Abstract

Nylon 12 is valued for its exceptional properties and diverse industrial applications. Traditional chemical synthesis of nylon 12 faces significant technical challenges and environmental concerns, while bioproduction from plant-extracted decanoic acid (DDA) raises issues related to deforestation and biodiversity loss. Here, we show the development of an engineered Escherichia coli cell factory capable of biosynthesizing the nylon 12 monomer, ω-aminododecanoic acid (ω-AmDDA), from glucose. We enable de novo biosynthesis of ω-AmDDA by introducing a thioesterase specific to C12 acyl-ACP and a multi-enzyme cascade converting DDA to ω-AmDDA. Through modular pathway engineering, redesign and dimerization enhancement of the rate-limiting P450, reconstruction of redox and energy homeostasis, and enhancement of oxidative stress tolerance, we achieve a production level of 471.5 mg/L ω-AmDDA from glucose in shake flasks. This work paves the way for sustainable nylon 12 production and offers insights for bioproduction of other fatty acid-derived products.

Similar content being viewed by others

Introduction

As an important representative of aliphatic polyamides, nylon 12 exhibits excellent properties, including low water absorption, low relative density, high abrasion resistance, flame resistance, chemical resistance, and good weather resistance. Due to these advantages, nylon 12 is widely used in various fields such as 3D printing, automotive manufacturing, oil and gas exploitation, medical instruments, electronics, and other fields such as offshore pipelines and automotive parts1. However, the chemical synthesis of nylon 12 involves multiple steps and the use of toxic and corrosive raw materials, leading to high technical barriers and environmental concerns. Consequently, the bio-based synthesis of nylon 12 has garnered increasing attention in recent years.

Currently, the bioproduction of nylon 12 monomers is mainly achieved through multi-enzyme cascade reactions converting dodecanoic acid (DDA) or its esters to ω-aminododecanoic acid (ω-AmDDA) or its esters2,3,4,5. In our previous work, we successfully constructed a cofactor self-sufficient multi-enzyme cascade pathway in E. coli for the biotransformation of DDA to ω-AmDDA6. This approach, combined with P450 directed evolution and enhanced heme supply, resulted in the production of 9.4 mM ω-AmDDA7. In all these studies, the substrate DDA and its derivatives were typically sourced from coconut oil and palm kernel oil. While the vegetable oil pathway offers high efficiency, it raises significant environmental concerns related to deforestation and biodiversity loss8. In addition, using edible vegetable oils for industrial oleochemical production intensifies the debate over whether land should be allocated for fuel or food9. These challenges could be mitigated if the nylon 12 monomer ω-AmDDA could be produced from glucose using microbial cell factories. The glucose pathway presents a more sustainable alternative with superior land use efficiency (please refer to Supplementary Note 1 for the calculation details), especially when utilizing non-food biomass. Although the theoretical maximum yield of the glucose pathway is lower due to its longer process, the substantially lower feedstock price and markedly higher land use efficiency of glucose production provide a strong foundation for its competitiveness. Moreover, ongoing advancements in metabolic engineering would steadily improve the actual yields of the glucose pathway. As research progresses, this pathway has the potential to not only match but also to surpass the overall efficiency of the vegetable oil pathway, when considering both economic and environmental factors.

Using E. coli as the chassis, genome-scale genetic perturbation has successfully produced up to 30 g/L of free fatty acids10. For de novo biosynthesis of nylon 12 monomer, the selective synthesis of fatty acid with a chain length of 12 carbons is essential. Voelker et al. have demonstrated the production of a high proportion of free DDA in E. coli by introducing the medium-chain acyl-ACP thioesterase BTE from Umbellularia californica11. If this enzyme could be heterologously expressed in E. coli together with the multi-enzyme cascade pathway that converts DDA to ω-AmDDA6, the selective accumulation of DDA as an intermediate may enable the de novo biosynthesis of ω-AmDDA from glucose.

A sufficient supply of DDA as the key precursor and its efficient conversion to ω-AmDDA is essential for high production of the nylon 12 monomer, which makes the regulation of the cell factory challenging. Dozens of genes are involved in the endogenous metabolic network and the heterologous synthetic pathway, along with the requirement for various metals and multiple cofactors such as NADPH, NADH, and pyridoxal 5’-phosphate (PLP) to support enzyme activities12. Additionally, the heterologous product and intermediates may exert adverse effects on the chassis cells13. Therefore, the performance of an ω-AmDDA cell factory is combinatorically determined by the balanced expression and activity of both endogenous and heterologous enzymes, availability of multiple cofactors, and tolerance to the toxic metabolites.

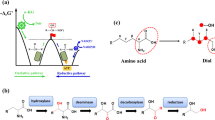

In this work, we develop a multi-level regulation strategy to enable efficient de novo biosynthesis of nylon 12 monomer ω-AmDDA from glucose, a cost-effective and renewable feedstock. We integrate modular pathway engineering, cofactor engineering, tolerance engineering, and protein engineering to optimize the complex synthetic pathway. By bridging endogenous fatty acid metabolism with a heterologous multi-enzyme cascade that converts DDA to ω-AmDDA, we construct an engineered E. coli strain capable of biosynthesizing ω-AmDDA from glucose. Additionally, we reconstruct the metabolic balance in this cell factory by strengthening and balancing the four pathway modules (glycolysis, acetyl-CoA activation, acyl-ACP synthesis, and heterologous DDA transformation), regulating NAD(P)H and ATP supply, enhancing oxidative stress tolerance, and engineering the rate-limiting P450 (Fig. 1). This comprehensive approach results in the construction of an efficient ω-AmDDA cell factory, paving the way for sustainable glucose-derived nylon 12 production.

Results

Construction of the de novo synthetic pathway of ω-AmDDA

In our previous study of ω-AmDDA bioproduction from DDA, E. coli strain B1-1 (E. coli BL21 (DE3)-ΔfadD::PlacUV5-alkL)6 was constructed as a chassis cell by deleting fadD encoding the key enzyme in fatty acid β-oxidation to block DDA degradation and integrating alkL encoding the outer membrane protein AlkL from Pseudomonas putida GPo1 to enhance DDA import. The U. californica thioesterase BTE with high catalytic specificity towards saturated C12-ACP11 was expressed on the high-copy plasmid pRSFDuet-1 (named module R-BTE) and transformed into B1-1, generating strain B1-1 (R-BTE), which produced DDA with high selectivity (Fig. 2). When module R-BTE was transformed together with the modules E-M1-3 and C-M2-26 composing the multi-enzyme cascade pathway for converting DDA to ω-AmDDA, the resulting strain B1-1 (R-BTE/E-M1-3/C-M2-2) produced 3.3 mg/L of ω-AmDDA from glucose after 24 h of cultivation (Fig. 2). In contrast, the control strain B1-1 (pRSF/E-M1-3/C-M2-2) without the bte gene produced no ω-AmDDA. After optimization of the culture conditions, including pH adjustment, inducer concentration, supplementation of ammonia salt and carbon source, flask type, and culture temperature, the ω-AmDDA titer reached 27.5 mg/L (Supplementary Fig. 1).

The left panels show the pathway modules constructed in strains B1-1 (R-BTE) and B1-1 (R-BTE/E-M1-3/C-M2-2). The upper right panel shows the GC spectra of the culture broth of strain B1-1 (R-BTE) and the DDA standard. The lower right panel shows the HPLC spectra of the culture broth of strains B1-1 (R-BTE/E-M1-3/C-M2-2) and B1-1 (pRSF/E-M1-3/C-M2-2) together with the ω-AmDDA standard. The OD600 at the time of induction was approximately 1.0 and the fermentation time was 24 h after induction. DDA dodecanoic acid, FA13 tridecanoic acid, ω-OHDDA ω-Hydroxydodecanoic acid, ω-AmDDA ω-aminododecanoic acid.

Recompositing the ω-AmDDA cell factory

In the de novo synthetic pathway of ω-AmDDA constructed above, the zinc dependence of BsADHC257L contradicts the zinc-inhibitory feature of BTE (100% inhibition with 1 mM Zn2+)14. Considering the crucial role of BTE in the synthetic pathway, which connects the heterologous pathway with the endogenous FAS II pathway by producing DDA from acyl-ACP, replacing BsADHC257L with an alcohol dehydrogenase that is not dependent on zinc would be advantageous. When the BsADHC257L-containing module C-M2-2 was replaced with module C-M2-A harboring the zinc-independent alcohol dehydrogenase AlkJ15 which utilizes ubiquinone as the electron acceptor to catalyze the irreversible oxidation of alcohols16, the resulting strain B1-1 (R-BTE/E-M1-3/C-M2-A) produced 48.1 mg/L of ω-AmDDA (Fig. 3A), representing a 75% improvement over strain B1-1 (R-BTE/E-M1-3/C-M2-2). In addition to zinc independence, other advantages of AlkJ include the independence of NAD+ availability and membrane-binding feature, which may facilitate easier access to hydrophobic substrates17. Some studies reported that AlkJ selectively oxidizes primary aliphatic alcohols to the corresponding aldehydes18, while others have noted its overoxidation activity19. In the de novo biosynthesis system of ω-AmDDA, no α,ω-dodecanedioic acid (α,ω-DCA) was detected (Fig. 3A), possibly due to the relatively lower overoxidation activity of AlkJ compared to the transamination activity of ω-transaminase (ω-TA) in the multi-enzyme cassette.

