Abstract

The study investigates the advantages of incorporating carob pod nanoparticles (CPNs) into frozen yogurt production. CPNs, abundant in carbohydrates, polyphenols, and antioxidants, were utilized as a multifunctional ingredient, serving as a sugar substitute, thickening agent, stabilizer, and natural colorant to enhance the manufacturing process of frozen yogurt. The research compared a control group (Ctrl) containing 15% sucrose in plain frozen yogurt with three groups where CPNs partially replaced sucrose at concentrations of 4% (FYC4), 8% (FYC8), and 12% (FYC12). Over a 45-day storage period, the chemical properties remained stable across all groups, with no significant differences observed (p < 0.05). Notably, the CPN-enriched frozen yogurts exhibited enhanced antimicrobial activity and antioxidant capacity, which improved the product’s physical microstructure and sensory attributes. The findings suggest that CPNs are a promising functional ingredient and food additive, offering the potential for the development of innovative, health-promoting frozen yogurt products.

Similar content being viewed by others

Introduction

In the realm of functional foods, a distinctive category of food products extends health benefits beyond their fundamental nutritional value. This classification includes nutrient-rich components like fruits and vegetables and foods fortified with vital vitamins, minerals, fiber, and probiotics1. Throughout the evolution of functional foods, plant-based elements, particularly fruits, have a rich history of serving as food additives to enhance sensory aspects such as flavor, texture, taste, and aroma. These elements inherently possess functional properties that can be leveraged to create functional foods2.

Frozen yogurt is a popular example of a functional food that combines the creamy texture of ice cream with the unique qualities of yogurt. Traditionally, frozen yogurts have been made with high sucrose levels, ranging from 15% to 28% of the total ingredients, resulting in a sweet and enjoyable experience3. However, with the increasing demand for healthier options, there is a growing need for sugar-free alternatives, particularly among consumers with lactose intolerance or metabolic syndrome4. These individuals actively seek sugar-free products that align with their dietary preferences and health goals5.

Carob pods are nutritionally rich, providing carbohydrates (40–60%), dietary fiber (30–40%), and protein (4–8%)6,7. Despite being low in fat (0.5–2%), they contain beneficial unsaturated fatty acids, including oleic and linoleic acid, important for immune function, bone health, and metabolism8. They also provide significant amounts of calcium, potassium, magnesium, phosphorus, and iron7, along with vitamins E, D, C, niacin, B6, and folic acid, while smaller amounts of vitamins A, B2, and B12, and abundant in polyphenols, which possess antioxidant properties9. The pulp (90% of the fruit) is rich in polyphenols such as tannins, flavonoids, phenolic acids, and minerals; seeds (10%) contain fibers, polyphenols, and minerals, and are gluten-free9. Carob flour, derived from the seeds, provides a nutritious, gluten-free option for those with celiac disease10.

Economically, carob pods (locust bean fruit) are increasingly valued for their diverse applications in food, pharmaceuticals, and cosmetics6. These pods exhibit a broad range of health benefits, which include potential alleviation of metabolic syndrome, improved management of diabetes, enhanced gut and heart health, and a reduction in cancer risk11,12.

The antioxidant and immune-supporting properties of carob pods significantly contribute to their attractiveness as a functional ingredient. Scientific research substantiates their anti-diabetic effects and highlights their potential anti-cancer properties, reinforcing the value of carob as a natural product for functional foods and food fortification. Given these qualities, carob pods represent a promising avenue for enhancing dietary health and well-being13.

Nanoparticle technology, with its unique properties (small size, high surface area, conductivity, biomimetic nature, and catalytic reactivity), offers significant potential across many applications. The use of eco-friendly, biodegradable nanocomposites derived from renewable resources like chitosan and alginate is increasing14. Their prebiotic properties and support of probiotic growth make them particularly attractive for food and agricultural applications due to their sustainability and multifunctionality15. Nanotechnology is revolutionizing the food industry by enhancing food quality, shelf life, safety, and nutritional value, leading to the development of healthier food products. Its applications span farming, food packaging, and microbial contamination prevention, significantly impacting food industry practices16. This study explores the use of carob pod nanoparticles (CPNs) as a sugar substitute in functional frozen yogurt. It examines the effects of CPNs on frozen yogurt’s composition, texture, taste, antimicrobial activity, and antioxidant capacity.

Results

Particle size and Zeta potential analysis

The particle size distribution analysis is displayed in several ways. A summary statistic summarizes key parameters of the particle size distribution (Fig. 1a), including the mean volume diameter (MV), mean number diameter (MN), mean area diameter (MA), and standard deviation (SD). The polydispersity index (PDI), moment of the distribution (Mz), span (si), skewness (Ski), and kurtosis (Kg) are also provided. These metrics describe the average size, spread, and shape of the particle size distribution. The size at different percentiles (10th, 20th,…95th), illustrates the range of particle sizes. For example, 50% of the particles are smaller than 242.9 nm (Fig. 1b). The diameter (Dia) of the main peak, the volume percentage (Vol%) it represents (100% in this case, indicating an unimodal distribution), and its width (Fig. 1c). A histogram and cumulative distribution curve visually represent the particle size data (Fig. 1d). The histogram shows the frequency of particles within specific size ranges. The cumulative curve shows the percentage of particles smaller than a given size.

Figure 1d illustrates the critical characteristics of carob pod nanoparticles (CPNs) highlighting an average particle size of 242.9 nm, a critical parameter influencing material properties such as viscosity, stability, and texture within suspensions. The zeta potential, recorded at a positive 45.5 mV, signifies robust electrostatic repulsion, enhancing the strength of the nanoparticle dispersion. The positive polarity and mobility of 6.91 µm/s/V/cm indicate the efficient movement of CPNs in the medium. Additional parameters include a conductivity (1149 µS/cm), and field strength ratio (10/9.4 kV/m). The standard operating procedure (SOP) for zeta potential measurements specified a 30-second analysis time per run. The dispersant medium had a fluid viscosity of 0.986 mPa·s at 20.66 °C and a dielectric constant of 79.0. These properties reflect the nature of the dispersant used in the formulation of CPNs. Understanding these characteristics is essential for optimizing CPN use and effectiveness in various applications.

Fourier transform infrared (FTIR) spectrometer

FTIR spectroscopy is a powerful analytical tool for identifying molecules by correlating spectral peaks with the vibrational frequencies of their corresponding functional groups. The spectral data were recorded within the range of 500 to 4000 cm⁻¹.

To interpret the results, a baseline for food samples was established, which includes peaks near 3300 cm⁻¹, typically indicating O-H stretching vibrations (associated with alcohols, phenols, and carboxylic acids) and N-H stretching vibrations (characteristic of amines and amides). Peaks around 2900 cm⁻¹ correspond to C-H stretching vibrations (common in alkanes and alkenes), while peaks near 1700 cm⁻¹ suggest C=O stretching vibrations (related to ketones, aldehydes, carboxylic acids, and amides). Additionally, C=O stretching vibrations generally appear around 1200 cm⁻¹, and C-N stretching vibrations are typically observed near 1250 cm⁻¹.

The FTIR peaks were analyzed to confirm the presence of carob pod nanoparticles (CNPs) in various formulations of frozen yogurt. Figure 2 illustrates the FTIR spectra of CNPs, Ctrl, and FYC samples.

The FTIR spectrum of the CNPs extract revealed four absorption peaks, 3262.58 cm⁻¹, indicating the presence of (O-H) groups associated with phenols and alcohols. The second peak of 2121.75 cm⁻¹ attributed to (–C=C–) stretching possibly from alkynes. The last two peaks 1639 cm⁻¹ and 681.91 cm⁻¹ suggest the presence of (C=O) stretching vibrations, indicative of aldehydes, ketones, and C-H bending vibrations, potentially from alkanes respectively.

The Ctrl sample’s FTIR spectrum showed peaks at 3262.59 cm⁻¹ (hydroxyl OH groups), 2118.29 cm⁻¹ (alkyne –C=C– groups), 1638.70 cm⁻¹ (primary amine N–H groups), and 1055.11 cm⁻¹ (aliphatic amine C–N groups).

The FYC samples exhibited peaks corresponding to these functional groups at 3500–3200 cm⁻¹, 2260–2100 cm⁻¹, and 1710–1665 cm⁻¹ respectively, indicating that the major peaks of CNPs were retained in the frozen yogurt matrix. The absorption peaks confirm the successful integration of CNPs into the FYC formulations, providing insights into the interactions between CNPs and the constituents of functional frozen yogurt.

These findings highlight the rich chemical composition of carob pods, which contain bioactive compounds such as phenols, ketones, and aldehydes. These components are likely responsible for the significant impact of CNPs on the antioxidant and antibacterial activities of frozen yogurt. The FTIR spectra confirm the incorporation of CNPs into the FYC matrix, offering valuable insights into their interactions with the yogurt components.

Chemical characterization of functional frozen yogurt

Table 1 presents the compositional analysis (total solids, fat, solids-not-fat, pH, and titratable acidity) of the frozen yogurt samples. No significant differences (P < 0.05) were observed among the groups, even after frozen storage.

