Abstract

This study presents a low residual tensile stress, flexible thin film encapsulation with a 2 mm bending radius based on atomic layer deposition (ALD), specifically plasma-enhanced ALD (PEALD). By utilizing polydimethylsiloxane (PDMS) to release stress during deposition, we achieved a wrinkled morphology film that reduces stress magnitude from 103 to 102 compared to conventional Al2O3 films. This wrinkled film enhances optical modulation to light extraction, increasing the external quantum efficiency (EQE) of organic light-emitting diode (OLED) by up to 14.95%. The water vapor transmission rate (WVTR) is 4.49 × 10−5 g/m2/day at 60 °C/90% RH, and the film retains about 90% of its initial properties after 10,000 bending cycles. This work introduces a novel solution for flexible ALD encapsulation, demonstrating ultra-flexible properties while improving device efficiency.

Similar content being viewed by others

Introduction

In the context of the comprehensive informatization of modern society, display technology is assuming an increasingly important role. This is reflected in the ongoing development and iteration of flexible and wearable display technologies1,2,3. In display devices, the organic light-emitting diode (OLED) has become the main research direction for flexible and wearable display devices due to their high efficiency, wide color gamut and good mechanical properties2,4,5,6,7. However, OLED devices are susceptible to the corrosive effects of water vapor and oxygen in the surrounding environment, which can result in accelerated degradation of device properties and reduced operational lifetime8,9,10. Atomic layer deposition (ALD) and chemical vapor deposition (CVD) are widely used to prepare thin film encapsulation (TFE) to protect OLEDs etc., as they can prepare thin films with good densification5,8,11,12,13,14. Furthermore, due to the low glass transition temperature of OLED device materials, low-temperature encapsulation films are frequently prepared using plasma enhanced atomic layer deposition (PEALD)12,15,16. However, the residual stress inherent to ALD’s own process, in conjunction with the additional residual stress introduced by plasma enhanced will result in a further degradation of the mechanical properties of the film1,17,18,19. This has the potential to significantly impact the applicability of ALD in flexible encapsulation.

By using ALD, Chang et al. prepared 50 nm-thick Al2O3 encapsulation film with an initial water vapor transmittance rate (WVTR) of 9.0 × 10−4 g/m2/day, the WVTR increased to 2.1 × 10−3 g/m2/day during the subsequent 1000 repetitions of 12 mm bending radius, indicating that the structure of the film was damaged during the bending process, resulting in the formation water vapor permeation paths20. Researchers have sought to enhance the mechanical properties of these films by reducing residual stresses. George et al. prepared the alucone/Al2O3 composite structure. The low residual stress of the alucone film effectively relieves the residual stress of the alucone/Al2O3 composite structure and enhances the tensile strain of the film21. Chae et al. grew SiNx prepared by plasma enhanced chemical vapor deposition (PECVD) on both sides of a poly ethylene naphthalate (PEN) substrate, and maintained the overall structure at a low stress level by means of contralateral stress neutralization22. Following 1000 repetitions of bending at a 15 mm bending radius, the increase of WVTR was 33% for the bilaterally film structure and 51% for the unilaterally film structure. Nevertheless, none of the aforementioned methods proved to be an effective solution to the issue of excessive residual stresses within the unilaterally film. Kim et al. discovered that the formation of defects during the film growth process also influences the residual stresses within the film during mechanical movement. When the film is subjected to mechanical movement, the stresses are concentrated at the defective locations, resulting in the film releasing the excessive stresses through delamination or fracture. Consequently, the rectification of defects within the film can enhance its mechanical properties23. Research group repairs defects in ALD-Al2O3 films using self-assembled 1-dodecanethiol (DDT) materials to good effect. However, if the size of the defects is smaller than the size of the self-assembled molecule, the latter will not be functional. It is therefore evident that the development of a straightforward method for the release of internal stresses in ALD films would represent a significant advance in the field of flexible, wearable devices24,25,26.

In this study, polydimethylsiloxane (PDMS) is used to release the large residual tensile stresses generated during the preparation of PEALD-Al2O3. PDMS drives the wrinkled morphology of Al2O3 due to the stresses during preparation. The magnitude of stress in the wrinkle Al2O3 film is decreased from the level 103 to 102, and the densification of the film was not affected. The WVTR of 4.49 × 10−5 g/m2/day (60 °C/90% RH) was obtained for the wrinkle Al2O3 film deposited at room temperature. The low residual tensile stress film exhibits minimal residual tensile stress, which markedly enhances its mechanical properties. The wrinkle film demonstrates a capacity to maintain about 90% or more of its initial properties over 10000 repetitions at the bending radius of 2 mm. The morphology of the wrinkle also has a strong scattering effect, which enables the light to exit the device more effectively and enhances the efficiency of the OLED device, thereby distinguishing it from the conventional thin-film encapsulation. This method proposes a novel approach for preparing low residual tensile stress thin films and flexible encapsulation. Additionally, its integrated light scattering effect provides new insights for the future development of more efficient and energy-efficient electronic devices.

Results

Formation and causes of wrinkled morphology

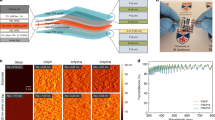

PEALD-Al2O3 film were prepared at 40 °C for 300 cycles illustrate atomic force microscope (AFM) images shown in Fig. 1a and optical microscope images in Supplementary Fig. 1. The pristine PDMS (4 μm) film appears flat without distinct morphology, while the PEALD- Al2O3 film on PDMS exhibits a pronounced wrinkled structure, with roughness increasing from 1.05 nm to 63.9 nm. This wrinkled morphology is consistently observed across various deposition conditions (Supplementary Fig. 2 and Supplementary Table 1) and increases with temperature and the number of ALD cycles.