A Re-selection of the alcohol dehydrogenase. B Re-selection of the host. C Re-selection of the selective marker. The OD600 at the time of induction was approximately 1.0 and the fermentation time was 24 h after induction. α, ω-DCA α,ω-dodecanedioic acid, ω-AmDDA ω-aminododecanoic acid, AmpR ampicillin resistance, AprR apramycin resistance. All values presented are the means of three biological replicates, and error bars represent standard deviations. Source data are provided as a Source Data file.

When R-BTE, E-M1-3, and C-M2-A modules were introduced into strain P1-16, where the PLP supply was strengthened by overexpressing Bacillus subtilis yaaDE, the ω-AmDDA production was further enhanced by 28%, reaching 61.6 mg/L (Fig. 3B). In contrast, when the same modules were transformed into strain BΔD that did not express AlkL for promoting substrate import6, the ω-AmDDA production was reduced by 20%. These results suggest that DDA and/or ω-OHDDA may be exported during the de novo biosynthetic process, highlighting the role of AlkL in importing the secreted DDA and/or ω-OHDDA back into the cells for further reactions. Therefore, strain P1-1 with both strengthened PLP supply and AlkL overexpression was used as the host in the subsequent experiments.

During cultivation of the engineered strains, obvious satellite colonies were observed after 16 h of growth on LB agar plates with selective pressure (Fig. 3C). The selective marker in the E-M1-3 module responsible for DDA hydroxylation was the ampicillin resistance (AmpR) gene, which functions by decomposing ampicillin20. It may lead to a partial loss of selective pressure during the prolonged cultivation required for the de novo biosynthesis of ω-AmDDA. To address this issue, the selective marker in the E-M1-3 module was changed from AmpR to apramycin resistance (AprR), which confers resistance to apramycin, an aminoglycoside antibiotic. Unlike AmpR, its mode of action involves inhibiting bacterial protein synthesis by blocking the ribosomal translocation step21. The resulting strain P1-1 (R-BTE/EApr-M1-3/C-M2-A) containing the EApr-M1-3 module produced 80.9 mg/L of ω-AmDDA, representing a 30% improvement (Fig. 3C).

Modular pathway engineering for enhanced de novo biosynthesis of ω-AmDDA

A sufficient supply of precursors is essential for efficient production. Therefore, ω-AmDDA biosynthesis may be further improved by strengthening the DDA synthesis in strain P1-1 (R-BTE/EApr-M1-3/C-M2-A). As critical precursors in the fatty acid synthesis pathway, acetyl-CoA and propionyl-CoA play key roles in DDA synthesis, and enhancing their flux may lead to increased DDA accumulation22,23. LpdA_EF from Enterococcus faecalis which has been reported to improve the production of acetyl-CoA24, the Corynebacterium glutamicum ACC that promotes the synthesis of various propionyl-CoA derivatives25, and the natural transcriptional regulator of fatty acid metabolism FadR10, were overexpressed in the R-BTE module. However, the yield of the recombinant strains containing these fatty acid synthesis modules all decreased (Supplementary Fig. 2), possibly due to the excessive metabolic burden caused by overexpressing these enzymes on a high-copy plasmid. These genes were then overexpressed in single copies by genomic integration instead.

To simplify the manipulation, the DDA synthetic pathway was divided into three modules based on the central metabolic pathways: the upstream glycolysis module GLY M composed of Pgk, GapA, AceE, AceF, and LpdA_EF from E. coli K12; the acetyl-CoA activation module ACA M composed of AccA, AccB, AccC, AccD, and FabD from E. coli K12 (or FabD_COE from S. coelicolor); and the acyl-ACP synthesis module FAS M composed of FabA, FabH, FabG, and FabI from E. coli K12 (Fig. 4A). Using the INTEGRATE system which combines the seamless integrations of transposases with the programmability of CRISPR-mediated targeting and could mediate highly accurate and marker-free DNA integration of long DNA fragments at high efficiency without requiring selection markers26, these modules were inserted individually or in combination into the genome of P1-1 (R-BTE/ EApr-M1-3/C-M2-A).

A Modular engineering of DDA supply (in gray) and conversion (in blue). B Effect of DDA supply engineering on ω-AmDDA synthesis. C Effect of regulating DDA formation and hydroxylation on ω-AmDDA synthesis. The numbers in the tables indicate the copy numbers of the corresponding modules integrated into the genome while indicating the presence of the corresponding modules on the plasmid. The OD600 at the time of induction was approximately 1.0 and the fermentation time was 24 h after induction. DDA dodecanoic acid, ω-OHDDA ω-hydroxydodecanoic acid, ω-ODDA ω-oxododecanoic acid, ω-AmDDA ω-aminododecanoic acid, FAS M acyl-ACP synthesis module, ACA M acetyl-CoA activation module, GLY M glycolysis module, R-BTE fatty acid synthesis pathway module, EApr-M1 DDA hydroxylation module with AprR marker, C-M2-A oxidation and transamination module. All values presented are the means of three biological replicates, and error bars represent standard deviations. Source data are provided as a Source Data file.

The genomic integration of FAS M, either in cassettes with multiple promoters and a single terminator (FAS M1) or with an equal number of promoters and terminators (FAS M2), enhanced the production of ω-AmDDA, with FAS M1 demonstrating superior performance. The recombinant strain P1D2 (R-BTE/EApr-M1-3/C-M2-A) constructed from P1-1 (R-BTE/EApr-M1-3/C-M2-A) by integrating FAS M1 produced 131.0 mg/L of ω-AmDDA (Fig. 4B). Integration of modules ACA M1 (overexpressing FabD from E. coli K12) and ACA M2 (overexpressing FabD_COE from S. coelicolor) into P1D2 (R-BTE/EApr-M1-3/C-M2-A) resulted in ω-AmDDA production of 148.1 and 139.7 mg/L, respectively. Integration of GLY M together with FAS M1 into P1D2 (R-BTE/EApr-M1-3/C-M2-A) generated strain P1D5 (R-BTE/EApr-M1-3/C-M2-A), which produced 164.6 mg/L of ω-AmDDA (Fig. 4B). Significant DDA accumulation (88.5 mg/L) was observed in this strain, indicating an overproduction of DDA. Further strengthening of DDA synthesis by integrating all three modules of GLY M, ACA M1, and FAS M1 decreased the ω-AmDDA production to 120.6 mg/L, and increasing the FAS M1 copy number further reduced ω-AmDDA titer (Fig. 4B), which suggests the cytotoxicity of over-accumulated DDA.

To restore the balance between DDA formation and its conversion, we attempted to adjust the relative expression levels of BTE and CYP153A-NCP. First, the BTE expression level was reduced by inserting the bte gene into FAS M1 for single-copy integration, which decreased the ω-AmDDA titer to 10.4 mg/L (Fig. 4C). Subsequently, BTE and CYP153A-NCP were expressed together on a high-copy plasmid in different constructs. In EApr-M1-B1, the absence of a termination signal in front of bte resulted in stronger BTE expression compared to CYP153A-NCP, significantly reducing ω-AmDDA production to 18.5 mg/L. These results again indicate that neither excessively high nor low DDA supply is beneficial for ω-AmDDA biosynthesis. In EApr-M1-B2 with both genes in a complete expression cassette, the ω-AmDDA titer was improved by 26% as compared to P1D5 (R-BTE/EApr-M1-3/C-M2-A), reaching 206.9 mg/L. In the recombinant strain P1D5 (EApr-M1-B3/C-M2-A), where the expression of CYP153A-NCP was more potent than that of BTE, the ω-AmDDA titer was the highest (242.8 mg/L), which was improved by 47% compared to P1D5 (R-BTE/EApr-M1-3/C-M2-A). In this strain, DDA accumulation was decreased to 43.9 mg/L.

Cofactor engineering of ω-AmDDA de novo biosynthesis

In the reactions that convert DDA to ω-AmDDA, NADPH is essential for DDA hydroxylation catalyzed by CYP153A-NCP, while NADH is required by AlaDH2 catalyzing regeneration of L-alanine which is used as the amine donor in the transamination reaction6. In the de novo biosynthesis of ω-AmDDA, not only do the catalytic enzymes in the heterologous pathway require reducing power, but DDA synthesis and the maintenance of cell growth and survival also involve significant consumption of reducing power. In E. coli, the balance between NADH and NADPH can be maintained by two pyridine nucleotide transhydrogenases, the membrane-bound PntAB catalyzing conversion of NAD(H) to NADP(H) and the soluble UdhA catalyzing conversion of NADP(H) to NAD(H)27. NadK can also phosphorylate NAD(H) to NADP(H). Therefore, we overexpressed UdhA, UdhA/NadK, PntAB, NadK, Pos5p, and PntAB/NadK in P1D5 (EApr-M1-B3/C-M2-A). These NADH kinase-like enzymes and the NADH kinase from Saccharomyces cerevisiae (Pos5p) can increase the ratio of NADP(H)/NAD(H)28. As shown in Supplementary Fig. 3B, overexpressing NadK and/or PntAB increased the ω-AmDDA production, and the recombinant strain P1D5N18 (EApr-M1-B3/C-M2-A) overexpressing PntAB alone outperformed the others, producing 303.1 mg/L of ω-AmDDA. In consistence, when UdhA was overexpressed or when the NADH-dependent AlaDH2 in module C-M2-A was mutated to an NADPH-dependent variant29 in module C-M-Am, the ω-AmDDA production decreased. These results implied a shortage of NADP(H) in the engineered E. coli caused by ω-AmDDA biosynthesis, and suggested enhancing NADP(H) supply as an effective strategy for improving ω-AmDDA production. However, further enhancement of PntAB expression on high-copy plasmid led to both decreased biomass and ω-AmDDA production.

