Abstract

Ultra-high-performance concrete combines exceptional strength and durability but carries a disproportionately high environmental burden due to its cement- and energy-intensive composition. Over the past decade, efforts to lower its carbon footprint have centred on incorporating supplementary cementitious materials, alternative binders such as low-carbon cements and nano-materials, and more recently, alkali-activated ultra-high-performance concrete systems. This review critically synthesises advances in low-carbon ultra-high-performance concrete, linking the chemical, mineralogical, and physical attributes of alternative constituents to hydration behaviour, microstructural evolution, and macroscopic performance. We highlight key microstructure–reactivity–performance relationships, evaluate sustainability trade-offs across diverse formulations, and identify the most viable pathways for reducing embodied carbon while maintaining mechanical performance. By integrating performance metrics with environmental assessments, this review provides clear guidance for the design, optimisation, and broader adoption of next-generation sustainable ultra-high-performance concrete.

Similar content being viewed by others

Introduction

Ultra-high-performance concrete (UHPC) is a class of advanced cementitious material defined by a 28-day compressive strength of at least 120 MPa (with fibres)1,2,3 and a tensile strength exceeding 5 MPa4. Owing to these remarkable properties, UHPC has been regarded as a long-term sustainable alternative to traditional concrete. The notion of UHPC as a “long-term” sustainable material originates from its ability to reduce cross-sectional dimension of structural components5,6, resulting in the overall weight of UHPC structural components can be as low as 35–50% compared to that of regular concrete structures7. This structural efficiency leads to substantial reductions in raw material consumption, including both cement and steel, and consequently lowers emissions associated with clinker production and transportation during the early phases of construction8. In addition to its material efficiency, UHPC exhibits a highly refined and dense microstructure that imparts exceptional durability characteristics. These include very low permeability, enhanced resistance to carbonation, chloride ingress, and chemical attacks, as well as superior fatigue performance9,10. Collectively, these attributes extend the service life of structural elements and reduce maintenance requirements over time, providing long-term cost savings and resource-efficient construction with UHPC compared to regular concrete11.

However, despite these performance advantages, UHPC has drawn criticism for its environmental sustainability, particularly from a material composition perspective. A conventional UHPC mix design incorporates a combination of finely graded, micron-scale constituents, such as cement, silica fume, quartz powder, quartz/silica sand, and steel fibres, that together contribute to its dense packing structure and high performance characteristics. UHPC mixes are typically characterised by a very low water-to-binder (w/b) ratio, often below 0.25, which results in a hardened matrix with minimal void content of less than 2%12. However, achieving this dense particle packing requires a high cement content, typically in the range of 800–1100 kg/m3, which is roughly three times that of normal strength concrete (NSC)13,14. As a result, the embodied carbon of conventional UHPC mixtures is also substantially higher. Based on quantitative assessment in the latter section of this review (‘Sustainability assessment’), conventional UHPC exhibits a three- to four-fold increase in embodied carbon relative to normal concrete (~900–1200 kg CO2 eq/kg). Of this increase, the cement component alone accounts for the dominant share (approximately threefold), while the remaining arises from the additional embodied carbon associated with steel fibres and chemical admixtures. An overview of the constituent proportions in NSC, high-strength concrete (HSC), and UHPC is presented in Fig. 1a. The limited water availability in UHPC significantly constrains cement hydration, with typical hydration degrees in the range of 30–35%. Consequently, a large proportion of the cement and silica fume remains unreacted, functioning more as expensive inert fillers rather than active binders15,16,17. Notwithstanding these issues, the combination of high cement content and low w/b ratio accelerates early-age hydration, generating significant heat and severe autogenous shrinkage—often reaching 1000–1500 microstrains within seven days18,19. This early shrinkage poses a major concern in UHPC due to the risk of early-age cracking, which compromises mechanical performance and long-term durability. On the other hand, silica fume contents in UHPC are generally very high, in the range of 150–250 kg/m320,21. With the very low w/b ratio, the presence of silica fume and its interaction with high-range water-reducing admixtures explain the mechanical performance22,23. However, similar to cement, the degree of reaction of silica fume is relatively low, typically around 30%, with the majority functioning as inert filler24. Originally regarded as an industrial by-product of silicon and ferrosilicon alloy production25, silica fume has evolved into a highly sought-after material, particularly in UHPC applications, which has led to increased market prices and raised concerns over long-term supply stability and sustainability.

a Typical proportions of key constituents in normal-strength concrete, high-strength concrete, and UHPC, data collected from36,368 (Note: Percentages are calculated based on the mass fraction of each constituent relative to the total mixture mass per cubic metre of concrete, expressed in kg/m3). b Sustainability and material-related limitations associated with the primary constituents of UHPC.

In addition to the binder-related concerns, UHPC production also places a substantial demand on natural mineral resources. Quartz sand (also known as silica sand), and in some cases natural river sand, is used as fine aggregate, typically constituting 50–60% of the total mix volume26,27. The extensive use of this material raises concerns over the depletion of finite natural resources, especially in regions where high-purity silica is scarce. In parallel, quartz powder and silica powder, employed as micro-fillers to optimise particle packing, are typically produced through energy-intensive grinding of natural quartz. This process not only incurs high economic costs but also generates ultrafine crystalline silica particles that pose serious occupational health risks12. Inhalation of these fine particulates, including silica fume, has been linked to serious health hazards such as silicosis28, and crystalline silica has been classified as ‘Group 1’ carcinogen by the International Agency for Research on Cancer29. Steel fibres, which are essential for achieving the strain-hardening behaviour and enhanced toughness of UHPC, present another sustainability challenge. While indispensable for mechanical performance, they significantly increase steel demand and are among the most expensive components (often accounting more than 50% of the material cost). The production of steel fibres contributes to the overall environmental footprint of UHPC due to the high energy consumption and greenhouse gas emissions associated with steel smelting and manufacturing. Considering that the steel industry is one of the largest industrial sources of global CO2 emissions, the extensive use of steel fibre-reinforced UHPC raises additional concerns regarding its environmental viability.

An overview of the limitations associated with the original constituents of UHPC is presented in Fig. 1b. In summary, the sustainability limitations of conventional UHPC from a material perspective can be broadly categorised into three key challenges: (i) high cement and silica fume content with limited hydration efficiency, (ii) extensive reliance on non-renewable natural resources such as silica sand and ground quartz; and (iii) increased environmental impact from the production of steel fibres. Since 2000s, the development trajectory of UHPC has gradually shifted from the pursuit of ever-higher performance toward addressing these pressing environmental and economic concerns30, with the aim of reducing both its embodied CO2 emissions and high initial material costs of UHPC. To this end, current research efforts have converged to three main sustainability-driven strategies: (i) reducing cement and silica fume content by incorporating high volumes of supplementary cementitious materials (SCMs); (ii) substituting natural fine aggregates with recycled or alternative aggregate sources, and (iii) lowering steel fibre usage through the adoption of waste-derived or hybrid reinforcement systems. Among these approaches, the reduction of cement content has received the most significant focus within the research community, largely driven by the urgent global need to curb greenhouse gas emissions from cement manufacturing. This prioritisation is well justified: cement production alone contributes ~7–8% of global CO2 emissions31,32, primarily due to the calcination of limestone and the combustion of fossil fuels during kiln operation. Moreover, as aformentioned, the large proportion of unhydrated cement functions merely as inert, high-cost filler, highlighting a critical inefficiency from both economic and environmental standpoints. As such, reducing the cement in UHPC not only mitigates carbon emissions but can also improve binder efficiency, provided that the designed mix is properly engineered to maintain—or even enhance—the performance of the composite.

