Abstract

The high aspect ratio (HAR) micro-electro-mechanical system trench array is a key component for the miniaturization of micro sensors, actuators, and other advanced precision equipment, with broad application prospects in defense, security, aerospace, energy, and other fields. Therefore, accurate and efficient measurement of the aspect ratio of microstructures will become a crucial method for monitoring and ensuring the reliability and stability of the device fabrication process. This paper presents a novel method that combines the lattice light field generated by a micro-axicon array with microscopic imaging technology to accurately measure the width and depth of HAR micro-trench structures. We designed and constructed a dedicated experimental system, initially using monochromatic microscopic imaging and edge extraction algorithms to obtain the width information of the trenches. Subsequently, the trench depth was measured using the diffraction lattice light field generated by the micro-axicon array. Experimental results indicate that as the light field propagates from the top to the bottom of the trench, the light spots in the lattice light field shift in position due to the presence of diffraction angles, with the displacement being closely related to the trench depth. A mapping between the displacement and depth is established through geometric relationships, enabling the calculation of the trench depth. We tested nine trench samples with different aspect ratios, with the maximum aspect ratio reaching 58.12. The experimental results, compared with the scanning electron microscope measurement values, show that the measurement errors are all <9%.

Similar content being viewed by others

Introduction

Three-dimensional micro-nano structures, characterized by miniaturization, intelligence, high integration, and excellent performance, have become a development trend in the field of sensors. They are widely applied in various fields, including national security, energy materials, aerospace, information science, and biomedical engineering1,2,3,4,5. HAR micro-trench structures are a typical design form in MEMS6. The aspect ratio refers to the ratio of the height of a vertical processed surface to the smallest feature size on that surface7. Structures with an aspect ratio greater than 10:1 are generally referred to as HAR structures8. HAR micro-trench structures feature nearly vertical sidewalls, making their development more challenging compared to structures with aspect ratios of 1 to 2 typically used in planar technologies. These structures are considered an intermediate state between two-dimensional (2D) and three-dimensional (3D) designs, essentially an extension of 2D planar designs into the vertical dimension, commonly referred to as 2.5D9,10. Therefore, the emergence of HAR micro-trench structures provides MEMS with greater vertical dimension space on the same footprint, significantly enhancing the charge storage capacity of microdevices. These structures offer higher energy and power densities, faster signal transmission speeds, better adhesion properties, and improved dynamic characteristics. They are considered core structures for micro-sensors and semiconductor components11,12,13,14,15. As semiconductor devices continue to evolve towards lighter, more compact, and integrated designs, the requirements for the aspect ratio of micro-trench structures are constantly increasing. Therefore, accurate and efficient measurement of the aspect ratio of microstructures will become an important method for monitoring and ensuring the reliability and stability of the device fabrication process.

Common methods for characterizing HAR microstructures can be classified into non-optical and optical characterization techniques. Non-optical methods primarily include scanning electron microscopy (SEM), focused ion beam (FIB), contact profilometry, atomic force microscopy (AFM) and electrical measurement techniques16,17,18,19,20,21. The basic principles of SEM and FIB are based on scanning the sample surface with a focused electron or ion beam. The interaction between the beam and the sample generates secondary electron or ion signals, which are detected by a collector. These secondary signals are then processed through a photomultiplier tube and signal amplifier, converted into electrical signals, and reconstructed into images by a computer, enabling high-resolution observation of the sample surface morphology. Both methods offer high measurement accuracy and provide intuitive measurement processes. However, when measuring HAR trenches, the sample must be sectioned, which leads to destructive testing. This process is non-repeatable and costly. Therefore, these techniques are more suitable as high-precision benchmarks to assist in the validation and supplementation of optical measurement methods. AFM and contact profilometry are both classified as scanning probe microscopy (SPM) techniques. SPM is a technology capable of directly operating, imaging, and measuring the properties of nanoscale structures. This method offers high resolution, particularly in the lateral direction22. AFM, which operates based on atomic interactions, is a three-dimensional surface characterization technique. It provides imaging of both insulating and conductive surfaces with nanometer-scale resolution23. AFM operates in several modes, including contact mode, noncontact mode, and tapping mode. In non-contact mode, during the scanning of the sample, the interaction between the probe’s atoms and the surface of the sample is controlled to maintain a constant van der Waals force. This causes the cantilever, equipped with a tip, to move vertically relative to the sample surface. Optical detection methods are used to track the position changes of the cantilever at each scanned point, thereby enabling the acquisition of surface morphology information of the sample. However, due to the limited diameter and length of the probe, there are constraints on the opening width and depth of the microstructures, making it impossible to measure HAR micro-trench structures. The contact profilometer measures surface profiles based on the optical lever amplification principle24, where the vertical motion of the probe is used to obtain structural information about the sample surface. However, since the probe makes direct contact with the sample surface, it can cause damage to both the sample and the probe. Additionally, the size of the probe limits the opening width and depth of the measurable microstructures. Therefore, scanning probe methods are also not suitable for measuring the depth information of HAR micro-trenches.

In the application of electrical characterization techniques for high-aspect-ratio micro/nanostructures, Vishnu Khemka’s research group developed a novel non-destructive electrical characterization technique based on npn bipolar transistor design. This approach exploits the exponential correlation between transistor current gain and trench depth, achieving 0.2 μm depth resolution through collector ratio variations. The operational principle relies on minority carriers being driven into heavily-doped substrate regions as trench depth increases, resulting in gain reduction. However, the method requires transistor integration within trenches and has a maximum measurable depth of 1 μm, making it unsuitable for micro-trench array characterization with aspect ratios > 10 (depth > 10 μm)20. Oliver D. Patterson’s research group developed a buried oxide (BOX) layer defect detection method for deep trench etching processes in IBM’s advanced SOI-based embedded DRAM technology. By optimizing electron beam parameters in voltage contrast (VC) inspection, this technique achieves high-sensitivity identification of subtle open defects in the BOX layer while effectively distinguishing them from oxide hard mask layer defects. It should be noted that while the method enables precise defect localization, it cannot provide depth information about the detected defects21.

