Abstract

This paper explored the practical utility of gas sensing applications based on the multi-degree-of-freedom (Multi-DoF) bulk acoustic wave (BAW) resonant sensors, including 1, 2, and 3-DoF devices, where piezoelectric actuation and sensing methods were adopted. Zeolitic imidazolate framework-8 (ZIF-8) was chosen for the adsorption and desorption of the ethanol vapor, thereby facilitating the gas sensing mechanism and introducing the external mass changes to the multi-DoF resonating system. Similar to conventional quartz crystal microbalance (QCM) gas sensors, the frequency shift of all the devices (1, 2, and 3-DoF devices) was tracked to characterize the sensitivity. Besides, for the 2 and 3-DoF devices, the amplitude ratio (AR) change was also recorded and observed with an enhancement in performance. Compared with the state-of-the-art gas sensor based on 2-DoFcapacitively coupled resonators, the presented devices achieved better Q factor in air, stability, and resolution in terms of both frequency shifts and AR changes. The dominant mass change (dominant stiffness change in the state-of-the-art) of the proposed resonant devices matched well with the theoretical mass sensing principle, which is both predictable and crucial for the accurate modeling of the practical mass sensor. Furthermore, a lower ethanol vapor concentration from 0.1% to 2% was successfully detected by the proposed 2-DoF device, demonstrating even better sensing performance than that of the state-of-the-art.

Similar content being viewed by others

Introduction

Micro-electro-mechanical system (MEMS) resonant sensors have garnered significant attention over the past few decades, encompassing various types such as inertial, pressure, mass, gas sensors, etc1,2,3,4. Among these, MEMS resonant gas sensors have been investigated and are particularly promising for applications in the environmental monitoring field3,5,6,7 The fundamental sensing mechanism of MEMS resonant gas sensors is analogous to that of traditional micromachined gas sensors, specifically those based on quartz crystal microbalance (QCM). This principle relies on mass perturbation caused by the adsorption of gas molecules onto the sensor surface, which is coated with various adsorbent materials. The added mass results in changes to the resonant frequency of the device7. In contrast to QCM, MEMS resonant gas sensors offer enhanced scalability and design flexibility, enabling higher sensitivity and diverse shape modifications8. Furthermore, the fabrication of thin film resonators is compatible with integrated circuit (IC) manufacturing processes, facilitating dense integration of on-chip level compact devices. However, miniaturization brings the challenges of surface functionalization with limited area, thermal stability, noise, etc, which need to be taken into account in the design of the MEMS resonant gas sensors.

Different gas sensors have been developed based on various MEMS resonators, including piezoelectric MEMS cantilevers, surface acoustic wave (SAW) resonators, and thin-film bulk acoustic wave resonators (FBAR). Shin et al.9 designed and fabricated a PZT microcantilever transducer operating at a resonance frequency of 17–29 kHz for detecting volatile organic chemicals (VOCs) via coated polymethyl methacrylate (PMMA) as the sensitive material. Zhou et al.10 proposed a self-excited piezoelectric microcantilever coated with zeolite nanomaterial for Freon gas detection. It was operated at a resonance frequency of 1.646 kHz and tested with 12 different concentrations of Freon gas ranging from 10 to 500 ppm. Devkota et al.11 developed a SAW gas sensor for detecting and monitoring carbon dioxide (CO2) in air at a working frequency of 436 MHz. The detection limit achieved was 0.38 ppm, and zeolitic imidazole framework-8 (ZIF-8) metal-organic framework (MOF) was coated on the surface of the SAW device as the sensitive material. Zhang et al.12 designed an FBAR gas sensor for ethanol vapor detection, where zinc oxide (ZnO) was deposited as the sensing and piezoelectric material. Hoffmann et al.13 developed a polyaminosiloxane- and ethylcellulose-functionalized FBAR device to sense CO2 with a resolution of 50 ppm. Yan et al.14,15 established an FBAR gas sensor with coated MOF material for detecting VOCs, where the MOF was formed with layer-by-layer solvents deposition and the detection limit was 1 ppm with a sensitivity of 0.28–1.27 kHz/ppm. Wang et al.16 proposed a high operating frequency FBAR device (4.8 GHz) for formaldehyde sensing at ppb levels (24–38 ppb) with a sensitivity of 1.29–1.90 kHz/ppb, in which the sensitive coating material was carbon nanotubes/polyethyleneimine multilayers. Similarly, Chang et al.17 fabricated another FBAR sensor (4.44 GHz) coated with different self-assembled monolayers (SAMs) sensitive material for E-nose gas sensing application. Among gas sensors based on various MEMS resonators, FBAR devices can achieve higher sensitivity due to higher resonance frequencies compared with SAW devices and microcantilever devices.