The integration of material-level sustainability strategies not only delivers immediate environmental benefits but also strengthens the long-term value of UHPC in sustainable infrastructure. Such strategies are especially critical given global decarbonisation trajectories, with numerous nations commit to carbon neutrality targets by 2050–206033. The global market outlook for UHPC (see Fig. 2a) highlights its sharp upward trajectory, with the market projected to nearly double from about USD 8.5 billion in 2024 to over USD 15.2 billion in 2033 (≈7.5% annual growth)34, reflecting its increasing adoption in infrastructure applications. In parallel, research activity has intensified (see Fig. 2b), with the number of publications on low-carbon and sustainable UHPC formulations more than tripling in the past decade, indicating strong academic alignment with industrial needs. This trend is further detailed in the Sankey diagram in Fig. 2c, which traces the diversification of research focus over time, showing a wide distribution of efforts into cement (≈73 studies), silica fume (≈13), aggregates (≈28), fillers (≈7), and fibres (≈15), underscoring the broad pursuit of greener and more resource-efficient UHPC solutions. Although several reviews have emerged alongside the growing body of research on low-carbon UHPC5,26,35,36,37,38,39,40, most evaluate SCMs solely through their macromechanical performance and often cover only a limited range of SCMs. Far fewer adopt a raw-material perspective, particularly in examining how the reactivity of different SCMs governs the hydration processes, and, in turn, the microstructural development of UHPC. Moreover, while many studies claim to produce “low-carbon” UHPC, a fair and systematic comparison of the actual embodied carbon reductions is hindered by the inconsistent use of embodied carbon inventories across constituent materials in different studies. This creates ambiguity around what can be considered truly low-carbon in practice. Compounding this issue are region-specific constraints on SCM availability, along with the scale and complexity of published data, which together make it difficult to identify the most effective and context-specific strategies for maximising environmental impact reductions.

a Global UHPC market size and scope, data collected from ref. 34 (Note: The 7.5% value represents the projected compound annual growth rate (CAGR) of UHPC market revenue over the period 2026–2033). b Annual number of publications focussing on sustainability and low-carbon initiatives in UHPC from 2008 to 2025 (Note: Counts are based on keyword searches including “low-carbon'', “sustainable'', and “green'', which may underestimate the actual number of relevant papers). c Sankey diagram illustrating the evolution of research focus on constituent replacements in UHPC from 2008 to 2025 (Note: Flow thickness on the left represents the number of studies in each year, while the values on the right indicate the cumulative number of studies for each replacement type).

Based on the above discussions, we present a comprehensive and up-to-date synthesis of sustainable alternatives to the conventional constituents of UHPC, collectively referred to as low-carbon UHPC. Here, “low-carbon” denotes UHPC mixes with an embodied carbon lower than that of conventional UHPC of the same strength class (<900–1200 kg CO2 eq/kg). Given the broad scope of this review, we focus on alternative binders, fillers, and aggregates explored in UHPC, while steel fibres are excluded from the discussion. We begin by outlining the spectrum of SCMs incorporated in UHPC, followed by discussion of their reactivity as governed by chemical and mineralogical compositions, morphological features, and physical properties. In particular, the replacement materials considered in this review span five broad classes: solid wastes, natural mineral sources, alternative cementitious binders, nano-materials, and emerging cement-free UHPC formulations. Recent advances in understanding the microstructure–reactivity–performance relationships are critically assessed, highlighting how different materials influence hydration mechanisms and composite performance. Finally, we assess the environmental impacts of these sustainable materials, considering their trade-offs with mechanical performance, and compare them against conventional recipes using a unified embodied carbon inventory developed under a consistent and transparent rationale for all material. Overall, this review advances the field by providing a comprehensive synthesis that links SCM reactivity and hydration mechanisms with both performance outcomes and embodied carbon reductions across a broad spectrum of sustainable UHPC constituents.

Understanding different alternative materials in UHPC

Utilisation form

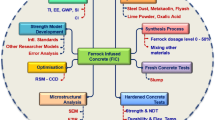

This section presents a state-of-the-art overview of various materials that have been explored as partial or full replacements for the conventional constituents of UHPC (excluding fibre). Figure 3 illustrates the spectrum of replacement materials, including a detailed breakdown of solid waste-derived sources. A comprehensive list of materials across different categories, along with their abbreviations, origins, and the types of UHPC constituents they replace, is provided in Table 1 for ease of reference. Broadly, these alternative materials can be classified into five classes: solid wastes, natural mineral resources, alternative cementitious binders, nanomaterials, and cement-free UHPC systems. Solid waste-derived materials—originating from industrial processes, agricultural residues, recycled construction and urban wastes—represent the most prominent category, accounting for ~67% of all reported replacement strategies. Their interest is largely driven by dual environmental benefits: diverting waste from landfills and simultaneously enabling their valorisation as high-performance constituents in UHPC. Natural mineral sources (e.g., CC/MK, NB, NP, DE) form the second-largest category, accounting for ~17% of reported studies. Commonly referred to as natural pozzolans, these materials are attractive due to their abundant availability in certain geographic regions and their minimal processing requirements, typically limited to drying and grinding41, making them low-energy and cost-effective alternative for use in UHPC. The development of cement-free UHPC using alkali-activated materials (AAMs), often referred to as ultra-high-performance alkali-activated concrete (UHP-AAC) or ultra-high-performance geopolymer concrete (UHPGC), constitutes the third-largest group, comprising around 12% of studies. These systems eliminate Portland cement entirely by utilising alkali activation of aluminosilicate-rich precursors—most commonly industrial by-products such as GGBFS and FA. Other material categories, although less dominant, include alternative cements (e.g., RBPC, PLC, SSC, etc.) as well as nano-materials (e.g., nSiO2 and nCaCO3), which reflect emerging research directions but still minor usage.

a Distribution of replacement material categories reported in the reviewed literature (Note: Percentages indicate the share of studies in each category relative to the total number of reviewed papers). b Sankey diagram illustrating the breakdown of solid waste-derived materials, grouped into industrial, agricultural, and recycled construction/urban wastes, and their respective roles in replacing cement, silica fume, micro-filler, and fine aggregate.

When discussing alternative material replacements in UHPC—whether for cement, silica fume, micro-filler (quartz/silica powder), fine aggregate—it is imperative to consider the physical, chemical, and mineralogical properties of the substitute materials, as these attributes directly determine their reactivity, compatibility, and overall performance within the UHPC matrix. Mineral additions used to partially replace cement can generally be classified into two categories: SCMs and inert fillers. This classification is based on whether the materials exhibit pozzolanic or latent hydraulic activity41, which in turn is fundamentally determined by the material’s origin, phase composition, and degree of amorphous content. SCMs actively engage in pozzolanic or latent hydraulic reactions, forming additional binding phases such as calcium silicate hydrates (C-S-H) that contribute directly to the enhancement of mechanical and long-term performance of UHPC. In contrast, chemically inert materials function primarily as physical filler. While they do not contribute to hydration reactions, they can improve packing density and promote hydration of clinker phases by acting as nucleation sites42. In light of the limited hydration degree of cement in UHPC, the incorporation inert fillers has been proposed as viable means to partially replacing cement without compromising performance 43. Meanwhile, materials lacking sufficient chemical reactivity (i.e., low amorphous content), are generally applied as fine aggregates. Their suitability is determined primarily based on physical properties such as particle size distribution, surface morphology, water absorption, and packing efficiency44, which indirectly influence workability and mechanical performance through the aggregate skeleton effect.

The following section (‘SCMs, AAM precursors, inert filler’) discuss the reactivity of various alternative materials, with particular emphasis on their individual morphological, chemical, and physical characteristics. Essentially, this section provides a critical background on the intrinsic properties of these raw materials, which are fundamental to understanding their contribution to the microstructural development and mechanical performance of UHPC, whether used individually or in synergistic combinations, as will be discussed in detail in ‘Microstructural mechanism and mechanical properties’.

SCMs, AAM precursors, inert filler

Chemical properties

To be considered promising candidates for use as SCMs, alternative material should ideally exhibit at least one of the following key characteristics: (i) pozzolanic reactivity, (ii) latent hydraulic activity, and (iii) activating capacity44. This section provides a detailed classification of SCMs based on their chemical oxide composition, which fundamentally governs their reactivity mechanisms and functional roles within UHPC systems. To visually facilitate this classification, Fig. 4a, b present ternary phase diagrams of CaO–SiO2–Al2O3 + Fe2O3 for solid waste-derived and other alternative materials, respectively. The plotted compositions are based on the molar ratios of CaO, SiO2, Al2O3, and Fe2O3, as reported in the literature, and were predominantly determined using X-ray fluorescence (XRF) analysis. Broadly, these materials can be categorised into three main groups according to their dominant activity profiles.