Optical characterization techniques mainly include white light micro-interferometry, confocal microscopy, and reflectance spectroscopy, infrared techniques, scatterometry, and holographic measurement methods25,26,27,28. The measurement principle of white light micro-interferometry is based on projecting two beams of white light onto the sample surface and a reference surface, and utilizing the interference effect between the two beams for measurement. During the interference process, the optical path difference for the zero-order fringe corresponds to zero, resulting in the maximum light intensity at this position. By analyzing the variation of fringes at the zero optical path difference points of the coherent light at different locations on the sample surface, the height variations of the sample surface can be precisely obtained. Chen-Yang Xue et al.29 used white light scanning interferometry to measure the depth of MEMS trenches, successfully measuring trenches with a depth-to-width ratio of 4:1. Taeyong Jo’s research group improved the traditional white light interferometry system by employing a low numerical aperture optical path, which altered the light intensity distribution and increased the light intensity reaching the bottom of the trench, thereby enhancing the system’s depth measurement capability. This modification enabled depth measurement of silicon through-hole structures with a depth-to-width ratio of 11.230. Similarly, R.K. Attota’s research group also applied the principle of white light interferometry to measure microstructures31. White light interferometry offers high longitudinal resolution and a large measurement area, but its optical system is relatively complex, the measurement process is time-consuming, and the results are susceptible to environmental factors32. Confocal microscopy is another common method for depth measurement, typically based on a confocal scanning optical microscope, to perform three-dimensional reconstruction of microstructures and depth measurement. A confocal scanning optical microscope operates on the principle of confocal imaging, using a scanning technique to perform tomography, thereby enabling the extraction and reconstruction of three-dimensional information33. Ravi Kiran Attota et al. conducted a study on the parameters influencing the performance of differential confocal scanning optical microscopy, achieving optimal depth measurement performance for the system. They also established a database containing differential information corresponding to the cross-sectional profiles of microstructures with high depth-to-width ratios34,35. Confocal microscopy-based measurement methods rely on the performance of the microscope used and are more suitable for measuring microstructures with depths below a few micrometers. Another commonly used measurement method is reflectance spectroscopy. The principle involves directing a broadband light beam vertically onto a sample with microstructures. The light reflected from the upper surface of the microstructure interferes with the light reflected from the lower surface. The interference signals in the reflected spectrum are collected and analyzed using a spectrometer, and an appropriate algorithm is employed to demodulate the quantitative mapping relationship between the reflected spectrum and the microstructure depth. Yi-Sha Ku’s research group proposed a method combining scattering theoretical models and the discrete Fourier transform algorithm to extract the bottom roughness and depth of through holes from the measured reflectance spectra. This approach is capable of measuring TSV profiles with a minimum diameter of 5 μm and a height-to-width ratio greater than 13:1, with a measurement accuracy of 0.02 μm. They also demonstrated that the spectral resolution and depth resolution improve as the spectral range of the spectrometer increases36,37. Reflectance spectroscopy offers advantages such as a simple optical setup and fast measurement speed; however, the measurement accuracy is limited by the interference intensity of the reflectance signals.

For infrared measurement techniques, David Marx’s research group developed a backside-illuminated infrared sensing technology that overcomes aspect ratio limitations, enabling depth measurements of through-silicon vias (TSVs) with feature sizes ranging from 1–18 μm (maximum aspect ratio 28:1, measurement repeatability <50 nm at 3σ). However, this method requires TSV spacing to exceed the system’s optical spot size and is unsuitable for periodic micro-trench arrays25. Nick Keller’s research group advanced the infrared critical dimension technique, which overcomes interference from hard mask thickness and sidewall scalloping effects inherent in conventional optical critical dimension methods through spectral analysis. This approach enables precise bottom-width measurements of deep trench isolation structures (applicable to 5 μm and 8 μm pitches), though it cannot provide depth information26. For scatterometry techniques, Peter Reinig’s research group developed a three-dimensional characterization method based on rigorous coupled-wave analysis. While capable of resolving complex structures incorporating amorphous silicon hard masks (e.g., bowed sidewalls), this approach faces challenges of exponentially increasing computational demands (requiring 500+ slices for \(10\,\mu m\) trenches) and demonstrates limited capability of existing models in characterizing deformations in deep trench structures27. Victor P. Korolkov’s research team developed a holographic measurement technique utilizing binary phase computer-generated holograms, which enables high-precision etch uniformity characterization within a 240 nm to 5 μm depth range. However, this method’s depth limitations preclude its application for high-aspect-ratio structures28.

In this paper, we propose a method that combines the lattice light field generated by a micro-axicon lens array and microscopic imaging techniques38,39,40 for measuring the width and depth of high aspect-ratio micro-trenches. To achieve this, we have designed and built a dedicated experimental system aimed at precisely measuring the width and depth of high aspect-ratio micro-trenches. First, single-wavelength microscopic imaging combined with edge detection algorithms is used to obtain the width information of the micro-trenches. Next, a micro-axicon array is introduced into the experimental system, which generates a lattice light field with a specific diffraction angle (θ) and projects this light field onto the surface of the trench array. Experimental observations show that during the process of light propagation from the top to the bottom of the trench, the lattice light points experience positional shifts due to the diffraction angle, and the magnitude of the shift is closely related to the trench depth. By using geometric relationships, we can establish a mapping between the shift and the trench depth, enabling the calculation of the trench depth based on the positional shift of the light points. We tested nine trench samples with different aspect ratios and compared the experimental results with the SEM values. The results show that the measurement error is less than 9%.

Structure and methods

Generation method of optical lattice illumination

Using an 8-bit grayscale laser direct writing system, we fabricated a 70 × 70 micro-axicon array on a quartz substrate for generating lattice light fields. At room temperature, the refractive index of quartz for 532 nm wavelength light is ~1.4607. Given the temperature coefficient of quartz (dn/dT ≈ (−0.5 to −0.6) × 10−5/°C)41 and assuming a temperature variation of ±5 °C, the maximum refractive index variation is Δn = 0.00003. Thus, under room temperature measurements, the refractive index uncertainty Δn remains below 0.00003, with the index ranging within 1.4607 ± 0.00003. Considering the negligible magnitude of this variation, its impact on experimental results can be effectively disregarded in practical testing.

The geometric structure of an ideal micro-axicon is shown in Fig. 1c, where Λ represents the array period, h denotes the height, and r indicates the radius at different positions. The fabricated micro-axicon array had a designed period (i.e., base diameter) of 40 μm with a tolerance of ±1 μm, and a designed height of 1.375 μm with a tolerance of ±0.1 μm. To accurately characterize the fabricated dimensions of the micro-axicon array, we employed AFM imaging over a 100 μm × 100 μm area (the maximum scan range of our AFM system), containing six microaxicon samples. The obtained 3D and 2D AFM images are presented in Fig. 1a, b, respectively. From the 2D image in Fig. 1b, we marked five dashed lines crossing the micro-axicon peaks and extracted corresponding AFM profiles (Fig. 1d–h). These profiles were analyzed to identify peak positions (micro-axicon apices) and valleys (between adjacent micro-axicons), yielding 13 period measurements (Λ1–13): 40.4463, 39.6647, 40.8371, 40.2551, 39.6689, 40.4505, 40.0352, 39.2540, 40.4258, 40.6501, 40.8455, 40.4505, and 40.6459 μm– all within specified tolerances, with a mean period of 40.5047 μm. Similarly, eight height measurements (h1–8) were obtained: 1.3859, 1.3421, 1.3349, 1.3828, 1.3381, 1.3704, 1.3868, and \(1.3320\,\mu m\), also within tolerances (mean height: 1.3591 μm). Finally, we calculated sample standard deviations (sΛ = 0.48933 μm for period; sh = 0.02380 μm for height) using Eq. 1 to estimate population standard deviations.