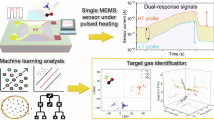

Current MEMS resonant gas sensors are based on a single resonator and their frequency shifts are chosen as the output metric, owing to the prominent nature of frequency output such as quasi-digital and stability. However, introducing the energy coupling theory to the resonator system has been recently proven to be feasible for achieving enhanced sensitivity with amplitude ratio (AR) as the output readout due to the mode localization phenomenon, such as stiffness sensing, acceleration sensing, and magnetic sensing18. The common mode rejection property of the mode localized resonant sensors allows them to suppress ambient pressure or temperature fluctuation19,20. Previously, we developed an ethanol gas sensor with 2-DoF mode-localized capacitive resonators coated with ZIF-8 material21. As the experimental results exhibited, the measurement range regarding the concentration of the ethanol vapor spans from 2% to 60%, and the sensor achieved 40 times higher sensitivity using the AR change than that based on the frequency shift21. However, the AR based resolution was ~150 times worse than the frequency shift based resolution. As we all know, sensitivity and instability mainly decide the resolution. Thus, the frequency shift is verified to be much more stable (more than two to three orders of magnitude) than the AR. Enhancement in the stability performance of the AR as the output readout has already been a challenge for the mode-localized resonant sensors. Another primary drawback of this device is the relatively low quality (Q) factor in air, which is mainly due to the thin-film damping from the capacitive transduction gaps and therefore, limits the frequency stability and signal-to-noise ratio. Besides, the dominant stiffness change over the mass change during gas sensing made it hard for accurate modeling to verify the device performance in theory and simulation. Thus, improvements in the Q factor of resonators are still desirable, especially for gas sensing in atmosphere pressure. As mentioned above, piezoelectric transduction has been increasingly used in gas sensing applications for MEMS resonators due to its measurement simplicity and the possibility of achieving high Q factors for the resonant gas sensors operating at atmospheric pressure with strong coupling efficiencies22,23. Compared to those working in flexural or torsional modes with bending motion24, the BAW resonators with in-plane motion undergo less energy loss, such as thermoelastic damping (TED) and viscous damping in air/liquid, thereby leading to higher Q factors25. In this premise, combining the approach of mode localization with BAW resonators in lateral bulk vibration modes using piezoelectric transduction is promising for improving mass sensing performance19. To further enhance sensitivity, multi-degree-of-freedom (DoF) coupled MEMS resonant gas sensors can be a wise choice, and so far, further sensitivity enhancement in a 3-DoF resonating system has been verified to be feasible4,26,27 but there is still no related gas sensing work on that.

Besides, the conventional solvent-based methods for coating gas sensing material on MEMS resonators can lead to contamination with residual solvents on the device, solvent exposure, solvent disposal, longer processing time, etc. Recently, MOFs have been proven to be feasible for gas detection, especially ZIF-8 which presents high chemical and thermal stability28,29. Integrating MOFs with MEMS resonators by an efficient solvent-free method has also demonstrated its availability and good functionality for gas sensing applications, where ZnO was deposited on the top surface of the resonator and then converted into ZIF-8 by chemical vapor deposition (CVD) which is solvent-free and more environmentally friendly. As the top surface of the piezoelectric devices is covered with metal and piezoelectric materials, the sensing material should be coated on the backside of the silicon device layer for gas sensing. In that case, the integration of sensing materials can only be done after the final microfabrication procedure: the backside etch of the substrate to release the structure with free motion. That simplifies the fabrication process, providing more possibilities for coating various sensing materials and making it more clear about the device performances with/without sensing materials coated, unlike work21 which integrated the sensing material during the fabrication process.

Therefore, in this paper, various multi-DoF BAW resonating devices operating in the contour extensional mode were developed for detecting ethanol vapor. These devices include configurations with 1, 2, and 3-DoF, and among them, the 3-DoF system was studied as a gas sensor for the first time. A simple solvent-free method of coating the gas sensing material on the MEMS devices has been developed, which can be easily applied to other MEMS devices. ZIF-8 was formed on the disks of the fabricated BAW resonators and synthesized through the transformation of sputtered ZnO on the backside of the device, facilitating the binding of ethanol molecules. To detect ethanol vapor at varying concentrations, we monitored both the frequency shift and the AR change of the devices. Notably, an enhancement in sensitivity was observed for the 2 and 3-DoF devices, with AR change as the output metric, contrasting with the frequency shift noted as the output metric. Additionally, the response of the devices to low concentrations of ethanol (0.5–2%) was demonstrated successfully, achieving performance that surpasses the state-of-the-art21. Overall, a novel ethanol gas sensor is realized with improved stability, resolution, and Q factors. The structure of this paper is organized as follows: Section (Results) details the sensing mechanism, device structure, and experimental findings, including device performance characterization and gas response metrics such as sensitivity, resolution, and noise floor. Section (Conclusion) summarizes the gas sensing performance of the proposed devices, while Section (Materials and Methods) outlines the experimental methodologies employed.

Result

Sensing mechanism

A single BAW resonator system can be modeled as a mass-spring-damper system and a representation that also extends to 2 and 3-degree-of-freedom (DoF) resonating devices30, as illustrated in Fig. 1. Figure 1a shows the proof mass is supposed to mainly move in the x-direction, i.e., one degree of freedom. Accordingly, each resonator in the coupled resonating system is free to move in the x-direction, as shown in Fig. 1b, c. Thus, the amount of coupled resonators decides the total degree of freedom of the system, forming the multi-DoF BAW resonators system. In this model, assuming all resonators are identical, m is the mass of each resonating disk, K = K1 = K2 = K3 is the suspension spring stiffness, c = c1 = c2 = c3 is the damping, and Kc is the coupling stiffness (Kc ≪ K for the weakly coupled BAW resonating system). Similarly, the displacements of each resonator are X, X1, X2, and X3, and the external forces applied to each resonator are F, F1, F2, and F3.