Alternatively, the GDH1-catalyzed reaction regenerating NAD(P)H using glucose as the substrate may be reinforced. In the multi-enzyme cassette for converting DDA to ω-AmDDA, GDH1 was introduced to supplement the reducing power6. Since E. coli primarily imports glucose in the form of 6-phospho-glucose via the phosphotransferase (PTS) system, only a small amount of glucose is transported into the cells in its unphosphorylated form through the MgIBAC-Glk and/or Galp-Glk transport systems for GDH1 reaction30. Consequently, the ability of GDH1 to regenerate reducing power may be limited by substrate availability. The sugar transport protein Glf from Z. mobilis, which transports unphosphorylated glucose at a high rate without additional energy input31, was introduced into the genome of P1D5 (EApr-M1-B3/C-M2-A), and the endogenous glucose kinase (Glk) gene that can phosphorylate glucose was deleted. To prevent the waste of carbon source and promote the re-entry of the GDH1 catalytic byproduct D-Gluconic acid (D-Glu) into cellular metabolism, gluconokinase (GntK), along with 6-phospho-glucarate dehydratase (Gnd) in the pentose phosphate (PPP) pathway or 2-keto-3-deoxy-6-phospho-glucarate aldolase (Eda) in the Entner-Doudoroff (ED) pathway, was co-expressed with Glf as module G-P M or G-ED M. As shown in Supplementary Fig. 3C, the highest ω-AmDDA yield was obtained when Glf was moderately expressed under control of Ptac, indicating that neither too low nor too high levels of unphosphorylated glucose transport are conducive to promoting product synthesis. Integration of the GDH1 enhancement module Ptac-glf/G-ED M into strain P1D5N25 (EApr-M1-B3/C-M2-A) increased the ω-AmDDA production by 29% compared to the control strain P1D5(EApr-M1-B3/C-M2-A). Further integration of the redox balance module PT7-pntAB increased the ω-AmDDA production by another 14%. The resulting strain P1D5N27 (EApr-M1-B3/C-M2-A) harboring both the GDH1 enhancement module and the redox balance module produced 289.6 mg/L of ω-AmDDA after 18 h of fermentation (Supplementary Fig. 3D).

Strengthening ATP supply is another possible strategy to improve the metabolic homeostasis of cell factories32. By knocking out the encoding gene for ATPase FecE in the citrate-dependent iron transport system that competitively consumes ATP33 in strain P1D5 (EApr-M1-B3/C-M2-A), the ω-AmDDA titer reached 291.0 mg/L, which was 20% higher than the control strain (Supplementary Fig. 3A). However, overexpression of the phosphoenolpyruvate (PEP) carboxykinase PckA from B. subtilis 168 for enhanced substrate-level phosphorylation of PEP to oxaloacetate34 showed no positive effect. Finally, deletion of fecE from strain P1D5N27 (EApr-M1-B3/C-M2-A) with enhanced NADP(H) supply generated strain P1D5A4N27 (EApr-M1-B3/C-M2-A), which produced 324.4 mg/L of ω-AmDDA after 18 h of shake-flask fermentation (Fig. 5B).

A Strategy for energy and cofactor engineering. B Effect of cofactor engineering on the synthesis of ω-AmDDA. C Effect of overexpression of OxyR and SoxR on the synthesis of ω-AmDDA. D Effect of Cofactor M and ROS M on the synthesis of ω-AmDDA. Control, P1D5 (EApr-M1-B3/C-M2-A). The OD600 at the time of induction was approximately 1.0 and the fermentation time was 18 h after induction. D-Gdl D-glucono-δ-lactone, DDA dodecanoic acid, ω-OHDDA ω-hydroxydodecanoic acid, ω-ODDA ω-oxododecanoic acid, ω-AmDDA ω-aminododecanoic acid, ROS reactive oxygen species, ROS M ROS defense module, Cofactor M cofactor optimization module. All values presented are the means of three biological replicates, and error bars represent standard deviations. Source data are provided as a Source Data file.

Tolerance engineering of the cell factory

The production and accumulation of DDA and its derivatives can damage the membrane structure and impair the function of the electron transfer chain (ETC) located in the membrane35, leading to the accumulation of reactive oxygen species (ROS), including H2O2, O2−, and hydroxyl radicals (·OH)36. Excessive ROS can damage essential cell components such as the cell membrane, proteins, and nucleic acids, resulting in ROS stress37. We attempted to overexpress the catalases (CAT) KatE and KatG, the superoxide dismutases (SOD) SodA, SodB and SodC, the peroxidases (POD) Bcp, BtuE, Tpx, EfeB and AphC, and YaaA which can chelate Fe2+, in P1D5 (EApr-M1-B3/C-M2-A) to enhance its ROS defense. The results indicated that while overexpressing combinations of CAT/SOD or CAT/POD improved cell survival to some extent, they did not positively impact ω-AmDDA production (Supplementary Fig. 4). Moreover, YaaA negatively affected both ω-AmDDA production and cell viability, possibly ascribed to excessive chelation of Fe2+ by YaaA38. Considering the complexity of the ROS defense network, the transcription factors OxyR and SoxRS globally regulate the network39 were overexpressed individually and in combination in P1D5 (EApr-M1-B3/C-M2-A). Strain P1D5R15 (EApr-M1-B3/C-M2-A) overexpressing OxyR showed a 35% increase in the ω-AmDDA titer and a 33% increase in the biomass (Fig. 5C). SoxR overexpression alone slightly enhanced ω-AmDDA production and cell growth, but co-overexpression of SoxR and OxyR was not better than OxyR overexpression alone. When OxyR was further overexpressed in multiple copies, significant negative impacts on cell growth and ω-AmDDA production were observed.

By combining the cofactor optimization module Cofactor M (Δglk::Ptac-glf + G-ED M/ΔfecE::PT7-pntAB) with the ROS defense module ROS M (PT7-oxyR), strain PDANR (EApr-M1-B3/C-M2-A) was constructed, which produced 370.9 mg/L of ω-AmDDA after 18 h of shake-flask fermentation (Fig. 5D). Meanwhile, a 64% increase in the biomass was observed.

Improving rate-limiting DDA hydroxylation by protein engineering

In both whole-cell catalysis and the de novo synthesis of ω-AmDDA, the hydroxylation of DDA to form ω-OHDDA by the P450 enzyme is crucial. In this study, CYP153A-NCP containing the G307A mutation in the heme domain was used40. If this rate-limiting enzyme could be further engineered via rational design41 or random mutagenesis42 towards improved activity, the ω-AmDDA production may be further enhanced.

In the heme domain of CYP153A-NCP, there are three tunnels possibly involved in the catalysis process, namely the 2c tunnel (M228, D241, E242, and M245), the 2e tunnel (Q129, S140, V141, and E142), and the 2ac tunnel (A231 and S233) (Fig. 6A), with formation rates of 76%, 98%, and 28%, respectively43. Residues P135, P136, and L139 constitute the tops of the three tunnels. Primary-structure-based multiple sequence alignment was conducted for all these tunnel residues (Supplementary Fig. 5A), and tertiary-structure-based multiple sequence alignment of the heme domain crystal structure (5FYG) was conducted with CYP153A enzyme subtypes cand_1 (6HQD), cand_10 (6HQG), cand_15 (6HQW) and CYP153A7 (3RWL) exhibiting higher DDA hydroxylation activities (Supplementary Fig. 5B). Based on the alignment results, M228A/I/V/T, D241H/Q/A/E/S/L, E242D/H/Q/A/R/W, M245Q/A/R, Q129A/G/H/N/S/T, S140G/Q/A/Y, V141A/K/L/Q/G, E142R/G/Q/P, A231S/T/L/I, S233A/H/Q/R/D, P135A/H/K/R/N/G, P136A/E/G/V, and L139A/H/R/S/I mutations were introduced into CYP153AG307A. Among them, variants carrying E242A (115%), M245Q (119%), Q129A (127%), S140Q (129%), V141A (121%), V141L (122%), and A231T (118%) mutations showed improved DDA hydroxylation activity (Fig. 6B). The positive hit rates were 7% (3 out of 46) and 16% (4 out of 25) for the primary-structure-based and tertiary-structure-based multiple sequence alignment, respectively.

A Tunnel recognition and analysis of the heme domain of CYP153A-NCP; B Hydroxylation of DDA by CYP153A-NCP mutants designed by alignment. C Schematic diagram of the colorimetric method for in situ detection of DDA terminal hydroxylation; D Mutants generated by combinatorial mutagenesis. DDA dodecanoic acid, ω-OHDDA ω-hydroxydodecanoic acid, ω-ODDA ω-oxododecanoic acid, ω-AmDDA ω-aminododecanoic acid. All values presented are the means of three biological replicates, and error bars represent standard deviations. Source data are provided as a Source Data file.