The transmittance of a single micro-axicon is as shown in Eq. 2:

where n is the refractive index of the substrate, λ is the wavelength of the incident beam, Λ is the period of the arrays, and h is the depth of each micro-axicon, as shown in Fig. 1c. Thus, by combining Eq. 2 and the period Λ of the micro-axicon array, we can express the transmittance of the microaxicon array as shown in Eq. 3:

where * represents the two-dimensional convolution operation. For the normal incident plane wave, the field U(x, y, 0) at the output plane of the micro-axicon array can be simplified as:

Therefore, the field of the beam generated by the micro-axicon array at a certain observing distance z after the output plane can be calculated by the Fresnel-Kirchhoff diffraction integral:

where \(r=\sqrt{{\left(x-{x}_{0}\right)}^{2}+{\left(y-{y}_{0}\right)}^{2}+{z}^{2}},\cos \theta =\frac{z}{r}\) and \(\phi\) is the diameter of the aperture used in the optical measurement system. In deriving the diffraction angle θ for the lattice light field, we restrict our analysis to the two-dimensional periodicity of the micro-axicon array owing to the mathematical complexity of Eq. 3. The Fourier transformation of the two-dimensional comb function comb(x/Λ)comb(y/Λ) appearing in Eq. 3 yields.

where j and l are the numbers of micro-axicon along the x and y axis, respectively. From Eq. 6, we observe that the Fourier spectrum of the lattice light field created by the micro-axicon array possesses discrete δ-function components:

This δ-function component is also two-dimensional and periodic. In the framework of Fourier optics, the spatial frequencies (fx, fy) at the observation plane are intrinsically related to the physical coordinates (u, v) through Eq. 7:

where λ denotes the wavelength, z represents the propagation distance, and (uM, vN) represent the physical coordinates of different light spots on the observation plane. This relationship arises from the phase term in the Fraunhofer diffraction integral and maintains dimensional consistency with the Fourier transform. Since the axicon array is a two-dimensional periodic structure, the derivations in the x and y directions are consistent. We take the derivation in the x direction as an example, so from Eqs. 7 and 8, we can obtain:

Therefore, we can conclude that:

Further, we can derive that the diffraction angle θ of the lattice light field generated by the micro-axicon array satisfies the relation:

In the experiment, we employed a laser wavelength of 532 nm with a micro-axicon array period of 40 μm. From these parameters, we derived the theoretical value tanθ = 0.0133. During subsequent data processing, we directly used tanθ in Equation (to be determined) without requiring the tanθ ≈ θ approximation, thereby avoiding associated errors. It should be noted that tanθ = 0.0133 represents our theoretically derived value. Based on the aforementioned experimental data, we measured 13 period values (Λ1-13, unit: μm) using the AFM. Through Eq. 10, we calculated the corresponding tanθ values for these 13 periods as: 0.01355, 0.01341, 0.01303, 0.01322, 0.01341, 0.01315, 0.01329, 0.01355, 0.01316, 0.01309, 0.01302, 0.01315, and 0.01309. Applying Eq. 1 to these values, we determined the sample standard deviation of tanθ as stanθ = 0.0001614, which serves as our estimate for the uncertainty of tanθ.

Experimental samples

The experimental samples were fabricated using the Bosch process in deep reactive ion etching, alternatively known as time-multiplexed deep etching. This process alternates between reactive ion etching and passivation layer deposition in a cyclic manner to prevent lateral sidewall erosion, thereby achieving highly vertical sidewalls. The technique consists of four key stages: base etching, sidewall protection, sidewall etching, and cyclic repetition. The Bosch process enables fabrication of structures with aspect ratios up to 90:1, with typical etch depths ranging from several micrometers to hundreds of micrometers. The etch rate varies between 3–20 μm/min, while the sidewall verticality can be precisely controlled within (90 ± 0.3)°42.

The parameters of the nine samples used in the experiment, including their identification numbers, depths, widths, and aspect ratios, are listed in Table 1. The maximum depth was 175 μm, the minimum width was 1.67 μm, and the maximum aspect ratio reached 58.12. The SEM images of samples 1# and 2#, acquired using a Hitachi ultra-high-resolution SEM S-5500 at an accelerating voltage of 3.0 kV for all samples, are shown in Fig. 2. The depth values extracted from the SEM images were 111 μm and 144 μm, while the corresponding widths were 1.91 μm and 5.08 μm, respectively. However, when measuring trench depth in SEM images, the accuracy is inherently limited by pixel resolution because the images consist of discrete pixel arrays and cannot represent sub-pixel values precisely. Specifically, edge localization at both the top and bottom of the trenches, as well as along the sidewalls, is subject to a positioning uncertainty of ±0.5 pixels (e.g., if the true edge position lies between 3.6 and 4.4 pixels, it will be recorded as 4 pixels), introducing a measurable uncertainty denoted as u. The uncertainty arising from image resolution primarily depends on the pixel size, p (in μm/pixel), which defines the physical dimension represented by each pixel. Since each edge contributes an error of ±0.5p, the total uncertainty can be expressed as:

The total error follows a uniform distribution; therefore, the standard deviation of the uniform distribution corresponds to the uncertainty, expressed as:

As illustrated in Fig. 2, the physical dimensions per pixel for samples 1# and 2# were determined from the scale bars in the SEM images to be p1 = 0.284091 μm/pixel and p2 = 0.165563 μm/pixel, respectively. By substituting these values into Eq. 4, the measurement uncertainties for samples 1# and 2# were calculated as u1 = 116.48 nm and μ2 = 67.88 nm, respectively. The uncertainties for the remaining samples were derived through an analogous computational procedure, with all results systematically compiled in Table 1.

Experimental system and method

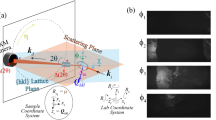

The experimental system consists of an illumination module and a microscopic imaging module, as illustrated in Fig. 3a, b. The illumination module utilizes a 532 nm continuous-wave solid-state laser (MGL-III-532) as the light source. The beam passes through a variable attenuator for power adjustment and undergoes spatial filtering via a spatial filter. The collimated beam is expanded by a plano-convex lens L1 (focal length f = 150 mm) and adjusted to a diameter of 4 mm using an aperture to match the micro-axicon array dimensions. The optimized incident beam is vertically incident on the micro-axicon array element (physical morphology and AFM characterization are shown in Fig. 3b, d). It is then relayed through an isomorphic dual-lens system (L2 and L3, f = 150 mm) for 1:1 transmission, generating a structured light field modulated by the microaxicon array. In the microscopic imaging module, the structured light field is directed into a ×40 flat-field apochromatic infinity-corrected microscope objective (NA = 0.65, WD = 0.17 mm) via a beam splitter, focusing onto the surface of a trench array sample (morphological features in Fig. 3e). The sample is placed on a two-dimensional translation stage, capable of independently moving the sample along the X axis (perpendicular to the trench direction) and the Z-axis (parallel to the incident light direction). The stage provides a maximum travel range of ±12.5 mm and a minimum displacement resolution of 10 μm in both axes. The reflected signal from the sample is collected by the objective, transmitted through the beam splitter, and focused onto a CMOS detector by an imaging lens L4(f = 150 mm), achieving a high signal-to-noise ratio optical imaging.