Assuming that the resonating system is in an ideal state without any external forces and damping, the resonators are vibrating at their resonance frequencies. When an external mass perturbation (∆m ≪ m) is introduced into the balanced system, both frequencies and amplitudes will change. Conventionally, the frequency shift with respect to the small mass change is regarded as the output metric of the resonating device, thence to define the normalized mass sensitivity, which is obtained as30:

For the 2 and 3-DoF BAW resonators, the AR change can be utilized as another output metric, alongside frequency shift, due to the mode localization effect31. The normalized mass sensitivity of the 2 and 3-DoF devices in terms of AR change can be expressed as30:

Based on Eq. 1 and Eq. 2, the normalized mass sensitivity in terms of the AR change of the 2-DoF device is observed to be more than K/Kc (Kc ≪ K) times greater than that of the frequency shift of the 1, 2, and 3-DoF devices. Moreover, when AR is employed as the output metric for the 3-DoF device, the normalized mass sensitivity is further enhanced by a factor of 2 compared to the 2-DoF device, as indicated by Eq. 2 and Eq. 3.

Device description

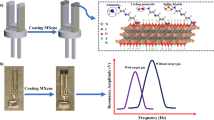

The 1, 2, and 3-DoF resonators had circular resonating disks of a 400 µm radius as shown in Fig. 2a. A mechanical beam was designed to weakly couple two adjacent resonating disks (Resonator 1 (R1), Resonator 2 (R2), and Resonator 3 (R3)) in the 2/3-DoF resonators. The length of the coupling beams was designed as half of the acoustic wavelength and equal to the diameter of the silicon disk32. A T-shaped tether with another two columns was designed to achieve smaller suspension stiffness and vibration, reducing the anchor loss. The final suspension dimensions (see Table 1) are limited to the fabrication constraints of an Al–AlN–Si stack. The minimum width can be 20 µm for low stiffness. The main dimensional parameters are listed in Table 1. The finite element (FE) simulated working mode, i.e., contour extensional mode, for each device is shown in Fig. 2b.

a Structural schematic. b FE simulated working mode: contour extensional mode. c Micrograph of the present three multi-DoF devices, including 1-DoF, 2-DoF, and 3-DoF devices. +Vac represents the actuation port and isense represents the sensing port. d Schematic for functionalization of ZIF-8 on the backside of the silicon resonating disks. CVD represents chemical vapor deposition

The fabricated devices are shown in Fig. 2c. Aluminum nitride (AlN) was selected as the piezoelectric material due to its higher acoustic velocity and lower internal mechanical loss compared to other piezoelectric materials such as ZnO and lead zirconate titanate (PZT)24,33. Notably, as illustrated in Fig.2c, each resonating disk features two separate top electrode pads—one for actuation ( + Vac) and the other for sensing (isense). The shape and area of the two top electrodes match with the radial extensional mode shape with expansion and contraction motion (see Fig. 2b), collecting the maximum charges accumulated on the device surface. Due to the fabrication constraints of an Al–AlN–Si stack, the radius of the electrodes is 5 µm smaller than that of the piezoelectric layer. The electrode area can be further optimized to enhance the device performance like the coupling coefficient. For the 2 and 3-DoF devices, only R1 was actuated during experiments, while the output signals (frequency and amplitude) from R1, R2, and R3 were monitored.

Device characterization

The resonant frequencies and Q factors for the proposed 1, 2, and 3-DoF devices, measured at atmospheric pressure, are detailed in Table 2. Among these, the 2-DoF device showed a higher Q factor in mode 2 than mode 1, leading us to select mode 2 as the preferred mode for gas sensing. Additionally, the 2-DoF device outperformed the 1-DoF device in the Q factor. For the 3-DoF device, FE simulations in previously reported work34 revealed that Mode 1 (in-phase mode) offers superior mass detection limits and better linearity compared to Mode 2, despite having approximately 0.2 times lower sensitivity. Consequently, this study will concentrate on the mass sensing performance of the 3-DoF device in both modes.

Measurement of gas responses

Temperature and humidity are critical environmental factors that influence ZIF-8-based ethanol gas sensing through their effects on adsorption-desorption dynamics, framework stability, and resonator behavior. Temperature variations probably introduce mechanical stress due to thermal expansion or contraction of ZIF-8, affecting the stability of the frequency and AR of the resonators. High temperatures make it hard for the ethanol molecules to stay absorbed in the framework of ZIF-8, potentially causing partial framework degradation or collapse. Conversely, low temperatures can enhance adsorption but slow the desorption rate, thereby delaying the response and recovery time. When it comes to the humidity effects, water can be absorbed by ZIF-8 because of its affinity for water molecules, especially at high humidity. This potentially causes minor structural deformation of ZIF-8, affecting the resonator stability, and leading to a decrease in ethanol adsorption. Given that, all measurements were conducted at a given temperature (22 ± 1°C) and under atmospheric pressure. The vapor concentration, denoted as p/p0, represents the ratio of the ethanol’s partial vapor pressure (p) to its saturated vapor pressure (p0) at room temperature (RT), and the symbol (%) was only used to represent the unit of vapor concentrations in calculating the sensitivity and resolution values. Prior to testing, the devices under test (DUTs) were exposed to pure nitrogen for 7 to 8 h to facilitate the desorption of residual substances within the ZIF-8 and to stabilize both the DUTs and the surrounding environment. Following this preparation, ethanol vapor with concentrations from 2.5% to 70% was generated using a dilution system and subsequently introduced into a sealed chamber for gas sensing experiments. During these experiments, ethanol vapor was first introduced to induce adsorption, followed by the introduction of pure nitrogen to induce the desorption of ethanol molecules. Each step lasted 20–30 min to finish, and the x-axis of Fig. 3 shows the time.