Three hypotheses explain the wrinkled morphology’s formation: first, the difference in thermal expansion coefficients (TEC) between PDMS and the PEALD-Al2O327. Second, the polymerization between the methyl groups in PDMS and the trimethylaluminum (TMA) precursor28. Thirdly, residual tensile stress and thermal stress are applied to the PDMS, which releases the stress to form wrinkles. The first hypothesis was tested by depositing at room temperature (RT). Figure 1b, c show optical microscope and schematic images at 0-500 cycles at RT. Supplementary Fig. 3 displays the AFM images prepared at RT, revealing that wrinkles still form without heating. Initially, wrinkles are not observed, but they become more pronounced with increased cycles, indicating that some factors accumulate during deposition to produce the wrinkled morphology. At the same time, it can be seen that regardless of changes in sedimentary conditions (Supplementary Fig. 2 and Supplementary Fig. 3), the wavelength of the wrinkled morphology generally ranges between 2-3 μm. This phenomenon may be due to the fact that the formation of wrinkled morphology, regardless of the cause, is spontaneous, non-directional, and tends to be irregular. Therefore, the formation of wrinkles in all directions influences each other, resulting in a wavelength of 2–3 μm, that tends to be stable.

Figure 2a illustrates the second hypothesis, where methyl group accumulation contributes to wrinkle formation. The Fig. 2b shows the in-situ quadrupole mass spectrometry (QMS) test for the preparation of Al2O3 thin film by PEALD. Based on the classical alumina reaction process of Eqs. 1 and 25, the signature by-products were selected for real-time monitoring of the by-product changes during the preparation process. Where the active site exposed to the substrate surface is marked with ‘*’:

Where Eq. 1 is a typical combustion reaction caused by O atoms embedded in the Al-C bond, and Eq. 2 is an atypical combustion reaction caused by O ions embedded in the Al-C-H. Based on the existence of these two reaction pathways, we selected three characteristic by-products: CH4, CO, and CO2, with corresponding mass-to-charge ratios (m/z) of 16, 28, and 44. Figure 2b shows a complete PEALD cycle, with O2 plasma pulse as the boundary. Before the O2 plasma pulse, there are TMA pulses and purge, and after the O2 plasma pulse, there are O2 plasma pulses and purge. As shown in the figure, when using traditional PEALD-Al2O3 as a reference, the relative intensity changes of by-products from the Al2O3 deposition process on PDMS are not significantly different from those of the traditional process, indicating that the relative content of by-products in the two processes is also not significantly different. However, if methyl group polymerization occurs during the deposition process, it would inevitably lead to a reduction in the relative content of CH4 as a by-product. Since there is no difference in the relative content of this by-product between the two processes, this suggests that the hypothesis of methyl groups polymerization is incorrect. Also, in Supplementary Fig. 4 presents Fourier transform infrared spectroscopy (FTIR) normalized spectra for samples prepared at 80 °C and RT, alongside pristine PDMS. Both samples show the Al2O3 peak near 850 cm−1, confirming that no new functional groups were created or destroyed during the process29,30,31. In Fig. 2c to e, the X-ray photoelectron spectroscopy (XPS) shows the spectra of Al 2p and C 1 s. The thickness of the Al2O3 was 10 nm, to verify the hypothesis, this thickness ensures that the XPS test location reaches the interface between aluminum oxide and PDMS or lower. The Al-O bonds deposited on PDMS were around 74.3 eV32, which is consistent with typical Al2O3, and there was no presence of Al-C bonds that would result from a polymerization situation33. The disappearance of the C-Si bond in C 1 s and the change in C-O and C=O bond generation is due to the effect of the O2 plasma pulsed into the PDMS during PEALD. This also explains the appearance of disrupted surface morphology of PDMS in the Supplementary Fig. 3. The XPS results indicate that the contact between the Al2O3 and the PDMS is only a physical covering effect, and that no polymerization reaction occurs during the deposition process, resulting in the formation of a special morphology. Additionally, a ZnO film was prepared at 60 °C for 300 cycles using thermal atomic layer deposition (TALD) with diethylzinc (DEZ) and deionized water, as depicted in Supplementary Fig. 5. The images and roughness of the ZnO wrinkle films for the remaining conditions (Supplementary Fig. 6 and Supplementary Table 2). This ZnO film also displayed a wrinkled morphology, suggesting that the wrinkling is not related to the polymerization of functional groups, since DEZ cannot polymerize with PDMS methyl groups. Notably, whether employing TALD or PEALD during film preparation, residual tensile stress is invariably generated. The introduction of plasma increases the residual tensile stresses in the film. Synthesizing these analyses, we conclude that the underlying cause of wrinkles is the release of residual tensile stress and thermal stress within the film.

Stress relief and mechanical properties of wrinkled encapsulation

By using a step profiler to determine the curvature of the film and calculated the residual tensile stress of the film using Stoney’s law34,35,36.

Where, Es is the Young’s modulus of the substrate, νs is the Poisson ratio of the substrate, ts and tf are the thickness of the substrate and the film, respectively. r2 and r1 correspond to the curvature radius before and after deposition.

