maximum displacement of piles is 0.24 mm. Position appears at piles 2. The cap is 0.36 mm. The position appears at the top of cap 3. When the excavation is completed, the maximum displacement of piles is 2.3 mm. The cap is 1.26 mm. The location is the same as that of excavation stage 1. By comparison, the displacement of piles increases by about 858.3%. Cap displacement increased by about 250%. This also shows that the excavation of foundation pit will have a certain influence on the displacement of nearby piles and caps. In addition, the displacement response of piles and caps at different locations to excavation is different. This shows that the excavation of foundation pit has a certain spatial effect on the nearby piles and cap.

In order to study the spatial effect of excavation on nearby piles and cap. The maximum displacement in Fig. 6 is extracted and sorted. Figure 7a shows the comparison diagram of maximum displacement of piles in XY direction. Obviously, with the increase of excavation depth, the maximum displacement of piles also increases gradually. When the excavation is completed, the maximum displacements of piles 1, 2, 3 and 4 are 2.26 mm, 2.31 mm, 0.71 mm and 0.15 mm, respectively. piles 1 showed a trend of “rapid increase at first, then slow increase”. piles 2 also showed a similar trend to piles 1. piles 3 and 4 showed a “slow growth” trend. At the same excavation stage, the displacement of piles 1 and 2 is relatively large. The displacement of piles 3 and 4 is relatively small.

In addition, the displacement of piles 2 and piles 1 is the largest, and the difference is small. This shows that the displacement effect of foundation pit excavation on piles is related to the distance between piles and the middle of the long side of foundation pit. The closer the distance, the greater the impact. It is important to note that although each excavation phase is increasing, the amount of increase is different. The increase of displacement in the first three stages is larger than that in the last three stages. The reason may be that in the first three stages, the depth of each excavation is 4 m. However, in the last three stages, the depth of each excavation is only 2 m. Obviously, the depth of each excavation in the first three stages is greater. It can be seen that each excavation depth also has a great influence on the displacement of piles. Moreover, if the excavation depth is deeper, the displacement change will be larger. This conclusion is consistent with the reference 34. Therefore, in the process of foundation pit engineering design, it is necessary to pay attention to the design of excavation conditions. In combination with the actual situation of the project, the trial calculation and simulation should be carried out constantly. By determining the reasonable depth of each excavation, the adverse effects of excavation on nearby piles can be reduced.

Figure 7b shows the comparison diagram of maximum displacement of the cap in the XY direction. Obviously, with the increase of excavation depth, the maximum displacement of the cap increases gradually. When the excavation is completed, the maximum displacements of cap 1, 2, 3, and 4 are 0.53 mm, 0.70 mm, 1.26 mm, and 0.26 mm, respectively. Cap 3 shows a trend of “first rapid increase, then slow increase”. Other caps have shown a “slow growth” trend. At the same excavation stage, the displacement of cap 3 is the largest. The displacement of cap 4 is the least. In addition, it can also be found that the displacements of caps 1, 2, and 4 are relatively close, and the values are relatively small.

Displacement of piles and caps in Z direction.

The displacement in the Z direction can reflect the deformation of the pile in the vertical direction. If the displacement of piles in Z direction is too large, the displacement of cap will also increase. This could cause the viaduct to tilt. A security accident may occur. Therefore, the Z direction displacement analysis of piles has important reference value for evaluating the stability and safety of adjacent viaducts during excavation. Figure 8 shows the displacement cloud diagram of piles in the Z direction. It should be noted that in order to facilitate the analysis and research, the maximum value (including the specific location and value) is marked in Fig. 8. Obviously, excavation will have a certain influence on the displacement of nearby piles. The displacement of piles will change with different excavation depth. This also shows that excavation will indeed have a certain impact on nearby piles.

It can also be seen that excavation will also have a certain impact on the cap. With different excavation depth, the displacement of cap will change constantly. Specifically: as the depth of excavation continues to increase. The displacements of both pile and cap show an increasing trend in general. At the excavation stage 1, the maximum displacement of piles in the Z direction is 2.4 mm. Appears in position at piles 1. The cap is 2.6 mm. The position that appears is on top of cap 1. When the excavation is completed, the maximum displacement of piles is 10.05 mm. The cap is 10.8 mm. It appears in the same position as the first phase of excavation. By comparison, the displacement of piles increases by about 317%. The cap has increased by about 315%. This also shows that excavation will have a certain influence on the displacement of nearby piles and caps. In addition, it can be seen that piles and caps at different positions have different responses to excavation. It also shows that the excavation of foundation pit has a certain spatial effect on the nearby piles and caps.