The total solids content was stable, with the control (Ctrl) group maintaining levels from 30.46% to 30.03%. Notably, an increase was observed in groups with higher CPNs content, peaking at 33.91% to 33.21% in the FYC12 group. SNF followed a similar pattern, starting at 23% to 22.81% in the Ctrl group and slightly increasing from 26.16% to 25.76% in CPNs-enriched groups, both initially and after 45 days of storage. Fat content remained consistent across all treatments, with the Ctrl group ranging from approximately 7.46% at the beginning to 7.22% after storage, while CPNs-enriched groups fluctuated around 7.13% to 7.75%.

The pH and titratable acidity (T.A%) of frozen yogurt enriched with CPNs were comparable to the Ctrl group, showing no significant differences. Initial pH values were slightly higher in the CPN-enriched groups (5.60–5.71) compared to the Ctrl (5.5–5.01). Minor pH fluctuations (5.32–5.55) occurred during the 45-day storage period, possibly due to the alkaloid minerals in CPNs. Titratable acidity remained stable (0.40–0.45%) across all groups throughout the storage period.

The addition of CPNs enhanced the nutritional content of the frozen yogurt, increasing total solids and solids-not-fat (SNF) without negatively affecting pH or titratable acidity, which are crucial for quality and consumer acceptance. The slight reduction in some components after storage likely reflects minimal water loss, indicating that the yogurt’s overall composition remained largely stable over time.

Evaluation of acetaldehyde and diacetyl contents

Table 2 shows significant changes (P < 0.05) in acetaldehyde and diacetyl content (mmol/100 g) of CPN-enriched frozen yogurt samples over time. Acetaldehyde levels increased progressively in all groups during storage.

The Ctrl formulation displayed an initial acetaldehyde content of 44.41 mmol/100 g, marginally escalating to 57.94 mmol/100 g after 45 days of storage. Conversely, the CPNs-enriched formulations exhibited higher initial acetaldehyde contents ranging from 46.68 to 62.41 mmol/100 g, experiencing significant increases to 67.90 to 83.27 mmol/100 g after the same storage duration. Similarly, the diacetyl content followed a parallel trajectory, with the Ctrl group commencing at 7.44 mmol/100 g on day 1 and escalating to 28 mmol/100 g after 45 days. In contrast, the CPNs-enriched groups displayed initial diacetyl contents spanning from 27.17 to 40.77 mmol/100 g, significantly rising to 43.83 to 65.78 mmol/100 g post-storage. These results underscore the substantial influence of CPNs on the formation of flavor compounds in functional frozen yogurt. Notably, there is a clear and consistent increase in flavor compounds, which directly correlates with the higher ratios of carob pod nanoparticles (CPNs) in the various treatments. This indicates a positive relationship between the concentration of CPNs and the enhancement of flavor compounds.

Rheological characterization of functional frozen yogurt

Table 3 presents an overview of viscosity, specific gravity, weight per gallon, and overrun values for four frozen yogurt formulations.

Viscosity, a pivotal measure of the rheological properties of frozen yogurt, reflecting its thickness and flow characteristics, was evaluated at two different rotational speeds: 10.0 rpm and 20.0 rpm. At the slower speed of 10.0 rpm, the Ctrl group registered a viscosity of 5020 cP. In comparison, the groups enriched with CPNs exhibited a substantial increase in viscosity that was directly proportional to the CPNs concentration, with values spanning from 5186.66 to 6626.66 cP. When the rotational speed was increased to 20.0 rpm, the Ctrl group’s viscosity decreased to 2386.46 cP. However, the viscosity within the CPNs-enriched groups continued to escalate with the increment of CPNs, ranging from 2386.66 cP at the lowest CPNs concentration to 4300 cP at the highest.

Collectively, viscosity increases significantly with higher CPN concentration (FYC8 and FYC12 differ from Ctrl and FYC4). These findings underscore how the addition of CPNs and the rotational speed significantly influence the yogurt’s viscosity, thereby affecting its overall texture and mouthfeel. The increase in viscosity with CPNs enrichment suggests that these nanoparticles act as effective thickening agents, enhancing the yogurt’s stability and creaminess. The rotational speed also plays a crucial role in determining the flow behavior of the frozen yogurt, with higher speeds generally leading to lower viscosity readings due to the shearing effect.

Specific gravity shows no significant differences across all treatments. The Ctrl had a specific gravity of 1.060 gm/cm³, while FYC treatments ranged between 1.091 and 1.024 gm/cm³, indicating that the addition of CPNs had no discernible impact on specific gravity. Similarly, Weight per gallon decreases significantly at higher CPN levels (FYC8 and FYC12 differ from Ctrl and FYC4). Ctrl was 5.019 kg, while FYC treatments ranged from 4.960 to 4.655 kg.

Conversely, an increase in CPNs concentration was associated with a decrease in overrun percentage. Overrun values for FYC-treated samples ranged from 47% to 40%, compared to 55% in the Ctrl group. This reduction was most pronounced in the FYC12 treatment, which showed a statistically significant difference from the Ctrl.

Texture profile analysis of functional frozen yogurt

The texture of frozen yogurt is a key factor in determining its quality. To assess the textural properties of different formulations of frozen yogurt stored at -20 °C, a series of tests were conducted, and the results are summarized in Table 4.

The incorporation of CPNs into frozen yogurt led to significant changes in various textural parameters, including hardness, adhesiveness, cohesiveness, springiness, and gumminess. Specifically, the hardness of FYC increased by approximately 2-3 times compared to the Ctrl (P < 0.05) after 45 days of storage. Moreover, the adhesiveness of FYC ranged from 12.6 to 18.6 mJ initially, contrasting with the Ctrl, which recorded a value of 4.537 mJ. This difference persisted over time, with FYC treatments reaching adhesiveness values of 49.6 to 57.5 mJ, while the Ctrl remained stable at 49.5 mJ throughout the 45-day storage period.

Consistent trends were observed in gumminess, springiness, and cohesiveness parameters, highlighting the significant impact of CPNs on the Texture Profile Analysis (TPA) of frozen yogurt. The addition of CPNs not only enhances the textural properties of the product but also improves its overall quality and sensory appeal. These results emphasize the potential of CPNs as an ingredient for enhancing the textural properties and consumer satisfaction of frozen yogurt.

The utilization of TPA with the specified parameters allowed for a comprehensive evaluation of the texture profile of the functional frozen yogurt samples, providing valuable insights into their sensory attributes and overall texture characteristics. This analysis facilitated the assessment and understanding of the inherent texture properties in functional frozen yogurt.

The insights in the table are valuable for understanding the rheological properties and characteristics of various frozen yogurt formulations. This knowledge is essential for optimizing frozen yogurt products’ texture, density, and sensory attributes, enabling manufacturers to make informed decisions to enhance the overall quality and consumer experience of their frozen yogurt offerings. Understanding the rheological behavior of these formulations is crucial for ensuring that the product meets desired standards and fulfills consumer expectations in terms of taste and texture.

Melting rate evaluation of functional frozen yogurt during storage

The first dripping point in minutes and the melting rate through 30 and 60 minutes of functional frozen yogurt samples at different stages of storage, serve as an indicator of the product’s stability. Initially, all formulations had similar first dripping points, which ranged from 4 to 7 minutes, suggesting that the frozen yogurt’s initial stability was uniform across the board (Fig. 3a).

As storage progressed, there was a significant divergence, particularly for the Ctrl group, which had a first dripping point of 17 minutes. In contrast, the groups with CPNs enrichment exhibited an increased first dripping point over time, signifying greater firmness and resistance to melting. These values ranged from 19 ± 2.15 to 22 ± 2.43 minutes, indicating that the presence of CPNs enhanced the yogurt’s stability and resistance to thawing throughout the storage period.

Figure 3b, provides a detailed analysis of the melting rate per gram for functional frozen yogurt samples enriched with CPNs during storage. The data presented indicates a significant positive correlation (p < 0.05) between the CPNs content and the melting rate.

The test evaluated the melting values per gram for 30 min and 60 min. In the first 30 minutes, the formulations had a notable variation in melting rates. The Ctrl recorded the highest melting rate at 42.36 grams, whereas the CPNs-enriched groups showed lower rates ranging from 29.4 to 24.0 grams. This suggests that the Ctrl formulation melted more rapidly compared to the CPNs-enriched groups, with FYC12, having the highest CPNs content, showing the slowest melting rate. As storage continued, the melting rates further decreased. The Ctrl group’s melting rate dropped to 18.1 ± 3.12 grams, while the CPNs-enriched treatments ranged from 15.86 to 11.38 grams. This trend suggests that the melting rates of the frozen yogurt formulations decreased over time, with the CPNs-enriched samples showing a more pronounced reduction.

Additionally, the melting rate data over 60 minutes, shows a general decline in melting rates for all formulations. Initially, the Ctrl had a melting rate of 96.5 grams, and the CPNs formulas ranged from 96.24 to 81.58 grams. After 45 days, the Ctrl showed the highest melting rate of 42.04 grams, while FYC12, with the highest CPNs proportion, exhibited the lowest rate at 30.1 grams.