Group I corresponds to materials with strong pozzolanic activity, encompassing both siliceous and aluminosilicate-rich sources. High-silica materials (located close to SiO2 apex) such as RHA, GP, and nano-silica, are valued in UHPC for their amorphous structure in facilitating rapid secondary hydration (i.e., pozzolanic reaction)45. Aluminosiliceous materials, characterised by substantial proportions of both SiO2 and Al2O3 (located on the right side, low on CaO axis), include industrial by-products such as FA (Class F) and RM, and various mine tailings, including MT, IOT, GT, and GRT. In addition, natural mineral sources originating from both clay-based materials (e.g., CC and NB) and volcanic or siliceous rock-derived minerals (e.g., NP, NBP, and DE) also fall within this category, as illustrated in Fig. 4b. These materials are collectively referred to as natural pozzolans, owing to their pozzolanic activity and geological origin. As also defined in ASTM C618-2246, pozzolanic materials refer to low-calcium silicates or aluminosilicates that do not possess self-cementing properties but chemically react with Ca(OH)2—a product of cement hydration—and water to form additional cementitious hydrates, most notably C–S–H. Although aluminosiliceous materials typically display lower pozzolanic reactivity than pure siliceous sources, they offer greater potential for higher clinker substitution. In particular, their incorporation reduces Ca/Si ratio and increases Al/Si ratio in the binder phase, favouring the formation of calcium aluminosilicate hydrate (C–A–S–H)47,48, which has been shown to contribute to denser microstructural packing and superior mechanical properties than C–S–H48.

Group II comprises materials with latent hydraulic materials, typically characterised by moderate to high CaO content (usually 39–55%49) and moderate levels of SiO2 and Al2O3, placing them in the central region. Unlike Portland cement, these materials do no readily hydrate on their own but require an alkaline environment (e.g., high pH of cement pore solution) to initiate hydration reactions50. Notable materials in this group include GGBFS, RCF, and SS, as shown in Fig. 4a. GGBFS followed by certain types of SS, owing to its latent hydraulic properties, is widely recognise as a primary precursor in the development of cementless UHPC systems (i.e., UHP-AAC and UHPGC)38. In these formulations, alkali activators like sodium hydroxide (NaOH) and sodium silicate (Na2SiO3) are incorporated to provide the alkaline conditions necessary for the dissolution of glassy phases and condensation of reaction products51. Although RCFs occupy a similar compositional region, it is important to note that its moderate CaO content primarily derives from unhydrated cement particles, portlandite, and carbonation product (e.g., calcium carbonate (CaCO3)). Meanwhile, the SiO2 component is largely contributed by crystalline quartz from fine aggregate52. As a result, the chemical composition of RCF tends to be relatively scattered, reflecting the variability in the source concrete grade, degree of hydration, and aggregate content. While the reactivity of RCF is generally low, its reactivity can be significantly enhanced through various pre-treatment methods such as mechanical grinding, thermal or chemical activation, and mineral carbonation53,54.

Group III corresponds to hydraulic materials—similar to Portland cement—that are capable of reacting directly with water to form cementitious hydrates, without requiring external sources of calcium or alkalinity. Most materials falling within this group are classified as alternative hydraulic cements, including RBPC, PLC, and CSAC, all of which have been employed as partial or full replacements for traditional cement in UHPC, as depicted in Table 1. These binders are engineered to reduce carbon emission while maintaining comparable performance by optimising clinker mineralogy or incorporating supplementary components, as described in Table 1. Their compositions typically place them in the high-CaO region in the ternary diagram, overlapping with the Portland cement (PC) zone, as seen in Fig. 4b, indicating their strong self-cementing ability.

Group IV comprises materials that are rich in CaO, positioning them near the CaO apex of the ternary diagram. These materials typically lack pozzolanic or hydraulic reactivity, but they exhibit activating potential due to their ability to contribute free CaO or promote high pH environments, thereby facilitating the hydration of other SCMs. It is important to distinguish however, that LP, despite its location near the CaO-rich corner due to its high CaO content, it is widely regarded as an inert filler. This classification is supported by many studies according to their heat release and calcium hydroxide (CH) consumption49,55,56.

According to ASTM C618-2246, a potential pozzolanic material should possess a minimum combined content of Al2O3 + Fe2O3 + SiO2 ≥ 70% by mass to ensure sufficient reactive silico-aluminous phase. On the other hand, EN 197-157 specifies that hydraulic materials should have a minimum combined content of CaO + SiO2 ≥ 50% by mass, which reflects the presence of hydraulic calcium silicates. Figure 4c illustrates a binary compositional mapping of various alternative materials, plotted in terms of Al2O3 + Fe2O3 + SiO2 versus CaO + SiO2. In general, most materials fall within the shaded domains that represent domains of pozzolanic or hydration-related potential. Specifically, materials located in the upper-left quadrant include latent hydraulic binders (e.g., GGBFS and SS), hydraulic binders (e.g., PC and alternative cements), RCF (which may exhibit a combination of pozzolanic and hydraulic properties depending on source and treatment), as well as LP. Notably, red mud is the only material located in the lower-right quadrant, indicating its pozzolanic potential rather than inherent hydraulic reactivity, as also noted in previous study58.

Mineralogical properties

The reactivity of different SCMs is determined by several factors, among which the content of amorphous (glassy) phases and specific surface area (SSA) are particularly critical (further discussed in ‘Physical and morphological properties’)41. While Fig. 4a, b provide useful information on the bulk oxide composition; however, they do not provide the details of crystalline and amorphous mineral phases, which are essential for understanding the true reactivity potential of these materials. For SCMs where the amorphous phase serves as primary reactive component, the quantity and structure of the amorphous phase are key indicators of reactivity41. In the most simplified sense, a higher proportion of amorphous content and a higher degree of depolymerisation of the glass network generally correlates with higher reactivity59,60, as the disordered atomic structure is more susceptible to dissolution and subsequent reaction with CH or in alkaline environments. Figure 5 provide an overview of the X-ray diffraction (XRD) patterns of various alternative materials incorporated in UHPC, compiled from published literature. In these patterns, amorphous phases are typically identified by broad, diffuse humps rather than well-defined peaks, reflecting their disordered atomic structure. In contrast, crystalline phases are characterised by sharp, distinct peaks, with each peak corresponding to a specific mineral phase.

Among the solid waste products, materials such as GGBFS, FA, CBA, RHA, and GP exhibit prominent diffuse humps in their XRD profiles, indicating a substantial amorphous content and, consequently, a high potential for pozzolanic or latent hydraulic reactivity. In particular, the amorphous calcium-alumino-silicate phase of GGBFS typically constitutes up to 95% of its mass61, primarily resulting from the rapid water quenching process that inhibits crystallisation during slag solidification62. As shown in Fig. 5, FA presents a broad hump between 20 and 40° 2θ, superimposed with sharp peaks corresponding to crystalline quartz and mullite63. The amorphous alumino-silicate glass generally accounts for ~60% of FA’s mass64, and is responsible for its pozzolanic behaviour in alkaline environments. Similarly, the XRD pattern of GP displays a wide, featureless hump between 20 and 40° 2θ65, consisting primarily of sodium-calcium silicate glass and virtually no detectable crystalline phase66. Comparable amorphous features have been observed in liquid-crystal display glass powder (LCDGP) derived from waste LCD panels found in televisions, mobile phones, and computer monitors67,68. The reactivity of GP is highly influenced by its fineness (i.e., the finer the particle size, the greater the pozzolanic activity)69. Studies have shown that GP with a particle size below 100 μm can exhibit pozzolanic reactivity similar to that of FA (class F)66,70. RHA, when produced under controlled combustion conditions at 500–700 °C, contains highly reactive amorphous silica typically ranging from 85 to 95% by weight—comparable to that of SF (>90 wt%)71. This high amorphous content is reflected in the broad diffuse hump centred near 22° 2θ in its XRD pattern, indicative of a disordered silica structure that significantly contributes to its strong pozzolanic activity.

Similarly, certain natural mineral sources, particularly CC (MK), DE, and NP, also exhibit a distinct amorphous phase. The pozzolanic reactivity of MK, derived from the calcination of kaolinitic clay (≥85% kaolinite), results from the thermal dehydroxylation of crystalline kaolinite into an amorphous alumino-silicate phase72,73. This is evidenced by a broad XRD hump between 15 and 35° 2θ and the disappearance of kaolinite’s characteristic peaks12,74. DE contains a significant amount of amorphous silica, indicated by a broad hump around 22° 2θ, along with peaks for quartz and illite75. This amorphous silica primarily forms through the biological precipitation in aquatic environment76, imparting a highly porous and high-surface-area morphology that is distinctly source-specific77. NP, on the other hand, contains a large amount of amorphous alumino-silicate glass, as characterised by the diffuse hump between 15 and 30° 2θ in its XRD patterns78. It glassy structure forms primarily from the rapid cooling and depressurisation of high-silica volcanic magma, with it reactivity can be further improved through mechanical grinding79,80.