In order to study the spatial effect of excavation on nearby piles and cap. The maximum value in Fig. 8 is extracted and sorted. Figure 9a shows the comparison diagram of maximum displacement in the Z direction. Obviously, with the increase of excavation depth, the maximum displacement of piles also increases gradually. During excavation stage 1, the maximum displacements of piles 1, 2, 3, and 4 are 2.44 mm, 2.29 mm, 1.51 mm, and 0.11 mm, respectively. When the excavation is completed, it is 10.05 mm, 9.34 mm, 6.21 mm, and 0.38 mm, respectively. By comparison, the maximum displacement increased by 317%, 304%, 313%, and 245%, respectively. It can be seen that the growth rate of piles 1 is the largest. piles 1 showed a trend of “rapid increase at first, then slow increase”. piles 2 and 3 also showed a similar growth law to pile 1. piles 4 showed a “slow growth” trend. At the same stage, the displacement of piles 1 is the largest. The displacement of piles 4 is the smallest.

In addition, the displacement of piles 1 and 2 is the largest, and the difference is small. This shows that the effect of foundation pit excavation on the displacement of piles in Z direction is related to the distance between the piles and the middle of the long side of the foundation pit. The closer the distance, the greater the impact. It is important to note that although the displacement increases at each stage, the amount of increase is different. The first three stages add more. The reason may be that in the first three stages, the depth of each excavation is 4 m. However, in the last three stages, the depth of each excavation is only 2 m. Obviously, the depth of each excavation in the first three stages is greater. It can be seen that each excavation depth also has a great influence on the displacement of piles. Moreover, if the excavation depth is deeper, the displacement change will be larger. This conclusion is consistent with the reference 34.

Figure 9b shows the comparison diagram of maximum displacement of the cap in the Z direction. Obviously, with the increase of excavation depth, the maximum displacement of cap in Z direction also increases gradually. During excavation stage 1, the maximum displacements of cap 1, 2, 3, and 4 are 2.64 mm, 2.46 mm, 1.63 mm, and 0.11 mm, respectively. When the excavation is completed, the maximum displacements are 10.8 mm, 10 mm, 6.71 mm and 0.38 mm respectively. By comparison, the maximum displacement increased by 816%, 754%, 508%, and 245%, respectively. It can be seen that the growth rate of cap 1 is the largest. Cap 1, 2, and 3 all show a trend of “first rapid increase, then slow increase”. On the contrary, cap 4 showed a “slow growth” trend. At the same excavation stage, the displacements of cap 1 and cap 2 are relatively maximum. The displacement of cap 4 is the least. In addition, it can also be found that the displacements of cap 1 and cap 2 are relatively close, and the values are relatively large. This may be because when the excavation is completed, the free surface in the middle of the long side of the foundation pit is the largest, and the overall displacement is the largest under the pressure of the surrounding soil. The distance between caps 1 and 2 and the middle of the long side of the foundation pit is relatively close, so it will have a greater impact.

Figure 10 is the comparison diagram of the maximum displacement of piles in the Z direction. Obviously, with different excavation depth, the displacement of pile in Z direction will also change continuously. With the increase of excavation depth, the displacement in Z direction of all piles increases. Moreover, in the first three stages, the displacement increases relatively quickly. In the last three stages, the displacement increases relatively slowly. The displacement of piles 1 and 2 is relatively large. The displacement of piles 4 is the smallest. Specifically, in Fig. 10a, the displacements from large to small are: piles 1–2, 1–1, 1–3, and 1–4. In Fig. 10b, the displacements in descending order are: piles 2 − 1, 2–2, 2–4, and 2–3. Besides, in Fig. 10c, the displacements in descending order are: piles 3 − 1, 3 − 2, 3–4, and 3–3. In addition, in Fig. 10d, the displacements in descending order are: piles 4 − 1, 4–4, 4 − 2, and 4 − 3. It is not difficult to find that the displacement of piles 1 and 2 is relatively larger. The reason may be that piles 1 and 2 are closer to the middle of the foundation pit, so the impact of foundation pit excavation may be greater. Therefore, the adverse effects of excavation on nearby piles should be considered in the design and construction of foundation pit. It also shows that the influence of foundation pit excavation on nearby piles has a certain spatial effect.

The bending moment of the piles.

The bending moment of piles can reflect the bending deformation of piles under external action. The part with large bending moment value may produce excessive bending deformation, which may lead to cracking and even damage on the tensile side of piles. This may lead to a reduction in the carrying capacity of the bridge. And it may cause security accidents. Therefore, the analysis of pile bending moment has important reference value for evaluating the stability and safety of adjacent viaduct during foundation pit excavation. Figure 11 is the cloud image of bending moment of piles. Obviously, excavation will have a certain influence on the bending moment of nearby piles. The bending moment will change with different excavation depth. This also shows that excavation will indeed have a certain impact on nearby piles. Specifically: as the depth of excavation continues to increase. The bending moment shows a trend of increasing in general. At the excavation stage 1, the maximum bending moment is 753.7 kN·m. When the excavation is completed, the maximum bending moment is 1,140.8 kN·m. The positions that appear are all at pile 1–1. By comparison, it can be obtained that the maximum bending moment increases by about 51.4%.