The contour curves and calculated residual tensile stresses for TALD and PEALD-Al2O3, shown in Supplementary Fig. 7. indicate that TALD film stress is 50.6% lower than that of PEALD. It is particularly noteworthy that when PEALD is prepared on flexible substrates, such as polyimide (Pi), the substrate will exhibit a notable tendency towards spontaneous curling. This phenomenon can be attributed to the presence of excessive residual tensile stress within the film, with the degree of spontaneous curling correlating directly with the magnitude of residual tensile stress. This phenomenon also occurs in other thin film preparation processes such as magnetron sputtering (Sputter). Figure 3a and b display that PEALD- Al2O3 at RT and 300 cycles causes less curling than at 500 cycles. Figure 3c and d depict the curling of indium tin oxide (ITO) on Pi (25 μm), showing less curling after 10 minutes of sputtering compared to 30 minutes. Figure 3e–h are the AFM images of the four samples; none of the four samples has any special morphology on their surfaces. Figure 3i–l shows that Al2O3 and ITO on Pi/PDMS substrate exhibit significantly reduced curling, and Fig. 3m–p shows the AFM images of the four samples. It can be found that the Al2O3 and ITO prepared on Pi/PDMS substrates have a wrinkled morphology, indicating stress release.

a, b Images of the curling phenomenon of 300/500 cycles of PEALD-Al2O3 prepared at RT on Pi substrate. c, d Images of the curling phenomenon of 10/30 min. of ITO prepared at RT on Pi substrate. e, f AFM images of 300/500 cycles of PEALD-Al2O3 prepared at RT on Pi substrate. g, h AFM images of 10/30 min. of ITO prepared at RT on Pi substrate. i, j Images of the curling phenomenon of 300/500 cycles of PEALD-Al2O3 prepared at RT on Pi/PDMS substrate. k, l Images of the curling phenomenon of 10/30 min. of ITO prepared at RT on Pi/PDMS substrate. m, n AFM images of 300/500 cycles of PEALD-Al2O3 prepared at RT on Pi/PDMS substrate. o, p AFM images of 10/30 min. of ITO prepared at RT on Pi/PDMS substrate. q Contour curves of deposited 300/500 cycle Al2O3 film as well as wrinkled Al2O3 film and calculated stress magnitude. r Schematic image of wrinkled morphology formation and residual tensile stress release.

The residual tensile stresses applied to the PDMS to form a wrinkled morphology can be split into the residual tensile stresses inherent in the ALD and the thermal stresses that occur when the material is deposited at relatively high temperatures. In previous experiments, various samples deposited at room temperature have been excluded from the temperature factor and produced a distinct wrinkled morphology, and the release of residual tensile stresses was proved to be one of the reasons for the wrinkled morphology by the curling test of the flexible substrate. However, if temperature is not one of the factors affecting the wrinkled morphology, it is not possible to explain that the roughness of the PEALD-Al2O3 wrinkled film at 40 °C (63.9 nm) is much smaller than that of the PEALD-Al2O3 wrinkle film at 80 °C (88.6 nm) for the same number of cycles. Therefore, although it is proved that the films still produce wrinkled morphology without temperature interference, suggesting that the release of residual tensile stresses will be the main factor in the formation of the wrinkled morphology. However, the mismatch of thermal stresses between the different materials will be a secondary factor in the formation of wrinkles at higher deposition temperatures. According to the thermal stress equation37,38:

Where Efilm is the Young’s modulus of the deposited film, α is the linear thermal expansion coefficient of the material, and ΔT is the difference between the deposition temperature and room temperature. According to the formula, the thermal stress on PDMS in the PDMS/PEALD-Al2O3 film system is about 22.5 MPa at the deposition temperature of 40 °C, and 67.5 MPa and 112.5 MPa at 60 and 80 °C, both of which are much larger than the Young’s modulus of the PDMS, and therefore the thermal stress on PDMS will also cause the deformation of PDMS. cause deformation of PDMS. Therefore, if the deposition is not carried out at room temperature, the increase in temperature will generate enough stress to deform the PDMS material, which will also lead to a wrinkled appearance of the whole system.

Figure 3q presents the contour curves of PEALD-Al2O3 film for 300 and 500 cycles, showing a significant reduction in residual tensile stress from 1794.22 MPa to 216.60 MPa and from 1825.22 MPa to 440.77 MPa, respectively. This indicates that the wrinkled morphology effectively releases residual tensile stress. Thus, in the ALD and PEALD processes, the residual tensile stress in the film affects the PDMS, leading to wrinkles that help release this stress during deposition, as illustrated in Fig. 3r.

It is worth highlighting that although previous studies have reported many ways of forming wrinkled morphologies39, the use of residual tensile stress inherent in ALD to form wrinkled morphologies in order to release stress and improve the mechanical properties of thin films is an interesting phenomenon discovered in this study. This method can reduce residual stress by an order of magnitude, providing a solution for tensile-compressive stress coupling engineering within devices.

Figure 4a, b include the cross-sectional SEM image confirming strong adhesion between PDMS and Al2O3 without void formation. The wrinkled morphology driven by PDMS wrinkles, preserves the film’s encapsulation properties while significantly reducing residual tensile stress, enhancing flexibility and preventing fracture during mechanical movement. The encapsulation temperature directly affects device properties. Consequently, the temperature of 30 °C (RT)-50 °C, lower than the previous low-temperature encapsulation of 80 °C was selected as the preparation temperature for the encapsulation film40,41. To test flexible encapsulation, 50 nm wrinkled Al2O3 films were prepared on Pi substrates and subjected to 10000 bending repetitions at 2 mm bending radius (approximately 0.725% strain). The bending strain is calculated as follows: where t is the thickness of the material and R is the bending radius.

a, b SEM image of the cross section of wrinkle Al2O3 film. c Optical microscope images of 500 cycles wrinkle Al2O3 before and after bending at RT. d WVTR of 500 cycles wrinkle Al2O3 at RT before and after bending from 1/R-Time curve. e Optical microscope images of 500 cycles PEALD-Al2O3 before and after bending at RT. f WVTR of 500 cycles PEALD-Al2O3 at RT before and after bending from 1/R-Time curve. g Optical microscope images in all directions of bending and before and after bending. h WVTR changes after all directions bending from 1/R-Time curve.