The remaining materials are either predominantly characterised by well-defined crystalline peaks or partially crystalline (i.e., presence of some amorphous phases), indicating limited intrinsic reactivity in their raw form. As such, their effectiveness as SCMs often depends on the application of additional beneficiation processing (i.e., activation). For instance, raw mine tailings (e.g., MT, IOT, GT, and GRT) possess highly stable crystalline structure with minimal to no amorphous content44, as evidenced by their XRD patterns. These material typically display limited reactivity and are generally considered inert unless subjected to pre-treatments such as mechanical, thermal, or chemical activation to enhance their reactivity. In fact, most alternative materials—including those previously noted for their significant amorphous content (except for DE and NP)—undergo some form of beneficiation either as a result of industrial processing (e.g., controlled combustion of FA and RHA) or through additional pre-treatments to enhance their performance in cementitious systems. For instance, mechanical activation, particularly high energy milling, is often used to activate materials such as clays, SS, WBA, BP, GP, and various mine tailings53,81,82,83,84,85. This technique increases fineness and alters the surface structure rather than the bulk composition, leading to disruption of crystalline phases and increased reactivity41. Thermal activation is another effective method, involving controlled temperature to induce dehydroxylation and convert crystalline phases into amorphous forms. This approach is particularly relevant for kaolinite clays, natural pozzolans, and certain mine tailings86,87,88. Conversely, chemical activation typically involves alkaline treatments to enhance solubility and dissolution of key reactive oxides (a concept widely applied in UHP-AAC and UHPGC systems) or acid/water leaching to remove excess alkalis and deleterious phases, for instance from WBA and RCA with adhered mortar89,90,91,92. In some cases, mineral carbonation—an emerging technique that combines carbon capture with beneficiation processing—is used to sequester CO2 and activate a range of Ca- and Mg-rich materials including GGBFS, SS, and RCF93,94,95. For instance, basic oxygen furnace steel slag (i.e., converter steel slag), a material rich in calcium silicates, exhibits relatively high carbonation reactivity94,96, with ~100–150 g of CO2 can be sequestered per kilogram of slag powder96. Initially regarded as an inert ingredient (low hydraulic reactivity)94, carbonated SS has since been intensively studied for use in UHPC as means to enhance the reactivity of SS, sequester CO2 while reducing free CaO and MgO94,96,97. Collectively, the amorphous phase content, dominant crystalline phases, and corresponding pre-treatments of various SCMs are summarised in Table 2.

Physical and morphological properties

Material fineness, typically characterised by particle size distribution (PSD) and SSA, is a key physical property influencing the reactivity of SCMs and the resulting strength development in blended cementitious systems98. Generally, a finer particle size enhances pozzolanic activity by accelerating the dissolution of reactive phases, thereby promoting the formation of additional strength-contributing hydration products. Moreover, smaller particles provide a greater surface area for the nucleation and growth of cement hydration products, which helps to accelerate early hydration kinetics and improve early-age strength development. However, increasing fineness does not always translate to improved performance. While it enhances the packing density of the granular skeleton, an excessively high SSA beyond the optimal threshold can elevate water demand to achieve desired workability, which can, in turn, compromise both strength and durability of the binder system31. Beyond fineness, particle morphology (i.e., sphericity, angularity, surface texture) is another critical feature that affects SSA and, consequently the performance of SCMs. Highly angular or irregularly shaped particles tend to exhibit greater surface area and inter-particle friction, leading to increased water demand and reduced flowability. Conversely, more spherical particles, such as those commonly found in FA, improve packing efficiency and flowability without adversely affecting strength99.

This sensitivity is especially pronounced in UHPC, where the fundamental design principle revolves around achieving a densely packed microstructure through careful optimisation of particle gradation and the use of extremely low w/b ratios. In such systems, the margin for adjusting water content is minimal, making the physical compatibility of SCMs, particularly their particle size and morphology, far more critical than in conventional concrete. Variations in water demand and reactivity arising from these differences can significantly influence fresh-state properties and disrupt the dense particle packing that underpins the superior mechanical and durability performance of UHPC. Therefore, selecting SCMs with particle sizes that offer sufficient reactivity without excessively increasing water demand is essential to ensure a balance between workability and long-term performance. To inform this selection, this section summarises the physical characteristics of various SCMs applied in UHPC systems, with a particular focus on the particle size and morphology. Figure 6 illustrates the distribution of mean particle size (i.e., D50 as determined from PSD) and the corresponding SSA for a range of replacement materials, categorised into solid waste-derived materials, mine tailings, natural mineral sources, alternative cements and nano-additives. The shaded region indicates the typical range of D50 and SSA values for conventional concrete ingredients100. As shown, the particle sizes of original UHPC constituents span from ~0.1 μm (silica fume) to 500 μm (fine aggregate), indicating the use of much finer particles compared to conventional concrete which typically include coarse aggregate. Micro-fillers such as quartz powder exhibit particle sizes comparable to that of Portland cement, indicating their primary role as inert physical fillers that enhance particle packing. Complementing Fig. 6, Fig. 7 presents scanning electron microscope (SEM) images that depict the morphological characteristics of various replacement materials.

a Distribution of mean particle size versus specific surface area for a wide range of materials considered for UHPC formulation, shown in comparison with conventional concrete constituents, reproduced from ref. 100. b–e Categorised scatter plots for: b Solid waste-derived materials, data collected from refs. 43,45,53,65,72,94,96,97,116,117,119,197,208,209,220,270,287,373,374; c Mine tailings (industrial solid waste), data collected from refs. 53,109,110; d Natural mineral sources, data collected from refs. 23,72,116,119,243,287; and e Nano-materials and alternative cements, data collected from refs. 119,124,131. Note: All data were compiled from existing literature specifically focussed on UHPC to ensure representativeness. Hence, some materials are not included due to the incomplete or unavailable data, including RM, WBA, CBA, GT, GRT, NB, NP, SSC, CSAC, and nCaCO3. In the plot, the abbreviations SF, PC, QP, and QS stand for silica fume, Portland cement, quartz powder, and quartz sand.

Note: The compilation is not exhaustive; several replacement materials are not shown due to limited availability of SEM imagery in the literature). GGBFS reproduced with permission141. Copyright 2023, Elsevier B.V.; FA reproduced with permission63. Copyright 2025, Elsevier B.V.; GP reproduced with permission158. Copyright 2023, Elsevier B.V.; SS reproduced with permission94. Copyright 2021, Elsevier B.V.; LP reproduced with permission152, Copyright 2025. Elsevier B.V.; RM reproduced with permission200. Copyright 2021, Elsevier B.V.; WBA reproduced with permission375. Copyright 2024, Elsevier B.V.; CBA reproduced with permission151. Copyright 2017, Elsevier B.V.; GRT reproduced under the CC BY-NC-ND license376; MT reproduced under the CC BY-NC-ND license377; IOTP/IOTS reproduced with permission110. Copyright 2024, Elsevier B.V.; GT reproduced with permission112. Copyright 2021, Elsevier B.V.; RHA reproduced with permission209. Copyright 2017, Elsevier B.V.; RCF reproduced with permission95. Copyright 2024, Elsevier B.V.; CC/MK reproduced with permission378. Copyright 2025, Elsevier B.V.; NB reproduced with permission123. Copyright 2023, Elsevier B.V.; NP reproduced with permission78. Copyright 2022, Elsevier B.V.; NBP reproduced with permission243. Copyright 2021, Elsevier B.V.; DE reproduced with permission379. Copyright 2005, Elsevier B.V.; NC and NS reproduced with permission128. Copyright 2018, Elsevier B.V.