In addition, at excavation stage 1, the minimum bending moment is −753.7 kN·m. When the excavation is completed, the minimum bending moment is -1,140.8 kN·m. The positions that appear are all at pile 1–1. By comparison, it can be obtained that the minimum bending moment increases by about 51.4%. This also shows that the excavation of foundation pit will have a certain influence on the bending moment of nearby piles. In addition, it can be seen that the bending moment of piles at different positions responds differently to excavation. It also shows that the influence of foundation pit excavation on nearby piles has a certain spatial effect.

In order to study the spatial effect of excavation on nearby piles. The maximum bending moment in Fig. 11 is extracted and sorted. Figure 12a shows the comparison of the maximum bending moment of piles. Obviously, with the increase of foundation pit excavation depth, the maximum bending moment of piles 1 also increases gradually. However, the maximum bending moments of piles 2, 3, and 4 remain almost constant. This shows that the bending moment of piles 1 is sensitive to the excavation depth. The bending moment of the other three piles is less affected by the excavation depth. This also shows that the excavation of foundation pit has a spatial effect on nearby piles. Therefore, in the process of foundation pit design and construction, it is necessary to strengthen the design and monitoring of the bending moment of the piles near the middle of the long side.

Specifically, during the excavation stage 1, the maximum bending moments of piles 1, 2, 3, and 4 are 754 kN·m, 241 kN·m, 437 kN·m, and 312 kN·m, respectively. When the excavation is completed, the values are 1141 kN·m, 245 kN·m, 483 kN·m, and 304 kN·m respectively. By comparison, the maximum displacement increased by 51.3%, 5.4%, 10.5%, and −2.6%, respectively. It can be seen that the growth rate of piles 1 is the largest. piles 1 showed a trend of “rapid increase at first, then slow increase”. piles 2, 3 and 4 showed different growth rules from piles 1. The change is relatively small. At the same excavation stage, the bending moment of piles 1 is the largest. On the contrary, the bending moment of piles 2 is the smallest.

Figure 12b shows the comparison diagram of the minimum bending moment of piles. It can be found that the minimum bending moment of piles in the same excavation stage is consistent with the maximum bending moment. It is worth noting that in the process of foundation pit excavation, the bending moment value of piles has positive and negative values. This indicates a change in the tension side of the bending moment. Therefore, in practical similar projects, it is necessary to determine the specific tension side and compression side of the pile by calculation or monitoring. And targeted bending design and monitoring.

The shear force of the piles.

The shear force of piles can reflect the shear deformation of piles under external action. If the shear force is too large, the pile will have large staggered shear deformation. This may lead to shear cracking of piles and even damage. This will reduce the carrying capacity of the viaduct. And it may cause security accidents. The maximum value and position of shear force have important reference value for evaluating the stability and safety of adjacent viaducts during excavation. Figure 13 shows the shear cloud diagram of piles. Obviously, the excavation of foundation pit will have a certain influence on the shear force of nearby piles. With different excavation depth, the shear value of piles will change constantly. This also shows that excavation will indeed have a certain impact on nearby piles.

Specifically, as the depth of excavation continues to increase. On the whole, the shear force shows a trend of increasing. The sign of shear force can be positive or negative. This shows that the direction of the piles shear force changes. The situation is relatively complicated. Specifically, at the excavation stage 1, the maximum shear value is 876 kN. The minimum value is −1,507 kN. When the excavation is completed, the maximum shear value is 1,206 kN. The minimum value is -2,282 kN. The positions that appear are all at stake 1–1. By comparison, it can be found that the maximum and minimum values of piles shear increase by about 37.7% and 51.4%, respectively. This also shows that excavation will have a certain influence on the nearby piles shear force. It is worth noting that the position of pile 1–1 is closest to the middle of the foundation pit. This also shows that the closer the distance to the foundation pit, the greater the influence of the pile shear force on excavation. In addition, it can be seen that the shear force of piles at different locations is affected by excavation differently. It also shows that excavation has a certain spatial effect on nearby piles.

In order to study the spatial effect of excavation on nearby piles. The maximum and minimum values in Fig. 13 are extracted and sorted. Figure 14a shows the comparison of the maximum shear force of piles at different excavation stages. Obviously, with the increase of excavation depth, the maximum shear force of piles 1 and 2 also increases gradually. The maximum shear values of piles 3 and 4 remain almost constant. During the excavation stage 1, the maximum shear forces of piles 1, 2, 3, and 4 are 649 kN, 490 kN, 876 kN, and 669 kN respectively. When the excavation is completed, it will be 1,206 kN, 490 kN, 965 kN, and 656 kN respectively. By comparison, the maximum values increased by 85.8%, 0%, 10%, and −1.9% respectively. It can be seen that the growth rate of piles 1 is the largest. It can also be seen that the maximum shear force of piles 1 shows a changing trend of “first rapid increase, then slow increase”. piles 3 showed a trend of “slow growth”. piles 2 and 4 showed a “stable and unchanged” trend. Generally speaking, the shear force of piles 1 is the largest in the same excavation stage. The value of piles 2 is the smallest. This can also show that the influence of excavation is related to the distance between the piles and the middle of the long side of the foundation pit. The closer the distance, the greater the impact.