a 3D schematic of the experimental system. b 2D schematic of the experimental system. c Photograph of the test sample. d Photograph of the micro-axicon array. e AFM characterization of the micro-axicon array. f Experimental and simulated lattice light field patterns generated by the micro-axicon array. g Measurement procedure for trench morphology parameters

The focal plane lattice light field distributions generated by the micro-axicon array under two distinct incident light intensities are shown in Fig. 3f, with the imaging region selected to exclude trench array structures. To establish a unified intensity characterization framework, the maximum intensity value was adopted as the normalization reference, enabling comparative analysis by converting the alternative intensity parameter into relative intensity. The rightmost column of Fig. 3f presents numerical simulations based on the geometric parameters and optical properties of the micro-axicon array, developed to facilitate direct comparisons between experimental and theoretical light fields. By extracting the spot distributions within dashed boxes (marked in each subplot) from both experimental and simulated light fields, corresponding intensity distribution profiles were plotted (as shown by the curves below each subplot). The simulations demonstrate close agreement between experimentally measured intensity profiles and numerical predictions under higher incident intensity conditions. However, discernible discrepancies emerge in the relative intensities of neighboring spots under reduced illumination. Notably, these intensity variations do not compromise trench depth measurement accuracy, as the methodology exclusively relies on the Y coordinate shift of individual spots for depth calculations.

The measurement procedure for trench morphology parameters is illustrated in Fig. 3g, comprising two modules: depth measurement and width measurement.

Depth measurement workflow

-

1.

Locate the sample’s feature region at the microscope field center and adjust the objective to align its front focal plane with the trench bottom plane.

-

2.

Activate the micro-axicon array to generate a structured light field.

-

3.

Drive the sample through \(\mu {\rm{m}}\)-level lateral displacement via a translation stage, sequentially covering the trench’s top and bottom regions with the spot array.

-

4.

Synchronously record Y-axis centroid offsets (ΔY) of the spots.

-

5.

Establish a mathematical model linking ΔY to trench depth through optical diffraction theory, ultimately deriving depth values.

Width Measurement Workflow:

-

1.

Position the sample at the center of the microscope imaging system’s field of view.

-

2.

Perform axial focusing calibration to align the front focal plane of the microscope objective with the trench edge.

-

3.

Extract trench contour features using an edge detection algorithm.

-

4.

Calculate the trench width based on the extracted edge data.

Results

Width

The width measurement of individual trenches in the trench array was achieved through collimated laser beam-based direct microscopic imaging, obviating the requirement for micro-axicon arrays in the experimental system. Precise focal plane adjustment was implemented via the microscope objective’s fine-focusing screw, enabling image acquisition at the trench array’s top surface. Figure 4a presents the microscopic imaging results for sample 2# under this configuration, demonstrating a measured trench width of 5.08 μm. As schematically illustrated in Fig. 4a (upper right inset), ideal trench width measurement requires objective focusing at the trench top surface (line AB plane). However, practical fabrication imperfections may induce non-ideal trench top morphology, as depicted in the schematic’s right panel. Under such conditions, focusing must be optimized at the line CD plane, as experimentally validated for sample 2# in Fig. 4a. A sharply focused 52 × 145 pixels region (yellow dashed box in Fig. 4a, detailed in Fig. 4b) was selected for analysis, where distinct white contours along trench edges were clearly resolved.

a Tested trench array sample 2# (SEM-measured width: 5.08 μm) with focal plane selection schematic for width measurement (upper right inset). b High-contrast trench edge region (yellow dashed box) selected for width calculation; c Threshold-based binarization of (b) with edge feature extraction. d 3D top-view intensity map of b (color scale: normalized intensity); e 3D front-view intensity profile showing edge peaks. f Transverse intensity curve at Y = 8(ΔX = 36 pixels \(=\) trench width). g Intensity curves at multiple Y positions from (b)

We performed binarization processing and three-dimensional light intensity characterization on the selected trench array region. Initially applying an optimal threshold segmentation method to Fig. 4b, we obtained the binarized image shown in Fig. 4c, enabling precise extraction of trench edge features. To systematically investigate the light intensity gradient distribution near trench edges, we constructed three-dimensional top-view projections (Fig. 4d) and front-view cross-sectional profiles (Fig. 4e), with light intensity amplitudes encoded through continuous color gradients. Our axial profile analysis in Fig. 4e revealed distinct light intensity peaks at trench edges, while front-view profiles demonstrated steep single-peak morphologies, confirming precise microscope objective focusing on the trench edge plane. Leveraging this abrupt intensity gradient transition, we established a trench width measurement method based on dual-peak spacing. As shown in Fig. 4f, we analyzed a 52-pixel transverse light intensity distribution curve along the Y = 8 position of Fig. 4b, determining the apparent trench width through dual-peak spacing (ΔX = 36 pixels). Since measurements were acquired using CMOS pixel units and a 40 × microscope objective (NA = 0.65), we implemented pixel-to-physical dimension(μm) conversion through the following calibration formula:

where Cellsize refers to the pixel size of the CMOS sensor used in the experiment, which is 5.86 μm, and M represents the magnification of the microscope objective, set at ×40. Therefore, using the formula (7), the experimentally measured width at Y = 8 is 5.274 μm, resulting in an error of 3.82%. Similarly, light intensity curves at Y = 28, 48, and 88 in Fig. 4b were plotted, as shown in Fig. 4g. It can be observed that the light intensity variation trends at different Y values are generally the same.