Among all the materials, RHA exhibits the highest SSA, despite having a particle size comparable to that of Portland cement. This exceptionally high SSA is primarily attributed to the highly porous microstructure formed during the combustion of rice husks101 (see Fig. 7) and the subsequent pulverisation process that reduces RHA to cement-like fineness, which significantly enhances its pozzolanic activity71. Other solid-waste materials including GGBFS, FA, GP, LP, SS, and RCF also share similar particle size as Portland cement, as depicted in Fig. 6b. As a result, these materials have been largely used to replace similar-sized granular materials in UHPC including cement and quartz powder, as also highlighted in Fig. 3. Yu et al.102 compared the individual replacement of cement with FA, GGBFS, and LP in UHPC, and reported the water demand (measured using Puntke test) in the following order: GGBFS > LP > FA. This trend was attributed to particle morphology, where the higher sphericity of FA contributed to lower inter-particle friction and improved flowability, while the more angular shapes of GGBFS and, to a lesser extent, LP resulted in greater water demand to achieve similar workability, as similarly reported in ref. 43. GP, on the other hand, exhibits a relatively smooth texture (see Fig. 7), which has been shown to decrease the friction with cementitious particles and enhance flowability when used as a partial cement replacement in UHPC65,103,104. However, this enhancement in flowability is contingent upon proper processing; specifically the glass must be adequately washed to remove impurities (e.g., papers), which can absorb water and adversely affect workability104. SS exhibits an angular morphology, characterised by a highly irregular and rough surface texture, with particle sizes predominantly below 30 μm. Studies have shown that SS subjected to ambient carbonation exhibits a further increase in surface roughness and pore volume, resulting in a higher SSA94. These changes are attributed to the formation of low-density carbonation products (CaCO3). This implies that while carbonation enhances reactivity, the associated increase in SSA and porosity can significantly elevate water demand and negatively impact fresh-state performance of UHPC. The morphology of RCF, whether derived from simulated pure cement paste or actual demolition waste, generally reveals a wide range of particle shapes, including irregular and bead-like particles, with the majority of these particles exhibit rough surfaces characterised by capillary pores and microcracks53,95,105,106. Depending on the activation method employed (e.g., mechanical/thermal/chemical), the microstructural characteristics of the RCF can be further improved53. Among these methods, mechanical grinding has proven to be particularly effective, as the smaller particle size promotes micro-aggregate filling effect and facilitates accelerated cement hydration by improving surface reactivity107,108.

Mine tailings, including MT, IOT, and GT, have been utilised to replace cement and fine aggregate, depending largely on their degree of fineness. As noted earlier, raw tailings typically possess highly stable crystalline structures, and thus require pre-treatments, most commonly mechanical activation, to enhance their reactivity before they can be effectively used as SCMs44. Tailings sand (e.g., MTS and IOTS), generally obtained through simple sieving remixing processes109,110, exhibit relatively larger particle sizes comparable to those of fine aggregates, as shown in Fig. 6c. In contrast, tailings powders (e.g., MTP and IOTP), suitable for replacing cement, are produced via mechanical grinding109,110,111, which reduces particle size, increases surface areas and induces structural modifications that enhance their pozzolanic reactivity. GT, on the other hand, exhibit a wide PSD (ranging from cement-sized particles to fine sand) and contains ~35% of micro-powder, enabling the possibility of full-scale recycling by simultaneously replacing both cement and fine aggregates in UHPC without the need for sieving or reprocessing treatment112. In terms of morphology (see Fig. 7), most tailings, regardless of whether in sand or powder form, exhibit relatively angular particle shapes and rough textures, with grooves observed on the surfaces53,110,112,113,114. The grooves are mainly scratches by quartz with comparatively high hardness during the grinding process112.

Interestingly, all natural pozzolans tend to exhibit significantly higher SSA, despite having a D50 comparable to that of Portland cement, as shown in Fig. 6d. These materials, including CC (MK), NBP, and DE, are typically ground to a fineness similar to that of cement; however, their inherently porous microstructures result in a much higher SSA than cement particles of equivalent size115. The porous features, clearly visible in the SEM images in Fig. 7, contribute positively to pozzolanic reactivity by providing more sites for dissolution of reactive silica and alumina12. Nevertheless, the high SSA also increases water demand, which can significantly affect workability73, especially in UHPC with low w/b ratios116,117,118. Consequently, while natural pozzolans are effective in enhancing long-term performance through pozzolanic reactions, their usage in UHPC typically requires careful optimisation and often limited to low-to-moderate replacement levels. For instance, MK has demonstrated pozzolanic reactivity and mechanical performance comparable to that of silica fume23; however, its high SSA, attributed to the rough surface generated during incineration process, significantly reduces flowability116,119. To maintain acceptable workability and limit water demand, the replacement level of MK is generally recommended to be in the range of 8–20%115,119. Similarly, DE, characterised by its intricate surface morphology and the high porosity of its disk-shaped diatom frustules, exhibits markedly elevated SSA and water demand120. As a result, its replacement level is typically limited to about 15% in mixes without superplasticiser121,122, and up to 10% in UHPC systems119. Other natural pozzolans such as NB, characterised by its layered structure123, and NP, with mostly unconnected honeycomb-shaped pores78, also exhibit high water absorption capacity due to their internal porosity, as demonstrated in Fig. 7.

Nano-materials, primarily nSiO2 and nCaCO3, with particle sizes typically in the tens of nanometres (see Fig. 6e), are commonly used as partial replacements for cement and silica fume in UHPC124,125,126,127,128,129. These nanomaterials are characterised by their extremely high SSA and surface energy; as such, they tend to absorb more mixing water and reduce the amount of free, lubricating water available within interparticle voids130. This effect is particularly pronounced in UHPC systems, where even at low replacement levels (typically 1–5% by wt. of binder), nanomaterials have been shown to cause a noticeable reduction in flowability124,127. Alternative cements, on the other hand, display SSA and D50 values comparable to those of Portland cement, as they are designed to match or exceed its reactivity while maintaining similar particle packing behaviour131.

Fine aggregates

As indicated earlier, materials with limited chemical reactivity are often employed as alternative fine aggregates in UHPC, replacing conventional quartz sand or river sand, both of which are regarded as non-renewable due to environmental constraints and resource depletion. Given the particle size of fine aggregates typically in the millimetre range (see Fig. 6), these alternative aggregates generally require only basic mechanical processing, such as crushing and sieving, in contrast to SCMs, which often demand more intensive beneficiation to achieve desired reactivity. Based on the current literature, the alternative materials used to replace fine aggregates in UHPC primarily originate from four major sources, as also indicated in Table 1: industrial solid wastes (e.g., FA, SS, and WBA), mining by-products (e.g., MT, IOT, GT, and GRT), recycled construction and urban wastes (e.g., RCA, GS), and naturally occurring resources (e.g., SSW).

Among the various materials, RCA, recovered from concrete demolition waste, is the most extensively studied fine aggregate replacements in UHPC systems91,118,132,133,134,135,136,137,138,139,140. Several types of SS aggregates have been investigated for use in UHPC, including high-magnesium nickel slag141, electric arc furnace slag142, and ferrochrome slag143. Similarly, waste glass with larger particle size (>100 μm) exhibiting limited pozzolanic reactivity is generally used as fine aggregate. Due to its high silica content, glass serves as a viable alternative to natural sand, which shares a similar silica composition104. Another notable alternative aggregate explored in UHPC is mine tailings. Several studies have highlighted the particular advantage of using tailings in UHPC systems, as the ultra-dense microstructure of UHPC significantly restricts the leaching and migration of heavy metal ions, which has increasingly driven research interest in the direct utilisation of tailings as aggregates in UHPC, including MT109,144, IOT53,110, GT145, and GRT112. Overall, the suitability of alternative aggregates for UHPC, regardless of the source or type, largely depends on their intrinsic physicochemical properties. These include particle fineness, angularity, water absorption capacity, crushing index, mud content, and apparent density, all of which play critical roles in determining their compatibility with the densely packed granular skeleton of UHPC. These characteristics directly influence the packing density, water demand, paste-to-aggregate ratio, which in turn affect both the fresh and hardened performance of UHPC. The roles of these parameters are further elaborated in the subsequent subsections for different material categories.

Microstructural mechanism and mechanical properties

Industrial by-products

Steelmaking and non-ferrous metallurgy slags

Steelmaking slags present a major area of research in the development of sustainable binder and aggregate alternatives for UHPC. As shown in Fig. 8, steel production typically follows two main routes: the conventional blast furnace–basic oxygen furnace (BF–BOF) route and the alternative electric arc furnace (EAF) route. In the BF–BOF process, iron ore and fluxes are smelted in a blast furnace to produce pig iron, which is subsequently refined in a BOF to produce carbon steel, with GGBFS and BOF slag generated as respective by-products. In contrast, the EAF route involves melting recycled steel scrap and fluxes directly in an EAF to produce carbon steel, producing EAF slag as a by-product.