Figure 14b shows the comparison diagram of the minimum shear force of piles. Obviously, with the increase of excavation depth, the minimum shear value of piles 1 and 3 also increases gradually. The minimum shear values of piles 2 and 4 remain almost unchanged. At the excavation stage 1, the minimum shear forces of piles 1, 2, 3, and 4 are −1,507 kN, -482 kN, -364 kN, and -493 kN respectively. When the foundation pit is completed, it is -2,282 kN, -469 kN, -466 kN, and -462 kN respectively. By comparison, the minimum shear increased by 51.4%, 2.6%, 28%, and -6.2%, respectively. It can be seen that the growth rate of piles 1 is the largest. It can also be seen that the minimum shear value of piles 1 shows a changing trend of “first rapid increase, then slow increase”. piles 4 showed a trend of “first decreasing, then increasing, and then stabilizing”. piles 2 showed a stable and unchanged trend. piles 3 showed a gradually increasing trend. Generally speaking, the shear force of piles 1 is the largest in the same excavation stage. The shear force of piles 3 is the smallest. This can also show that the influence of foundation pit excavation is related to the distance between the piles and the middle of the long side of the foundation pit. The closer the distance, the greater the impact.

The axial force of the piles.

Axial force can reflect the compression and tension of piles under external action. If the axial force is too large, the pile will have a large axial deformation. This will lead to piles cracking and even damage. Furthermore, the bearing capacity of the bridge span may be reduced. And it may cause security accidents. The maximum value and location of axial force have important reference value for evaluating the stability and safety of adjacent viaducts during excavation. Figure 15 shows the axial force cloud diagram of piles. It should be noted that the plus sign means tension, and the minus sign means pressure. Obviously, the pile is mainly under pressure. In addition, the axial force values of piles remain basically unchanged with different excavation depths. This shows that excavation has relatively little influence on the axial force of nearby piles. In other words, the axial force of piles is not sensitive to excavation. This may be because the spatial position of the pile is straight up. Axial force is the axial pull or pressure of the pile. Therefore, the vertical load will have a great influence on the axial force of the pile. The influence of excavation on pile in this study is mainly horizontal. The horizontal direction and vertical direction are in the orthogonal state, so the influence on the pile axial force is small. This also verifies the reliability of the model established in this study from another perspective.

Specifically, as the depth of excavation continues to increase. On the whole, the axial force of piles shows the trend of “stable and unchanged”. The signs of axial forces can be positive or negative. This shows that the axial force produced by the piles is not only the tension but also the pressure. Specifically, in the excavation stage 1, the maximum tensile force value of piles is 3,384 kN. The maximum pressure is −12,945 kN. When the excavation is completed, the maximum tensile force value of piles is 3,377 kN. The maximum pressure is -13,116 kN. By comparison, it can be obtained that the maximum tensile force and pressure of piles increase by about -0.2% and 1.3% respectively. It also shows that the influence of foundation pit excavation on the axial force of nearby piles is relatively small.

In order to study the influence of foundation pit excavation on the axial force of nearby piles. The maximum axial force of piles in Fig. 15 is extracted and sorted out. Figure 16a comparison of the maximum tensile force of piles. Obviously, with the increase of excavation depth, the maximum tensile force of all axial forces is basically stable. When the excavation is completed, the maximum tensile forces of piles 1, 2, 3 and 4 are 2,668 kN, 3,269 kN, 3,377 kN and 1,270 kN, respectively. Obviously, piles 3 has the greatest pull. The value of piles 4 is the smallest. It should be noted that, although it can be seen from the above analysis that the axial force of piles is not sensitive to the depth of excavation. But the axial force of piles at different positions is different. It also shows that excavation has a certain spatial effect on nearby piles.

Figure 16b shows the comparison diagram of the maximum pressure of piles at different excavation stages. Obviously, with the increase of excavation depth, the maximum axial force pressure of all piles remains stable. When the excavation is completed, the maximum pressure values of piles 1, 2, 3 and 4 are −13,116 kN, -10,853 kN, -11,689 kN and -11,194 kN, respectively. Obviously, piles 1 has the greatest pressure. The value of piles 2 is the smallest. The biggest reason for the value of piles 1 may be that the excavation will cause the adjacent soil to move in the horizontal direction to the interior of the foundation pit. This will cause some loosening of the soil around the nearby piles. Then the horizontal contact force between pile and soil is reduced17. As a result, the ultimate friction force of pile side decreases. In order to maintain the balance of vertical forces, the pile will produce greater axial forces. The spatial position of piles 1 is closest to the middle of foundation pit. Therefore, the impact of foundation pit excavation will be greater. Then, the phenomenon of maximum pressure of piles 1 appears.