The WVTR of the film was tested using an electrical calcium corrosion test method over an area of 10 × 2.25 mm. WVTR results at 60 °C/90% RH showed in Fig. 4c, d, the wrinkled film had a WVTR of 4.49 × 10−5 g/m²/day before bending and 4.96 × 10−5 g/m²/day after, indicating a change rate of approximately 10.4% due to the wrinkle encapsulation. WVTR was calculated using the following equation:

The stoichiometric constants are denoted by n. M (H2O) and M (Ca) represent the molar mass of water and calcium, respectively, δCa represents the density of calcium, ρCa represents the electrical resistivity of calcium, and R represents the resistance of the calcium film. The length and width of the calcium film are denoted by L and b. The length and width of the calcium film are denoted by L and b11,42.

This demonstrates that wrinkled films can meet the requirements for single-direction bending at room temperature. Comparatively, PEALD- Al2O3 film (50 nm) of the same thickness was also tested. The PEALD-Al2O3 film exhibited cracking (approximately 0.625% strain), accompanied by a significant decrease in WVTR from 4.70 × 10−5 g/m2/day to 6.20 × 10−3 g/m2/day, representing a two-order-of-magnitude decrease and a 131-fold increase (Fig. 4e, f). As a result, the PEALD- Al2O3 film failed the flexible encapsulation test. The WVTR test results and associated statistics for the same bending radius and number of repetitions at preparation temperatures of 35/40/45/50 °C (Fig. 5, Supplementary Fig. 8 and Table 1). To prove the advantages of the encapsulation properties of wrinkle films, the WVTR test was carried out under harsh environment with the temperature of 85 °C & 85% RH. As shown in Supplementary Figure 9, The WVTR only increased 12.3%, which further demonstrated the great encapsulation properties of wrinkle films. In Fig. 5, each temperature group had ten samples, including the data presented in the manuscript. The wrinkled film demonstrates excellent encapsulation and mechanical properties under low-temperature conditions, beneficial for temperature-sensitive organic optoelectronic devices. If wrinkles are unidirectional, stress is released only in that direction, enhancing mechanical properties there while leaving others unchanged. For future flexible, wearable devices, encapsulation films must possess strong mechanical properties in all directions. The wrinkled morphology, as shown in Supplementary Fig. 10, is anisotropic, with an almost equal distribution of wrinkles across all directions, ensuring mechanical properties in all directions. The release of residual tensile stress in all directions allows the wrinkled film to exhibit excellent mechanical properties uniformly testing the film by bending it in four directions (Fig. 4g). Optical microscope revealed no fractures after four vertical bends, indicating minimal damage during mechanical movement. Since the vertical range encompasses all pinch angles, bending at four angles perpendicular to each other can be representative of bending at all angles. This demonstrates that the wrinkled film can bend freely while maintaining its mechanical properties, making it suitable for future flexible and wearable device encapsulation. Figure 4h shows that after repetitions of 10000 consecutive bending in four directions, the WVTR of the film does not decrease significantly from 4.31 × 10−5 g/m2/day to 4.66 × 10−5 g/m2/day, with a decrease rate of 8.1%. The excellent mechanical and encapsulation properties of the wrinkle encapsulation film after bending in four directions are demonstrated. The WVTR before and after strain with a strain amount equivalent to the bending radius is shown in Supplementary Fig. 11 . To investigate the mechanical performance limits of the wrinkled morphology, we further reduced the bending radius in Supplementary Fig. 12 . The results showed that when the bending radius was 1 mm (strain of approximately 1.45%), the WVTR of the film increased from 4.66 × 10-5 g/m2/day to 3.05 × 10-4 g/m2/day, representing 550% increase. When the bending radius was 0.5 mm (strain of approximately 2.90%), the WVTR of the film increased from 4.82 × 10−5 g/m2/day to 3.47 × 10−3 g/m2/day, representing a 71-fold increase. The film begins to break at a bending radius of 1 mm and is severely damaged at 0.5 mm. Table 2 compares the flexible encapsulation effects of this study with those of other types of flexible encapsulation. The wrinkled encapsulation has excellent performance in terms of bending radius and WVTR.