Reproduced with permission41. Copyright 2023, Elsevier B.V.

As noted in ‘Chemical properties’, GGBFS exhibit latent hydraulic properties, enabling its use as direct cement replacement for PC. However, due to its inherently slow hydration kinetics compared to PC, chemical activation is typically required. Among the most common activators is Ca(OH)2, a by-product of cement hydration, which increases the pore solution alkalinity146,147. When the pH surpasses 13, the glassy phase of GGBFS begins to dissolve, releasing calcium and silica species that subsequently promote the precipitation of C–S–H gels148. In UHPC systems, numerous studies have consistently reported a decline in early-age compressive strength (typically 1–3 days) with increasing levels of GGBFS replacement149,150. This behaviour is primarily limited due to the slow initial reactivity of GGBFS and its dependence on gradual activation by Ca(OH)2 released during cement hydration, as shown in the early-age hydration heat evolution in Fig. 9a. As the GGBFS replacement ratio increases, the dilution of cement reduces the availability of Ca(OH)2, thereby limiting the extent of GGBFS activation (see Fig. 9b). This reduction in activator availability, combined with the inherently sluggish dissolution of GGBFS, suppresses early-stage C–S–H formation and delays strength development. Moreover, the C–S–H gels formed from the GGBFS–Ca(OH)2 reaction tend to have lower density and Si/Ca ratios compared to those produced from ordinary Portland cement, which may further contribute to the decline in strength149. As a result, UHPC mixtures with higher GGBFS contents often exhibit reduced early compressive strength due to delayed pozzolanic reactivity and more porous binding phases149,150. However, enhancing the fineness of GGBFS particles has proven effective in improving early hydration behaviour by accelerating the dissolution kinetics and increasing reactivity. For instance, a study by Pyo and Kim151 showed that finely ground GGBFS, relative to coarser particles, significantly increased heat evolution and accelerated early-age hydration. This improvement in reactivity resulted in a notable improvement in early compressive strength, with the highest gains observed as early as 3 days of curing. Additionally, the finer GGBFS slightly improved flowability and contributed to higher elastic modulus and Poisson’s ratio.

a Hydration evolution profiles comparing UHPC mixtures with high (ULC1) and low (LC) volumes of GGBFS, illustrating lower initial hydration. Reproduced with permission129. Copyright 2019, Elsevier B.V. b XRD patterns showing dilution effect on 1-day cement hydration with increasing GGBFS replacement levels (Note: E: Ettringite, A: Alite, CC: Calcite, CH: Portlandite). Reproduced with permission149. Copyright 2021, Elsevier B.V. c ITZ characteristics between steel fibres and matrix at varying GGBFS contents, with corresponding failure patterns, adopted from ref. 152. d Influence of curing regime on the compressive strength development of GGBFS-blended UHPC. Reproduced with permission43. Copyright 2017, Elsevier B.V.

Nevertheless, given sufficient curing time (typically >28 days), the secondary reaction between GGBFS and Ca(OH)2 contributes to additional C–S–H formation, resulting in a denser microstructure and enhanced long-term strength150. This long-term benefit has been well-documented, with several studies demonstrating that GGBFS-containing UHPC can achieve comparable or even superior compressive strength to reference mixtures without GGBFS102,128,149,151,152. For instance, Yu et al.102 reported that GGBFS-based UHPC outperformed mixtures containing fly ash and limestone powder at both 28 and 91 days, consistent with findings reported in ref. 153. However, an excessive replacement level can still compromise long-term compressive strength due to a persistent dilution effect that compromises the quality of C–S–H gels at the fibre–matrix interfacial transition zone (ITZ)152. When GGBFS is incorporated in optimal proportions, nanoindentation results reveal a refined ITZ microstructure that facilitates the development of high-density (HD) and ultra-high-density (UHD) C–S–H gels at the fibre–matrix interface, thereby increasing the energy required for crack initiation. As the replacement level increases (up to 45%), the dilution effect becomes more pronounced, leading to the predominance of low-density (LD) C–S–H formation, higher porosity, and more severe microstructural damage under equivalent strain loading, as illustrated in Fig. 9c. Similar findings are also reported in154. These findings suggest that the long-term mechanical performance of UHPC incorporating hydraulic SCMs such as GGBFS is predominantly governed by the continued hydration of the SCM.

To address the issue of low early-age compressive strength in GGBFS-containing UHPC, various accelerated curing methods, such as hot water curing, steam curing, and autoclave curing, have been investigated in recent studies43,129. Wu et al.43 reported that applying hot water and steam curing for 48 h significantly enhanced both compressive and flexural strengths, surpassing those achieved through standard curing even after 90 days, as shown in Fig. 9d. This improvement is primarily attributed to the accelerated binder reaction and the formation of longer C–S–H chains, which contribute to a denser microstructure and higher strength hydration products. Moreover, Shi et al.129 found that autoclave curing at 180 ± 2 °C for 8 h yielded superior performance compared to steam curing, achieving ~10–32% higher compressive strength. A particularly noteworthy study by Dixit et al.149 examined the effects of fresh-state carbon curing (i.e., exposure to high concentration of CO2 during hardening) on the carbon uptake and performance of GGBFS-based UHPC, with the aim to further substantiate its low-carbon potential through CO2 sequestration. A schematic of the carbonation setup, along with the corresponding mechanical performance and carbon uptake results, is presented in Fig. 10a. The study found that although carbon curing caused a slight reduction in compressive strength, it significantly increased CO2 uptake by converting CH and C–S–H to calcite (CaCO3). This strength loss was primarily attributed to CH depletion, which disrupted the nanocomposite structure of UHD C–S–H/CH gels where CH contributes to gel densification through pore filling. Despite this, the strength loss was minimal, and a marked increase in carbonation degree was observed in UHPC with 30% GGBFS substitution. This is particularly beneficial in dense UHPC matrices, where partial cement replacement with GGBFS, owing to its low early-age reactivity, creates additional space that facilitates the precipitation of CH and C–S–H and their subsequent conversion to carbonates. However, a 30% GGBFS replacement was found to be optimal for promoting carbonation as higher replacement levels induced a dilution effect that limited the formation of hydration products available for carbonation. Based on the collective findings of these studies, a GGBFS replacement level of 20–40% is generally recommended, as it offers better fibre–matrix bonding and flexural performance43,128, enhanced carbon capture without significant strength compromise149, and improved dynamic compressive strength under high-strain-rate loading150.

a Fresh-state carbonation applied to GGBFS-UHPC mixtures, showing its influence on 28-day compressive strength and degree of carbonation. Reproduced with permission149. Copyright 2021, Elsevier B.V. b Incorporation of pre-carbonated (wet carbonation) GGBFS into UHPC, promoting the formation of needle-like aragonite crystals that contribute to enhanced flexural strength. Reproduced with permission154. Copyright 2025, Elsevier B.V.

To further increase the utilisation of low-reactivity GGBFS in UHPC, Shah et al.154 recently explored the use of pre-carbonated GGBFS as a partial cement replacement at high substitution levels of 40 and 60%. This approach leverages the calcium-rich nature of slag by subjecting it to wet carbonation, whereby exposure to CO2 leads to the formation of CaCO3 and amorphous silica gel on the slag particle surfaces, as illustrated in Fig. 10b. Remarkably, the inclusion of 40–60% carbonated slag resulted in significant gains in 28-day compressive and flexural strengths, demonstrating the viability of high-volume GGBFS substitution. These improvements can be attributed to several synergistic mechanisms: (i) the in-situ formed CaCO3 reacts with C3A to form monocarboxylate and hemicarbonate phases that improve microstructure; (ii) CaCO3 provides nucleation sites that accelerate hydration kinetics and contributes a filler effect that densifies the matrix; (iii) the amorphous silica gel promotes additional pozzolanic reactions with CH, increasing C–S–H production; and (iv) the growth of needle-like aragonite crystals on the slag surface functions as microfibres and fillers to enhance the microstructure and ITZ155. Nevertheless, one challenge associated with using carbonated slag is the increased demand for high-range water reducers (HRWR) to maintain flowability, due to particle agglomeration, which can adversely affect early-age strength.