The resonant frequencies of all three devices exhibited a decrease during ethanol vapor adsorption and an increase during desorption, consistent with the theoretical analysis of mass-induced frequency shifts (refer to Fig. 3a, b, d, f). The extent of these frequency shifts varied with ethanol vapor concentrations from 2.5% to 70%. Notably, greater frequency shifts were observed at higher ethanol concentrations, attributable to increased mass loading. Unlike state-of-the-art21, where frequency increased with mass loading due to the predominant effect of stiffness changes (instead of mass change) caused by ethanol vapor adsorption, our results align with theoretical predictions well. In the 2 and 3-DoF devices, resonator amplitudes increased variably across the ethanol concentration range, with amplitude ratios (R1/R2 and R1/R3) showing a general upward trend (see Fig. 3c, e, g), indicating the presence of mode localization. During the nitrogen purging stage, the frequencies, amplitudes, and amplitude ratios of all three devices returned to their baseline levels, confirming the effectiveness of ZIF-8 for ethanol vapor detection. Additionally, larger variations in frequency and amplitude ratios were observed at higher ethanol concentrations; however, these variations plateaued between 60% and 70%. That can be attributed to the full saturation of ethanol vapor in ZIF-835,36.

Sensitivity analysis

To further verify the gas detection performances of the proposed devices, the frequency shift and AR change as a function of the ethanol vapor concentrations were presented in Fig. 4, respectively. It can be seen that a higher sensitivity (calculated via the linear fitting) was obtained at lower concentrations from 2.5% to 15% while a lower sensitivity was observed at higher concentrations from 15% to 70%; this corresponds to the S-shaped isotherm of ZIF-8 for ethanol adsorption37,38,39 with low ethanol uptakes at low concentrations from 2.5% to 5% and the cage-filling phenomenon37 occurs at higher concentrations from 5% to 70%. The strong uptake of ethanol molecules occurred at concentrations from 5%-15% and afterward, a plateau occurred, on which the rate of the uptake of ethanol molecules dropped at high concentrations from 15% to 70%. However, large frequency shifts and AR variations at concentrations from 15% to 70% were still observed, which can be attributed to the mass loading caused by the condensation phenomena during the gas sensing test. The saturation concentration of ethanol vapor for ZIF-8 is around 15%. When the concentration exceeds the saturation point at the given room temperature, the vapor cannot remain entirely in the gaseous phase. This leads to the formation of liquid ethanol droplets on the surfaces of the resonator and ZIF-8. Furthermore, high concentrations increase the likelihood of ethanol molecules clustering on the surface of ZIF-8, forming liquid microdroplets. Therefore, the presence of condensed ethanol introduces an extra amount of mass to the resonator system, causing a much larger shift in the resonance frequencies and ARs. In that case, the choice of ethanol vapor concentrations for the future gas sensing test will be considered not to exceed the saturation concentration to avoid the condensation problem.

a The 1-DoF device (frequency shifts). b The 2-DoF device in Mode 2 (frequency shifts). c The 2-DoF device in Mode 2 (AR changes). d The 3-DoF device in Mode 1 (frequency shifts). e The 3-DoF device in Mode 1 (AR changes). f The 3-DoF device in Mode 2 (frequency shifts). g The 3-DoF device in Mode 2 (AR changes)

Table 3 summarizes the sensitivity values obtained by the linear fitting curves which accurately represent the relationship between the extracted frequency shifts/AR changes and ethanol vapor concentrations in Fig. 4. The sensitivity of all three proposed devices, decreased with the concentration of ethanol vapor increasing, matching the S-shaped isotherm of ZIF-8 for ethanol adsorption37,38,39 and achieving better sensitivity and resolution than the state-of-the-art. The 2-DoF device exhibited a sensitivity approximately 212 times greater, and the 3-DoF device demonstrated a sensitivity approximately 40.24 times greater when evaluated based on AR changes, compared to sensitivity derived from frequency shifts. Compared to the 1-DoF device using the frequency shift as the readout for sensitivity, the 2-DoF and 3-DoF devices achieved enhancements in AR-based sensitivity of over two orders of magnitude, approximately 697 times and 214 times, respectively. The observed sensitivity enhancements in terms of AR matched well with the FEM simulation results (272 times and 424 times for the simulated 1 and 2-DoF device, respectively); this further verifies the feasibility of the developed multi-DoF BAW resonating devices serving as gas sensors.

Furthermore, at lower concentrations (below 8%), the 3-DoF device achieved the highest frequency shift based sensitivity at −2.50 × 10−6 /(%), while the 2-DoF device recorded the best AR-based sensitivity at 3.27 × 10−4 /(%). It can be also noted that the 3-DoF device achieved higher AR based sensitivity in Mode 2 and higher frequency shift based sensitivity in Mode 1 than the 2-DoF device for the gas sensing test. Lower sensitivity for frequency shifts in Mode 2 than in Mode 1 is in accordance with the theoretical and FEM simulation results.

2-DoF device with lower vapor concentration

The higher sensitivity observed at low concentrations for all three devices demonstrated a higher uptake of the ethanol molecules21. Subsequently, the gas sensing test with a lower concentration of the ethanol vapor from 0.1% to 15% was carried out and only the developed 2-DoF device exhibited better sensing performance for the ethanol gas detection. Figure 2 indicates that both frequency and AR (R1/R2) decreased with the increase of the ethanol vapor adsorption as expected. The extracted maximum sensitivity based on the AR change (−1.96 × 10−3 /(%)) was about 307 times higher than that based on the frequency shift (−6.39 × 10−6/(%)) for the 2-DoF device at the ethanol vapor concentration from 0.1% to 2%, as indicated in Fig. 5. Compared to the device tested with the ethanol vapor concentration from 2.5% to 70%, it achieved ~4.13, and ~6 times enhancement in the frequency shift and AR change based sensitivity, respectively.