Alternatively, saturation mutagenesis was conducted for the tunnel entrance residues A231 and E142 in the heme domain 2ac. To facilitate high-throughput screening of the mutants, a colorimetric detection system for in situ DDA hydroxylation detection was developed (Fig. 6C). By constructing module C-screen M, which contains AlkJ and CV2025, and co-expressing it with module EApr-M1-3mx, which includes the P450 mutants, we were able to differentiate the P450 activity based on the amount of ω-AmDDA produced. This was indicated by the red precipitate formed from the conversion product of the amine doner 4-nitrophenylamine in a dose-dependent manner44. The significant color difference observed between the wild type (WT) and G307A mutant of CYP153A-NCP validated the feasibility of this screening method (Fig. 6C). Screening of the saturation mutagenesis library identified two positive mutants, E142T (121%) and A231R (132%) (Supplementary Fig. 6). Based on the best mutant G307A/A231R, combinatorial mutagenesis was conducted, finding out two positive triple mutants G307A/A231R/Q129A (158%) and G307A/A231R/S140Q (151%) as well as a four-point mutant G307A/A231R/Q129A/S140Q (CYP153Am4-NCP) with 189% activity of CYP153AG307A-NCP (Fig. 6D).

RMSD analysis of the simulated trajectories of CYP153Am4-NCP in comparison to CYP153AG307A-NCP revealed that the introduction of A231R/Q129A/S140Q significantly increased the probability of the catalytic conformation (99% vs. 31%) (Supplementary Fig. 7). Formation of an ionic bond between the positively charged residue R231 and the negatively charged carboxyl group of DDA leading to substrate anchoring was also observed in the mutant (Fig. 7A), where the distances between the two oxygen atoms, DDA_O14 and DDA_O15, with negative charges in the DDA carboxyl group, and the R231_NH1 atom with a positive charge, were both within the bonding range of 4 Å (105) (Fig. 7B). The MM-PBSA analysis revealed a much lower binding free energy ΔGbind of the mutant (−30.4 ± 5.7 kcal/mol vs. −15.4 ± 5.1 kcal/mol), and per-residue energy decomposition emphasized the significant contribution of R231 to the stable binding of DDA (Table 1). Arginine is often described as a possible binding site for the carboxylate group of fatty acids in P450 enzymes capable of fatty acid hydroxylation43. In addition, the flexibility of the BC-Loop structure decreased after the introduction of Q129A and S140Q (Fig. 7C), which possibly stabilized DDA in the catalytic conformation, as found previously for other fatty acid substrates43.

CYP153A-NCP has a similar structure to CYP102A1, which is only active when it forms a homodimer; dimerization primarily occurs in its NCP domain (residues 651–883)45. Therefore, the active form of the CYP153A-NCP might also be a homodimer. To further enhance the catalytic activity of CYP153Am4-NCP, we attempted to introduce different intermolecular affinity-enhancing structures at its N-terminus or C-terminus to promote the formation of dimerization-active quaternary structures (Fig. 8A), including the artificial self-assembling dimeric helical bundle CC-Di and the GCN4 leucine zipper helical bundle Zip from S. cerevisiae S288C46, the C-terminal oligomerization domains from the blocking protein CI and CI43447, the dimerization domain RIDD from the cAMP-dependent protein kinase PKA48, the N-terminal oligomerization domains from the Pseudomonas aeruginosa H-NS protein family member MvaT49, the Brucella abortus zinc finger protein Ros/MucR family member MucR50, the Citrobacter freundii bacterial microcompartment PduA* protein which can aggregate to form N-terminally exposed hollow filaments in bacteria51, and the C-terminal membrane anchoring sequence of the membrane-related protein MinD52. It turned out that CYP153Am4NZ-NCP (144%) and CYP153Am4NC-NCP (132%), where the Zip dimeric coiled coil and CC-Di dimeric helix-loop-helix were fused at the N-terminus of the P450 enzyme respectively, both showed improved activity (Fig. 8B). In contrast, none of the chimeric proteins constructed by fusing the oligomerization domains at the C-terminus showed significantly enhanced activity, but rather obviously decreased activity in most cases.

A Different intermolecular affinity-enhancing structures. B Hydroxylation of DDA by fusion constructs with different oligomerization enhancing domains. C Effects of enhancing DDA hydroxylation on the de novo synthesis of ω-AmDDA. Control, PDANR (EApr-M1-B3/C-M2-A). The OD600 at the time of induction was approximately 1.0 and the fermentation time was 18 h after induction. DDA dodecanoic acid, ω-OHDDA ω-hydroxydodecanoic acid. All values presented are the means of three biological replicates, and error bars represent standard deviations. Source data are provided as a Source Data file.

Replacing CYP153AG307A with CYP153Am4NZ-NCP generated the final strain PDANR (EApr-M1-B3mut/C-M2-A), which produced 471.5 mg/L of ω-AmDDA after 18 h incubation, 54% higher than that of the control strain PDANR (EApr-M1-B3/C-M2-A) (Fig. 8C). Meanwhile, DDA accumulation was decreased from 43.9 mg/L to 25.3 mg/L.

Discussion

To establish a green and sustainable production route of nylon 12 monomer, de novo biosynthesis of ω-AmDDA using glucose as feedstock was achieved by introducing a thioesterase for selective DDA production, along with a multi-enzyme cassette for converting DDA to ω-AmDDA into E. coli. However, the significantly lower ω-AmDDA titer (27.5 mg/L) in the engineered cell factory, even after optimizing culture conditions, compared to that of resting cells harboring the same multi-enzyme cassette (1.04 g/L)6, suggests a higher complexity in the de novo biosynthesis system. This discrepancy may be attributed to an unbalanced supply and conversion of DDA as the key intermediate in the cell factory, disturbed metabolic homeostasis, and intermediate/product toxicity associated with ω-AmDDA biosynthesis in growing cells.

Fatty acids, including DDA, may be secreted after biosynthesis, leading to substrate inaccessibility for the DDA-converting enzymes. Secretion of palmitic acid was observed during the biosynthesis of ω-hydroxypalmitic acid, and the overexpression of the endogenous outer membrane protein FadL enhanced ω-hydroxypalmitic acid production by improving the re-uptake of secreted palmitic acid53. Additionally, overexpressing the outer membrane protein AlkL from P. putida GPo1 in recombinant E. coli containing the alkane monooxygenase AlkBGT for dodecanoic acid methyl ester oxygenation addressed the substrate mass transfer issue and increased oxygenation activity by 28-fold54. When DDA was used as the substrate for biotransformation using recombinant E. coli strains, AlkL overexpression improved the ω-AmDDA yield by 20.3%6. Changes in the intracellular/extracellular distribution of DDA before and after AlkL overexpression in the ω-AmDDA cell factory confirmed the secretion of DDA during ω-AmDDA de novo biosynthesis and suggested that the re-uptake of secreted precursors contributed to the improved production of ω-AmDDA (Supplementary Fig. 8).

Besides DDA loss by secretion, its synthesis and conversion efficiencies determined the flux towards ω-AmDDA biosynthesis. DDA biosynthesis from glucose involves enzymes for glycolysis, acetyl-CoA activation, acyl-ACP synthesis, and thioesterification of C12 acyl-ACP, while its conversion is mediated by the heterologous pathway composed of a chimeric P450, an alcohol dehydrogenase, an ω-TA, and the cofactor-regenerating GDH1, AlaDH2, and yaaDE. The involvement of dozens of genes in ω-AmDDA de novo biosynthesis renders its regulation challenging. The modular pathway engineering strategy, which divides the complex pathway into several modules, largely simplified the manipulation. By designing and overexpressing the glycolysis, acetyl-CoA activation, acyl-ACP synthesis modules individually and in combination together with the heterologous ω-AmDDA formation module, the rate-limiting steps of ω-AmDDA de novo synthesis were identified as glycolysis, acyl-ACP synthesis and the P450-mediated DDA hydroxylation. Meanwhile, the key genes from difference sources with better performance in acetyl-CoA activation and acyl-ACP synthesis were selected out, leading to 3-fold higher ω-AmDDA production. However, excessive accumulation of DDA, resulted from simultaneous overexpressing the glycolysis, acetyl-CoA activation, and acyl-ACP synthesis modules, or multi-copy expression of the acyl-ACP synthesis module, or elevating BTE expression, decreased both the biomass and ω-AmDDA production, indicating cytotoxicity. Exogenous addition of DDA has shown substantial toxicity against bacteria55, and the synthesis of fatty acids in the cells exacerbates the adverse effects on cell viability and productivity56. These results suggested sufficient but not excessive DDA supply as a key to efficient de novo biosynthesis of ω-AmDDA, and demonstrated the effectiveness of modular pathway engineering in regulating such complex pathways.

To reconstruct the balance between DDA formation and conversion, DDA hydroxylation was reinforced by engineering CYP153A-NCP. Tertiary-structure-based multiple sequence alignment was found to be more efficient in identifying positive engineering targets compared primary-structure-based multiple sequence alignment, provided that tertiary structures are accessible. These structures can be obtained using protein structure prediction tools such as Alphafold357. Besides the rational engineering of residues in or on top of the substrate-binding tunnels, saturation mutagenesis of the residues at the tunnel entrance also generated positive variants. Finally, a combinatorial mutant CYP153Am4-NCP with 89% activity improvement was obtained. In this process, a colorimetric high-throughput screening method for in situ DDA hydroxylation detection was developed based on the coupled transamination reaction using 4-nitrophenylamine as the amine donor, which provides the possibility for in vivo directed evolution or co-evolution of single or multiple enzymes involved in ω-AmDDA biosynthesis. In addition, the hydroxylation activity was further elevated by N-terminal fusion of intermolecular affinity-enhancing structures to enhance protein dimerization of CYP153Am4-NCP. Studies have shown that increasing the affinity between homodimer or oligomer protein molecules can promote the formation of the correct quaternary structure and improve their function58. Interestingly, C-terminal fusion constructs all failed to enhance the activity. Since the C-terminus of NCP is part of the FAD-binding pocket and is less exposed to solvents45, domain dimerization may limit its accessibility for FAD and thus hinder catalysis.