Discussion

Through this study, it is found that deep foundation pit excavation has a certain influence on the stress and deformation characteristics of adjacent bridge piles. The displacement, bending moment and shear force of bridge pile are sensitive to the excavation depth of foundation pit. It increases with the increase of excavation depth. The axial force is not sensitive to the depth of excavation. The deformation and internal force of bridge piles have obvious spatial distribution characteristics, and the closer the distance to the middle of the long side of the foundation pit, the greater the value. Therefore, in the future related projects, it is necessary to strengthen the monitoring of the displacement and internal force of the bridge piles closest to the middle of the long side of the foundation pit to prevent engineering accidents. Therefore, the results of this study can be used in the design stage and construction stage of engineering construction. However, the distance between foundation pit and piles is small (See Fig. 1 for specific locations). The stress and deformation characteristics of the supporting structure may also be affected by nearby piles. Therefore, it is necessary to discuss the deformation characteristics of the foundation pit supporting structure of adjacent piles.

In this discussion, the underground diaphragm wall is selected as the research object. Figure 17 shows the total displacement cloud image of the underground diaphragm wall. Obviously, the total displacement cloud image shows asymmetric characteristics. This is different from the excavation results under conventional conditions18,31,32,33. This shows that the adjacent piles do have a certain influence on the excavation of the foundation pit. At the same time, it also shows that the general displacement of both sides of the diaphragm wall is different. Obviously, with the increase of excavation depth, the displacement of the underground diaphragm wall near the piles is smaller than that on the other side. This may be because the piles are relatively close to the diaphragm wall. The structural characteristics of bridge piles are rigid, which together with the cap forms the foundation of the bridge. The pile and cap limit the displacement of the surrounding soil. The effect of surrounding soil on the diaphragm wall is reduced. It is shown that the total displacement of the diaphragm wall near the piles side is smaller than that on the other side. In other words, the deformation of the diaphragm wall is inhibited by piles.

In addition, the displacement response of diaphragm walls at different locations is different. Therefore, the reinforcement configuration of the underground continuous wall on both sides of the foundation pit should consider the actual situation of the influence of close piles on the deep foundation pit respectively. Specifically: as the depth of excavation continues to increase. The total displacement showed an increasing trend. The maximum value occurs in the middle of the diaphragm wall. When the excavation is completed, the maximum displacement is 22.31 mm. The place where the maximum displacement occurs is small, accounting for about 4.4% of the entire underground diaphragm wall area. The minimum displacement is 13.48 mm. The area where the minimum displacement occurs is large, accounting for about 10.6% of the entire underground diaphragm wall area. The minimum value occurs at the corner of the diaphragm wall. It can be seen that the middle of the underground diaphragm wall will have the largest deformation during the excavation of the foundation pit. Therefore, the middle part is the weak part. It is necessary to focus on the design and monitoring of the middle part of the underground diaphragm wall to ensure safety. The changes of the maximum and minimum total displacement of the underground diaphragm wall are shown in Fig. 18.

The disadvantages of this study are as follows: Firstly, there are relatively few influencing factors in the process of foundation pit excavation. The influence factors such as pipeline, earthmoving truck load, building, rain weather, excavator construction disturbance, and site loading are not considered. There are relatively few influencing factors, and there is room for further enrichment. Secondly, this paper mainly studies the influence of deep foundation pit excavation on the stress and deformation characteristics of adjacent piles. There is no relevant research on the stress and deformation characteristics of the supporting structure of the deep foundation pit near the piles. Thirdly, the effect of groundwater on excavation of foundation pits was not considered in this study. In addition, this study did not consider the influence of changes in some influencing factors, such as the length of the pile, the diameter of the pile, and the distance between the pile and the foundation pit.

Future research directions are as follows: Firstly, consider more influencing factors. More comprehensive consideration of environmental factors around the foundation pit. Including, the possible pipeline around the foundation pit, earthmoving truck load, buildings, rain weather, excavator construction disturbance, foundation pit dewatering, soil creep, formation parameters, and site loading and so on. Secondly, on the basis of this study, relevant studies on the stress and deformation characteristics of the supporting structure of deep foundation pit near the piles will be carried out. Thirdly, the influence of foundation pit excavation on nearby buildings, tunnels and underground pipelines are also taken into account. In addition, the future research will focus on the possible surface rainfall and the influence of groundwater on the excavation of the foundation pit. On the one hand, a related potential experiment is to simulate surface rainfall. On the other hand, according to the relevant field research for part of the need for dewatering foundation pit. The influence of foundation pit dewatering is monitored during construction. In addition, according to the actual needs, the influence of foundation pit dewatering on foundation pit excavation is selectively added in the numerical simulation process. Besides, the length of the pile, the diameter of the pile, and the distance between the pile and the foundation pit are also important factors to consider in future research.

Conclusions

In this paper, a three-dimensional finite element model is established to study the influence of foundation pit excavation on the mechanical behavior of adjacent piles. The main conclusions drawn from this investigation are as follows:

-

(1)

Based on the modified Mohr-Coulomb constitutive model, MIDAS GTS NX software is used to numerically simulate the whole process of excavation and support installation. The influence of foundation pit excavation on the mechanical behavior of adjacent piles is studied. The reliability of the model is verified by comparing the simulation results with the measured data.