We conducted edge extraction analysis on the nine trench array samples. The sample IDs and their corresponding pixel widths based on SEM calibration are shown in Table 2. Figure 5a displays representative micro-imaging regions and their edge extraction results, categorized into two contrast-based detection modes: white edges on a dark background and dark edges on a white background, both enabling effective edge detection. Following the methodology outlined in Fig. 4, 30 feature locations per sample were analyzed to extract light intensity profiles for width determination. A representative intensity profile from each sample’s 30 locations was randomly selected and plotted in Fig. 5b. Based on binarized image characteristics in Fig. 5a, distinct measurement criteria were applied: peak-to-peak distance for white-edge/dark-background cases (e.g., Samples 1# and 2#) and valley-to-valley distance for dark-edge/white-background cases (e.g., Samples 3#–9#). To ensure experimental reproducibility and data reliability, we conducted triplicate measurements for each sample. The measurement results from each trial are presented in Fig. 5c, while Table 2 summarizes the width values (ΔY) obtained from the three experimental trials, their corresponding mean values, and the relative errors compared with SEM measurements for each sample. Error analysis histograms in Fig. 5d compare experimental and SEM-calibrated widths (yellow bars), with error bars indicating absolute deviations. Relative errors, calculated as Δ = (|measured–SEM|/SEM) × 100%, are annotated above error bars.

a The experimental results and extracted trench edge results for all trench array samples. The sample numbers and their corresponding width SEM measurement values in pixels are: 1#(13.04 px),2#(34.68 px),3#(68.94 px),4#(17.61 px),5#(12.63 px),6#(14.06 px),7#(16.66 px),8#(11.4 px),9#(12.76 px). b Intensity variation curve of each trench sample at any given Y value used to extract trench width (ΔY). c Three width measurement experiments were conducted for all trench array samples, and the results of the three measurements are shown as a scatter plot with connecting lines. In each experiment, 30 Y values were selected for each sample, and the trench width at each position was extracted and plotted. d The histogram of SEM measured widths for different samples, with error bars indicating the discrepancy between measured values and SEM measurement values

Depth

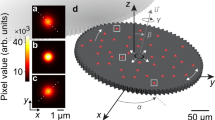

To measure trench depth, a micro-axicon array was integrated into the experimental system, as illustrated in Fig. 3. The lattice light field generated by the micro-axicon array exhibits a point-like distribution, as shown in Fig. 6a. The light spot highlighted by the yellow circle in the figure corresponds to a tracking point, whose coordinates (478, 1011) were determined based on the pixel with the highest intensity value. The maximum displacement of this point along the Y-direction was monitored by tracking variations in its Y-coordinate. To minimize noise from stray light and improve the visibility of the lattice light field, the beam size was intentionally reduced by adjusting the aperture in the experimental setup. Although the beam illuminated only a partial region of the micro-axicon array and the intensity distribution among spots was nonuniform, this did not affect the experimental results, as individual spots were analyzed independently. For clearer visualization of the lattice light field, a 3 × 3 subset of the point array (marked by the white rectangular region in Fig. 6a) was converted into a color-mapped image (Fig. 6b), where the X- and Y-axis represent pixel coordinates, and distinct colors denote intensity levels. The 3 × 3 lattice structure is highlighted by red circles. For the \(1{\rm{\#}}\) trench array sample, the microscopic image of the trench bottom (focused by the objective lens) is presented in Fig. 6c. A color-mapped image of the white rectangular region (Fig. 6d) further clarifies the intensity contrast between the trench top and bottom.

a Lattice light field generated by a micro-axial conical mirror array, with the tracking point (yellow circle) monitoring Y-direction variations. b Color-coded 3 × 3 lattice field (white box in a), highlighting intensity distribution; 3 × 3 points marked by red dashed circles. c SEM-characterized trench array sample 1# (depth: 111 μm, width: 1.91 μm, aspect ratio: 58.12); experimental objective focused on trench base. d Color-mapped intensity contrast between trench top/bottom (white box in c), e Schematic of microscopic imaging setup, f Lattice light interaction with trench array, g Geometric principles for depth calculation. h Video-derived Y-coordinate evolution (frames 1–600); i–k Maximum Y-coordinate case for sample 1#: peak intensity pixel at (474, 1014) (j); intensity profile along line A1(k). l–n Minimum Y-coordinate case: peak intensity pixel at (478, 1005) (m); corresponding profile (n). o The extracted 4 × 5 lattice light field array. p Case with a unique maximum-intensity pixel. q Case with non-unique maximum-intensity pixels; r The coordinate variations of light spots at different wafer positions

The microscopic imaging module of the experimental system, as schematically depicted in Fig. 6e, comprises a high-magnification objective lens, a beam splitter, a focusing lens, a CMOS sensor, and the sample under test. The lattice light field was projected through the high-magnification objective lens to focus onto the 1# trench array sample (Fig. 6f), with the objective lens precisely positioned at the trench bottom. Subsequently, the trench array was translated horizontally along the X-direction (as indicated by the red arrow in Fig. 6f). During this motion, the relative displacement between the trench array and the lattice light field caused the tracking point to sequentially illuminate the trench top and bottom, resulting in a Y-axis displacement (ΔY). The trench depth was then calculated from the measured ΔY.

The geometric principle for deriving the trench depth from the Y-axis displacement (ΔY) of the tracking point is illustrated in Fig. 6g. The lattice light field is incident at a diffraction angle θ. Point C represents the light spot illuminating the trench top. When the trench array is translated along the X-direction, the light spot shifts to the trench bottom (Point B). The vertical displacement between Points C and B along the Y-axis corresponds to the displacement Δy generated by the transition from the trench top to bottom. Based on the geometric relationship, the trench depth h can be expressed as a function of Δy:

The Cellsize represents the pixel size of the CMOS sensor used in the experiment, which is 5.86 μm, and M is the magnification of the objective lens, with a value of ×40. From Eq. 11, we already know that tanθ is 0.0133. Therefore, by substituting this value into Eq. 15, we can calculate the value of the depth h.

During the experiment, the trench array was moved horizontally along the X axis, and the process of the array sequentially illuminating the top and bottom of the trench array was recorded in the form of video data. As shown in Fig. 6h, we performed frame-by-frame analysis of frames 1 to 600 in the video data, extracting two cases corresponding to the maximum and minimum Y coordinates of the tracking point, as shown in Fig. 6i, l. Specifically, we used the coordinates of the pixel with the highest intensity as the coordinates of the tracking point, as shown in Fig. 6j, m. In this process, the coordinates of the tracking point when the Y coordinate is maximum and minimum are (474,1014) and (478,1005), respectively. The lines A1 and A2 pass through these two coordinates, and Fig. 6k, n show the intensity variation curves at the positions of lines A1 and A2, with maximum intensity values of 50 and 52, respectively. Therefore, we can conclude that when using lattice light to measure the depth of the 1# trench array sample, the maximum change in the Y coordinate of the tracking point, ΔY, is 9. Substituting this value into Eq. 8, the calculated depth of the sample, h, is 99.14 μm, while the SEM measured depth is 111 μm (from SEM results). Thus, the error between the experimentally calculated depth and the SEM depth is 10.68%. If multiple tracking points are selected during the experiment, and their corresponding ΔY values are calculated separately and averaged, the error in the calculated depth h will significantly decrease. This point will be further discussed in the following sections.