These results offer valuable insights into the melting behavior of functional frozen yogurt during storage, demonstrating a consistent decrease in melting rates over time. The CPNs-enriched formulations, particularly FYC12, showed superior resistance to melting, which is crucial for improving the quality and shelf life of frozen yogurt products. These findings are significant for optimizing the formulation and storage conditions to enhance the yogurt’s melting resistance and overall quality.

Color properties of functional frozen yogurt

The incorporation of carob nanoparticles (CPNs) into frozen yogurt at varying concentrations (4%, 8%, and 12%) significantly influenced its color characteristics (p < 0.05), as assessed using the Hunter color system (Fig. 4). The L*, a*, and b* values provided objective measurements of lightness, redness, and yellowness, respectively, revealing distinct trends associated with increasing CPNs concentration. The Ctrl sample exhibited the highest L* value (~75), indicating maximum lightness, whereas samples containing CPNs showed a progressive decrease in lightness, with FYC12 being the darkest (~55). This dose-dependent reduction in L* values reflects the inherent darker, brownish-red hue of the carob nanoparticles, which intensified with higher incorporation levels. A corresponding increase in redness (a*) was also observed, rising from ~10 in FYC4 to ~23 in FYC12, likely due to the natural pigments present in carob that contribute chromatic richness to the final product. While the effect on yellowness (b*) was less pronounced, a slight but consistent increase was noted between FYC8 (~4) and FYC12 (~6), suggesting a secondary influence of CPNs on this parameter. Collectively, these findings demonstrate that CPNs effectively modulate the color profile of frozen yogurt in a concentration-dependent manner. Importantly, they offer a viable natural alternative to synthetic colorants, aligning with growing consumer demand for clean-label and functional ingredients. By tailoring CPNs concentration, manufacturers can achieve targeted visual attributes while enhancing nutritional and textural properties. These optical modifications may also positively influence sensory perception and consumer acceptance, particularly in dairy desserts where appearance plays a pivotal role in product appeal.

L: brightness; a: redness; b: yellowness; Control (Ctrl); Frozen yogurt carob pod nanoparticles 4% (FYC4); Frozen yogurt carob pod nanoparticles 8% (FYC8); Frozen yogurt carob pod nanoparticles 12% (FYC12). The data were presented as M ± SD, the “a, b, c…” different letters are significantly different (P < 0.05).

Evaluation of the antioxidant activity

Figure 5 presents an assessment of the total phenolic componend (TPC) and antioxidant activity in functional frozen yogurt samples. The data reveals significant differences (p < 0.05) in these parameters with varying levels of carob pod nanoparticles (CPNs).

a Antioxidant activity (%); b Total flavonoid content (mg CE/100 g); c Total phenolic componend (mg GAE/100 g). Control (Ctrl); Frozen yogurt carob pod nanoparticles 4% (FYC4); Frozen yogurt carob pod nanoparticles 8% (FYC8); Frozen yogurt carob pod nanoparticles 12% (FYC12). * p < = 0.05; ** p < = 0.01; *** p < = 0.001.

The treatments enriched with CPNs exhibited the highest antioxidant activity, reaching a peak of 93.71%, while the control group (Ctrl) showed the lowest activity at 44.10%. Antioxidant activity levels across all treatments varied from 72.9 to 91.46%, with a clear trend of increasing activity with higher proportions of CPNs. In terms of the total flavonoid content (TFC), CPNs demonstrated a peak at 7.21 mg GAE/g, contrasting with the Ctrl group’s lowest peak at 3.46 mg GAE/g. The FYC treatments showcased TFC values ranging from 5.10 to 9.5 mg GAE/g. Similarly, the total phenolic compound (TPC) followed a similar pattern, with CPNs reaching a peak at 10.26 mg EC/g and Ctrl exhibiting the lowest peak at 6.77 mg EC/g. The FYC treatments displayed a TPC range from 8.7 to 16.87 mg EC/g. These results highlight that the FYC12 formulation, containing the highest CPNs concentration, possessed the most substantial TPC among all samples.

Briefly, the incorporation of CPNs, particularly at the level utilized in the FYC12 treatment, significantly boosted both the TPC and antioxidant activity of the functional frozen yogurt. This indicates that CPNs can serve as valuable additives for enhancing the health-promoting properties of frozen yogurt products.

Antimicrobial activity assessment

Figure 6 demonstrates that while nanoparticles (CPNs) and lactic acid bacteria both inhibited microbial growth, the differences in growth between the treatment groups were not statistically significant (p < 0.05).

Bacillus subtilis (B. subtilis); Staphylococcus aureus (Staph. aureus); Escherichia coli (E. coli); Klebsiella pneumoniae (K. pneumoniae); Candida albicans (C. albicans), and Aspergillus niger (A. niger); Control (Ctrl); Frozen yogurt carob pod nanoparticles 4% (FYC4); Frozen yogurt carob pod nanoparticles 8% (FYC8); Frozen yogurt carob pod nanoparticles 12% (FYC12). No statistically significant difference was observed between the groups (P < 0.05).

The CPNs treatments for B. subtilis ATCC 6633 showed the most substantial antibacterial effect, with a clear zone measurement of 32 ± 0.22 mm. The control (Ctrl) formulation had a smaller clear zone of 24 ± 1.32 mm. The FYC formulations, which include CPNs, demonstrated clear zones ranging from 27 ± 3.25 to 29 ± 2.21 mm, indicating their antibacterial properties.

Against Staph. aureus ATCC 6538, CPNs again exhibited significant antibacterial activity, with a clear zone of 35 ± 3.24 mm. The Ctrl group showed the smallest clear zone at 28 ± 1.32 mm, while the FYC formulations displayed high antibacterial activity with clear zones between 28 ± 2.22 and 32 ± 3.34 mm. The CPNs also demonstrated antibacterial activity against other pathogens, including E. coli ATCC 8739, K. pneumoniae ATCC 13883, C. albicans ATCC 10221, and Asp. niger, with clear zones measuring approximately 29 ± 2.54, 25 ± 1.42, 25 ± 4.28, and 22 ± 1.27 mm, respectively. The FYC treatments showed similar antibacterial effects against these pathogens. Although the Ctrl formulation showed good antibacterial activity, it was less effective compared to the FYC treatments.

These results suggest that frozen yogurt, particularly when enriched with carob pulp nanoparticles (CPNs), demonstrates increased antimicrobial activity with higher CPNs concentrations. This suggests its potential as a functional food promoting public health due to its broad-spectrum antimicrobial properties.

Microstructure of frozen yogurt (SEM)

Figure 7 presents SEM micrographs that illustrate the effect of carob pod nanoparticles (CPNs) on the microstructure of frozen yogurt samples. The images demonstrate that the inclusion of CPNs induces a significant refinement in the gel’s filamentous network, evidenced by a more uniform and compact structure with smaller, less visible pores. SEM analysis shows that frozen yogurt samples enriched with CPNs have a cohesive gel matrix with extended casein filaments, suggesting a stronger and more integrated structure. In contrast, the control samples (Ctrl) display a less cohesive gel matrix with larger, more irregular pores and a lack of filament connectivity. The casein filaments in these samples are shorter and more isolated, leading to a less uniform gel structure. Furthermore, the microstructure of the control samples exhibits inconsistent pore sizes, indicating a higher degree of heterogeneity. The SEM micrographs underscore the substantial influence of CPNs in enhancing the microstructural properties of frozen yogurt, resulting in a more refined and homogeneous filament structure with numerous smaller pores. These observations provide crucial insights for the optimization of frozen yogurt formulations, potentially leading to improved product quality and texture. The SEM micrographs offer a clear visual representation of how CPNs can contribute to the development of a more stable and consistent frozen yogurt matrix.

Sensory evaluation

Table 5 presents the sensory evaluation scores for frozen yogurt, assessing criteria such as appearance, body and texture, flavor, and overall acceptability. The results indicate that frozen yogurt enriched with carob pod nanoparticles (CPNs) did not significantly differ from the control (Ctrl) sample in terms of sensory attributes, except for color. The addition of CPNs imparted a distinct brown hue reminiscent of chocolate, which was significantly different from the control (p < 0.05) and favored by the sensory panelists.

Interestingly, the brown coloration due to CPNs was preferred over the control’s appearance. This suggests that CPNs can be incorporated into frozen yogurt at concentrations of 4% to 12% without adversely affecting its sensory appeal. During the initial storage period, the sensory properties of the CPNs-enriched samples (FYC) were comparable to the control, with overall acceptability scores ranging from 95.3% to 98.3% for all treated formulations. This similarity can be attributed to the familiar characteristics of the control and the chocolate-like color and aroma of the CPNs treatments. However, as the storage period extended beyond 45 days, the FYC8 formulation, with 8% CPNs, received the highest overall acceptability score, peaking at approximately 97.94%.