Stability and resolution

The stability and resolution characteristics of the proposed 1, 2, and 3-DoF devices were then investigated with pure nitrogen filled in the chamber which was used for the purging process. Figure 6 shows the calculated resolution curves in terms of the frequency shift and the AR change. The obtained instability and resolution of all devices were calculated and summarized in Tables 4 and 5.

As the comparison indicates, the 3-DoF device showed the best instability of 2.62 ppb at an integration time of 0.196 s for the frequency shift among the three devices. It also achieved the best AR change instability of 5.29 ppm at an integration time of 0.31 s. The 2-DoF device exhibited an instability of 8.824 ppm at an integration time of 1.654 s and an instability of 9.8 ppb at an integration time of 0.44 s. The 1-DoF device achieved an instability of 4.65 ppb at an integration time of 0.049 s.

In accordance with the characterized normalized sensitivity, the mass resolution based on the AR change and frequency shift was calculated, as shown in Table 6. With the ethanol vapor concentration from 2.5% to 70%, the 3-DoF device achieved the best resolution of 1.06 × 10−3 (%) in terms of the frequency shift while the 2-DoF device achieved the best resolution of 0.027 (%) in terms of the AR change. Moreover, an even better resolution based on the AR change was obtained as 1.06 × 10−3 for the 2-DoF device with a lower ethanol vapor concentration from 0.1% to 2%. Compared to state-of-the-art21 (2.05 × 10−6 for frequency shift and 1.73 × 10−3 for AR change), the presented devices achieved better stability performances (more than 2 to 3 orders of magnitude). Moreover, ~48 (AR change) and ~1.82 (frequency shift) times better resolution were also achieved, although the DUTs in this work demonstrated a relatively lower sensitivity. The higher sensitivity in21 can be attributed to the ~3.87 fold smaller size of the device and stiffness change contribution to the final sensitivity. In state-of-the-art21, both stiffness changes and mass changes resulting from vapor absorption are considered when assessing amplitude ratio (AR) variations, which are then used to determine the final sensitivity; this can explain the higher sensitivity than that in our work to some extent. Besides, these two factors—stiffness and mass—cannot be easily distinguished or separated from one another. Consequently, the positive frequency shift, primarily reflecting the stiffness change, tends to overshadow the effect of mass change. This is problematic because, in practical applications of mass sensors, the mass change effect should be the dominant and most significant factor, as it is both predictable and crucial for accurate modeling. In this work, the observed negative frequency shift upon gas molecule adsorption highlights the dominant influence of mass change, which aligns well with the theoretical principles governing mass loading. The sensitivity derived from AR variations in this study is predominantly influenced by mass change due to vapor adsorption, while the impact of stiffness change is negligible. Therefore, the devices proposed in this study demonstrate clear advantages and practical potential as true mass sensors for gas detection applications.

Furthermore, the relatively small discrepancy of ~2.72-fold in the resolution concerning the two output metrics (frequency shift and AR change) makes it evident that the proposed 2-DoF device yielded better stability using AR than state-of-the-art21 (~150-fold difference). That is also solid proof of the feasibility of the mode localized resonant gas sensors using AR change as the output metric to further augment the mass sensitivity by two to three orders of magnitude, without compromising the resolution.

A comparison of the proposed devices with other reported work related to ethanol sensing is indicated in Table 6. For the 2-DoF electrostatic resonant gas sensor21 operating at the low-frequency mode, a capacitive coupling via DC voltages was adopted rather than the mechanical coupling beam in this work. The sensing material ZIF-8 was chosen for the ethanol gas sensing application of the coupled electrostatic resonating system; this is the same as this work. Due to the existence of the transduction gap in the capacitive transduction, its Q factor in air (not mentioned) was drastically reduced due to the air damping compared to the proposed piezoelectric BAW device. Higher AR-based sensitivity (~2.46 times), better stability, and better resolution (~132.55) were achieved by the proposed piezoelectric BAW devices despite lower frequency shift based sensitivity (~60.24 times) than the state-of-the-art 2-DoF weakly coupled electrostatic devices21. The high sensitivity in terms of frequency shift can be attributed to the smaller size of the electrostatic resonant device and the extra stiffness change contribution to the final sensitivity based on the observed positive frequency shift with increased mass by the adsorption of ethanol molecules. Compared to the SAW and FBAR devices operating at high working frequencies, a comparable resolution was achieved with higher AR based sensitivity but lower frequency shift based sensitivity. The realization of the coupling theory in this work also provides references for the SAW and FBAR gas sensing devices to further improve sensing performance such as sensitivity, stability, and resolution. Enhancements in the detection limit of the proposed devices will be carried out in the future like by scaling down the device.

Response and recovery times

Besides, the response and recovery times of the proposed 1, 2, and 3-DoF BAW devices at different concentrations of ethanol vapor are also collected and listed in Table 7. Overall, the recovery time is tested to be longer than the response time and high ethanol vapor concentrations need more response and recovery time. Since this work mainly aims to improve the gas sensing performances such as sensitivity, stability, and resolution by designing novel coupled BAW resonating devices compared to state-of-the-art (see Table 6), a detailed study on the response and recovery time of the proposed novel devices will be carried out in the future.