In the spot centroid coordinate extraction process, laser intensity and aperture size were carefully controlled during experimental design to minimize optical noise in the acquired images and enhance lattice spot observation quality. These measures ensured symmetric, concentrated intensity distributions with single brightness peaks in the resulting optical field images, where spot centers exhibited high intensity without large-area overexposure, conforming to Gaussian distributions (Fig. 6k, n). Under these conditions, the maximum-intensity pixel’s coordinates most accurately represent the true centroid. Thus, we designated these coordinates as the spot centroid, directly using the unique maximum-intensity pixel’s position (Fig. 6p) or averaging multiple maximum-intensity pixels’ coordinates when coexisting (Fig. 6q) to minimize extraction errors.

To assess the positioning precision of the centroid extraction method, as illustrated in Fig. 6o, we randomly selected a 4 × 5 lattice array comprising 20 light spots-a sample size chosen to ensure evaluation accuracy and repeatability, with each point numerically labeled in the figure. The test sample was replaced with a featureless silicon wafer, onto which the lattice light field was projected. We then captured 10 images of the projected lattice pattern at different regions and extracted the centroid coordinates of all 20 points in each image using the centroid method. The positional precision was evaluated by analyzing the coordinate variations of these 20 points across the 10 images. As shown in Fig. 6r, the coordinate variations of Point 1 across the 10 images (representing different light field positions on the wafer) demonstrate maximum deviations of ΔX = 1 pixel and ΔY = 2 pixels. We used the standard deviation as the evaluation metric for centroid extraction accuracy, and the calculation formula for the standard deviation is as follows:

where N = 10 represents the number of images, while (\(({\bar{{x}}}_{{i}},\,{\bar{{y}}}_{{i}})\)) denotes the average centroid coordinates of the i-th spot across these 10 images. The calculated standard deviations (unit: pixels) of positional variations for all 20 spots at 10 locations were: 0.87, 1.08, 1.03, 0.94, 1.05, 1.04, 1.39, 1.21, 0.95, 1.18, 0.85, 0.82, 0.52, 1.19, 1.03, 0.66, 0.91, 1.03, 0.97, and 0.76. The mean value of these 20 standard deviations was 0.97 pixels. These results demonstrate that our centroid localization method achieves sub-pixel precision (standard deviation <1 pixel), confirming its high positioning accuracy.

The systematic investigation of Y-coordinate variations in tracking points for sample 1# trench array captured sequential positional changes from Y = 1005 to 1014, as demonstrated in Fig. 7a through ten magnified views revealing pixel-level structural evolution. Using the reference coordinate (478,1005) marked by a green pentagram (Y = 1005), subsequent positions at Y = 1006–1014 are indicated by yellow pentagrams, visually illustrating the progressive ΔY increase from 0 to 9 pixels. Temporal analysis across 600 video frames (Fig. 7b) presents characteristic Y-coordinate fluctuations, with representative frames from initial, intermediate, and final stages highlighted. Spatial-statistical characterization in Fig. 7c maps the (X, Y) coordinate distribution across all frames, where color intensity correlates with occurrence frequency (darker hues indicating higher density), complemented by quantitative Y-value histogram analysis in Fig. 7d. In this experiment, we tested nine samples, with the experimental results including each sample’s identification number, depth data (μm, SEM-measured values) and corresponding ΔY values (pixels), as detailed in Table 3. To minimize potential errors introduced by single tracking point measurements, we selected 30 tracking points per sample, yielding 30 ΔY values. Each sample underwent three replicate experiments to ensure reproducibility and reliability, with specific results presented in Fig. 7f. For each experimental trial, we calculated the mean of the 30 ΔY values as the trial result. The final test results were then determined by averaging outcomes from the three trials, which were subsequently substituted into Eq. 15 to derive corresponding depth values h. The triplicate measurements (ΔY) for all nine samples and their averaged results are presented in Table 3. We compared experimentally obtained depth data with SEM measurements, with comparative results shown in Fig. 7e, presenting both ΔY values and calculated depth values h versus their SEM-measured counterparts, where comparison errors for each sample are annotated. Taking Sample 1 as an example, the error in a single tracking point test was 10.68%, whereas after selecting 30 tracking points and conducting three tests, the error was significantly reduced to 4.37%, demonstrating that averaging multiple tracking points effectively minimizes measurement errors and enhances result accuracy.

a Y-coordinate evolution of tracking points in 1# trench array (1005–1014). b Frame-wise Y-coordinate variation (Frames 1–600; initial/middle/final frames marked). c Spatial distribution of tracking point coordinates (X, Y). d Frequency histogram of Y-coordinate values. e Comparison between the averaged triplicate measurement results and SEM measurements for the nine samples (top: μm; bottom: pixels), with error annotations. f The line-scatter plot of triplicate depth measurements for the nine samples

Discussion

In this study, we propose a novel method for precisely measuring the width and depth of high-aspect-ratio (HAR) micro-trench structures by integrating a lattice light field generated by a micro-axicon array with microscopic imaging technology.

Our approach constitutes a non-destructive measurement technique that calculates depth information by analyzing the displacement of lattice light spots projected onto the sample surface. In contrast to SEM, FIB and SPM, this method eliminates the need for sample cross-sectioning or direct surface contact, thereby effectively preventing sample damage. Furthermore, the technique is inherently unconstrained by probe-size limitations at micro-trench openings and remains unaffected by trench array periodicity-enabling reliable measurements regardless of whether trenches are densely or sparsely arranged.

In a single measurement, we can simultaneously acquire and process data from 30 light spots, with the entire measurement and data processing procedure taking approximately half an hour. Without considering time constraints, an even larger number of light spots could be selected for measurement. By processing the data from these 30 light spots, depth information at 30 distinct locations within the micro-trench array can be obtained, and the average of these values is used to represent the measured depth of the trench. This approach yields a depth value that reflects comprehensive information from multiple locations, offering superior representativeness. Furthermore, owing to the simplicity of our optical system design, the measurement results are less susceptible to environmental disturbances, thereby enhancing both stability and accuracy. In contrast, conventional methods such as confocal microscopy and reflectance spectroscopy typically require sequential scanning and processing of individual locations to obtain multi-point depth information, which significantly increases time costs.

In depth measurement, compared to traditional methods that can only achieve measurements of micro-trenches with depths ranging from a few micrometers to several tens of micrometers and aspect ratios below 10 or merely around 10, our method enables precise measurements of micro-trench depths from 41.20 μm to 175.00 μm, with aspect ratios ranging from 17.33 to 58.12, successfully realizing measurements for aspect ratios exceeding 50. Compared to SEM measurements, the minimum measurement error of our method can reach 0.42%. The measurement error is primarily depth-dependent, gradually increasing as the depth increases. However, based on our method, a single experiment can extract hundreds of light spots suitable for depth measurement. For samples with greater depths, the error can be further reduced by increasing the number of processed light spots, thereby improving measurement accuracy. For instance, in the measurement of the sample \(1{\rm{\#}}\), the depth measurement error for a single light spot was 10.68%, while the error decreased to only 4.37% when calculated as the average of 30 light spots.