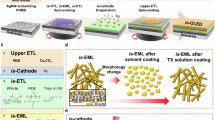

Organic light-emitting diode applications in wrinkle encapsulation

Encapsulated and unencapsulated OLED devices were tested at 30 °C and 40% RH with the 50 nm wrinkled encapsulation layer. Figure 6a and b display that the encapsulated device maintained stable current density and experienced a slight brightness increase. The spectrum of OLED is shown in Supplementary Fig. 13 . Results from standing experiments and external quantum efficiency (EQE) tests in Supplementary Figs. 14 and 15 indicate that the wrinkled encapsulation OLED retained 95% of its original EQE over 35 days, while the unencapsulated device failed within 35 days. This demonstrates the effectiveness of wrinkled encapsulation for OLED and other organic optoelectronic devices. Figure 6b shows increased brightness in the wrinkled encapsulation device compared to the unencapsulated device, leading to enhanced EQE. To ensure accuracy, additional tests at 35 °C to 50 °C were conducted (Supplementary Fig. 16 and Table 3). As in Table 3, the increase of EQE in OLEDs linked to increased wrinkle degree. The wrinkled morphology enhances light scattering at the air-substrate interface, reducing light extraction losses and improving the device’s light extraction capability (Fig. 6c)43,44,45,46,47. As shown in Supplementary Fig. 17 , the normalized electroluminescence intensity (EL) indicates that the OLED encapsulated with wrinkle exhibits stronger lateral emission, which also proves the light scattering effect of the wrinkled morphology, thereby allowing more light energy to be emitted from the substrate. To verify the light scattering effect of the wrinkled morphology, we tested the refractive index of wrinkle film prepared at different temperatures by the ellipsometer, as shown in the Supplementary Fig. 18 . We then selected the refractive index value at 510 nm, the wavelength with the highest intensity in the OLED spectrum, for comparison. In wrinkled films, since the degree of wrinkle may vary slightly, we introduce the concept of “equivalent refractive index” to describe the overall refractive index of the wrinkled film. We used the Fresnel equation in MATLAB to calculate the transmission coefficient (in which, θi is the angle of incidence). The results are shown in Supplementary Fig. 19 and Table 4.

When the wrinkled film is prepared at 50 degrees Celsius, the equivalent refractive index is 1.3, and the transmission coefficient can reach 0.87. In comparison, the glass substrate is 0.8, proving that more light will be emitted into the air. Additionally, when the preparation temperature is 50 °C, the critical angle for light exiting the wrinkle film into air is 50.3 °, which is greater than the critical angle of 41.8 ° between glass and air, further optimizing the light emission effect. These results indicate that the bigger the roughness, the better the light scattering effect and the more significant the improvement in EQE. The EQE maximum increase of 14.95% (50 °C and 500 cycles). Therefore, the wrinkle encapsulation not only protects the device from steam corrosion but also improves the device’s properties to a certain extent, which is different from the traditional thin film encapsulation. In future-oriented display applications, whether the transmittance and its haze situation will be important indicators in the application process. As shown in Supplementary Fig. 20, in the visible light, the transmittance of the vast majority of the film can be maintained above 90%. In 350–400 nm, the reason for the relatively low transmittance mainly depends on the limitations of the PDMS material itself48. At 50 °C, the haze of the film can reach 72%, indicating that the film has a strong scattering effect, further verifying its light scattering effect to enhance the effect of EQE.

Finally, to observe the change in properties of flexible OLED after bending, flexible OLED with and without encapsulation were tested by bending them 1000 repetitions at the bending radius of 2 mm (approximately 2.6% strain) (The JVL figure after bending is in Supplementary Fig. 21 ). The OLED was then exposed to 30 °C and 40% RH for 840 h. As shown in the bending damage test area in Fig. 6d, the bending process took 4000 seconds, and the properties of the unencapsulated flexible OLED degraded faster than the encapsulated OLED due to the accelerated ingress of water into the device as a result of the disruption of the device material structure during the bending process. As shown in the stability test area, the unencapsulated OLED was close to failure after 672 h, with the EQE of only 20% of the original, and after 840 h the OLED had completely failed. The encapsulated device, on the other hand, retained more than 95% of its efficiency (after bending) after 840 h.

Discussion

To address the issue of excessive stress in PEALD films deposited at low temperatures, we developed a low-stress, flexible atomic layer deposition encapsulation film with a wrinkled morphology. This innovation utilizes PDMS to effectively release residual tensile stress during the plasma-enhanced atomic layer deposition process. The resulting film shows a significant reduction in stress, decreasing from approximately 1385 MPa at 500 cycles and 1578 MPa at 300 cycles, while maintaining densification, evidenced by a WVTR of 4.49 × 10−5 g/m2/day for the Al2O3 film at RT. Its mechanical properties allow it to retain about 90% of its initial performance after 10000 bending repetitions at the 2 mm bending radius. The wrinkled morphology enhances light scattering at the air-substrate interface, improving the film’s optical modulation and device’s light extraction capability and increasing the EQE of OLEDs by up to 14.95%. This work represents a significant advancement in ALD flexible thin film encapsulation, achieving excellent encapsulation properties alongside improved device efficiency. The implications extend beyond organic optoelectronic devices; the proposed research method provides a new approach to tensile stress regulation for the entire future structure. We can use simpler techniques to release tensile stress in the encapsulation film while enhancing its mechanical properties to meet the requirements of full-stack stress engineering (such as tensile-compressive stress coupling) control. Compared with the currently widely used PECVD-SiN + organic material encapsulation, this study proposes an integrated solution: innovatively combining a flexible encapsulation layer prepared using stress control engineering with a light scattering enhanced layer to achieve both flexible encapsulation and light scattering enhancement with a single structure. Therefore, the method used in this study can be used to prepare low-stress, flexible films with enhanced light extraction and encapsulation properties, which have broad prospects for various optical modulation films and semiconductor applications, and can meet the demand for smaller, more efficient and more energy-efficient electronic devices.

Methods

Materials

Polydimethylsiloxane (PDMS; Dow Corning 184) was purchased from Dow Corning. Trimethylaluminum (TMA, 99.9999%) and diethylzinc (DEZ, 99.9999%) were purchased from Nanjing Aimouyuan Co. Indium tin oxide (ITO) target (In2O3: SnO2 = 9:1, 99.99%) and lithium fluoride (LiF, 99.99%) purchased from Zhongnuo New Material Co. Molybdenum trioxide (MoO3, 99.99%), 4,4’-Cyclohexylbis[N, N-bis(4-methylphenyl)aniline] (TAPC, 99.99%), 4,4’,4’-Tris(carbazol-9-yl)triphenylamine (TCTA, 99.99%), Tris(2-phenylpyridine)iridium, (Ir(ppy)3, 99.99%), Tris(2-phenylpyridine)iridium, (TMPyPB, 99.99%), aluminum pellets (Al, 99.99%) were purchased from Xi’an Polymer Light Technology Co. Pi (polyimide, 100HN, 25 μm) was purchased from DuPont Co, Potassium bromide(KBr) purchased from national drug reagent website.