Conclusion

In this work, 1, 2, and 3-DoF BAW disk MEMS resonators operating in the extensional mode using piezoelectric transduction were proposed for the ethanol vapor gas sensing application for the first time. The functionalization of ZIF-8 on the presented devices was realized via a solvent-free method on the backside of the devices. Following the adsorption and desorption of the ethanol molecules by ZIF-8, controllable mass change to the multi-DoF resonating system was introduced. As the experimental validation revealed, all devices showed their potential to be high-precision mass/gas sensors for ethanol vapor detection. The 2-DoF device operating in Mode 2 exhibited the best sensing performances using the AR change as the output metric, including better stability and better resolution, while the 3-DoF device operating in Mode 1 achieved better sensing performance in terms of the frequency shift. More than two to three orders of magnitude enhancement in AR based sensitivity was achieved than that of the frequency shift based. The small difference between the resolution regarding those two output metrics for the proposed 2 and 3-DoF devices demonstrated enhanced stability in the AR change for the mode localized resonators compared to the state-of-the-art21.

In theory, the 3-DoF device can achieve higher sensitivity than the 1 and 2-DoF devices. The experimental results also indicated at the same concentrations of the ethanol vapor, the best AR change and frequency shift based sensitivity were achieved by the 3-DoF device and the 2-fold difference in the AR based sensitivity matches well with the theoretical values. However, the best resolution in terms of the AR change was achieved by the 2-DoF device. As we all know, the resolution is mainly related and limited to the sensitivity and instability values of the device. The pre-mode localization (initial amplitude differences between R1 and R3) caused by the fabrication errors defines the initial AR values, thereby deciding the final sensitivity. The obtained AR based sensitivity follows the theoretical value. Then the instability performance probably be also affected much more than the sensitivity due to the nonlinearity as described in the previously reported FE simulation work34. The potential solution to this issue should be to optimize the fabrication process to avoid or decrease fabrication errors, getting more well-fabricated devices ready for the test.

Furthermore, the proposed resonant mass sensor conforms with the theoretical mass sensing principle, whereby the influence of the mass change caused by vapor adsorption and desorption was dominant, thus circumventing the deviations of AR change sensitivity ascribed to the stiffness change. On the other hand, the 2-DoF device was proved to be able to detect lower ethanol vapor concentrations (0.5–2%), hence expanding the actual measurement range. Besides, a higher Q factor of ~3800 was also achieved in air. The findings of this work affirmed the feasibility of the ZIF-8 coating technique, particularly incorporated with MEMS resonating devices. The practical study of piezoelectric BAW resonators conducted in this subject constitutes an important step towards high-performance resonant MEMS gas sensors. Therefore, for future gas sensing applications based on MEMS resonant mass sensors, the weakly coupled resonating system, especially the 2-DoF system, should be a good choice for achieving higher sensitivity, better instability, better resolution, better noise performance, etc. Besides, piezoelectric transduction enables the device to operate in air or even in liquid with reasonably high Q factors compared to capacitive transduction in state-of-the-art21.

Materials and methods

Microfabrication and functionalization of ZIF-8

All three devices were fabricated on a silicon-on-insulator (SOI) wafer via the MEMSCAP commercialized manufacturing PiezoMUMPs foundry process40 and the fabrication schematic for the 1-DoF device as an example is shown in Fig. 7a. The top surface of the silicon structure layer, serving as the bottom electrical ground layer, was first highly doped to achieve high conductivity. AlN was then grown on the top surface of the silicon as the piezoelectric layer. Afterward, chromium (Cr) and aluminum (Al) were sequentially sputtered to form the top electrode layer. Finally, DRIE was used to form the silicon device layer and etch the backside of the substrate for the following release process of the whole structure.

Referring to the previous work21, ZnO was first deposited on the backside (see Fig. 1c) of the silicon resonating disk (R1 for the 2 and 3-DoF devices) of the fabricated device since the top surface of the silicon disk was almost fully occupied by AlN and metal materials. It is well acknowledged that only one resonator needs to be disturbed to introduce the mass or stiffness perturbations for the conventional weakly coupled resonant sensors4,26,27,30. Considering the fact that the AR R1/R3 is a metric for better sensing performance compared to R1(R3)/R2 for the 3-DoF device, R1 or R3 should be the choice for the coating of ZIF-8. As shown in Fig. 1d, ZnO-sputtered devices were then transferred to a CVD reaction chamber filled with HmIM vapor for conversion41,42. ZIF-8 was eventually formed by replacing the oxygen atoms (O) in ZnO with deprotonated 2-methylimidazole (mIM). For the 2 and 3-DoF devices, only one resonator (R1) was coated with ZIF-8 for the following gas sensing test.