Brefilly, the sensory evaluation results highlight the potential of carob pod nanoparticles (CPNs) as a functional ingredient in frozen yogurt, effectively enhancing color attributes while maintaining key sensory properties throughout storage. Notably, the appearance scores of FYC8 and FYC12 were consistently higher than those of the control (Ctrl), indicating improved visual appeal. In contrast, no significant differences were observed in body, texture, or flavor among the treatments across all storage periods. Overall acceptability scores revealed that FYC8 performed best at all time points, showing statistically significant improvement compared to the control.

Microbiological analysis of functional frozen yogurt

Table 6 provides the outcomes of the microbial analysis for Streptococcus salivarius subsp thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, and the total microbial count across various treatments and storage durations. The results indicated no significant variations (P < 0.05) in Streptococcus salivarius subsp thermophilus counts between the different treatments or throughout the storage periods. For the control group (Ctrl), the initial count was 7.31 cfu/mL, which showed a decline to 4.21 cfu/mL after a 45-day storage period. In contrast, the FYC treatments, which included CPNs, demonstrated initial counts that varied from 7.54 to 9.71 cfu/mL. These counts experienced a notable reduction after 45 days of frozen storage, dropping to a range of 5.21 to 7.21 cfu/mL.

The microbial analysis presented in the study reveals the effects of carob pod nanoparticles (CPNs) enrichment on Lactobacillus delbrueckii subsp. bulgaricus counts and total microbial counts in frozen yogurt over a 45-day storage period. Initially, the control (Ctrl) group had a count of 8.65 cfu/mL for L. delbrueckii subsp. bulgaricus, which significantly decreased to 4.78 cfu/mL after storage. In contrast, the CPNs-enriched frozen yogurt (FYC treatments) exhibited initial counts ranging from 8.76 to 10.06 cfu/mL, with a subsequent decline to 6.45 to 7.65 cfu/mL after 45 days.

Regarding the total microbial count, the Ctrl group started with a count of 7.87 cfu/mL, which dropped to 5.69 cfu/mL after 45 days. The FYC treatments, with initial counts varying from 8.82 to 11.59 cfu/mL, showed a reduction to 6.06 to 7.62 cfu/mL post-storage. Notably, the absence of mold and yeast throughout the study indicates high product quality, as these microorganisms were not detected in any samples.

The increased total microbial counts in CPNs-enriched treatments could be attributed to the nutrients in CPNs that promote a favorable environment for microbial growth. However, the observed antimicrobial activity may also contribute to the regulation of microbial growth, ensuring the product’s safety and stability. These findings suggest that the incorporation of CPNs does not adversely affect the microbial quality of frozen yogurt and may even improve certain aspects. The consistent microbial counts within safe limits after an extended storage period highlight the potential of CPNs as a valuable ingredient in frozen yogurt formulations, enhancing product quality without compromising safety.

In summary, both Streptococcus salivarius subsp thermophilus, Lactobacillus delbrueckii subsp. bulgaricus counts increased with higher concentrations of CPNs, particularly at later stages of frozen storage, suggesting that CPNs may enhance the survival or activity of probiotic bacteria under these conditions. FYC8 and FYC12 consistently exhibited higher microbial counts compared to the control (Ctrl) and FYC4, indicating a potential protective or growth-promoting effect of CPNs on lactic acid bacteria. Total microbial counts followed a similar trend, further supporting the role of CPNs in maintaining microbial viability during storage. The absence of mold and yeast contamination throughout the study period confirms the microbiological safety of the formulations.

Discussion

This study investigated the effects of incorporating carob pod nanoparticles (CPNs) as a sugar substitute in functional frozen yogurt, focusing on its impact on physiochemical properties, antimicrobial activity, and antioxidant capacity.

Carob nanoparticle size significantly impacts their properties; smaller particles have larger surface areas, enhancing their utility in various applications. The average particle size was 242.9 nm, consistent with findings showing that nanosized materials exhibit unique physical, chemical, and biological properties compared to larger particles. The positive zeta potential ( + 45.5 mV) indicates a stable nanoparticle dispersion17. This finding is consistent with the observations of Nguyen, et al.18, who noted that the magnitude of zeta potential serves as a reliable indicator of the stability of nanoparticle formulations. A high zeta potential suggests that the particles possess a significant charge, which inhibits aggregation and promotes redispersion through repulsive electrostatic forces; conversely, a low zeta potential may lead to coagulation. Sikora, et al.19, state that zeta potential values exceeding +30 mV and up to +60 mV indicate good to excellent stability. Similarly, Gumustas, et al.20 emphasize that a zeta potential of at least ±30 mV correlates with monodisperse formulations that exhibit minimal aggregation, thus ensuring the uniformity and stability of nanoparticles in suspension. Moreover, the zeta potential measurement of 45.5 mV for CPNs indicates a positive charge, which is in line with previous research by Samimi, et al.21. This positive charge suggests a strong electrostatic repulsion among the nanoparticles, contributing to the stability of the dispersion. High zeta potential values are indicative of a stable nano formulation, as they prevent particle aggregation and promote redispersion22.

FTIR spectroscopy is a powerful analytical tool for identifying functional groups and assessing compound concentrations in food samples23,24. Peaks near 3300 cm⁻¹ typically indicate O-H stretching vibrations (associated with alcohols, phenols, and carboxylic acids), which significantly influence taste, stability, and nutritional value. The presence of N-H stretching vibrations (characteristic of amines and amides) highlights complex molecular interactions within the samples.

The FTIR spectra (recorded within 500–4000 cm⁻¹) confirmed the successful integration of carob pod nanoparticles (CPNs) into frozen yogurt (FYC) formulations. The CPN group spectra revealed distinct peaks: 3262.58 cm⁻¹: O-H stretching vibrations, likely from hydroxyl (OH) groups in phenols and alcohols25. The peak of 2121.75 cm⁻¹: –C=C– stretching vibrations, attributed to alkynes; 1639 cm⁻¹: C=O stretching vibrations, indicative of aldehydes and ketones; and 681.91 cm⁻¹: C-H bending vibrations, potentially from alkanes26.

These functional groups align with the bioactive compounds in carob, contributing to its antioxidant and antibacterial properties27. The Ctrl sample exhibited peaks at 3262.59 cm⁻¹ (O-H groups), 2118.29 cm⁻¹ (alkynes), 1638.70 cm⁻¹ (primary amines), and 1055.11 cm⁻¹ (aliphatic amines), representing the base components of yogurt. The FYC samples retained the major CPN peaks within the ranges of 3500–3200 cm⁻¹, 2260–2100 cm⁻¹, and 1710–1665 cm⁻¹, confirming the successful and stable incorporation of CPNs into the frozen yogurt matrix while preserving their bioactive properties. This supports the potential of CPNs in functional food development.

Variations in the spectral region between FYC and Ctrl samples, as highlighted by24, may indicate differences in compound concentrations that could influence flavors and aromas in food products. This underscores the potential of functional ingredients like CPNs to enhance sensory attributes and overall food quality. The insights from FTIR spectroscopy reveal the diverse compositional profiles of FYC samples compared to controls, suggesting that CPNs can improve both the nutritional and sensory properties of food products.

This study investigated replacing some sucrose in frozen yogurt with carob pod nanoparticles (CPNs), supported by previous research showing that adding probiotics doesn’t significantly alter frozen yogurt’s chemical composition during storage5. The observed stable total solids content (p < 0.05) in the yogurt samples containing CPNs corroborates these findings and supports the importance of total solids in maintaining frozen yogurt quality3.

However, Senaka Ranadheera, et al.28 reported a slight increase in total solids over a 60-day storage period, which they attributed to the partial loss of free water. This finding, along with others, reinforces the notion that the total solids content in frozen yogurt remains relatively stable during storage. Similarly, Pinto and Dharaiya29 observed no substantial changes in total solids, fat, protein, and titratable acidity values when certain modifications were made to frozen dessert formulations. These findings suggest that alternative ingredient substitutions and formulation adjustments have minimal impact on the key chemical properties of ice cream and frozen desserts.

Yogurt’s pH typically decreases during freezing due to continued lactic acid production by yogurt cultures. However, studies indicate that pH and titratable acidity remain relatively stable during subsequent storage3, preserving flavor, nutritional quality, and consumer acceptability. This stability is influenced by factors including initial yogurt composition, LAB concentration, freezing conditions, and the overall buffering capacity of the formulation (including sweeteners and flavorings)30. Published data shows considerable variation in frozen yogurt pH and acidity (pH 4.3–5.25, lactic acid 0.47–0.77%), with higher acidity (above 0.7%) potentially affecting sensory attributes31. In this study, higher acidity likely stems from using solely fermented yogurt and potentially enhanced fermentation due to increased glucose from lactose hydrolysis or carob pod nanoparticles.

Acetaldehyde and diacetyl are important aroma compounds in dairy products, contributing to desirable flavors, but excessive levels cause off-flavors32. Carob nanoparticles (CPNs), rich in polyphenols with antioxidant properties, can influence their concentration in dairy products33, stabilizing volatile compounds and controlling acetaldehyde levels by scavenging free radicals and inhibiting oxidation. CPNs also contain prebiotic components (soluble fibers and polyphenols) that promote lactic acid bacteria growth34.