Preparations of the thin films

The glass substrate was first wiped with Decon 90 detergent, deionized water, and anhydrous ethanol, and then ultrasonically cleaned in the same order for 20 min each time. After cleaning, the glass substrate was blown dry using a nitrogen gun and dried in a drying oven for 30 min to obtain a clean glass substrate. The Pi substrate was attached to the surface of the clean glass substrate using double-sided tape. The PDMS host agent and curing agent were mixed in a mass ratio of 10:1 and spun-coated onto the substrate at a spin-coating rate of 6000 rpm/min and an acceleration of 3000 rpm/s. The PDMS was followed by curing at a heated 60 °C for 4 h, obtaining PDMS film. High-purity Ar (99.999%) at a flow rate of 90 sccm was used as the carrier gas and precursor cleaning gas in the PEALD-Al2O3 preparation process. Trimethylaluminum (TMA, 99.9999%) and oxygen plasma were used as the aluminum and oxygen sources for PEALD- Al2O3.TMA was kept at room temperature, and oxygen plasma was generated with 15 sccm of oxygen (99.999%) at 100 W RF power. The substrate temperature was set at room temperature/35/40/45/50/60/80 °C. The process parameters for growing PEALD- Al2O3 were TMA pulse for 0.06 s, TMA purge for 80 s, oxygen plasma pulse for 10 s, and oxygen plasma purge for 100 s (1 Å per cycle). High-purity Ar (99.999%) with a flow rate of 90 sccm was used as the carrier gas and precursor purge gas in the TALD-ZnO preparation process. Diethyl zinc (DEZ, 99.9999%) and deionized water (99.999%) were used as zinc and oxygen sources for TALD-ZnO. DEZ and deionized water were kept at room temperature. The substrate temperature was set at 60/80 °C. The process parameters for growing TALD-ZnO were DEZ pulsed for 0.06 s and DEZ purged for 80 s, and deionized water pulsed for 0.05 s and deionized water purged for 100 s.

Preparations of the OLEDs

The cleaning process for ITO is the same as for the glass substrate. ITO/PEN is used for flexible OLEDs. Subsequently, the device was prepared in a thermal evaporation, and the device structure was as ITO/5 nm MoO3/50 nm TAPC/10 nm TCTA/1 nm Ir(ppy)3/40 nm TmPyPB/1 nm LiF/ 100 nm Al. In rigid OLEDs, a 50 nm wrinkle film is used to encapsulate the cathode. In flexible OLEDs, 50 nm wrinkle film is used to encapsulate the cathode and the PEN’s back.

Test equipment and methods

The surface morphology of the films was observed by using an Olympus optical microscope (BX51M) and an atomic force microscope (AFM, ICON-PT, Bruker). PDMS and PEALD-Al2O3 preparations were subjected to Fourier transform infrared spectroscopy (FTIR) by ALD 300 cycles on KBr compacts. The cross-sectional state of the wrinkled films and the elemental composition were observed and analyzed using scanning electron microscopy (SEM). Folding experiments using three-axis bending equipment (Fold Test System FT-300, Fstar) in the simulation of the real bending situation, the bending radius is set to set to 2 mm, the bending speed of 180 °/s, and the bending state lasts for 1 s. The thickness of the PDMS was determined using a step profiler at 4 μm. Wrinkled Al2O3 or Al2O3 was deposited on 25 mm × 25 mm Si wafers, and the curvature of the films was determined using a step profiler. The WVTR of the encapsulation film was examined using an electrical calcium corrosion test. The calcium film with a thickness of 200 nm was evaporated over an area of 10 × 2.25 mm, and an Al film with a thickness of 100 nm was deposited on both sides of the calcium film to serve as the contact electrode. Conductivity (1/R) of the calcium film was measured using an Agilent B2902A precision source (Agilent Technologies, Inc., Santa Clara, CA, USA). The refractive index of the film is calculated from Ψ and Δ using an ellipsometer.

Data availability

The data on which the findings of this study are based are available upon reasonable request to the corresponding author.

Code availability

The MATLAB code on which the findings of this study are based are available upon reasonable request to the corresponding author.

References

Li, Z. et al. Complete stress release in monolayer ALD-Al2O3 films based on mechanical equilibrium homeostasis to realize a bending radius of 1 mm. Soft Matter 18, 4756–4766 (2022).

Jeong, H., Kim, H.-M., Kim, J., Jeong, W. & Jang, J. Highly robust, flexible top-emission organic light-emitting diode exhibiting stable performance under infolding of curvature radius of 0.32 mm. Adv. Eng. Mater. 23, 2100045 (2021).

Kang, H., Jung, S., Jeong, S., Kim, G. & Lee, K. Polymer-metal hybrid transparent electrodes for flexible electronics. Nat. Commun. 6, 6503 (2015).

Weerasinghe, H. C., Dkhissi, Y., Scully, A. D., Caruso, R. A. & Cheng, Y.-B. Encapsulation for improving the lifetime of flexible perovskite solar cells. Nano Energy 18, 118–125 (2015).