In addition to the metabolic flux of the target synthetic pathway, maintaining metabolic homeostasis is also crucial for the fermentative production of microbial cell factories59. However, the burden of ω-AmDDA de novo synthesis may disrupt this homeostasis. A redox imbalance can arise from the substantial consumption of NAD(H) and NADP(H) during fatty acid biosynthesis and the conversion of DDA to ω-AmDDA, which can significantly hinder cellular metabolism and impair the growth and biosynthesis performance of the engineered strains60. Moreover, the production and accumulation of DDA and its derivatives can lead to ROS accumulation, which may be exacerbated by redox imbalance and insufficient electron transfer efficiency during heterologous pathway oxidoreductase reactions, such as P45017,35,61,62,63. Therefore, the redox homeostasis and ROS tolerance of the cells were modulated to further improve the performance of the cell factory.

Due to the lower abundance of NADP(H) than NAD(H) in cells64, enhancing the supply of NADP(H) is often beneficial for restoring redox balance. Overexpression of the NADH kinase Pos5p has proven to be an efficient strategy in the metabolic engineering of S. cerevisiae, resulting in increased production of retinoids65 and tocotrienols66 by bolstering NADPH supply. Similarly, PntAB and NadK in E. coli catalyze the conversion of NAD(H) to NADP(H). As anticipated, overexpression of these enzymes contributed to enhanced production of ω-AmDDA. However, excessive PntAB overexpression significantly impaired cell growth and ω-AmDDA production. This may be attributed to the excessive consumption of NADH and ATP by PntAB28. Besides the NADP(H)/NAD(H) ratio, the ratio of the reduced form to the oxidized form also affects the redox homeostasis. In the multi-enzyme cassette for converting DDA to ω-AmDDA, the glucose dehydrogenase GDH1 had been introduced to regenerate NAD(P)H from NAD(P)+ 6, but its efficiency may be limited by the availability of unphosphorylated glucose as its substrate, since most glucose is transported via the PTS system in the form of 6-phospho-glucose. By introducing the Z. mobilis Glf to strengthen transportation of unphosphorylated glucose, both glucose consumption and NADPH regeneration were enhanced (Supplementary Table 1), leading to further improvement in ω-AmDDA production. These results suggest moderately expanding the NADP(H) pool and accelerating NADPH regeneration rather than excessively enhancing the NADP(H)/NAD(H) ratio as an efficient approach to regulate the redox cofactors. In addition, ATP is required in the bioconversion of NAD(H) to NADP(H), and also in fatty acid biosynthesis32,33. Therefore, there may be a shortage of ATP supply in the cell factory, which can be addressed by blocking reactions that competitively consume ATP or by enhancing substrate-level phosphorylation. However, because PEP plays a crucial role in the native metabolism of E. coli, its consumption during substrate-level phosphorylation may have adverse effects. Accordingly, deleting the gene encoding the ATPase in the citrate-dependent iron transport system, rather than overexpressing the heterologous PEP carboxykinase, improved ω-AmDDA production.

Studies have shown that strengthening the ROS defense enzyme system in E. coli can significantly increase its survival rate under ROS stress67,68,69 and improve the production of chemicals that induce oxidative stress69. Overexpression of the ROS defense regulator OxyR significantly reduced the ROS level in the engineered cells (Supplementary Table 1), and improved both the ω-AmDDA titer and biomass (Fig. 5 and Supplementary Table 1). However, its excessive overexpression negatively affected the cell factory. This might be universal for transcription factors with broad regulation targets, as observed in a previous study where moderate rather than excessive overexpression of the transcriptional factor Gal4p improved isoprene production in S. cerevisiae70. It is worth noting that the effect of engineering oxidative stress tolerance was more pronounced in the strain where the NADP(H) supply was not strengthened (Fig. 5D). This suggests that the imbalance in intracellular redox homeostasis may be a possible source of oxidative stress.

In conclusion, efficient de novo biosynthesis of the nylon 12 monomer ω-AmDDA using glucose as feedstock has been achieved in an E. coli cell factory. Although the current yield of ω-AmDDA from glucose is modest at 0.01 g per gram, this milestone underscores both the challenges ahead and the significant potential for further research and optimization. This work establishes a foundational framework for the fermentative production of nylon 12, marking a crucial advancement toward sustainable bioproduction. To regulate such a complex pathway composed of glycolysis, acetyl-CoA activation, fatty acid selective synthesis, and DDA transformation processes involving multiple genes and different cofactor requirements, and meanwhile to mitigate the adverse effects caused by cytotoxic intermediates and product, a combinatorial engineering strategy was proposed, which integrates modular pathway engineering, cofactor engineering, tolerance engineering, and protein engineering (Fig. 9). This multi-level metabolic regulation strategy covering the rate-limiting enzyme, pathway flux, cofactor, energy supply, and oxidative stress tolerance would provide a valuable reference for optimizing the biosynthesis of ω-AmDDA and other fatty acid-derived compounds.

Methods

Sources of materials

ω-AmDDA was purchased from TCI (Shanghai, China). DDA, 12-hydroxydodecanoic acid (ω-OHDDA) and α,ω-DCA were from Adamas-beta Ltd. (Shanghai, China). Other chemicals were obtained from Sangon Biotech Ltd. (Shanghai, China). Phusion high-fidelity DNA polymerase, restriction endonucleases, and T4 DNA ligase were purchased from TAKARA Ltd. (Dalian, China). Oligonucleotides were synthesized by Sangon Biotech Ltd. (Shanghai, China). The bte gene from U. californica, lpdA_EF from E. faecalis, glf from Zymomonas mobile, accBC_GL and accAD_GL from C. glutamicum, the coding sequences of the artificial self-assembling dimeric helical bundle CC-Di and the GCN4 leucine zipper helical bundle Zip from S. cerevisiae S288C, the C-terminal oligomerization domains from the blocking protein CI and CI434, the dimerization domain RIDD from the cAMP-dependent protein kinase PKA, the N-terminal oligomerization domains from the P. aeruginosa H-NS protein family member MvaT, the B. abortus zinc finger protein Ros/MucR family member MucR, the C. freundii bacterial microcompartment PduA* protein, and the C-terminal membrane anchoring sequence of the membrane-related protein MinD, were codon-optimized and synthesized by Sangon Biotech Ltd. (Shanghai, China). The NADH kinase gene POS5 was cloned from S. cerevisiae S288C, and the PEP carboxyl kinase gene pckA_BS was cloned from B. subtilis 168. The plasmids pTnsABC, pDonor, pQCascade-entry, and pCutamp71 were gifts from Prof. Sheng Yang at the Chinese Academy of Sciences. The alkJ gene from P. putida GPo1, aladh2 from B. subtilis 168, and the expression plasmids pETDute-1, pCDFCDuet-1, pRSFDuet-1 and pACYCDuet-172 were provided by Prof. Zhi Li from National University of Singapore.

Construction of plasmids and strains

The recombinant plasmids constructed, the primer information required for creating these plasmids, and the specific details on the recombinant strains constructed are shown in Supplementary Data 1–3.

For constructing the fatty acid synthesis pathway module, bte was cloned into the Nco I/Xho I sites of pRSFDuet-1 to construct R-BTE. Meanwhile, lpdA_EF from E. faecalis, fadR from E. coli K12, accBC_GL and accAD_GL from C. glutamicum were inserted into pCDFDuet-1 to construct a T7 expression cassette. Subsequently, the lpdA_EF expression cassette (without terminator) was inserted in front of the T7 promoter controlling bte expression in R-BTE to construct R-L-BTE. The accBC_GL and accAD_GL expression cassette (without terminator) was then inserted in front of the T7 promoter controlling lpdA_EF expression in R-L-BTE to construct R-AL-BTE. Finally, the expression cassette of fadR (without terminator) was inserted in front of the T7 promoter controlling bte expression in R-AL-BTE to construct R-ALF-BTE.

To replace the resistance screening marker, the ampicillin resistance gene aprR from pCutamp was cloned into the E-M1-3 plasmid6 to replace the original ampicillin resistance gene ampR, constructing EApr-M1-3. By placing the bte expression cassette after gdh1 or in front of the T7 promoter with or without the terminator in EApr-M1-3, EApr-M1-B1, EApr-M1-B2 and EApr-M1-B3 were constructed, respectively. Similarly, P15Akan was constructed by replacing the chloramphenicol resistance gene on pACYCDuet-1 with the kanR kanamycin resistance gene. The pntAB or oxyR gene from E. coli K12 was then cloned at the Nco I/Xho I sites of P15Akan to construct P15Akan-PT7-pntAB and P15Akan-Ptac-oxyR, respectively.