After comparing with traditional detection methods and demonstrating the advantages of our approach, it is of significant importance to further explore the etching processes applicable to this method and the impact of micro-trench etching morphology on the measurement results. In this study, the test samples were fabricated using the Bosch process, a representative cyclic/time-multiplexed etch approach. Other common cyclic/time-multiplexed etch approaches include DREM (Deposit, Remove, Etch, Multistep), DREAM (Deposit, Remove, Etch, Ash, Many times), and CORE (Clear, Oxidize, Remove, and Etch). Investigating the compatibility of our proposed high-aspect-ratio micro-trench measurement method with various etching processes and the influence of trench morphology on measurement results is of significant importance. In this study, the test samples were fabricated using the Bosch process, a representative cyclic/time-multiplexed etching approach. Other common cyclic/time-multiplexed techniques include DREM, DREAM, and CORE. The DREM (Deposit, Remove, Etch, Multistep) process optimizes the Bosch technique by addressing mask erosion and non-uniform scalloped profiles43,44. The DREAM (Deposit, Remove, Etch, Ash, Many times) process further enhances DREM by resolving fluorocarbon accumulation-induced trench sealing45. The CORE (Clear, Oxidize, Remove, and Etch) process represents a fluorocarbon-free silicon etching technology. By alternating SF6 and O2 plasmas, it eliminates fluorocarbon deposition while enhancing etch selectivity and stability46,47.

In cyclic/time-multiplexed etch approaches, the alternating sequence of etching and passivation steps inevitably induces sidewall undulations-commonly referred to as scalloping-with typical dimensions ranging from tens to hundreds of nanometers. In contrast, non-cyclic/time-multiplexed etch techniques, such as cryogenic etching and hybrid gas etching, achieve simultaneous etching and passivation without gas switching, thereby producing smooth sidewall profiles in deep trenches. Our method calculates the trench depth by leveraging the offset of light spots between the upper surface and the lower surface of the trench. The trench sidewall morphology (e.g., scalloped or smooth surfaces) exhibits negligible influence on the measurement accuracy. Therefore, our method is equally applicable for detecting high-aspect-ratio micro-trenches prepared by both cyclic/time-multiplexed etch approaches (e.g., Bosch, DREM, DREAM, and CORE) and non-cyclic/time-multiplexed etch methods (e.g., cryogenic etching and hybrid gas etching).

Beyond trench sidewall morphology, non-smooth and irregular bottom features arising during the etching process require consideration, such as micro-trenching, footing, and grass. These morphologies cause deformation at the trench bottom, resulting in irregular and non-smooth surfaces that subsequently affect light spot shapes. When a light spot illuminates an uneven trench bottom, shape distortion may occur, introducing errors in spot centroid extraction and consequently leading to depth measurement deviations. Among these, grass morphology is particularly prominent - grass-like structures growing at the trench bottom may cause light reflection and scattering, resulting in intensity attenuation and shape deformation of the light spot, which in turn increases the difficulty and error in centroid extraction. Although trench bottom smoothness does impact our method’s accuracy, as previously stated, our approach captures hundreds of measurable light spots in a single experiment. During data processing, points exhibiting centroid extraction failure due to bottom irregularities (e.g., grass-grown trench bottoms) can be excluded, while normal light spots from flat bottom regions are selected for precise depth calculation.

In summary, we have provided a detailed discussion of the advantages of the proposed novel measurement method for HAR micro-trenches, including non-destructive measurement, rapid detection, and the ability to detect high aspect ratios. We have also analyzed the method’s applicability to trenches fabricated by different etching processes. Therefore, this method shows great potential for practical application, as it meets the high demands for detection efficiency, accuracy, and compatibility in industrial inspections, and is expected to be applied in production-scale environments.

Conclusion

This study presents a novel method for precisely measuring the width and depth of HAR micro-trench structures by integrating a lattice light field generated by a micro-axicon array with microscopic imaging technology. A dedicated experimental system was designed and constructed, where trench width was initially determined using monochromatic microscopic imaging combined with edge extraction algorithms. Subsequently, trench depth was quantified by analyzing the diffraction-induced positional shifts of spots in the lattice light field generated by the micro-axicon array. Experimental results demonstrate that as the light field propagates from the trench top to the bottom, the lattice light field spots exhibit displacement due to diffraction angles, with the magnitude of displacement strongly correlated to trench depth. A geometric mapping between spot displacement and trench depth was established, enabling accurate depth calculation. Nine trench samples with varying aspect ratios were tested, with the maximum aspect ratio reaching 58.12. Comparative analysis with reference measurements revealed that all measurement errors were below 9%, validating the high accuracy and effectiveness of this method for characterizing HAR microtrench structures.

Acknowledgements

The authors gratefully acknowledge Tianjin University and the Institute of Microelectronics, Chinese Academy of Sciences, for providing the experimental samples. We also sincerely appreciate the editors and reviewers for their time and valuable feedback on this paper.

References

Ali, F., Raza, W., Li, X., Gul, H. & Kim, K. Piezoelectric energy harvesters for biomedical applications. Nano Energy 57, 879–902 (2019).

Mahmud, M. P. et al. Advances in MEMS and microfluidics-based energy harvesting technologies. Adv Mater. Technol. 7, 2101347 (2022).

Okasha, M. M., Mativenga, P. T., Driver, N. & Li, L. Sequential laser and mechanical micro-drilling of Ni superalloy for aerospace application. CIRP Ann. Manuf. Technol. 1, 59 (2010).

Xu, J. L., Liu, F., Wang, F. P., Yu, D. Z. & Zhao, L. C. Microstructure and corrosion resistance behavior of ceramic coatings on biomedical NiTi alloy prepared by micro-arc oxidation. Appl. Surf. Sci. 254, 20 (2008).

Hsiung, S. K., Lee, G. B., Lin, C. H. & Lee, C. H. Microcapillary electrophoresis chip device integrated with micro focusing lens structures and its biomedical applications. Fooyin J. Health Sci. 1, 11–20 (2009).

Wu, B. Q., Kumar, A. & Pamarthy, S. High aspect ratio silicon etch: a review. J. Appl. Phys 108, 051101 (2010).

Veltkamp, H. W. et al. High-aspect-ratio trench refill by LPCVD. Micromachines 13, 1908 (2022).

Ma, J. Q. et al. Three-dimensional topography of high-aspect ratio trenches by sample-induced aberration-compensable coherence scanning interferometry. ACS Photon. 11, 1068–1077 (2024).

Cadarso, V. J., Chidambaram, N., Jacot-Descombes, L. & Schift, H. High-aspect-ratio nanoimprint process chains. Microsyst. Nanoeng. 3, 17017 (2017).

Schift, H. Nanoimprint lithography: 2D or not 2D? A review. Appl. Phys. A 121, 415–435 (2015).

Häusler, G. & Ettl, S. Limitations of optical 3D sensors. In Optical Measurement of Surface Topography, 23–48 (2011).