Wang, H. et al. Hermetic seal for perovskite solar cells: An improved plasma enhanced atomic layer deposition encapsulation. Nano Energy 69, 104375 (2020).

Salehi, A., Fu, X., Shin, D. & So, F. Recent advances in OLED optical design. Adv. Funct. Mater. 29, 1808803 (2019).

Jeong, S. Y. et al. Foldable and washable textile-based OLEDs with a multi-functional near-room-temperature encapsulation layer for smart e-textiles. npj Flex. Electron 5, 15 (2021).

Chen, R. et al. Atomic layer deposition in advanced display technologies: from photoluminescence to encapsulation. Int. J. Extrem. Manuf. 6, 022003 (2024).

Park, E. K., Kim, S., Heo, J. & Kim, H. J. Electrical evaluation of crack generation in SiN and SiO N thin-film encapsulation layers for OLED displays. Appl. Surf. Sci. 370, 126–130 (2016).

Park, J.-S., Chae, H., Chung, H. K. & Lee, S. I. Thin film encapsulation for flexible AM-OLED: a review. Semicond. Sci. Technol. 26, 034001 (2011).

Wang, Z. et al. Crosslinking and densification by plasma-enhanced molecular layer deposition for hermetic seal of flexible perovskite solar cells. Nano Energy 109, 108232 (2023).

Wei, H. et al. Plasma-enhanced atomic-layer-deposited gallium nitride as an electron transport layer for planar perovskite solar cells. J. Mater. Chem. A 7, 25347–25354 (2019).

Lee, Y. I. et al. A low-temperature thin-film encapsulation for enhanced stability of a highly efficient perovskite solar cell. Adv. Energy Mater. 8, 1701928 (2018).

Lee, S. et al. Study of mechanical degradation of freestanding ALD Al2O3 by a hygrothermal environment and a facile protective method for environmentally stable Al2O3: toward highly reliable wearable OLEDs. Mater. Horiz. 10, 4488–4500 (2023).

Lin, Y.-Y., Hsu, C.-C., Tseng, M.-H., Shyue, J.-J. & Tsai, F.-Y. Stable and high-performance flexible ZnO thin-film transistors by atomic layer deposition. ACS Appl. Mater. Interfaces 7, 22610–22617 (2015).

Rontu, V. et al. Elastic and fracture properties of free-standing amorphous ALD Al2O3 thin films measured with bulge test. Mater. Res. Express 5, 046411 (2018).

Süss, T., Braeuninger-Weimer, P. & Hierold, C. Stress reduction in ultra-small thin film Al2O3 diaphragms by atomic layer deposition. Sens. Actuators A: Phys. 212, 159–164 (2014).

Ylivaara, O. M. E. et al. Aluminum oxide from trimethylaluminum and water by atomic layer deposition: The temperature dependence of residual stress, elastic modulus, hardness and adhesion. Thin Solid Films 552, 124–135 (2014).

Kwon, J. H. et al. Design of highly water resistant, impermeable, and flexible thin-film encapsulation based on inorganic/organic hybrid layers. ACS Appl. Mater. Interfaces 11, 3251–3261 (2019).

Chang, C.-Y., Lee, K.-T., Huang, W.-K., Siao, H.-Y. & Chang, Y.-C. High-performance, air-stable, low-temperature processed semitransparent perovskite solar cells enabled by atomic layer deposition. Chem. Mater. 27, 5122–5130 (2015).

Jen, S.-H., Lee, B. H., George, S. M., McLean, R. S. & Carcia, P. F. Critical tensile strain and water vapor transmission rate for nanolaminate films grown using Al2O3 atomic layer deposition and alucone molecular layer deposition. Appl. Phys. Lett. 101, 234103 (2012).

Park, J. S., Yong, S. H., Choi, Y. J. & Chae, H. Residual stress analysis and control of multilayer flexible moisture barrier films with SiNx and Al2O3 layers. AIP Adv. 8, 085101 (2018).

Kim, H. G., Lee, J. G. & Kim, S. S. Self-assembled monolayers as a defect sealant of Al2O3 barrier layers grown by atomic layer deposition. Org. Electron. 52, 98–102 (2018).

Sutherland, L. J., Weerasinghe, H. C. & Simon, G. P. A review on emerging barrier materials and encapsulation strategies for flexible perovskite and organic photovoltaics. Adv. Energy Mater. 11, 2101383 (2021).

Woo, J.-H. et al. Amorphous alumina film robust under cyclic deformation: a highly impermeable and a highly flexible encapsulation material. ACS Appl. Mater. Interfaces 13, 46894–46901 (2021).

Chen, Z. et al. Stress-matched laminated thin film of SiOxNy /SiO2 / SiOxNy for enhanced encapsulation of organic light-emitting devices. Opt. Express 29, 33077 (2021).

Chen, Z.-Y. et al. Efficient and stretchable organic light-emitting devices based on spontaneously formed disordered wrinkles. Opt. Lett. 47, 3744 (2022).

Chung, J. J., Jones, J. R. & Georgiou, T. K. Toward hybrid materials: group transfer polymerization of 3-(Trimethoxysilyl)propyl Methacrylate. Macromol. Rapid Commun. 36, 1806–1809 (2015).

Lee, B. H., Yoon, B., Anderson, V. R. & George, S. M. Alucone alloys with tunable properties using alucone molecular layer deposition and Al2O3 atomic layer deposition. J. Phys. Chem. C. 116, 3250–3257 (2012).

Batra, N. et al. Influence of deposition temperature of thermal ALD deposited Al2O3 films on silicon surface passivation. AIP Adv. 5, 067113 (2015).