CPNs’ interactions with LAB during fermentation affect acetaldehyde and diacetyl production Rachwał and Gustaw35,36, impacting both antioxidant activity and LAB metabolism. These reports agreed with the obtained results, which show increased acetaldehyde and diacetyl in FYC samples with higher CPN concentrations compared to the Ctrl group, and levels changed significantly with increased frozen storage time37.

Viscosity plays a pivotal role in the sensory attributes of frozen yogurt, influencing creaminess and mouthfeel, with higher viscosities typically preferred for their luxurious texture. The study illustrates the significant impact of incorporating carob pod nanoparticles (CPNs) on the rheological properties of frozen yogurt (p < 0.05). Following a 24 h aging period at 5 ± 1 °C, there was a notable increase in apparent viscosity, plastic viscosity, and consistency index. This trend persisted with rising CPNs concentrations, resulting in higher viscosity compared to the control samples. The viscosity enhancement can be attributed to CPNs’ capacity to bind water, forming a dense gel network. The addition of carob powder significantly boosts viscosity owing to its soluble fibers and polysaccharides, contributing to a denser consistency. These findings align with prior research by Froiio et al.38 highlighting the substantial impact of carob powder on yogurt’s rheological properties. According to, Skryplonek et al.4 carob’s natural thickening agents enhance viscosity, retain moisture, and establish a cohesive structure, thereby improving mouthfeel and preventing separation.

Nasrallah et al.39 attributed the viscosity enhancement to CPNs’ effective water-binding ability, resulting in a denser gel network and increased viscosity in treated samples compared to the control. Öner et al.40 demonstrated that carob pod powder can effectively replace a portion of the sweetener, enhancing the texture and aeration of the final product. This substitution leads to increased specific gravity and weight per gallon, indicating a positive impact on the overrun of frozen yogurt and ice cream.

The speed of rotation during the freezing process significantly influences the texture of frozen yogurt. Rotational speeds of 10 or 20 rpm can affect the formation of ice crystals and the distribution of air bubbles, ultimately impacting the creaminess of the product. Generally, higher speeds result in smoother textures by incorporating more air and preventing large ice crystals. However, the optimal speed varies depending on the recipe and desired characteristics of the frozen yogurt41. These findings highlight the rheological effects of incorporating carob pod powder in ice cream production, particularly on overrun, viscosity, and melting resistance.

El-Kholy42, rheological results indicate a positive correlation (p < 0.05) between carob pod powder levels used for replacement and ice cream’s melting resistance or low melting ability. Overall, Guler-Akin et al.43 conclude the ability of carob pod powder to replace part of the SNF while enhancing the sensory and textural qualities of frozen desserts highlights its potential as a valuable ingredient.

The positive impact of CPNs on the rheological, physical, and sensory properties of frozen yogurt is evident from the study’s findings. The incorporation of CPNs leads to a significant enhancement in these properties, which is crucial for the development of high-quality frozen yogurt with improved texture and mouthfeel.

The increase in frozen yogurt hardness and significant changes in springiness, cohesiveness, and adhesiveness may stem from alterations in pore structure. Extensive interactions or cross-linking between CPNs, milk casein, and denatured whey proteins likely lead to a denser, rigid gel structure. This corresponds with findings by Bullock and Gruen44 who noted similar effects when thickeners like starch and whey protein concentrates were added to yogurt. Additionally, Supavititpatana et al.45 observed enhanced hardness, springiness, and adhesiveness in corn yogurts with the inclusion of gelatin.

To gain a thorough understanding of the interactions between carob pod nanoparticles (CPNs) and frozen yogurt components, a range of techniques can be utilized, including scanning electron microscopy (SEM), Fourier transform infrared (FTIR) spectroscopy, Raman spectroscopy, and other surface characterization methods. These analytical tools offer valuable insights into the physical distribution, interaction mechanisms, and potential chemical bonding between CPNs and the frozen yogurt matrix46.

The SEM images provide visual confirmation of the structural changes induced by CPNs, highlighting their role in modifying the air cell structure and, consequently, the melting rate of the frozen yogurt47.

SEM allows for high-resolution imaging of the microstructure, enabling the observation of the physical arrangement of CPNs within the frozen yogurt. The inclusion of carob pod nanoparticles (CPNs) in functional frozen yogurt formulations has brought about a significant transformation in the appearance of the gel network. Microscopic analysis has revealed that frozen yogurt samples treated with CPNs displayed a denser and more compact structure with reduced pore size and aggregation compared to the control samples. This alteration led to the formation of a thicker and tightly structured gel, which effectively minimized dehydration and shrinkage. The polysaccharides present in CPNs formed bonds with water molecules within the yogurt, enhancing consistency and stability in the gel structure48,49. Furthermore, the incorporation of CPNs increased the gel strength of functional frozen yogurt, attributed to the presence of soluble sugars and pectin in CPNs, which contributed to bolstering the stability of the gel network. The interaction between polysaccharides and proteins played a crucial role in reinforcing the gel network, resulting in a more compact structure with smaller pores, and a smoother and denser gel network. This discovery suggests that CPNs have the potential to enhance the quality and shelf life of frozen yogurt products50.

Qu, et al.51 highlighted that in the process of frozen yogurt fermentation, the aggregation of casein micelles and denaturation of whey proteins occur, culminating in the creation of an intricate three-dimensional network within the yogurt. Changes in formulation can notably impact the microstructure of the resulting gel, a phenomenon that can be elucidated through the use of sophisticated tools like the scanning electron microscope (SEM) for observing and analyzing these microstructural alterations.

Color serves as a crucial factor in the sensory assessment of frozen desserts like frozen yogurt, often being the initial characteristic that shapes consumer perception. A visually pleasing color can significantly elevate a product’s sensory appeal, impacting consumer preferences. Hence, attaining an attractive color without resorting to artificial additives is pivotal for market approval. The natural hue of food, devoid of additives, heavily relies on the makeup of raw materials like protein, dietary fiber, phenolics, pigments, and other components utilized in crafting frozen yogurt5.

Colorimetric analysis has seen a rise in popularity in recent years52. The findings of this study are in line with those of Arribas et al.53 suggesting that varying concentrations of whole carob fruit, carob powder, molasses, and fiber can impact the brown color of final food items. Furthermore, the integration of these components has been shown to decrease lightness (L*) and yellowness (b*) values in food products. These results highlight the significance of color and its assessment in evaluating the quality and attributes of food products.

The study’s findings are in line with previous research by OzdemİR, et al.54, indicating that the addition of carob molasses pulp (CMP) does not negatively impact the sensory qualities of bakery products. Interestingly, the panelists in the study particularly favored the brown color imparted by CMP flour in cones, with no significant impact on other sensory attributes. These results underscore the importance of sensory attributes in consumer food acceptance, where factors such as appearance, color, consistency, odor, and flavor play crucial roles in food choice decision-making.

The growing interest in functional foods has spurred efforts to incorporate carob pods into health-conscious diets, offering potential health benefits55. The antioxidant properties of frozen yogurt enriched with carob nanoparticles (FYC) warrant exploration, driven by two key factors. i) Carob pods are a nutrient-dense source rich in essential micro - and macro-elements, including vitamins, and minerals7, and phenolic compounds such as D-pinitol in carob seeds, along with dietary fiber, all of which offer numerous health benefits56. ii) Probiotic bacteria, which enhances the immune activity by modulating the maturation and function of immune cells, such as dendritic cells, which in turn boost T-cell activity.

This immune regulation contributes to improved health and the restoration of gut microbiota balance. Additionally, specific components in carob fruit, such as dietary fibers (particularly soluble fibers) and polyphenols (e.g., phenolic acids), act as prebiotics. These components promote the growth of beneficial gut bacteria and support gut health indirectly. By creating a favorable environment for probiotics, these prebiotic components help maintain their effectiveness in promoting gut health34.

The results demonstrate increased antioxidant activity and phenolic compound levels in FYC samples compared to the Ctrl. These findings align with Méndez-Galarraga et al.33 who showed that probiotic fermentation in fruit and vegetable beverages can both reduce and enhance phenolic compound levels. While lactic acid bacteria (LAB) fermentation may degrade certain phenolics, it can also release others from the food matrix, improving their bio-accessibility, bioavailability, and antioxidant properties. The production of secondary metabolites during fermentation may further contribute to enhanced antioxidant capacity.

Incorporation of CPNs to functional frozen yogurt increases total phenolic compound and antioxidant activity, proportionally to the CPN concentration. This aligns with27 who showing that carob pulp flour enhances yogurt’s probiotic viability, fermentation, and antioxidant capacity during storage, acting as a prebiotic to maintain high probiotic levels and antioxidant properties throughout shelf life.