Experimental method

As depicted in Fig. 7b, a 3D-printed cap equipped with an injection port (inlet) and an extraction port (outlet) was designed to facilitate gas transport. The 1, 2, and 3-DoF devices, along with the cap, were then mounted on a printed circuit board (PCB) with an interface circuit. The inclusion of an O-ring between the cap and the carrier created a sealed chamber for the DUT. Nitrogen and ethanol vapor at varying concentrations were subsequently introduced in cycles from the vapor dilution system into the chamber for gas measurements, as shown in Fig. 7b. The vapor delivery system, based on a bubbler, generates a saturated vapor stream by passing nitrogen through a gas washing bottle (bubbler). This saturated vapor is then diluted with pure nitrogen via the dilution system to achieve the desired vapor concentration. The flow of nitrogen through the bubbler is controlled by Bronkhorst El-Flow mass flow controllers. The vapor delivery system is connected to the reaction chamber for the DUTs via a line, allowing vapor at a specific concentration to enter the chamber through the inlet port. The vapor concentration, denoted as p/p0, represents the ratio of the ethanol’s partial vapor pressure (p) to its saturated vapor pressure at room temperature (RT), which was maintained at 22 ± 1°C20 to prevent condensation within the lines. Additionally, an HF2LI lock-in amplifier from Zurich Instruments was employed to provide the actuation signal and acquire data during the gas sensing tests, along with two power supplies for the PCB, as shown in Fig. 7b. The schematic of the PCB and carrier for mounting the DUTs and the detailed device configuration are shown in Fig. 7c. The DUTs were first wire bonded to the carrier and then mounted to the PCB via the pin headers on the left and right sides for the electrical connection. Taking the 1-DoF device as an example, one of the top electrode pads was used for applying an AC voltage, and the bottom silicon device layer was used for ground electrical connection; this facilitates the piezoelectric transduction mechanism. The other top electrode pad was used for signal collection with accumulated charges.

References

Li, Y. et al. A micromachined resonant differential pressure sensor. IEEE Trans. Electron Devices 67, 640–645 (2020).

Zhang, H., Li, B., Yuan, W., Kraft, M. & Chang, H. An acceleration sensing method based on the mode localization of weakly coupled resonators. J. Microelectromech. Syst. 25, 286–296 (2016).

Abdolvand, R., Bahreyni, B., Lee, J. & Nabki, F. Micromachined resonators: a review. Micromachines 7, 160 (2016).

Wang, Y. et al. A mass sensor based on 3-DOF mode localized coupled resonator under atmospheric pressure. Sens. Actuators A Phys. 279, 254–262 (2018).

Lin, A. T.-H., Yan, J. & Seshia, A. A. Electrically addressed dual resonator sensing platform for biochemical detection. J. Microelectromech. Syst. 21, 34–43 (2012).

Moon, S. E. Semiconductor-Type MEMS gas sensor for real-time environmental monitoring applications. ETRI J. 35, 617–624 (2013).

Wang, L. Metal-organic frameworks for QCM-based gas sensors: a review. Sens. Actuators A Phys. 307, 111984 (2020).

Pang, W. et al. Piezoelectric microelectromechanical resonant sensors for chemical and biological detection. Lab Chip 12, 29–44 (2012).

Shin, S. et al. Gas sensor application of piezoelectric cantilever nanobalance; electrical signal read-Out. Ferroelectrics 328, 59–65 (2005).

Zhou, J. et al. Self-excited piezoelectric microcantilever for gas detection. Microelectron. Eng. 69, 37–46 (2003).

Devkota, J. et al. Zeolitic imidazolate framework-coated acoustic sensors for room temperature detection of carbon dioxide and methane. Nanoscale 10, 8075–8087 (2018).

Zhang, M., Du, L., Fang, Z. & Zhao, Z. A sensitivity-enhanced film bulk acoustic resonator gas sensor with an oscillator circuit and its detection application. Micromachines 8, 25 (2017).

Hoffmann, R., Schreiter, M. & Heitmann, J. The concept of thin film bulk acoustic resonators as selective CO<sub>2</sub> gas sensors. J. Sens. Sens. Syst. 6, 87–96 (2017).

Yan, X. et al. Surface engineering of metal–organic framework prepared on film bulk acoustic resonator for vapor detection. ACS Appl. Mater. Interfaces 12, 10009–10017 (2020).

Hui, Z., Yan, X., Qu, H., Pang, W. & Duan, X. Zeolitic imidazolate framework modified film bulk acoustic resonator for highly sensitive and selective alcohol vapors detection. In 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII) 1325–1328 (IEEE, Berlin, Germany, 2019). https://doi.org/10.1109/TRANSDUCERS.2019.8808267.

Wang, W. et al. Film bulk acoustic formaldehyde sensor with layer-by-layer assembled carbon nanotubes/polyethyleneimine multilayers. J. Phys. D Appl. Phys. 51, 055104 (2018).

Chang, Y. et al. Detection of volatile organic compounds by self-assembled monolayer coated sensor array with concentration-independent fingerprints. Sci. Rep. 6, 23970 (2016).

Thiruvenkatanathan, P., Yan, J. & Seshia, A. A. Common mode rejection in electrically coupled MEMS resonators utilizing mode localization for sensor applications. in 2009 IEEE International Frequency Control Symposium Joint with the 22nd European Frequency and Time forum 358–363 (IEEE, Besancon, France, 2009). https://doi.org/10.1109/FREQ.2009.5168201.

Wang, L. et al. A review on coupled bulk acoustic wave MEMS resonators. Sensors 22, 3857 (2022).

Anderson, P. W. Absence of diffusion in certain random lattices. Phys. Rev. 109, 1492–1505 (1958).

Wang, C. et al. A zeolitic imidazolate framework-8-Coated coupled resonant gas sensor. J. Microelectromech. Syst. 32, 371–380 (2023).

Ali, A. & Lee, J. E.-Y. Single device on-chip feedthrough cancellation for enhanced electrical characterization of piezoelectric-on-silicon resonators in liquid. Sens. Actuators A Phys. 260, 131–138 (2017).

Pillai, G. & Li, S.-S. Piezoelectric MEMS resonators: a review. IEEE Sens. J. 21, 12589–12605 (2021).