Goldstein, D. N., McCormick, J. A. & George, S. M. Al2O3 atomic layer deposition with trimethylaluminum and ozone studied by in situ transmission FTIR Spectroscopy and Quadrupole Mass Spectrometry. J. Phys. Chem. C. 112, 19530–19539 (2008).

Alshehri, A. H. et al. Quantum-tunneling metal-insulator-metal diodes made by rapid atmospheric pressure chemical vapor deposition. Adv. Funct. Mater. 29, 1805533 (2019).

Xiang, J. et al. Investigation of N Type Metal TiAlC by thermal atomic layer deposition using TiCl4 and TEA as precursors. ECS J. Solid State Sci. Technol. 5, P299–P303 (2016).

Pandey, A. et al. Growth and comparison of residual stress of AlN films on Silicon (100), (110) and (111) substrates. J. Electron. Mater. 47, 1405–1413 (2018).

Shangguan, L. et al. Modulating residual stress based on atomic layer deposition to enhance the adhesion of parylene C for encapsulation of flexible organic light-emitting diodes. Appl. Phys. Express 16, 041004 (2023).

Stoney, G. G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. Lond. A 82, 172–175 (1909).

Callister, W. D. & Rethwisch, D. G. Materials Science and Engineering: An Introduction. (John Wiley & Sons, Hoboken, NJ, 2010).

Materials Science & Engineering. (ASM International, Materials Park, Ohio, 2010).

Sarabia-Vallejos, M. A. et al. Smart polymer surfaces with complex wrinkled patterns: reversible, non-planar, gradient, and hierarchical structures. Polymers 15, 612 (2023).

Yong-Qiang, Y. & Yu, D. Optimization of Al2 O3 films deposited by ALD at low temperatures for OLED encapsulation. J. Phys. Chem. C. 118, 18783–18787 (2014).

Han, J.-H. et al. Optimization of a SiOx/SiNxOyCz multilayer structure for a reliable gas diffusion barrier via low-temperature plasma-enhanced atomic layer deposition. Ceram. Int. 45, 7407–7412 (2019).

Jeong, E. G., Kwon, J. H., Kang, K. S., Jeong, S. Y. & Choi, K. C. A review of highly reliable flexible encapsulation technologies towards rollable and foldable OLEDs. J. Inf. Disp. 21, 19–32 (2020).

Hong, K. & Lee, J.-L. Review paper: Recent developments in light extraction technologies of organic light emitting diodes. Electron. Mater. Lett. 7, 77–91 (2011).

Chen, J. et al. Fabrication of wrinkle-patterned polydimethylsiloxane films as light out-coupling structure for white OLEDs. J. Lumin. 255, 119548 (2023).

Jeon, Y. et al. Highly efficient and reliable organic light–emitting diodes enabled by a multifunctional hazy substrate for extreme environments. Adv. Funct. Mater. 34, 2310268 (2024).

Afolayan, E. O. et al. Improved light extraction in organic light-emitting diodes via semiconductor dilution. Adv. Optical Mater. 12, 202302588 (2024).

Kang, K., Byeon, I., Kim, Y. G., Choi, J. & Kim, D. Nanostructures in organic light-emitting diodes: principles and recent advances in the light extraction strategy. Laser Photonics Rev. 18, 202400547 (2024).

Cruz-Félix, A. S., Santiago-Alvarado, A., Márquez-García, J. & González-García, J. PDMS samples characterization with variations of synthesis parameters for tunable optics applications. Heliyon 5, e03064 (2019).

Sun, Q. et al. Electric field controlled CO2 capture and CO2/N2 separation on MoS2 monolayers. Nanoscale 9, 19–24 (2017).

Kim, S. J. et al. Flexible Al2O3/plasma polymer multilayer moisture barrier films deposited by a spatial atomic layer deposition process. J. Vac. Sci. Technol. A: Vac. Surf. Films 38, 022418 (2020).

Han, Y. C. et al. Reliable thin-film encapsulation of flexible OLEDs and enhancing their bending characteristics through mechanical analysis. RSC Adv. 6, 40835–40843 (2016).

Kwon, J. H. et al. Functional design of highly robust and flexible thin-film encapsulation composed of quasi-perfect sublayers for transparent, flexible displays. ACS Appl. Mater. Interfaces 9, 43983–43992 (2017).

Kwon, B.-H. et al. Organic/inorganic hybrid thin-film encapsulation using inkjet printing and PEALD for industrial large-area process suitability and flexible OLED application. ACS Appl. Mater. Interfaces 13, 55391–55402 (2021).

Kwon, J. H. et al. Functional design of dielectric–metal–dielectric-based thin-film encapsulation with heat transfer and flexibility for flexible displays. ACS Appl. Mater. Interfaces 9, 27062–27072 (2017).

Acknowledgements

This work was supported by the Project of Science and Technology Development Plan of Jilin Province (Grant No. 20230201040GX), The National Natural Science Foundation project (Grant No. 62374070), Changchun Science and Technology Development Plan Project (Grant No. 23JQ02).

Author information

Authors and Affiliations

Contributions

G.W. and Z.W. are responsible for the preparation and testing of thin films. J.R. and Z.W. are responsible for the preparation and testing of OLED. G.W. and J.R. wrote the original draft. Z.W. and Y.D. are supervised the project and revision of the manuscript. Y.D. provisioned of fund. All authors helped shape the research and revise the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, G., Wang, Z., Ren, J. et al. Innovative stress-release method for low-stress flexible Al2O3 encapsulation films in OLED applications. npj Flex Electron 9, 94 (2025). https://doi.org/10.1038/s41528-025-00468-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-025-00468-7