Incorporating carob nanoparticles (CPNs) into frozen yogurt leverages the combined benefits of probiotics. The study investigated the antimicrobial effects of even Ctrl, CPNs, and FYC groups due to several factors. i) Probiotics not only improve flavor, texture, but also gut health by outcompeting harmful microbes, maintaining a balanced gut microbiome57. ii) Prebiotic and antioxidant properties due to polyphenolic compounds, including tannins, epicatechin, catechin, gallic acid, procyanidins, and phenolic acids which act as prebiotics, fostering the growth and activity of probiotics in frozen yogurt8. Additionally, they exhibit potent antioxidant properties, comparable to carotenoids and vitamins, and possess well-documented antimicrobial effects. These properties inhibit the growth of harmful bacteria, contributing to a healthier microbial environment7. iii) Synergistic antimicrobial activity, this interaction between carob polyphenols and probiotics aligns with previous studies, such as those by58,59, which demonstrated the antimicrobial activity of carob leaf and pod extracts against pathogens.

Methods

Materials

Mature carob pods and sugar were purchased from the local market in Egypt, while pasteurized buffalo milk (6% fat) and buffalo cream (52% fat) were provided by the Animal Production Research Institute (APRI) in Egypt. Skim milk powder (95% SNF) extra grade-spray dried (California Dairies, Inc., Fresno, CA, USA). The sodium carboxy methyl cellulose (CMC E466) (El- Nasr Com., Egypt) served as a stabilizer.

Bacterial strains and growth conditions

Lyophilized yogurt starter cultures consisting of Streptococcus salivarius subsp thermophilus and Lactobacillus delbrueckii subsp bulgaricus were procured from Misr Food Additives (MIFAD, Egypt). The starter cultures were provided as freeze-dried Vat Set (DVS, nu-Trish ABY ˗ 1, Chr. Hansen’s, Denmark).

The freeze-dried yogurt starter culture was reactivated in 200 mL of reconstituted skimmed milk 10% (w/w). The starter cultures were added to the milk, and the mixture was incubated at 42 °C for 24 h this incubation period allowed the yogurt starter cultures to ferment and develop the desired flavor and texture. Subsequently, 3% (v/v) of the activated yogurt starter cultures were transferred to 300 mL of buffalo milk and incubated at 42 °C until the pH reached 4.6. At this point, the yogurt was considered ready and refrigerated at a temperature of 4 ± 1 °C to maintain its quality and freshness.

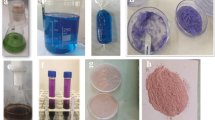

Preparation of Carob Pod Nanoparticles (CPNs)

The preparation of carob pod nanoparticles (CPNs) was adapted from the method described by Chaâbani et al.60 with minor adjustments. Fresh carob pods were first washed thoroughly with distilled water to remove surface contaminants such as dust, soil particles, and other debris. Following this, the pods were subjected to microwave-assisted drying using a 720 W domestic microwave oven (Hotpoint Ariston, USA) for 15 min. This step not only ensured rapid and uniform dehydration but also helped preserve the structural integrity and bioactive constituents of the carob tissue, which are crucial for functional applications in food systems.

Once dried, the pods were milled into fine particles using a high-performance laboratory mill (Braun, Germany). The milling process was optimized through multiple cycles of grinding followed by sieving. The resulting powder was passed through a precision stainless-steel sieve with a pore size of 0.149 mm (Laboratory Test Sieve D-42757; Retsch GmbH, Germany), ensuring a consistent and homogeneous particle size distribution.

To further reduce particle size toward the nanoscale, the powder underwent additional rounds of high-speed mechanical milling in short bursts, followed by re-sieving to remove larger residual particles. Although comprehensive nanoparticle characterization via electron microscopy was not included in this study, the multi-step mechanical refinement procedure was based on previously validated methodologies used in food-grade nanoparticle production, supporting the generation of a fine, functionally viable powder.

To ensure microbial safety, the final CPN powder was exposed to ultraviolet (UV) irradiation for 30 min under a laminar flow hood. Immediately after sterilization, the nanoparticles were sealed in sterile plastic bags and stored at 4 °C in a Combi Bottom Freezer (BOSCH, Germany) until further use in experimental formulations.

Particle size and Zeta potential measurements

Carob pod nanoparticle (CPNs) size distribution was characterized using dynamic light scattering (DLS) with a Microtrac S3500 instrument. The measurements were performed at 25 °C after appropriate dilution of samples with water, following the methodology outlined by Karmous et al.61. Additionally, the zeta potential of the CPNs was measured using a Zetatrac device (Microtrac, USA) to assess their surface charge.

Fourier-transform infrared spectroscopy (FTIR) analysis

Taha et al.62 utilized Fourier-transform infrared spectroscopy (FTIR) to analyze the spectra of functional frozen yogurt enriched with carob pod nanoparticles (CPNs) and to elucidate any structural disparities between the pure CPNs compounds and the various types of functional frozen yogurt produced. The FTIR analysis was conducted using an FTIR spectrometer (NICOLET iS10, Thermo Scientific Inc., USA) in attenuated total reflection (ATR) mode. The spectra were captured across the wave number range of 600–4000 cm-1. This comprehensive range allowed for the detailed examination of various functional groups and molecular structures present in the functional frozen yogurt samples, providing insights into their chemical composition and interactions.

Preparation of functional frozen yogurt

Frozen yogurt was crafted according to Abdelazez et al.3. Table 7 delineates the ingredient composition and quantities for the Control (Ctrl) group and experimental groups with incremental carob pod nanoparticle (CPNs) concentrations: FYC4 (4%), FYC8 (8%), and FYC12 (12%). The manufacturing process commenced by splitting each 3 kg batch of buffalo milk (6% fat) into two parts. The first part (1 kg) incorporated skim milk powder (95% SNF) and varying sucrose % according to the CPNs levels. The second part (2 kg) included cream (52% fat), 0.5% sodium carboxy methyl cellulose (CMC), and a gradient of CPNs (4%, 8%, 12%). The Ctrl batch comprised 3 kg of buffalo milk, skim milk powder, 15% sucrose, cream, and 0.5% CMC.

All mixtures underwent heating to 85 °C for 5 minutes, followed by homogenization. The first batch was cooled to 5 °C, while the second was reduced to 42 °C. A 3% yogurt starter culture was then introduced, initiating fermentation at 42 °C until a pH of 5.5 was achieved. Afterward, both batches were merged, aged at 6 °C ± 1 for 24 h, and frozen using a vertical batch freezing machine (Profigel 600, Italy) for 30 min. The resulting frozen yogurt products were packed into 100 mL and 200 mL plastic cups and stored at −18 °C for further analysis. This methodical approach ensured consistency across treatments and provided a comprehensive evaluation of CPNs’ impact on frozen yogurt’s characteristics.

Chemical analysis

The chemical analysis was conducted according to the protocols authorized by the Association of Official Agricultural Chemists63. The total solids (TS%) were determined using the standard AOAC ˗ 941.08, while the amount of fat% was determined using the Gerber method outlined in the AOAC-2000.18 standard. The solid-not-fat (SNF%) content was calculated by subtracting fat% from the total solid%. Additionally, the detection of acetaldehyde and diacetyl in the frozen yogurt samples was detected using the method described by Xanthopoulos et al.64.

Titratable acidity (TA%), expressed as a percentage of lactic acid, was determined by titration to a pink endpoint using a 0.5% phenolphthalein indicator. Lactic acid content in the samples was assessed using titration with 0.9 N NaOH63 as refered in Eq. (1), and pH levels were measured with a standard electrode pH meter.

Where, Titratable Acidity (TA); Titration volume (V1); Volume of the sample (V2); normality of titrant (N), and 90 = Equivalent weight for lactic acid.

Evaluation of overrun

The overrun, quantifying the volume expansion during freezing, was determined following Akın et al.65 as refered in Eq. (2). Initially, the weight of the mix (W1) was recorded, followed by the measurement of the weight of the frozen yogurt of equivalent volume after wiping (W2). Subsequently, the overrun was computed employing the formula:

Specific gravity, and weight per gallon

Specific gravity and weight per gallon were determined as described by Marshall et al.66.

Meltdown assessment

The melting rate of the frozen yogurt samples was determined using a modified version of the method described by Melanie and Kochki67. A 50 g scoop of frozen yogurt was placed on a stainless steel mesh with 1 × 1 mm apertures, positioned above a beaker to collect the melted product. The setup was maintained at a temperature of 20 ± 2 °C for a total of 60 min. The weight of the melted portion collected in the beaker was recorded at three time intervals: the initial melting point (first drop), after 30 min, and after 60 min. The melting rate was expressed as a percentage of the initial sample weight, as detailed in Eq. (3).

Where (A); Weight of the melted sample; (B); the weight of the scoop

Viscosity assessment

Viscosity measurements were conducted using a rotational viscometer (Brookfield Viscometer DV II pro-Middleboro, MA, USA). Each measurement utilized a 150 mL sample volume, maintaining a consistent spindle immersion depth. Viscosity assessments were performed at ambient temperature (20 ± 1 °C) to simulate consumption conditions. Viscosity analysis was conducted at speeds of 10 and 20 rpm with 1 min rotation 3 replicates were performed, using spindle number LV5. The viscosity values are expressed in centipoises (cp)68.