Ali, A. & Lee, J. E.-Y. Electrical characterization of piezoelectric-on-silicon contour mode resonators fully immersed in liquid. Sens. Actuators A Phys. 241, 216–223 (2016).

Elsayed, M. Y., Cicek, P.-V., Nabki, F. & El-Gamal, M. N. Bulk mode disk resonator with transverse Piezoelectric actuation and electrostatic tuning. J. Microelectromech. Syst. 25, 252–261 (2016).

Zhao, C. et al. A three degree-of-freedom weakly coupled resonator sensor with enhanced stiffness sensitivity. J. Microelectromech. Syst. 25, 38–51 (2016).

Kang, H., Yang, J., Zhong, J., Zhang, H. & Chang, H. A mode-localized accelerometer based on three degree-of-freedom weakly coupled resonator. in 2017 IEEE SENSORS 1–3 (IEEE, Glasgow, 2017). https://doi.org/10.1109/ICSENS.2017.8234065.

Stassen, I. et al. An updated roadmap for the integration of metal–organic frameworks with electronic devices and chemical sensors. Chem. Soc. Rev. 46, 3185–3241 (2017).

Tian, H., Fan, H., Li, M. & Ma, L. Zeolitic Imidazolate Framework Coated ZnO nanorods as molecular sieving to improve selectivity of formaldehyde gas sensor. ACS Sens. 1, 243–250 (2016).

Zhao, C. et al. A review on coupled MEMS resonators for sensing applications utilizing mode localization. Sens. Actuators A Phys. 249, 93–111 (2016).

Chollet, F. & Liu, H. A (not so) short introduction to MEMS. Version 5.2, 2015, http://memscyclopedia.org/introMEMS.html.

Iqbal, A., Zhang, W. & Lee, J. E.-Y. Enhanced piezoresistive sensing via synchronized oscillations in a mechanically coupled disk array. In 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII) 1384–1387 (IEEE, Barcelona, Spain, 2013). https://doi.org/10.1109/Transducers.2013.6627036.

Ho, G. K., Abdolvand, R., Sivapurapu, A., Humad, S. & Ayazi, F. Piezoelectric-on-Silicon lateral bulk acoustic wave micromechanical resonators. J. Microelectromech. Syst. 17, 512–520 (2008).

Wang, L. et al. A Novel 3-DoF mode localized BAW resonant mass sensor with high quality factor and resolution. IEEE Trans. Electron Devices 71, 4926–4931 (2024).

Mu, L. et al. A novel method to improve the gas storage capacity of ZIF-8. J. Mater. Chem. 22, 12246 (2012).

Khaletskaya, K. et al. Self‐directed localization of ZIF‐8 thin film formation by conversion of ZnO nanolayers. Adv. Funct. Mater. 24, 4804–4811 (2014).

Zhang, K., Lively, R. P., Zhang, C., Koros, W. J. & Chance, R. R. Investigating the intrinsic ethanol/water separation capability of ZIF-8: an adsorption and diffusion study. J. Phys. Chem. C. 117, 7214–7225 (2013).

Claessens, B. et al. Macroscopic and microscopic view of competitive and cooperative adsorption of alcohol mixtures on ZIF-8. Langmuir 35, 3887–3896 (2019).

Cousin-Saint-Remi, J. & Denayer, J. F. M. Applying the wave theory to fixed-bed dynamics of Metal-Organic Frameworks exhibiting stepped adsorption isotherms: water/ethanol separation on ZIF-8. Chem. Eng. J. 324, 313–323 (2017).

Cowen, A., Hames, G., Glukh, K. & Hardy, B. PiezoMUMPsTM Design Handbook, Rev. 1.3, 2014, https://people.eecs.berkeley.edu/~pister/147fa15/Resources/PiezoMUMPs.DR.1.3a.pdf.

Cruz, A. J. et al. Effect of different oxide and hybrid precursors on MOF-CVD of ZIF-8 films. Dalton Trans. 50, 6784–6788 (2021).

Stassen, I. et al. Chemical vapour deposition of zeolitic imidazolate framework thin films. Nat. Mater. 15, 304–310 (2016).

Chen, D. et al. Micro-electromechanical acoustic resonator coated with Polyethyleneimine nanofibers for the detection of formaldehyde vapor. Micromachines 9, 62 (2018).

Li, D. et al. A surface acoustic wave ethanol sensor based on uniform ZnO nanoparticles-reduced graphene oxide composite film. IEEE Sensors J. 1–1 https://doi.org/10.1109/JSEN.2020.2988561 (2020).

Acknowledgements

This work was supported by The Science and Technology Development Fund, Macau SAR (FDCT), 004/2023/SKL, and The Science and Technology Development Fund, Macau SAR (FDCT), 0087/2023/ITP2.

Author information

Authors and Affiliations

Contributions

L.W.: conceptualization, methodology, formal analysis, measurement, validation, data curation, writing - original draft, writing – review & editing; Y.W, and C.W.: conceptualization, resources, methodology, writing - review & editing, supervision, project administration, funding acquisition; M.T. and B.P.M.: sample conversion, measurement, data curation; R.M. and P.M.: methodology resources, writing - review & editing; N.C., D.R., M.S., and R.A.: measurement resources. All authors contributed through scientific discussions.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, L., Wang, Y., Tietze, M. et al. Multi-DoF AlN-on-SOI BAW MEMS resonators with coated ZIF-8 for gas sensing application. Microsyst Nanoeng 11, 69 (2025). https://doi.org/10.1038/s41378-025-00917-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41378-025-00917-3