-

(2)

With increasing excavation depth, the displacements of piles and cap in XY and Z directions increase. When the excavation is completed, the maximum displacement of the pile in the XY direction is 2.3 mm. The maximum value occurs at piles 2. The maximum displacement of the cap is 1.26 mm. The maximum value occurs at the top of cap 3. The maximum displacement of piles in the Z direction is 10.05 mm. The maximum value occurs at piles 1. The cap has a value of 10.8 mm. The maximum value occurs at the top of cap 1. Each excavation depth has a great influence on the displacement of piles. The deeper the excavation, the greater the displacement change. The displacement of piles and cap has obvious spatial distribution characteristics. The closer it gets to the middle of the long side of the deep excavation, the larger the value becomes.

-

(3)

With the continuous increase of excavation depth, the bending moment and shear force of piles show an increasing trend. When the excavation is completed, the maximum bending moment of piles is 1,140.8 kN·m. The minimum value is −1,140.8 kN·m. The maximum shear value of piles is 1,206 kN. The minimum value is -2,282 kN. The maximum value is at pile 1–1. The bending moment and shear force of piles also have obvious spatial distribution characteristics. The closer to the middle of the long side of the deep excavation, the greater the value will become.

-

(4)

Piles are mainly under pressure. The axial force is not sensitive to the depth of excavation. The axial force values of piles remain unchanged when changing the excavation depth. When the excavation is completed, the maximum tensile force value of piles is 3,377 kN. The maximum pressure is −13,116 kN. The maximum pressure value occurs at piles 1.

-

(5)

When there are piles near a deep excavation, it is necessary to comprehensively analyze the influence of various factors (e.g., the depth of deep foundation pit excavation and construction conditions) on adjacent piles from multiple dimensions. At the same time, it is necessary to strengthen the monitoring and measures for controlling the displacement and internal force of the piles closest to the middle of the long side of the deep excavation. This will prevent excessive displacement and internal forces from having detrimental effects on the stability and safety of the engineering structure.

Data availability

All data generated or analysed during this study are included in this article.

References

Shi, X. et al. Stability analysis of deep foundation pit with a double-row cast-in-place piles and diagonal steel lattice braces under sloped excavation conditions. Sci. Rep. 14, 22761. https://doi.org/10.1038/s41598-024-73528-z (2024).

Zhang, Z. et al. Study on the critical stable height of vertical excavation in rocky foundation pit within layered structural plane. Sci. Rep. 14, 12191. https://doi.org/10.1038/s41598-024-63063-2 (2024).

Mu, Z. et al. Analysis of shield tunnel response to bilateral pit excavation with a focus on perimeter pressure and deformation mechanisms. Sci. Rep. 14, 23167. https://doi.org/10.1038/s41598-024-72731-2 (2024).

Niu, Y., Wang, Q. & Ma, F. Study on the influence of reverse faulting on deformation of foundation pit retaining piles. Sci. Rep. 13, 17460. https://doi.org/10.1038/s41598-023-44805-0 (2023).

Wei, X. et al. ANN deformation prediction model for deep foundation pit with considering the influence of rainfall. Sci. Rep. 13, 22664. https://doi.org/10.1038/s41598-023-49579-z (2023).

Guo, P. et al. Analysis of observed performance of a deep excavation straddled by shallowly buried pressurized pipelines and underneath traversed by planned tunnels[J].Tunnelling and underground space technology, (2023). https://doi.org/10.1016/j.tust.2022.104946

Guo, P., Gong, X. & Wang, Y. Displacement and force analyses of braced structure of deep excavation considering unsymmetrical surcharge effect[J]. Comput. Geotech. 113 (SEP.), 103102DOI. https://doi.org/10.1016/j.compgeo.2019.103102 (2019).

He, M., Sui, Q. & Tao, Z. Excavation compensation theory and supplementary technology system for large deformation disasters. Deep Undergr. Sci. Eng. 2, 105–128 (2023).

Guo, P. et al. Predicting response of constructed tunnel to adjacent excavation with Dewatering[J].Geofluids, 2021(3):1–17. (2021). https://doi.org/10.1155/2021/5548817

Guo, P. et al. Minimum cover depth estimation for underwater shield tunnels[J]. Tunn. Undergr. Space Technol. 115 (5), 104027. https://doi.org/10.1016/j.tust.2021.104027 (2021).

Guo, P. et al. Soil Creep Effect on Time-Dependent deformation of Deep Braced Excavation[J]. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2022/5655592 (2022).

Wang, J. et al. Control and prevent land subsidence caused by foundation pit dewatering in a coastal lowland megacity: indicator definition, numerical simulation, and regression analysis. Environ. Earth Sci. 82, 66. https://doi.org/10.1007/s12665-022-10708-y (2023).

Han, Y. et al. Application of regularized ELM optimized by sine algorithm in prediction of ground settlement around foundation pit. Environ. Earth Sci. 81, 413. https://doi.org/10.1007/s12665-022-10542-2 (2022).

Wang, Y. et al. Simplified Analytical solutions for tunnel Settlement Induced by axially loading single pile and Pile Group[J]. J. Eng. Mech. https://doi.org/10.1061/(asce)em.1943-7889.0002035 (2021).