Texture profile analysis (TPA)

The texture profile analysis (TPA) was conducted using a CNS-Farnell texture analyzer (Boreham-Wood, Hertfordshire, UK), adhering to the methodology specified by Zhang et al.69. Before the TPA, the samples were equilibrated at room temperature for one hour to standardize the testing conditions.

The TPA was performed with a P/0.5 probe at a measurement speed of 1.0 mm/sec, with pre - and post-measurement speeds set at 5.0 mm/sec. A 5-second interval was programmed between the first and second compressions, and the compression ratio was set to 30%. Each sample underwent two compression cycles to assess key textural attributes. The texture analyzer produced force-deformation curves, offering insights into the hardness, chewiness, and cohesion of the frozen yogurt, which are indicative of the product’s firmness, resilience, and consistency. To ensure the reliability of the results, a minimum of three measurements were conducted for each sample type, and the average values of the texture characteristics were documented.

Color measurement

The color variances among the frozen yogurt samples were quantified utilizing a tristimulus colorimeter (HunterLab Scan XE, Reston, VA), featuring the CIE Lab color scale. To ensure accuracy, the instrument was calibrated against black-and-white standards as per the manufacturer’s guidelines before each experimental session. Subsequently, the color characteristics of the samples were assessed concerning lightness (L*), redness (a*), and yellowness (b*), following the methodology outlined by Chen et al.70.

Microbiological analysis

The enumeration of potential probiotics was carried out using the traditional plate count method. One gram of the sample was diluted with 9 mL of 0.1% (w/v) sterile buffered peptone water and mixed for one minute, followed by a series of tenfold dilutions as described by Abdelazez et al.2. For the quantification of Streptococcus salivarius subsp thermophilus, M17 agar (Oxoid, UK) was used, and the plates were incubated aerobically at 42–45 °C for 48 h. Lactobacillus delbrueckii subsp. bulgaricus counts were determined on MRS agar (Oxoid, UK), with anaerobic incubation at 42–45 °C for 48 h. Total microbial counts were performed using nutrient agar (Oxoid, UK) incubated at 37–42 °C for 48 h. Mold and yeast identification followed the criteria established by Acharya and Hare71. The results from triplicate analyses were expressed as logarithms of the colony-forming units per milliliter (cfu/mL).

Sensory evaluation

The sensory evaluation of the functional frozen yogurt samples involved a diverse group of 20 participants, comprising men and women of varying ages, all without dairy allergies or significant health conditions that could affect their sensory perceptions. The evaluation criteria were structured to assign points for each attribute of the yogurt: appearance (10 points), body and texture (30 points), taste (60 points), and overall acceptability (100 points), as per the methodology by Abdelazez et al.2.

To prevent sensory fatigue and interference, a three-minute interval was observed between the evaluation of each sample. During this break, participants were provided with drinking water to cleanse their palates and maintain the integrity of their sensory assessments. The experimental procedure was authorized by the Egyptian Organization for Standardization and Quality of Milk and Dairy Products, under the ethical number (No. 154 –7/2005). The authorization also came from the economic growth/sector policy branch in Cairo, Egypt, which was submitted by USAID (Contract # 263-C-00-96-00001-00). The study adhered to the ethical principles outlined in the Helsinki Declaration, ensuring the protection of participants’ rights and welfare72.

Antioxidant activity (%)

The study evaluated the antioxidant activity of the samples through their radical scavenging capacity, measured as a percentage using the DPPH (1,1-diphenyl-2-picrylhydrazyl) assay73. The process involved mixing 1.5 mL of the test samples, prepared at concentrations of 1.25, 2.5, and 5 mg/mL, with 1.5 mL of a 0.1 mM DPPH solution in ethanol. The mixtures were vortexed to ensure thorough blending and then incubated in the dark at room temperature for 30 minutes to allow for reaction completion. After incubation, the absorbance of each mixture was measured at a wavelength of 517 nm using a spectrophotometer, providing a quantitative assessment of the samples’ antioxidant potential as referred to in Eq. (4).

Here, A0 represents the absorbance of the control sample, which contains the DPPH solution without the test material. A1 is the absorbance of the test material after interaction with the DPPH solution.

Total phenolic componend (TPC)

The total phenolic component was determined using a modified Folin-Ciocalteau assay, as described by Chang et al.74. For extraction, 1.0 g of each sample was homogenized with 10 mL of 80% v/v methanol. The mixture was centrifuged at 4500 g for 15 minutes, filtered, and the supernatant was reserved for analysis. A 0.2 mL aliquot of the extract was combined with 1.5 mL of Folin-Ciocalteau reagent and allowed to react in the dark for 5 min. Subsequently, 1.5 mL of a saturated sodium carbonate (Na2CO3) solution and 4 mL of distilled water were added. The mixture was incubated in the dark for 1 hour at room temperature, after which the absorbance was measured at OD765 nm. The results were reported in milligrams of gallic acid equivalents (GAE) per 100 grams of dry weight (dw) extract.

Total flavonoid content (TFC)

The total flavonoid content (TFC) was ascertained using a spectrophotometric method as outlined by Liu et al.75. The absorbance of the samples was measured at OD510 nm. A standard curve was constructed using catechin as the reference compound. The TFC results were quantified and expressed in terms of milligrams of catechin equivalent (CE) per 100 grams of the dry weight (dw) of the extract. This approach provides a standardized measurement of flavonoid content in the samples analyzed.

Determination of antimicrobial activity

The antimicrobial potency of carob pod nanoparticles (CPNs) was assessed employing a modified semi-solid diffusion disc method, in line with the protocol established by Abdel-motaal et al.76. The study targeted a spectrum of pathogenic strains, including Bacillus subtilis ATCC 6633, Staphylococcus aureus ATCC 6538, Escherichia coli ATCC 8739, Klebsiella pneumoniae ATCC 13883, Candida albicans ATCC 10221, and Aspergillus niger.

For the assay, a 2 µL aliquot of the functional frozen yogurt was thawed and deposited onto MRS agar, which was then incubated at 40 °C for 24 h. Concurrently, a semi-solid medium was formulated by combining Brain Heart Infusion (BHI) broth with 0.5% agarose; however, for Candida albicans, Sabouraud dextrose agar (SDA) was utilized, and for Aspergillus niger, Potato Dextrose Agar (PDA) was specified. To evaluate the inhibitory impact on the pathogenic strains, a blend comprising 6 mL of BHI, SDA, or PDA (as required) and 100 µL of the respective strain was prepared. This blend was then poured over the MRS agar plate. After incubation at 40 °C for 24 to 48 h, the diameter of the clear zone of inhibition was measured in triplicate using a digital caliper (Vernier Caliper DL3944, China), providing a quantifiable assessment of the antimicrobial activity of the CPNs against the tested strains.

Microstructure of functional frozen yogurt (SEM)

The microstructure analysis of the functional frozen yogurt samples was conducted using scanning electron microscopy (SEM, Akishima, Tokyo, Japan), following the procedures detailed by Zhao, et al.77. For SEM preparation, approximately 5 μg of each sample was carefully placed on a silica plate and flash-frozen in liquid nitrogen to preserve its microstructure. The samples were then subjected to lyophilization using a freeze dryer (Telstar-Cryodos, USA) to eliminate residual moisture, a critical step for SEM analysis. The freeze-dried samples were coated with a 15 nm layer of gold-palladium using a sputter coater (Model SC7620, Quorum Technologies) to enhance image contrast and minimize charging effects during scanning.

Mounted on aluminum stubs, the samples were inserted into the SEM instrument for examination. The SEM was set to an accelerating voltage of 30 kV to optimize the imaging of the sample’s microstructure. Photomicrographs were taken at various magnifications from 10 to 50 µm, emphasizing the 2000 x magnification to discern structural variations within the samples. These high-resolution images provided valuable insights into the textural properties of functional frozen yogurt.

Statistical analysis

The results were presented as the Mean ± SD. For data comparisons, a one-way ANOVA was employed. The analysis was conducted using Origin Lab software (version 2024b), a comprehensive scientific data analysis and graphing tool. To ensure the reliability of the findings, each experiment was conducted in triplicate, thereby reinforcing the validity of the outcomes through repetition.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Abdelazez, A. et al. Potential antimicrobial activity of camel milk as a traditional functional food against foodborne pathogens in vivo and in vitro. Food Sci. Technol. Int. 30, 239–250, https://doi.org/10.1177/10820132221146322 (2024).

Abdelazez, A., Mohamed, D. M., Refaey, M. M. M. & Niu, J. Intervention effect of freeze‑dried probiotic and unripe banana pulp combination on set‑type Bio‑yogurt production during storage. J. Food Meas. Charact. 2461–2478 https://doi.org/10.1007/s11694-023-02208-9 (2024).

Abdelazez, A. et al. Production of a functional frozen yogurt fortified with Bifidobacterium spp. Biomed. Res., Int. 2017, 6438528, https://doi.org/10.1155/2017/6438528 (2017).

Skryplonek, K. et al. Characteristics of lactose-free frozen yogurt with κ-carrageenan and corn starch as stabilizers. J. Dairy Sci. 102, 7838–7848, https://doi.org/10.3168/jds.2019-16556 (2019).