For replacement of the alcohol dehydrogenase, bsadhC267L in C-M2-26 was replaced with alkJ encoding a non-Zn2+ dependent alcohol dehydrogenase to construct C-M2-A. D196A/L197R mutation was then performed on the aladh2 sequence in C-M2-A to construct plasmid C-M2-Am expressing the NADPH-dependent L-alanine dehydrogenase AlaDH2m.

pDonor-n was constructed from pDonor by eliminating the Plac promoter. The rrnB T1 terminator and the bacteriophage lambda t0 terminator sequences were cloned from the pQE-80L plasmid and inserted into pDonor-n to construct pDonor-n Knockout for gene knockout manipulations. gapA, pgk, aceE, and aceF from E. coli K12 and lpdA_EF were cloned into pCDFDuet-1 using cloning primers to construct a T7 expression cassette. The Golden Gate method was used to assemble gapA, pgk, aceE, aceF, and lpdA_EF expression cassettes into pDonor-n to construct a transposable donor plasmid pDonor-n-GLY M. Using the same method, the E. coli K12-derived accA, accB, accC, accD, and fabD were assembled into pDonor-n to construct a transposable donor plasmid pDonor-n-ACA M1. The fabD gene in pDonor-n-ACA M1 was replaced with fabD_COE from Streptomyces coelicolor to construct pDonor-n-ACA M2. FabA, fabH, fabG, and fabI from E. coli K12 were assembled into pDonor-n to construct pDonor-n-FAS M2. The T7 terminators after fabA, fabH, and fabG in pDonor-n-FAS M2 were removed to construct pDonor-n-FAS M1.

The BTE expression cassette was inserted before the terminator of FAS M1 in pDonor-n-FAS M1 to construct pDonor-n-FAS M1B. PckA_BS was connected to the Nco I/Xho I site of pCDFDuet-1 to construct a T7 promoter-controlled expression cassette, which was subsequently ligated with pDonor-n and construct pDonor-PT7-pckA_BS.

To facilitate genome editing, pTnsABC and pQCascade-entry were assembled using the INTEGRATE system26 to form a pEffector entry that expresses the transposable working element. The 32 bp sgRNA sequences targeting T9, T12, T13, T14, T15, T16, and T186 sites were inserted into the pEffector entry using the Golden Gate method73 to construct transposable pEffector plasmids targeting the corresponding sites. The pEffector plasmids targeting fecE, yahK and glk were constructed using the same method. Genome editing using the transposon-encoded CRISPR-Cas system was conducted by construction, transformation, verification, and plasmid elimination of the targeting plasmid pEffector and donor plasmid pDonor. The loci targeted by the pEffectors are listed in Supplementary Data 1. pDonor-n containing specific cargo gene fragments (in gene knockout experiments, donor plasmids were selected as pDonor-n-Knockout), pEffector, and the Cas9 plasmid pCutamp that can eliminate both pDonor-n and pEffector, were transformed into the target strain. After selection on an LB agar containing streptomycin, ampicillin, and ampicillin, the colonies were incubated in LB broth with the same antibiotics, followed by a secondary screening on triple-selective LB agar. Colony PCR was conducted to verify the genomic integration of the target fragment. Finally, plasmid elimination was performed. During the incubation in LB broth containing amphotericin, 15 mM L-rhamnose was added to induce the decomposition of pEffector and pDonor-n by pCutamp. Subsequently, the cells were cultured in non-selective LB broth containing 10 g/L sucrose for 8 h at 37 °C. The cells were then plated for purification of single colonies, followed by culturing in LB broth with or without antibiotics for 12 h at 37 °C. Those only grew in the non-selective medium were identified as plasmid-free.

Shake-flask fermentation for ω-AmDDA production

Single colonies were picked from the plates and transferred to 5 mL LB liquid medium containing the corresponding antibiotic. The culture was then incubated at 37 °C and 220 rpm for 12 h and then inoculated (2% v/v) into M9 mineral salt medium72 containing 1–3% glucose. The culture was then incubated under the same condition for 3–4 h until OD600 reached approximately 1.0, followed by induction at 30 °C using 0.1 mM isopropyl-β-D-thiogalactoside (IPTG) as the inducer. Meanwhile, 2 g/L NH4HCO3 was added as the NH4+ source, together with supplementation of 0.2 mM thiamine hydrochloride (VB1), 0.5 mM 5-aminolevulinic acid (δ-ALA), 1 mL/L metal element stock solution (0.5 g/L MgCl2, 30 g/L FeCl2.4H2O, 84 g/L ZnCl2, 0.2 g/L CoCl2.6H2O, 1 g/L Na2MoO4.2H2O, 0.5 g/L CaCl2.2H2O, 1 g/L CuCl2 and 0.2 g/L H2BO3), and 25 mg/L D-biotin. The pH and glucose concentration were monitored during the culture and maintained at 7.5–7.7 and 0.5% by periodically adding ammonium hydroxide and glucose, respectively.

Construction, screening, and characterization of CYP153A-NCP mutants

Multiple sequence alignment based on the primary structure of the heme domain of CYP153A-NCP was performed using the Phyre2 website (http://www.sbg.bio.ic.ac.uk/phyre2/html/page.cgi?id=index). The crystal structure of the heme domain (5FYG) was compared with the crystal structures of CYP153A enzyme subspecies cand_1 (6HQD), cand_10 (6HQG), cand_15 (6HQW), and CYP153A7 (3RWL), which had better DDA hydroxylation activity than the wild-type heme domain, using the “MultiSeq” function of VMD via a tertiary structure-based multi-sequence alignment74.

CYP153A-NCP with single or multiple site mutations were constructed by PCR with CYP153A directed mutagenesis primers (Supplementary Data 2), using plasmid EApr-M1-3 as the template. For enhancing oligomerization of the chimeric P450, the oligomerization enhancement modules Zip, CC Di, MvaT and MurR were fused with the N-terminus of CYP153Am4-NCP (G307A/A231R/Q129A/S140Q) through a (GGS)3-junction sequence to construct CYP153Am4NZ-NCP, CYP153Am4NC-NCP, CYP153Am4NT-NCP and CYP153Am4NR-NCP, respectively. The C-terminal membrane anchor sequences of oligomerization enhancement modules Zip, CC Di, CI, CI434, RIDD, PduA*, and MinD were fused with the C-terminus of CYP153Am4 NCP through a (GGS)3 linker sequence to construct CYP153Am4- NCPCZ, CYP153Am4-NCPCC, CYP153Am4-NCPCI, CYP153Am4-NCPCR, CYP153Am4-NCPCP and CYP153Am4-NCPCD, respectively.

For colorimetric screening of CYP153A-NCP mutants, a screening module plasmid C-Screen M was constructed by removing AlaDH2 from C-M2-A. Transformation of this plasmid into strain B1-1 generated a colorimetric screening platform strain B1-1 (C-Screen M). Subsequently, EApr-M1-3-derived plasmids containing different CYP153A-NCP mutants and EApr-M1-3 (control) were transformed into B1-1 (C-Screen M) competent cells. The cells were resuspended to 20 g wet cells per liter (gcww/L) in a sodium phosphate (100 mM, pH 8.0) buffer containing 1% glucose, NH3·H2O/NH4Cl (200 mM, NH3·H2O: NH4Cl = 1:10), and 0.1 g/L FeCl2·4H2O. After aliquoting (500 µL) into a 24-well deep plate, 5 mM DDA (dissolved in 2% DMSO) was added, and the mixture was incubated at 30 °C and 220 rpm for 30 min. Subsequently, 300 µL of reaction buffer containing 150 mM of the chromogenic amino donor (4-nitrophenylacetaldehyde) was added and the reaction continued for 30–60 min. The red precipitate formed in each well was observed by the naked eye and compared to the WT. Whole-cell reactions were conducted for strains displaying a darker red color than the WT to determine their catalytic performance further.

For whole-cell biotransformation, the EApr-M1-3 derived plasmids containing the variants of CYP153A-NCP were transformed into B1-1 competent cells, and EApr-M1-3 was used as the control. The cells were resuspended to 30–50 gcww/L in a sodium phosphate buffer (100 mM, pH 8.0) containing 1% glucose, NH3·H2O/NH4Cl (200 mM, NH3·H2O: NH4Cl = 1:10), and 0.1 g/L FeCl2·4H2O. Two mL of the resuspended cells were transferred to a 20 mL serum bottle, and 10–15 mM DDA (2% DMSO) was added, followed by shaking at 30 °C and 220 rpm for 2–4 h. Immediately after the reaction, 200 µL of the sample was taken, quenched with an equal volume of glacial acetonitrile, and then used for product analysis.

Molecular dynamics simulations

ChemDraw 20.0 software was used to construct a deprotonated DDA structure and minimize its energy. MGLTools was employed to convert PDB format receptor 5FYG_A and DDA input files to AutoDock4 compatible pdbqt format. Subsequently, the partial charge of the iron atom in the receptor was set to 0.2575. The grid parameters were configured to encompass the heme active center with a moderate size, and the parameters for the docking process, including the genetic algorithm and the conformation number (300), were defined. The final docking conformation obtained with AutoDock4 was analyzed for tunnel recognition using the Pymol plugin CAVER 3.0.

After introducing mutations G307A and G307A/A231R/Q129A/S140Q into the original tertiary structure 5FYG_A containing DDA using UCSF Chimera software, all information except for the amino acid residues that make up the protein chain was removed from the PDB file and submitted to the H++ website (http://newbiophysics.cs.vt.edu/H++/). Using a solvent with a pH of 7.4 and a salinity of 0.1 M, residue protonation Amber labeling was performed under implicit calculation with an internal dielectric constant of 10 and an external dielectric constant of 80. The residue H152 near the heme in both protein chains was manually labeled and protonated into protonated histidine (HIP). Subsequently, the water molecules, heme, and DDA coordinate information from the original crystal structure 5FYG_A were added again to the two PDB files. The antechamber program in AmberTools 18 was used to build the force field file for DDA. The parameters of the penta-coordinate ferric high-spin sextet state geometry (HEM IC6) and the heme-bound cysteine residue (CYP IC6) obtained from the literature75 were added to the enzyme. Parameter topology and trajectory input files for dynamic simulation were generated using the tLEaP program. After three energy minimization steps: relaxing solvent but limiting protein residues, relaxing protein but limiting protein main chains, and unrestricted relaxation simulation, a whole enzyme simulation system with energy minimization was obtained. Afterwards, starting from the energy minimization system, after heating up, constant pressure, and equilibrium, a constant temperature and pressure equilibrium simulation of 8 ns was conducted.