Ma, S. et al. Research on the protection effect and parameter optimization design of isolation pile-diaphragm wall combination support structure. Sādhanā 49, 82. https://doi.org/10.1007/s12046-024-02432-z (2024).

Xie, W. et al. A Novel Stability Analysis Method of Diaphragm Wall Trench and its application. Geotech. Geol. Eng. 41, 1603–1613. https://doi.org/10.1007/s10706-022-02356-7 (2023).

Saadi, R., Khennouf, A. & Baheddi, M. Seismic design of diaphragm wall nearby building to minimize the differential displacement during an earthquake. Innov. Infrastruct. Solut. 9, 151. https://doi.org/10.1007/s41062-024-01468-8 (2024).

Al-Ne’aimi, R. M. S. & Nasir, H. K. Numerical study of design parameters influencing anchored diaphragm walls for deep excavation. Innov. Infrastruct. Solut. 8, 301. https://doi.org/10.1007/s41062-023-01261-z (2023).

Pan, J., Sharma, V. & Chen, W. Influence of several structural parameters on the behavior of a dual row diaphragm wall supporting structure system. Innov. Infrastruct. Solut. 7, 176. https://doi.org/10.1007/s41062-022-00779-y (2022).

Liu, T. Y. et al. Challenges and sustainability-based solutions of Diaphragm Wall Construction for LG06 Underground Station in Taipei MRT. Transp. Infrastruct. Geotech. 10, 17–40. https://doi.org/10.1007/s40515-021-00208-0 (2023).

Ma, S. et al. A combined support method of isolation pile and diaphragm wall for protection of buildings adjacent to deep foundation pit. Arab. J. Geosci. 14, 2005. https://doi.org/10.1007/s12517-021-08345-z (2021).

Laboyko, R. Y. & Solsky, S. V. Improving the Condition monitoring of an embankment dam with a Clay-Cement-Concrete Diaphragm. Power Technol. Eng. 58, 412–416. https://doi.org/10.1007/s10749-024-01827-6 (2024).

Haque, M. F. & Ansary, M. A. Seismic performance of concrete tunnel–sand–pile interaction by the shake table test. Deep Undergr. Sci. Eng. 1–21. (2024).

Wang, Y. et al. Performance of Deep Braced Excavation under embankment surcharge load. Geotech. Geol. Eng. 41, 3575–3586. https://doi.org/10.1007/s10706-023-02474-w (2023).

Yin, H. et al. Sheltering effect induced by established station to the new station excavation in Zhengzhou. Archiv Civ. Mech. Eng. 23, 175. https://doi.org/10.1007/s43452-023-00716-5 (2023).

Li, Y. et al. Mechanical response analysis of buried natural gas pipelines due to excavation unloading. Sādhanā 49, 129. https://doi.org/10.1007/s12046-024-02488-x (2024).

Lin, P. et al. Deformation Monitoring Analysis and Numerical Simulation in a Deep Foundation pit. Soil. Mech. Found. Eng. 58, 56–62. https://doi.org/10.1007/s11204-021-09706-2 (2021).

Wang, H. Effect of genetic algorithm in optimizing deep foundation pit supporting structure. Arab. J. Geosci. 14, 266. https://doi.org/10.1007/s12517-021-06602-9 (2021).

Shaaban, M. G. I. et al. Effects of excavation and construction sequence on behavior of existing pile groups. Innov. Infrastruct. Solut. 8, 223. https://doi.org/10.1007/s41062-023-01193-8 (2023).

Yeh, T. Y., Ou, C. Y. & Lim, A. A case study of strut-free excavation retaining system. Acta Geotech. 17, 5557–5571. https://doi.org/10.1007/s11440-022-01526-4 (2022).

Van Nguyen, D., Kim, D. & Choo, Y. Nonlinear seismic performance of buildings considering deep excavation-soil-structure interaction. Bull. Earthq. Eng. 22, 5119–5145. https://doi.org/10.1007/s10518-024-01966-1 (2024).

Zhang, W. et al. Research on Support Technology of a soil-rock combination deep excavation in Qingdao. KSCE J. Civ. Eng. 28, 3208–3223. https://doi.org/10.1007/s12205-024-2199-5 (2024).

Rao, P. et al. Field study on Rectangular Inclined Deep Foundation Excavation in Soft soils. Geotech. Geol. Eng. 42, 2151–2168. https://doi.org/10.1007/s10706-023-02666-4 (2024).

Wang, H. & He, S. Monitoring and Simulation Analysis of Deep Foundation Pit Excavation of Subway Station in Watery and weak stratum. Indian Geotech. J. https://doi.org/10.1007/s40098-023-00837-x (2024).

Peng, T. et al. Deformation characteristics of Soft Soil Induced by Deep Excavation and its impact on adjacent tunnels: a Case Study in Shanghai. KSCE J. Civ. Eng. 28, 1715–1728. https://doi.org/10.1007/s12205-024-0487-8 (2024).