Atallah, A. A. et al. Physicochemical, microbiological, and microstructural characteristics of sucrose-free probiotic-frozen yogurt during storage. Foods 11, 1099, https://doi.org/10.3390/foods11081099 (2022).

Laaraj, S. et al. Nutritional value, HPLC-DAD analysis and biological activities of Ceratonia siliqua L. pulp based on in vitro and in silico studies. Sci. Rep. 14, 31115, https://doi.org/10.1038/s41598-024-82318-6 (2024).

Tounsi, L. & Kechaou, N. Characterization of Tunisian carob pods (Ceratonia siliqua L.) and processed juice. J. Biochem. Int. 9, 27–36, https://doi.org/10.56557/jobi/2022/v9i17444 (2022).

Rodríguez-Solana, R., Romano, A. & Moreno-Rojas, J. M. Carob pulp: A nutritional and functional by-product worldwide spread in the formulation of different food products and beverages. A review. Processes 9 https://doi.org/10.3390/pr9071146 (2021).

Azab, A. D-Pinitol—Active natural product from carob with notable insulin regulation. Nutrients 14, 1453, https://doi.org/10.3390/nu14071453 (2022).

Tsatsaragkou, K., Gounaropoulos, G. & Mandala, I. Development of gluten free bread containing carob flour and resistant starch. LWT 58, 124–129, https://doi.org/10.1016/j.lwt.2014.02.043 (2014).

Laaraj, S. et al. Nutritional benefits and Antihyperglycemic potential of carob fruit (Ceratonia siliqua L.): An overview. Ecol. Eng. Environ. Technol. 25, 124–132, https://doi.org/10.12912/27197050/178456 (2024).

Spizzirri, U. G. et al. Carob pulp flour as an innovative source of bioactive molecules for the preparation of high-value-added jellies. Heliyon 10, e38354, https://doi.org/10.1016/j.heliyon.2024.e38354 (2024).

Shaker, S. E., Fayed, D. B., Shawky, H. & Farrag, E. K. Co-administration of Ceratonia siliqua extract nanoparticles promotes the oral bioavailability and neurotherapeutic efficacy of donepezil in a dementia model. J. Pharm. Pharmacol. 77, 153–169, https://doi.org/10.1093/jpp/rgae094 (2024).

Shah, Y. A., Bhatia, S., Al-Harrasi, A. & Khan, T. S. Chitosan/sodium alginate/ethyl cellulose-based multilayer film incorporated with l-ascorbic acid for improved barrier and antioxidant properties. Int. J. Biol. Macromol. 284, 138169, https://doi.org/10.1016/j.ijbiomac.2024.138169 (2025).

Khan, S. T., Musarrat, J. & Al-Khedhairy, A. A. Countering drug resistance, infectious diseases, and sepsis using metal and metal oxides nanoparticles: Current status. Colloids Surf. B. Biointerfaces 146, 70–83, https://doi.org/10.1016/j.colsurfb.2016.05.046 (2016).

Amini, S. M., Gilaki, M. & Karchani, M. Safety of nanotechnology in food industries. Electron. Physician 6, 962–968, https://doi.org/10.14661/2014.962-968 (2014).

Jalaluddin, M., Dar, M. S., Tahir, A. & Sahu, D. Evaluation, preparation, and description of chitosan nanoparticles, as well as improving rivaroxaban bioavailability. South Asian J. Case Rep. Rev. 9, 86–91, https://doi.org/10.18231/j.sajcrr.2022.018 (2022).

Nguyen, V. H., Thuy, V. N., Van, T. V., Dao, A. H. & Lee, B.-J. Nanostructured lipid carriers and their potential applications for versatile drug delivery via oral administration. OpenNano 8, 100064, https://doi.org/10.1016/j.onano.2022.100064 (2022).

Sikora, A. et al. A systematic comparison of different techniques to determine the zeta potential of silica nanoparticles in biological medium. Anal. Methods 7, 9835–9843, https://doi.org/10.1039/C5AY02014J (2015).

Gumustas, M., Sengel-Turk, C. T., Gumustas, A., Ozkan, S. A. & Uslu, B. in Multifunctional Systems for Combined Delivery, Biosensing and Diagnostics (ed Alexandru Mihai Grumezescu) 67–108 (Elsevier, 2017).

Samimi, S., Maghsoudnia, N., Eftekhari, R. B. & Dorkoosh, F. in Characterization and Biology of Nanomaterials for Drug Delivery (eds Shyam S. Mohapatra et al.) 47–76 (Elsevier, 2019).

Xie, D. et al. Insight into sensory characteristics and volatile differences of freeze-dried Citrus aurantium L. var. amara Engl. flower essential oil-casein phospholipid nanocomposites sustained-release scented tea by combining GC-E-nose and SBSE-GC-MS. Food Cont. 166, 110714, https://doi.org/10.1016/j.foodcont.2024.110714 (2024).

El-Sayed, S. M., Kholif, A. M. M., El-Sayed, H. S. & Youssef, A. M. Augmenting the quality and shelf life of ras cheese by adding microencapsulated allspice berry extract nanoemulsion. Food Bioproc. Tech. 18, 588–604, https://doi.org/10.1007/s11947-024-03473-2 (2025).

Ma, L. et al. Raman plus X” dual-modal spectroscopy technology for food analysis: A review. Compr. Rev. Food Sci. Food Saf. 24, e70102, https://doi.org/10.1111/1541-4337.70102 (2025).

Christou, C., Agapiou, A. & Kokkinofta, R. Use of FTIR spectroscopy and chemometrics for the classification of carobs origin. J. Adv. Res. 10, 1–8, https://doi.org/10.1016/j.jare.2017.12.001 (2018).

Tan, G. & Sargin, I. The catalytic activity of carob extract-capped silver nanoparticles in the remediation of recalcitrant nitroaromatics. Catal. Lett. 155, 31, https://doi.org/10.1007/s10562-024-04884-8 (2024).

Arab, R. et al. Impact of carob (Ceratonia Ciliqua L) pulp flour supplementation on probiotic viability, milk fermentation and antioxidant capacity during yogurt storage. Nor. Afr. J. Food Nutr. Res. 6, 154–164, https://doi.org/10.51745/najfnr.6.14.154-164 (2022).

Senaka Ranadheera, C., Evans, C. A., Adams, M. C. & Baines, S. K. Production of probiotic ice cream from goat’s milk and effect of packaging materials on product quality. Small Rumin. Res. 112, 174–180, https://doi.org/10.1016/j.smallrumres.2012.12.020 (2013).

Pinto, S. & Dharaiya, C. Development of a low fat sugar free frozen Dessert. Inter J. Agric. Sci. 4, 90–101 (2014).

Isik, U., Boyacioglu, D., Capanoglu, E. & Nilufer Erdil, D. Frozen yogurt with added inulin and isomalt. J. Dairy Sci. 94, 1647–1656, https://doi.org/10.3168/jds.2010-3280 (2011).

Guner, A., Ardıc, M., Keles, A. & Dogruer, Y. Production of yogurt ice cream at different acidity. Int. J. Food Sci. Technol. 42, 948–952, https://doi.org/10.1111/j.1365-2621.2006.01315.x (2007).

Cadwallader, K. R. & Singh, T. K. in Advanced Dairy Chemistry: Volume 3: Lactose, Water, Salts and Minor Constituents (eds Paul McSweeney & Patrick F. Fox) 631–690 (Springer New York, 2009).

Méndez-Galarraga, M. P., Pirovani, M. E., García-Cayuela, T. & Van de Velde, F. Fruit and vegetable beverages fermented with probiotic strains: Impact on the content, bioaccessibility, and bioavailability of phenolic compounds and the antioxidant capacity. Curr. Res. Food Sci. 3, 4, https://doi.org/10.1007/s43555-024-00049-1 (2025).

Maftei, N.-M. et al. The potential impact of probiotics on human health: An update on their health-promoting properties. Microorganisms 12, 234, https://doi.org/10.3390/microorganisms12020234 (2024).

Rachwał, K. & Gustaw, K. Lactic acid bacteria in sustainable food production. Sustainability 16, 3362, https://doi.org/10.3390/su16083362 (2024).

Suo, B., Chen, X. & Wang, Y. Recent research advances of lactic acid bacteria in sourdough: origin, diversity, and function. Curr. Opin. Food Sci. 37, 66–75, https://doi.org/10.1016/j.cofs.2020.09.007 (2021).

El-rahmany, A. S., El-Dardiry, A. I., Abdelazez, A. & Khalil, O. S. F. Functional low-fat labneh fortified with resistant potato starch as prebiotic and assessed physicochemical, microbiological, and sensory properties during storage. Egypt. J. Chem. 65, 555–568, https://doi.org/10.21608/ejchem.2022.157450.6824 (2022).

Froiio, F., Cristiano, M. C., Mancuso, A., Iannone, M. & Paolino, D. Vegetable-milk-based yogurt-like structure: Rheological properties influenced by gluten-free carob seed flour. Appl. Sci. 10, 6963, https://doi.org/10.3390/app10196963 (2020).