The cpptraj module of AmberTools 18 was used to simulate and analyze trajectory files, such as calculating the root mean square deviation (RMSD), B-factor, and distance between specific atoms of the protein skeleton. The MMPBSA.py module was employed to analyze the binding free energy ΔGbind and its energy decomposition based on residues.

Analytical methods

For quantification of ω-AmDDA, ω-OHDDA and α,ω-DCA, 200 µL of the culture medium or whole-cell reaction mixture were collected by centrifugation and mixed with an equal volume of ice-cold acetonitrile. The samples were analyzed on a Shimadzu LC-20AT HPLC system equipped with a Phenomenex Luna C8(2) column (00F-4249-E0, Phenomenex, Aschaffenburg, Germany) and an Alltech 3300 ELSD detector. Gradient elution was performed using ultrapure water containing 0.1% trifluoroacetic acid (TFA) as mobile phase A and anhydrous methanol containing 0.1% TFA as mobile phase B under the following conditions: 0–2 min, 70% A/30% B; 2–5 min, 40% A/60% B; 5–14 min, 15% A/85% B; 14–25 min, 15% A/85% B; 25–32 min, 2% A/98% B; 32–35 min, 70% A/30% B. The injection volume was 20 µL, the flow rate was 0.8 mL/min, and the column temperature was maintained at 40 °C.

For quantification and identification of the residual DDA, the reaction mixture was acidified with 50 μL of 37% HCl, followed by the addition of tridecanoic acid as the internal standard to a final concentration of 1 mM. The reaction mixtures were extracted twice with tert-methyl butyl ether (2:1, v/v). The organic phase was collected, dried over anhydrous MgSO4, and evaporated. For derivatization of DDA, samples were resuspended in 100 μL of 14% BF3-methanol and incubated at 95 °C for 30 min. The derivatives were analyzed and quantified with reference to standard compounds on a GC system (Fuli, Wenling, China) equipped with an HP-5 column (30 m × 0.25 mm, 0.25 μm, Agilent) and a flame ionization detector (FID). The temperature program employed was 100 °C for 1 min, followed by a linear temperature gradient, increasing to 250 °C at a speed of 10 °C/min. The injection volume was 1 μL, and a split ratio of 20:1 was used. For determination of the intracellular and extracellular distribution of DDA, the supernatant and precipitate were collected respectively after centrifugation of the culture broth. After resuspension of the precipitate with ddH2O, both samples were derivatized for GC analysis as described above.

Determination of NADP(H) and NAD(H) levels was performed using NADP+/NADPH assay kit (Beyotime, Shanghai, China) and NAD+/NADH assay kit (Beyotime, Shanghai, China) respectively, while measurement of ROS levels was conducted using reactive oxygen species assay kit (Beyotime, Shanghai, China), all following the manufacturer’s instructions.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data supporting the findings of this work are available within the paper and its Supplementary Information files. A reporting summary for this article is available as a Supplementary Information file. Source data are provided with this paper.

References

Delgado, G. F., Pinho, A. C. & Piedade, A. P. 3D printing for cartilage replacement: a preliminary study to explore new polymers. Polymers 14, 1044 (2022).

Schrewe, M. et al. Direct terminal alkylamino-functionalization via multistep biocatalysis in one recombinant whole-cell catalyst. Adv. Synth. Catal. 355, 1693–1697 (2013).

Ladkau, N. et al. Efficient production of the nylon 12 monomer ω-aminododecanoic acid methyl ester from renewable dodecanoic acid methyl ester with engineered Escherichia coli. Metab. Eng. 36, 1–9 (2016).

Ahsan, M. M. et al. Biosynthesis of the nylon 12 monomer, omega-aminododecanoic acid with novel CYP153A, AlkJ, and omega-TA enzymes. Biotechnol. J. 13, e1700562 (2018).

Ahsan, M. M. et al. Biosynthesis of nylon 12 monomer, ω-aminododecanoic acid using artificial self-sufficient P450, AlkJ and ω-TA. Catalysts 8, 400 (2018).

Ge, J. et al. High-yield whole cell biosynthesis of nylon 12 monomer with self-sufficient supply of multiple cofactors. Metab. Eng. 62, 172–185 (2020).

Yu, J. M. et al. Improved bioproduction of the nylon 12 monomer by combining the directed evolution of P450 and enhancing heme synthesis. Molecules 28, 1758 (2023).

Mazzorato, A. C. M., Esch, E. H. & MacDougall, A. S. Prospects for soil carbon storage on recently retired marginal farmland. Sci. Total Environ. 806, 150738 (2022).

Pfleger, B. F., Gossing, M. & Nielsen, J. Metabolic engineering strategies for microbial synthesis of oleochemicals. Metab. Eng. 29, 1–11 (2015).

Fang, L. X. et al. Genome-scale target identification in Escherichia coli for high-titer production of free fatty acids. Nat. Commun. 12, 4976 (2021).

Voelker, T. A. & Davies, H. M. Alteration of the specificity and regulation of fatty-acid synthesis of Escherichia coli by expression of a plant medium-chain acyl-acyl carrier protein thioesterase. J. Bacteriol. 176, 7320–7327 (1994).

Liu, J. H. et al. Redox cofactor engineering in industrial microorganisms: strategies, recent applications and future directions. J. Ind. Microbiol. Biotechnol. 45, 313–327 (2018).

Rahman, Z. et al. Escherichia coli as a fatty acid and biodiesel factory: current challenges and future directions. Environ. Sci. Pollut. Res. 23, 12007–12018 (2016).

Davies, H. M. et al. Developmental induction, purification, and further characterization of 12:0-ACP thioesterase from immature cotyledons of Umbellularia californica. Arch. Biochem. Biophys. 290, 37–45 (1991).

Van Nuland, Y. M. et al. Expansion of the omega-oxidation system AlkBGTL of Pseudomonas putida GPo1 with AlkJ and AlkH results in exclusive mono-esterified dicarboxylic acid production in E. coli. Microb. Biotechnol. 10, 594–603 (2017).

Kirmair, L. & Skerra, A. Biochemical analysis of recombinant AlkJ from Pseudomonas putida reveals a membrane-associated, flavin adenine dinucleotide-dependent dehydrogenase suitable for the biosynthetic production of aliphatic aldehydes. Appl. Environ. Microbiol. 80, 2468–2477 (2014).

Bowen, C. H. et al. Engineering Escherichia coli for conversion of glucose to medium chain omega-hydroxy fatty acids and alpha, omega-dicarboxylic acids. ACS Synth. Biol. 5, 200-206 (2016).

Schrewe, M. et al. Reaction and catalyst engineering to exploit kinetically controlled whole-cell multistep biocatalysis for terminal fame oxyfunctionalization. Biotechnol. Bioeng. 111, 1820–1830 (2014).

Bayer, T. et al. In vivo synthesis of polyhydroxylated compounds from a "hidden reservoir” of toxic aldehyde species. ChemCatChem 9, 2919–2923 (2017).

May, T., Ito, A. & Okabe, S. Induction of multidrug resistance mechanism in Escherichia coli biofilms by interplay between tetracycline and ampicillin resistance genes. Antimicrob. Agents Chemother. 53, 4628–4639 (2009).

Fan, P. H. et al. Biosynthetic origin of the octose core and its mechanism of assembly during apramycin biosynthesis. J. Am. Chem. Soc. 145, 21361–21369 (2023).

Goh, E. B. et al. Substantial improvements in methyl ketone production in E. coli and insights on the pathway from in vitro studies. Metab. Eng. 26, 67–76 (2014).

Davis, M. S., Solbiati, J. & Cronan, J. E. Overproduction of acetyl-CoA carboxylase activity increases the rate of fatty acid biosynthesis in Escherichia coli. J. Biol. Chem. 275, 28593–28598 (2000).

Wu, J. J. et al. Construction of artificial micro-aerobic metabolism for energy- and carbon-efficient synthesis of medium chain fatty acids in Escherichia coli. Metab. Eng. 53, 1–13 (2019).

Lai, N. Y. et al. One stone two birds: biosynthesis of 3-hydroxypropionic acid from CO2 and syngas-derived acetic acid in Escherichia coli. Synth. Syst. Biotechnol. 6, 144–152 (2021).

Vo, P. L. H. et al. CRISPR RNA-guided integrases for high-efficiency, multiplexed bacterial genome engineering. Nat. Biotechnol. 39, 480–489 (2021).

Sauer, U. et al. The soluble and membrane-bound transhydrogenases UdhA and PntAB have divergent functions in NADPH metabolism of Escherichia coli. J. Biol. Chem. 279, 6613–6619 (2004).

Chen, Y. W. et al. Manipulating multi-system of NADPH regulation in Escherichia coli for enhanced S-adenosylmethionine production. RSC Adv. 5, 41103–41111 (2015).

Lerchner, A., Jarasch, A. & Skerra, A. Engineering of alanine dehydrogenase from Bacillus subtilis for novel cofactor specificity. Biotechnol. Appl. Biochem. 63, 616–624 (2016).