Vartanian, V. et al. Metrology needs for through-silicon via fabrication. J. Micro-Nanolithogr. 13, 011206 (2014).

Ku, Y. S. et al. 3D Interconnect metrology in CMS/ITRI. Opt. Meas. Syst. Ind. Inspect VII 8082, 808201 (2011).

Mu, J. J. et al. Fabrication of high aspect ratio silicon microstructures based on aluminum mask patterned by IBE and RIE processing. Microsyst. Technol. 22, 215–222 (2016).

Xie, J. Fabrication challenges and test structures for high-aspect-ratio SOI MEMS devices with refilled electrical isolation trenches. Microsyst. Technol. 21, 1719–1727 (2015).

Choi, S. H. et al. In-situ characterization of thin films by the focused ion beam. J. Vac. Sci. Technol. A 18, 1701–1703 (2000).

Bennett, J. M. & Dancy, J. H. Stylus profiling instrument for measuring statistical properties of smooth optical surfaces. Appl. Opt. 20, 1785–1802 (1981).

Hsieh, M. H., Yeh, J. H., Tsai, M. & Yang, C. L. Use in-line AFM to monitor STI profile in 65 nm technology development. In Proceedings of SPIE-The International Society for Optical Engineering. 6152, 615235 (2006).

Guo, T., Chang, H., Chen, J. P., Fu, X. & Hu, X. T. Micromotion analyzer used for dynamic MEMS characterization. Opt. Lasers Eng. 47, 512–517 (2009).

Khemka, V. et al. A nondestructive electrical test structure to monitor deep trench depth for automated parametric process control. IEEE Trans. Semicond. Manuf. 17, 98–103 (2004).

Patterson, O. D. et al. Methodology for trench capacitor etch optimization using voltage contrast inspection and special processing. In 2010 IEEE/Semi Advanced Semiconductor Manufacturing Conference, 109–114 (2010).

Hansen, H. N., Carneiro, K., Haitjema, H. & De Chiffre, L. Dimensional micro and nano metrology. CIRP Ann. Manuf. Technol. 55, 721–743 (2006).

Binning, G., Quate, F. C. & Gerber, C. Atomic force microscope. Phys. Rev. Lett. 56, 930–933 (1986).

Mitsui, K. In-proces sensors for surface roughness and their applications. Precis. Eng. 8, 212–220 (1986).

Dao, T., Thomas, T., Marx, D. & Grant, D. Evaluation of nondestructive etch depth measurement for through silicon vias. In 2012 IEEE International Conference on IC Design & Technology. 1–4 (2012).

Keller, N. et al. Non-destructive measurement of bottom width in deep trench isolation structures using IRCD metrology. In Metrology, Inspection, and process control XXXVIII. 12955 (2024).

Reinig, P. et al. Metrology of deep trench etched memory structures using 3D scatterometry. Metrol. Inspect. Process Control Microlithogr. XIX 5752, 559–569 (2005).

Korolkov, V. P. et al. Etch depth mapping of phase binary computer-generated holograms by means of specular spectroscopic scatterometry. Opt. Eng 52, 091722 (2013).

Xue, C. Y. et al. Measurement of MEMS deep groove structures using white light interference principle. J. Sens. Technol. 19, 1516–1518 (2006).

Jo, T., Kim, S. & Pahk, H. 3D Measurement of TSVs using low numerical aperture white-light scanning interferometry. J. Opt. Soc. Korea 17, 317–322 (2013).

O’ Mahony, C., Hill, M., Brunet, M., Duane, R. & Mathewson, A. Characterization of micromechanical structures using white-light interferometry. Meas. Sci. Technol. 14, 1807–1814 (2003).

Wilson, T. & Sheppard, C. Theory and practice of scanning optical microscopy. (Academic Press, 1984).

Carlsson, K. et al. Three-dimensional microscopy using a confocal laser scanning microscope. Opt. Lett. 10, 53–55 (1985).

Attota, R. K. et al. Nondestructive shape process monitoring of three dimensional high aspect ratio targets using through-focus scanning optical microscopy. Meas. Sci. Technol. 12, 29 (2018).

Attota, R. K. & Kang, H. Parameter optimization for through focus scanning optical microscopy. Opt. Express 24, 14915–14924 (2016).

Ku, Y. S., Huang, K. C. & Hsu, W. T. Characterization of high density through silicon vias with spectral reflectometry. Opt. Express 19, 5993–6006 (2011).

Hsu, W. T. & Ku, Y. S. Reflectometry for TSV etching depth inspection. Opt. Meas. Syst. Ind. Insp. VII 8082, 808226 (2011).

Petsas, K. I., Coates, A. B. & Grynberg, G. Crystallography of optical lattices. Phys. Rev. A 50, 5173–5189 (1994).

Betzig, E. Sparse and composite coherent lattices. Phys. Rev. A 71, 063406 (2005).

Chen, B. C. et al. Lattice light-sheet microscopy: imaging molecules to embryos at high spatiotemporal resolution. Science 346, 439–43 (2014).

Malitson, I. H. Interspecimen comparison of the refractive index of fused silica. J. Opt. Soc. Am. 55, 12051208 (1965).

Wang, Z. Y. Microsystem design and manufacturing. Tsinghua University Press (2008).

Chang, B. D. et al. DREM: Infinite etch selectivity and optimized scallop size distribution with conventional photoresists in an adapted multiplexed Bosch DRIE process. Microelectron. Eng. 191, 77–83 (2018).

Chang, B. D., Jensen, F., Hubner, J. & Jansen, H. 'DREM2: a facile fabrication strategy for freestanding three dimensional silicon micro and nanostructures by a modified Bosch etch process. J. Micromech. Microeng 28, 105012 (2018).

Chang, B. Technology development of 3D silicon plasma etching processes for novel devices and applications. Technical University of Denmark. 194 (2018).

Nguyen, V. T. H. et al. The CORE sequence: a nanoscale fluorocarbon-free silicon plasma etch process based on SF6/O2 cycles with excellent 3D profile control at room temperature. ECS J. Solid State Sci. Technol 9, 024002 (2019).

Nguyen, V. T. H. et al. Ultrahigh aspect ratio etching of silicon in SF6-O2 plasma: the clear-oxidize-remove-etch (CORE) sequence and chromium mask". J. Vacuum Sci. Technol. A 38, 053002 (2020).

Author information

Authors and Affiliations

Contributions

D.K. contributed to the idea conception. X.L. and X.S. were responsible for setting up the experimental system and measurements. X.L. performed simulations. X.L. and X.S. wrote the manuscript. D.K. reviewed and revised the manuscript. All authors commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, X., Sui, X. & Kuang, D. Fast and accurate measurement of high aspect ratio MEMS trench array with optical lattice illumination. Microsyst Nanoeng 11, 165 (2025). https://doi.org/10.1038/s41378-025-01017-y

Received:

Revised:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41378-025-01017-y