SS generally refers to BOF slags, also known as converter steel slags. In UHPC, BOF slag is predominantly utilised as a cement replacement due to to its potential hydraulic reactivity (see Fig. 4). The hydraulic activity of SS is largely influenced by its fineness: finer particles (<6 μm) contain reactive cementitious phases, while coarser particles (>60 μm) are dominated by the RO phase with almost no hydration activity, making it chemically inert156. The presence of calcium silicate phases in SS powder (particularly larnite (C2S), see Table 2) underpins its hydraulic potential; however, their reactivity is considerably slower than cement 157,158. The low reactivity of SS is mainly related to its low tricalcium silicate (C3S) content and the morphology of C2S, which further slows the already inherently slow hydration of C2S159. Consequently, its incorporation often leads to delayed setting and reduced early-age compressive strength160,161. In UHPC, several studies have reported that increasing SS contents typically leads to a reduction in compressive strength94,158,162, with more pronounced negative effects at early ages162. The early-age strength reduction is primarily attributed to the delayed early hydration reactions caused by the low hydraulic reactivity of SS, as evidenced by a prolonged induction period and a lower main hydration peak in the isothermal calorimetry heat flow curves 94,162. While indicative of slower hydration, this reduced exothermic peak beneficially mitigates hydration-induced thermal expansion, leading to a reduction in autogenous shrinkage162. As hydration progresses, both the continued hydration of SS and its physical filling effect become more pronounced94,162. The filler effect, in particular, effectively increases the effective water-to-cement ratio, thereby facilitating a higher degree of cement hydration94. Consequently, the strength reduction at later ages tends to be less severe. In terms of microstructure, SS-incorporated UHPC exhibits a noticeable presence of unhydrated cement grains and increased porosity at 28 days, both of which indicate limited later-age hydration and restrained long-term strength development associated with higher SS replacement levels158,162. At the structural scale, similar strength reductions have also been observed in UHPC beams under flexural loading, where higher SS contents tend to decrease the cracking load, yield load, peak load of the structural members163.

Due to its high content of non-carbonate Ca- and Mg-bearing minerals, SS has been explored as a potential feedstock for CO2 sequestration, while simultaneous serving as a SCM in UHPC164. Compared to coarse SS aggregates, which typically require pressurised carbonation treatment, SS powder demonstrates significantly higher carbonation reactivity even under ambient conditions165,166. Its CO2 sequestration capacity can reach up to 100–150 g CO2/kg for particles finer than 38 μm167, making them particularly suitable as an SCM in finely-graded UHPC mixtures. Liu et al.94 and Li et al.96 investigated the use of carbonated SS as a cement replacement in UHPC, with the latter focussing on its application in coarse aggregate-containing UHPC (UHPC-CA). Both studies employed a similar ambient carbonation method, wherein pre-wetted SS powder was exposed to a continuous flow of 20% CO2 gas in a controlled climate chamber. This treatment resulted in precipitation of CaCO3 (from Ca-bearing minerals) and amorphous silica gel (from larnite), leading to a more porous microstructure and increased SSA of carbonated SS. The amorphous silica gel enhanced pozzolanic reactivity and promoted the generation of additional strength-contributing C–S–H gel, thereby improving mechanical performance relative to those incorporating normal SS. However, when the replacement level is excessively high (>60%), the dilution effect limited the cement available for hydration, leading to reduced formation of hydration products, increased porosity, and a substantial decrease in strength94. In UHPC-CA, higher replacement levels of carbonated SS was found to negatively impact mechanical performance, mainly due to the degradation to the ITZ between coarse aggregate and UHPC matrix96. In particular, meso-scale fracture analysis revealed a more porous ITZ with fewer cement grains near the aggregate boundary, reducing the mechanical contribution of coarse aggregates and promoting matrix cracking, thereby compromising both compressive and flexural strengths. On the other hand, instead of externally carbonating slag prior to incorporation, Hu et al.97 applied a direct carbonation approach by subjecting fresh SS-incorporated UHPC to pressurised CO2 curing (4 bar, 99.9% CO2 concentration). This gas-liquid-solid phase carbonation process in cementitious materials generally proceeds through three key stages168: (i) dissolution of early hydration products (e.g., CH and C–S–H), (ii) dissolution of CO2 into alkaline pore solution, forming carbonate ions (\({{\rm{CO}}}_{3}^{2-}\)), and (iii) precipitation of CaCO3 through the reaction between leached Ca2+ ions and \({{\rm{CO}}}_{3}^{2-}\). The study observed a drastic exothermic carbonation reaction within 30 min, followed by a distinct hydration heat flow, indicating accelerated early-age reactions. This mechanism contributed to enhanced dynamic mechanical performance and superior carbon sequestration efficiency, with a 22.4% higher CO2 uptake than that of FA-incorporated UHPC.

A key concern associated with using SS as a SCM is its content of trace heavy metals (e.g., B, Ba, Cr, V, and Pb) and its inherently high alkalinity, both of which can affect the mobility of hazardous elements under environmental exposure169. Therefore, its incorporation in infrastructure applications must be evaluated with respect to potential environmental risks, particularly the leaching of heavy metals. In UHPC, however, SS incorporation generally exhibits favourable leaching behaviour, with studies reporting reduced release of harmful elements compared to untreated slag94,162. Furthermore, it has been shown that increasing SS content can dilute metals such as Zn and Pb, while cement hydration products immobilise contaminants and keep concentrations well below regulatory limits. Even though carbonation of SS increases Cr and V leaching in the raw slag, Liu et al.94 showed that UHPC blended with carbonated slag effectively suppresses this release due to the stabilising effects of the high-pH pore solution and phases such as AFt and AFm.

EAF slag, another steelmaking slag rich in Fe, has been explored as full aggregate replacement to improve the electrical conductivity of UHPC142. Although it slightly reduced compressive strength, EAF slag notably improved the self-sensing capabilities (i.e., crack detection), with enhancements outperformed those achieved with carbon fibre additions. Its predominantly spherical particles also demonstrated a ball-bearing effect that improved the flowability. Beyond steelmaking slags, non-ferrous metallurgy slags (i.e., by-products from the production of non-steel matals) have also been used as fine aggregate substitutes in UHPC. These include high-magnesium nickle slag141 and ferrochrome slag aggregate (FSA)143, both of which have demonstrated good compatibility within the UHPC matrix. Notably, the rigid crystalline structure and high density of FSA improved compressive strength; however, its porous surface resulted in high water demand, which reduced flowability, prolonged setting time, and accelerated autogenous shrinkage. In this regard, the synergistic use of FSA with aritificial aggregates as internal curing agents has proven effective, as the gradual release of pre-absorbed water mitigates the aforementioned drawbacks while also promoting cement hydration and enhancing the pozzolanic reactivity of SCMs.

At present, the steel industry has been progressively transitioning from traditional blast furnace methods to scrap-based electric and hydrogen-driven processes in pursuit of reaching CO2-neutral steel production170,171. Hence, the availability of GGBFS and BOF slag is expected to decline and the share of EAF carbon steel slags is expected to steadily increase at the expense of BOF over the coming years172. In the medium term, the adoption of carbon direct avoidance steel production (e.g., hydrogen or electricity-based metallurgy) may also alter the steel slag properties, introducing uncertainties in the downstream utilisation41. The gradual phase-out of the most widely used GGBFS and BOF slag highlights a pressing need to investigate alternative SCM sources for long-term sustainability, which will be discussed in the following sections.

Energy- and waste-derived ashes

Energy-derived ashes herein refer to coal combustion products (CCPs), which are the solid residues formed during the combustion of pulverised coal in thermal power plants for electricity generation. Waste-derived ashes, on the other hand, originate from municipal solid waste incineration (MSWI), a conventional alternative to landfilling for municipal waste treatment and disposal. While differing in feedstocks, both processes involve high-temperature treatment in incineration furnaces and typically produce two main types of particulate by-products: fly ash and bottom ash. Fly ashes comprises finer, lighter particles captured from flue gases using dust collection systems, whereas bottom ashes consists of coarser, denser particles that accumulate at the base of the furnace173. Conventionally, the nomenclature of these ashes reflects their source material, with prefixes denoting origin—for instance, coal fly ash (CFA) and coal bottom ash (CBA) from CCPs, and MSWI fly ash (WFA) and MSWI bottom ash (WBA) from municipal waste incineration residues. However, CFA is by far the most extensively investigated type of fly ash in UHPC; therefore, it will be referred to simply as FA throughout this study.