Ganesh, K. M. et al. Sensitivity analysis of Excavation Support systems using Numerical Modelling. J. Inst. Eng. India Ser. D. 105, 1127–1136. https://doi.org/10.1007/s40033-023-00589-1 (2024).

Ding, W. et al. Analysis of the influence of Pile Underpinning of the Pile Group under the viaduct of the overlapping Shield tunnel on the surrounding environment. Int. J. Civ. Eng. 22, 1807–1833. https://doi.org/10.1007/s40999-024-00988-9 (2024).

Lei, H. et al. Influence of Foundation pit groups’ excavation on the deformation characteristics of adjacent railway Subgrade and Protection measures. Geotech. Geol. Eng. 41, 3877–3895. https://doi.org/10.1007/s10706-023-02493-7 (2023).

Feng, S. et al. Influencing factors and control measures of excavation on adjacent bridge foundation based on analytic hierarchy process and finite element method. Front. Struct. Civ. Eng. 15, 461–477. https://doi.org/10.1007/s11709-021-0705-0 (2021).

Wang, C. et al. Study of Ground Vibration caused by high-speed trains through bridges based on finite element Model: test validation. KSCE J. Civ. Eng. 28, 3758–3767. https://doi.org/10.1007/s12205-024-1316-9 (2024).

Zhao, R. et al. State-of-the-art and annual progress of bridge engineering in 2021. ABEN 3 (29). https://doi.org/10.1186/s43251-022-00070-1 (2022).

Yang, Y. et al. Influence of deep excavation on adjacent bridge piles considering underlying karst cavern: a case history and numerical investigation. Acta Geotech. 17, 545–562. https://doi.org/10.1007/s11440-021-01213-w (2022).

Phutthananon, C. et al. Improved prediction of pile bending moment and deflection due to adjacent braced excavation. Front. Struct. Civ. Eng. 17, 1739–1759. https://doi.org/10.1007/s11709-023-0961-2 (2023).

Cheng, K. et al. Performance of Diaphragm Walls in Soft Clay of a deep basement excavation. Soil. Mech. Found. Eng. 59, 159–166. https://doi.org/10.1007/s11204-022-09797-5 (2022).

Laboyko, R. Y. Features of Monitoring Ground-Dam conditions using a diaphragm from clay-cement concrete bored-secant piles. Power Technol. Eng. 57, 852–857. https://doi.org/10.1007/s10749-024-01747-5 (2024).

Li, D. et al. A new method for piping risk evaluation on unconfined aquifers under dewatering of Deep Foundation Pits. KSCE J. Civ. Eng. 26, 3275–3286. https://doi.org/10.1007/s12205-022-0965-9 (2022).

Zhao, P., Sun, Y., Wang, Z. & Guo, P. Mechanical characteristics of deep excavation support structure with asymmetric load on Ground Surface. Symmetry 16, 1309. https://doi.org/10.3390/sym16101309 (2024).

Lyman, R. A., Lim, A. & Rahardjo, P. P. Estimating System Stiffness of Soil Nailing Wall for Deep Excavation in Clay. Int. J. Civ. Eng. 20, 1009–1025. https://doi.org/10.1007/s40999-022-00722-3 (2022).

Liu, G. et al. Measured behaviors of an oversized irregular basement excavation and its surrounding responses in thick soft clay. Arab. J. Geosci. 13, 3. https://doi.org/10.1007/s12517-019-4979-7 (2020).

Acknowledgements

This research was funded by the Fundamental Research Funds for the Central Universities, grant numbers JZ2023HGQA0094 and JZ2023HGTA0193, the Tongling Huabao Project Management Co., LTD Sponsored Research Project, grant number 2024tlxyxdz214, and the Opening Project of State Key Laboratory of Explosion Science and Technology (Beijing Institute of Technology), grant number KFJJ23-05 M.

Author information

Authors and Affiliations

Contributions

Conceptualization, P.Z. and P.G.; methodology, P.G.; software, P.Z.; validation, Z.W. and P.Z.; formal analysis, P.Z. and Z.W.; investigation, P.Z. and Y.Q.; resources, P.G. and Z.W.; data curation, P.Z.; writing—original draft preparation, P.Z. and Y.Q.; writ-ing—review and editing, P.G. and Z.W.; visualization, Y.Q.; supervision, P.G.; project administration, Z.W. and P.Z.; funding acquisition, P.G. and Z.W.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, P., Qiu, Y., Wang, Z. et al. Mechanical response of elevated bridge piles to adjacent deep excavation. Sci Rep 15, 1766 (2025). https://doi.org/10.1038/s41598-025-85853-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-85853-y

Keywords

This article is cited by

-

Parameters determination methods and project validation of hardening soil model with small strain stiffness based on finite element method

Scientific Reports (2025)

-

Investigation on performance of steel strut servo system braced deep excavation adjacent to existing buildings: a case study

Scientific Reports (2025)

-

Performance of typical structural components in basement-addition for existing building

Scientific Reports (2025)

-

Hotel underground parking garage renovation project: finite element analysis of deep excavation induced effects

Discover Applied Sciences (2025)