Luo, Y. E., Zhang, T. & Wu, H. The transport and mediation mechanisms of the common sugars in Escherichia coli. Biotechnol. Adv. 32, 905–919 (2014).

Kurgan, G. et al. Directed evolution of Zymomonas mobilis sugar facilitator Glf to overcome glucose inhibition. J. Ind. Microbiol. Biotechnol. 49, kuab066 (2022).

Man, Z. W. et al. Regulation of intracellular ATP supply and its application in industrial biotechnology. Crit. Rev. Biotechnol. 40, 1151–1162 (2020).

Shen, Y. P. et al. ATP and NADPH engineering of Escherichia coli to improve the production of 4-hydroxyphenylacetic acid using CRISPR. Biotechnol. Biofuels 14, 100 (2021).

Jiang, M. et al. Co-expression of phosphoenolpyruvate carboxykinase and nicotinic acid phosphoribosyltransferase for succinate production in engineered Escherichia coli. Enzym. Microb. Technol. 56, 8–14 (2014).

Jaswal, K., Shrivastava, M. & Chaba, R. Revisiting long-chain fatty acid metabolism in Escherichia coli: Integration with stress responses. Curr. Genet. 67, 573–582 (2021).

Doukyu, N. & Taguchi, K. Involvement of catalase and superoxide dismutase in hydrophobic organic solvent tolerance of Escherichia coli. AMB Express 11, 97 (2021).

Imlay, J. A. Where in the world do bacteria experience oxidative stress?. Environ. Microbiol. 21, 521–530 (2019).

Chen, Y. W. et al. Enhanced glutathione production by bifunctional enzyme coupling with ydaO-based ATP regulating system in Escherichia coli. J. Funct. Foods 75, 104211 (2020).

Seo, S. W. et al. Genome-wide reconstruction of OxyR and SoxRS transcriptional regulatory networks under oxidative stress in Escherichia coli K-12 MG1655. Cell Rep. 12, 1289–1299 (2015).

Malca, S. H. et al. Bacterial CYP153A monooxygenases for the synthesis of omega-hydroxylated fatty acids. Chem. Commun. 48, 5115–5117 (2012).

Xue, H. J. et al. Controlling chemo- and regioselectivity of a plant P450 in yeast cell toward rare licorice triterpenoid biosynthesis. ACS Catal. 10, 4253–4260 (2020).

Zhou, P. P. et al. Directed coevolution of β-carotene ketolase and hydroxylase and its application in temperature-regulated biosynthesis of astaxanthin. J. Agric. Food Chem. 67, 1072–1080 (2019).

Rapp, L. R. et al. Substrate anchoring and flexibility reduction in CYP153AM. aq leads to highly improved efficiency toward octanoic acid. ACS Catal. 11, 3182–3189 (2021).

Baud, D. et al. A rapid, sensitive colorimetric assay for the high-throughput screening of transaminases in liquid or solid-phase. Chem. Commun. 51, 17225–17228 (2015).

Zhang, H. M. et al. The full-length cytochrome P450 enzyme CYP102A1 dimerizes at its reductase domains and has flexible heme domains for efficient catalysis. J. Biol. Chem. 293, 7727–7736 (2018).

Smith, A. J. et al. Guiding biomolecular interactions in cells using de novo protein-protein interfaces. ACS Synth. Biol. 8, 1284–1293 (2019).

Hou, J. R. et al. Engineering the ultrasensitive transcription factors by fusing a modular oligomerization domain. ACS Synth. Biol. 7, 1188–1194 (2018).

Kang, W. et al. Modular enzyme assembly for enhanced cascade biocatalysis and metabolic flux. Nat. Commun. 10, 4248 (2019).

Castang, S. & Dove, S. L. High-order oligomerization is required for the function of the H-NS family member MvaT in Pseudomonas aeruginosa. Mol. Microbiol. 78, 916–931 (2010).

Pirone, L. et al. Identifying the region responsible for Brucella abortus MucR higher-order oligomer formation and examining its role in gene regulation. Sci. Rep. 8, 17238 (2018).

Lee, M. J. et al. Engineered synthetic scaffolds for organizing proteins within the bacterial cytoplasm. Nat. Chem. Biol. 14, 142–147 (2018).

Feng, J. et al. Renewable fatty acid ester production in Clostridium. Nat. Commun. 12, 4368 (2021).

Kim, J. et al. Rewiring fadr regulon for the selective production of omega-hydroxy palmitic acid from glucose in Escherichia coli. Metab. Eng. 47, 414–422 (2018).

Julsing, M. K. et al. Outer membrane protein alkl boosts biocatalytic oxyfunctionalization of hydrophobic substrates in Escherichia coli. Appl. Environ. Microbiol. 78, 5724–5733 (2012).

Wu, Y. P. et al. Serum metabolome and gut microbiome alterations in broiler chickens supplemented with lauric acid. Poult. Sci. 100, 101315 (2021).

Woo, J. M. et al. Activation of the glutamic acid-dependent acid resistance system in Escherichia coli BL21(DE3) leads to increase of the fatty acid biotransformation activity. PLoS ONE 11, e0163265 (2016).

Abramson, J. et al. Accurate structure prediction of biomolecular interactions with alphafold 3. Nature 630, 493–500 (2024).

Beyer, N. et al. P450(BM3) fused to phosphite dehydrogenase allows phosphite-driven selective oxidations. Appl. Microbiol. Biotechnol. 101, 2319–2331 (2017).

Tong, T. et al. Engineering microbial metabolic energy homeostasis for improved bioproduction. Biotechnol. Adv. 53, 107841 (2021).

Liu, R. M. et al. Iterative genome editing of Escherichia coli for 3-hydroxypropionic acid production. Metab. Eng. 47, 303–313 (2018).

Sazykin, I. et al. Cyclohexane, naphthalene, and diesel fuel increase oxidative stress, CYP153, sodA, and recA gene expression in Rhodococcus erythropolis. Microbiologyopen 8, e00855 (2019).

Cao, Y. J. et al. Metabolic engineering of Escherichia coli for the production of hydroxy fatty acids from glucose. BMC Biotechnol. 16, 26 (2016).

Xiao, K. et al. Metabolic engineering for enhanced medium chain omega hydroxy fatty acid production in Escherichia coli. Front. Microbiol. 9, 139 (2018).

Sung, C. et al. The production of ω-hydroxy palmitic acid using fatty acid metabolism and cofactor optimization in Escherichia coli. Appl. Microbiol. Biotechnol. 99, 6667–6676 (2015).

Hu, Q. et al. Selective biosynthesis of retinol in S. cerevisiae. Bioresour. Bioprocess 9, 22 (2022).

Jiao, X. et al. Efficient secretory production of δ-tocotrienol by combining pathway modularization and transportation engineering. J. Agric. Food Chem. 71, 9020–9030 (2023).

Arenas, F. A. et al. The Escherichia coli BtuE protein functions as a resistance determinant against reactive oxygen species. PLoS ONE 6, e15979 (2011).

Ding, L. et al. The role of peroxidase EfeB in Escherichia coli under cell oxidative stress. Food Ferment. Ind. 46, 33–39 (2020).

Zhu, C. C. et al. Enhancing 5-aminolevulinic acid tolerance and production by engineering the antioxidant defense system of Escherichia coli. Biotechnol. Bioeng. 116, 2018–2028 (2019).

Wang, M. et al. Cofactor engineering for more efficient production of chemicals and biofuels. Biotechnol. Adv. 35, 1032–1039 (2017).

Zhang, Y. W. et al. Multicopy chromosomal integration using crispr-associated transposases. ACS Synth. Biol. 9, 1998–2008 (2020).

Wu, S. et al. Highly regio- and enantioselective multiple oxy- and amino-functionalizations of alkenes by modular cascade biocatalysis. Nat. Commun. 7, 11917 (2016).

HamediRad, M. et al. Highly efficient single-pot scarless golden gate assembly. ACS Synth. Biol. 8, 1047–1054 (2019).

Fiorentini, F. et al. The extreme structural plasticity in the CYP153 subfamily of P450s directs development of designer hydroxylases. Biochemistry 57, 6701–6714 (2018).

Shahrokh, K. et al. Quantum mechanically derived amber-compatible heme parameters for various states of the cytochrome P450 catalytic cycle. J. Comput. Chem. 33, 119–133 (2012).

Acknowledgements

We thank Prof. Sheng Yang from the Chinese Academy of Sciences and Prof. Zhi Li from the National University of Singapore for generously providing experimental materials. This work was supported by the National Key Research and Development Program of China (Grant No. 2020YFA0908400), the National Natural Science Foundation of China (Grant No. 22278360), and the Fundamental Research Funds for the Central Universities (Grant No. 226-2022-00055).

Author information

Authors and Affiliations

Contributions

The manuscript was written through the contributions of all authors. All authors have approved the final version of the manuscript. J.G. and T.W. performed the experiments, analyzed the results, and prepared the manuscript. H.Y. provided resources and supervised the project. L.Y. designed the study, supervised the project, discussed the results, and revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Bruno Bühler, who co-reviewed with Adrian Tüllinghoff, Yi Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ge, J., Wang, T., Yu, H. et al. De novo biosynthesis of nylon 12 monomer ω-aminododecanoic acid. Nat Commun 16, 175 (2025). https://doi.org/10.1038/s41467-024-55739-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-55739-0

This article is cited by

-

Towards sustainable long-chain dicarboxylic acid production: challenges and opportunities

World Journal of Microbiology and Biotechnology (2026)