As defined by ASTM C61846, FA is classified into two categories based on its chemical composition: Class C and Class F. Class C FA is typically derived from subbituminous or lignite coal and is characterised by a higher calcium content, which imparts self-cementing properties. In contrast, Class F FA is produced from bituminous coal and is predominantly siliceous, exhibiting pozzolanic rather than cementitious behaviour174. This characteristic is evident from the broad amorphous hump observed in the XRD pattern (Fig. 5), as already been discussed in ‘Mineralogical properties’. Among the two, FA-F is more frequently employed in UHPC studies as a partial cement replacement (the focus of this section), although it has also been used to replace fine aggregate175. As shown in Fig. 7, FA particles, regardless of type, exhibit a predominantly spherical and glassy morphology, with sizes typically ranging from less than 1 to about 300 μm120. This morphology provides a ball-bearing or lubricating effect when FA is used to replace cement, generally enhancing the flowability of UHPC mixtures, particularly with increasing levels of substitution43,102,117,145. However, consistent with findings in conventional concrete systems174,176, the incorporation of FA in UHPC has been associated with reductions in compressive strength, especially at higher replacement levels and during early ages (≤7 days)43,117,128. Notably, the early-age strength reductions were much higher than that of GGBFS, due to the stronger retardation effect of FA on cement hydration, as it binds free Ca2+ through aluminate reactions or surface adsorption, thereby delaying C–S–H formation and prolonging the induction period177,178. Although a modest strength gain was observed at the later ages (>28 days)43, the improvement was found to be comparable to that achieved with LP, an inert filler102. This limited strength development is primarily attributed to the specific characteristics of UHPC system that hinder the pozzolanic activity of FA, even beyond 91 days. Specifically, the combination of high superplasticiser dosages and low w/b ratios imposes two key constraints: (i) the complexation of Ca2+ ions with polymer chains from the superplasticiser, which inhibits nucleation and growth of hydration products, and (ii) the insufficient availability of free water to sustain continued hydration and promote pozzolanic reaction.

Conversely, FA has demonstrated a beneficial influence on the flexural performance of UHPC at a moderate substitution levels (around 20%)43,117. The enhancement is primarily attributed to improved interfacial bond characteristics between the matrix and embedded steel fibres, facilitated by the additional pozzolanic activity, filler effect, and nucleation sites introduced by FA43,128. However, beyond optimal replacement levels, FA can disrupt the Ca/Si ratio of the binder system and reduce the overall reactivity43. In UHPC incorporating graphite tailings as aggregate, Bai et al.145 observed a slight improvement in compressive strength with up to 15% cement replacement by FA. This enhancement was explained by the favourable particle size distribution of FA (between silica fume and cement), which contributes to a beneficial micro-aggregate filling effect. In a recent study, Zheng et al.179 examined the role of ultra-fine fly ash (UFFA, D50 = 1.52 μm) and silica fume (USF, D50 = 0.31 μm) in promoting autogenous self-healing of UHPC under carbonation conditions. As shown in Fig. 11a, UHPC incorporating UFFA exhibited the highest crack-healing capacity, followed by USF and plain UHPC (designated as C), for both initial crack widths of 40 μm and 200 μm. The dominant healing phase formed during carbonation varied depending on the type of replacement materials used (see Fig. 11b): (i) in C, portlandite was converted to CaCO3, which primarily sealed only the crack surface; (ii) in USF-blended UHPC, carbonation led severe decalcification of C–S–H, forming a multi-layered healing structure comprising original cement matrix–silica gel–CaCO3; (iii) in UFFA-blended UHPC, ettringite transformed into CaCO3-encapsulated ettringite. Notably, in UFFA-blended UHPC, the early formation of needle-like ettringite crystals stimulated the nucleation of CaCO3 and exhibited expansive behaviour, contributing to densely interlocked network that enhanced crack sealing and improved the impermeability recovery. While UFFA-blended UHPC demonstrated superior sealing capacity, USF-blended UHPC achieved better mechanical property restoration. This improvement is attributed to the formation of silica gel, which acts as a binding agent between CaCO3 and the cement matrix, thereby strengthening the interfacial bonding between the healing products and the original matrix. Owing to these distinct regenerated microstructure, the two blends exhibited different failure modes during flexural loading (see Fig. 11c): (i) shear failure within the regenerated CaCO3 (and ettringite) phases in UFFA-blended UHPC, primarily due to the absence of silica gel; and (ii) tensile debonding at the interface between CaCO3 (and ettringite) and the silica gel in USF-blended UHPC, leading to a better flexural performance restoration. Unlike its use as a cement replacement, the utilisation of FA used as a partial fine aggregate replacement has shown promising results. Kou and Xing175 reported that replacing up to 50% of silica sand with FA still resulted in an increase in both compressive and flexural strengths, primarily attributed to the enhanced packing density offered by the finer FA particles, supplementary pozzolanic activity, and improved interfacial bonding.

a Optical imaging showing crack closure over time under carbonation curing for two initial crack widths (40 μm and 200 μm). b Autogenous self-healing mechanisms in UHPC incorporating different replacement materials. c Two distinct cracking modes observed in regenerated UHPC structure under flexural loading: shear cracking within healing products (observed in UFFA), and tensile debonding at the interface between the healing products and the original cement matrix (observed in USF). Reproduced with permission179. Copyright 2025, Elsevier B.V.

CBA, when compared to FA, typically exhibits lower crystallinity as evidenced by the XRD patterns shown in Fig. 5 and supported by prior studies180,181. However, its broader utilisation is hindered by less favourable particle characteristics: (i) a coarse size and rough surface texture that necessitate additional processing (e.g., sieving and milling/grinding)180, and (ii) a relatively high unburned carbon content (i.e., LOI >6%) which often falls short of pozzolanic performance standards182. When properly processed, CBA exhibit pozzolanic activity superior to that of FA, as also demonstrated in UHPC mixtures by Pyo and Kim151. In the study, CBA showed greater potential as a silica powder replacement compared to FA, due to its higher pozzolanic reactivity, attributed to its lower crystallinity. Notably, mixtures incorporating CBA did not exhibit significant strength reductions at any age, whereas FA substitution led to substantial early-age strength loss within the first 24 h (as previously discussed). WBA, on the other hand, has been incorporated as fine aggregate replacement in UHPC183,184. It is well-established that the use of WBA in conventional concrete is often associated with elevated risk of cracking due to expansive reactions resulting from: (i) hydrogen gas generation from the reaction of metallic aluminium in the alkaline medium of concrete, (ii) potential ASR triggered by residual glass phases, and (iii) excessive ettringite formation caused by the high sulphate content (i.e., gypsum). In UHPC, Yu et al.183 reported that incorporating 20% WBA led to significant increase in porosity, attributed to hydrogen release, which in turn contributed to a reduction in compressive strength. However, a later study by Shen et al.184 presented contrasting findings, demonstrating that application of WBA in UHPC had dual and opposing effects on mechanical properties: porous structure (see Fig. 7) and internal curing effect. Specifically, at moderate replacement levels (<25%), the internal curing benefit outweighed the adverse effect of increased porosity, leading to improved compressive strength. However, beyond this threshold, the negative influence of excessive porosity became dominant, resulting in a reduction in strength. Importantly, the expansive reactions commonly observed in conventional concrete due to the presence of metallic Al, glass, and gypsum appeared to be mitigated in UHPC. This mitigation was attributed to UHPC’s dense microstructure, high self-dessication, presence of SCMs (e.g., silica fume), which collectively suppress such deleterious expansion.

As part of global efforts to combat climate change, the world is gradually phasing out coal-fired power plants, even in coal’s birthplace, the United Kingdom185. As a result, CCPs such as FA and CBA, which have long been served as SCMs, are expected to become increasingly scarce. In contrast, MSW generation is closely tied to population size and urban density, and can increase by an order of magnitude in industrialised, densely populated regions. This shift highlights the growing importance of valorising MSWI ashes, particularly WBA which has shown promise in dense UHPC systems, as more sustainable and readily available SCM alternatives in the post-coal era.

Limestone powder